9

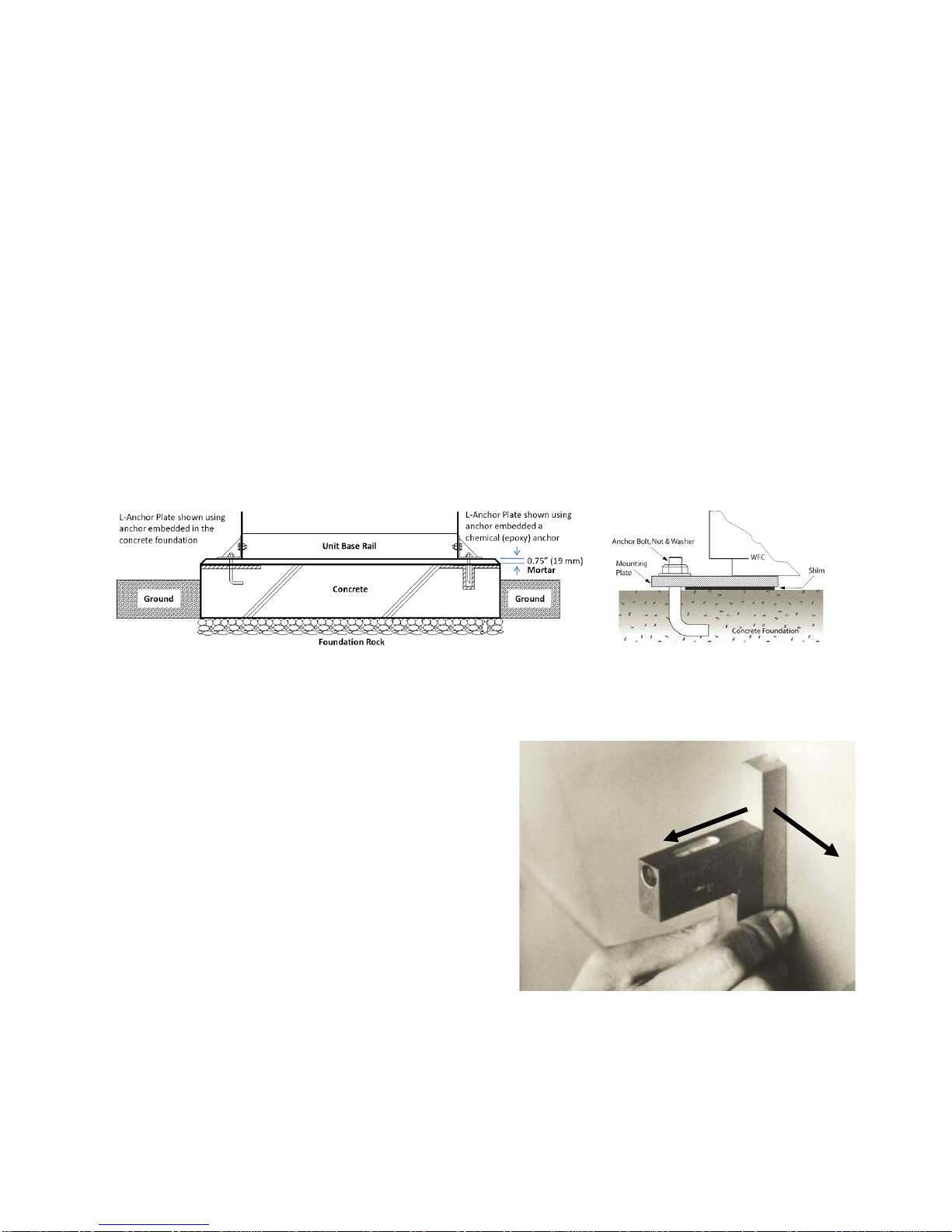

FOUNDATION

All aspects of foundation and support

computations must be in accordance with

national and local codes.

The chiller must be mounted on a

level, non-combustible foundation

capable of supporting the considerable

weight of the machinery. This is

particularly important for rooftop

installations. Always make certain the

structure can support not only the chiller,

but also the pumps, piping, cooling

towers, etc. as may be required. The

rooftop area should be well-drained and

be at least 7 feet (2 meters) from the edge

of the roof. Anti-fall measures should

always be taken if the chiller is installed

within 12 feet (4 meters) of the roof edge.

Additionally, for protection of the

roofing material, it is recommended a

suitable platform or walkway be provided

around all sides of the unit.

If the chiller is to be installed outside,

but at ground level, make certain the

concrete base and the soil beneath are

sufficient for the task. Settling over time

could cause the unit to become unlevel,

which could have a negative impact on

the performance and lifespan of the unit.

