GENERAL INFORMATION

9

1.8