Concrete foundations are recommended

to be sized so that it extends at least 12”

(300 mm) beyond the unit in all directions

in order to accommodate potential

mounting and anchoring hardware.

Figure 6 –Foundation Detail

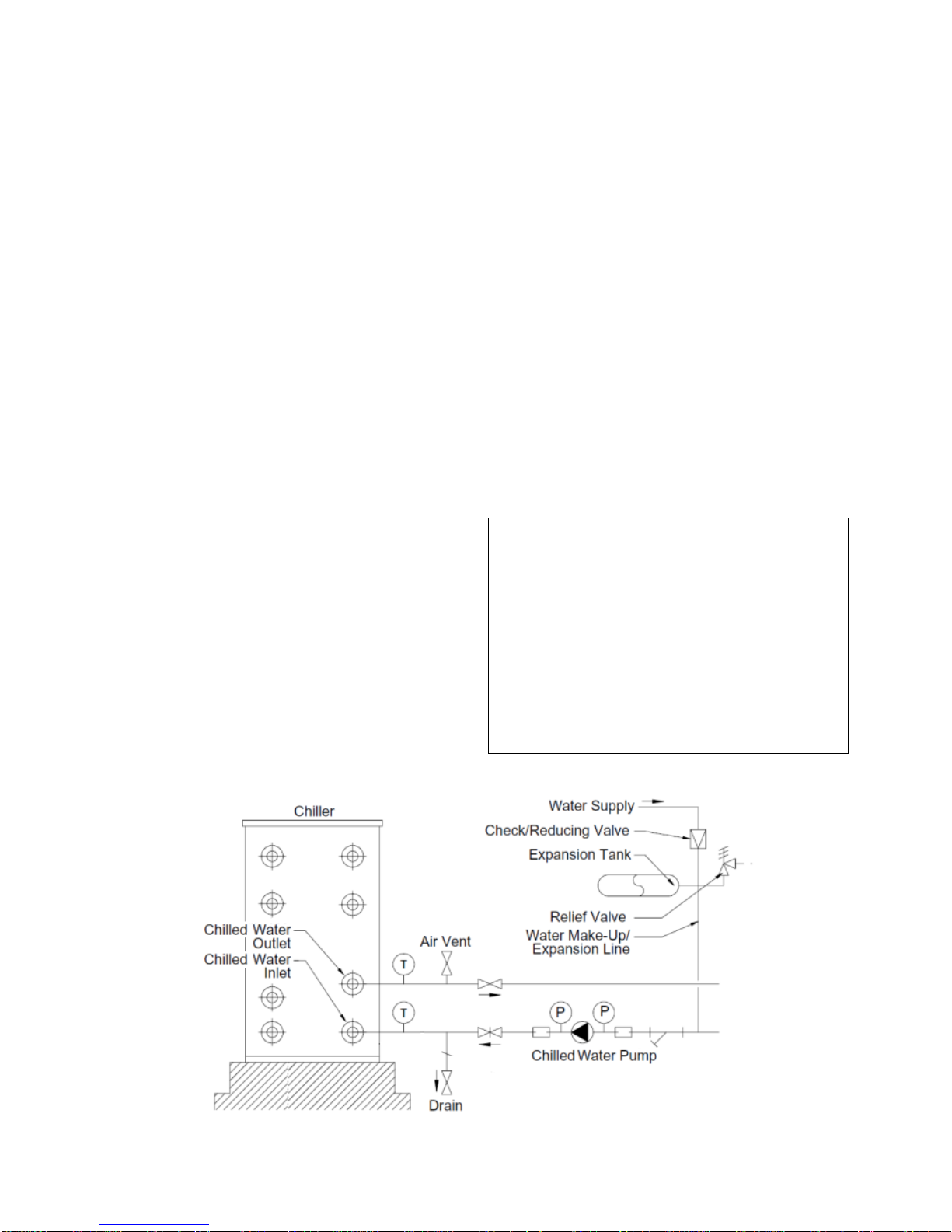

LEVELING

WFC-S Series units must be level in

order for the fluids to be distributed

properly over their respective tube

bundles. There is a level bar mounted

on the front of the main vessel of the

machine, right above the control box.

The unit must be level to both the

longitudinal and transverse alignments.

It is essential that all leveling be

completed before any piping connections

are attempted.

Leveling of the unit is typically

accomplished by use of field-supplied

metal shims. In cases where the unit is

required to be secured to the pad, anchor

bolts, nuts, and washers must be field-

supplied.

Figure 7 –Level Bar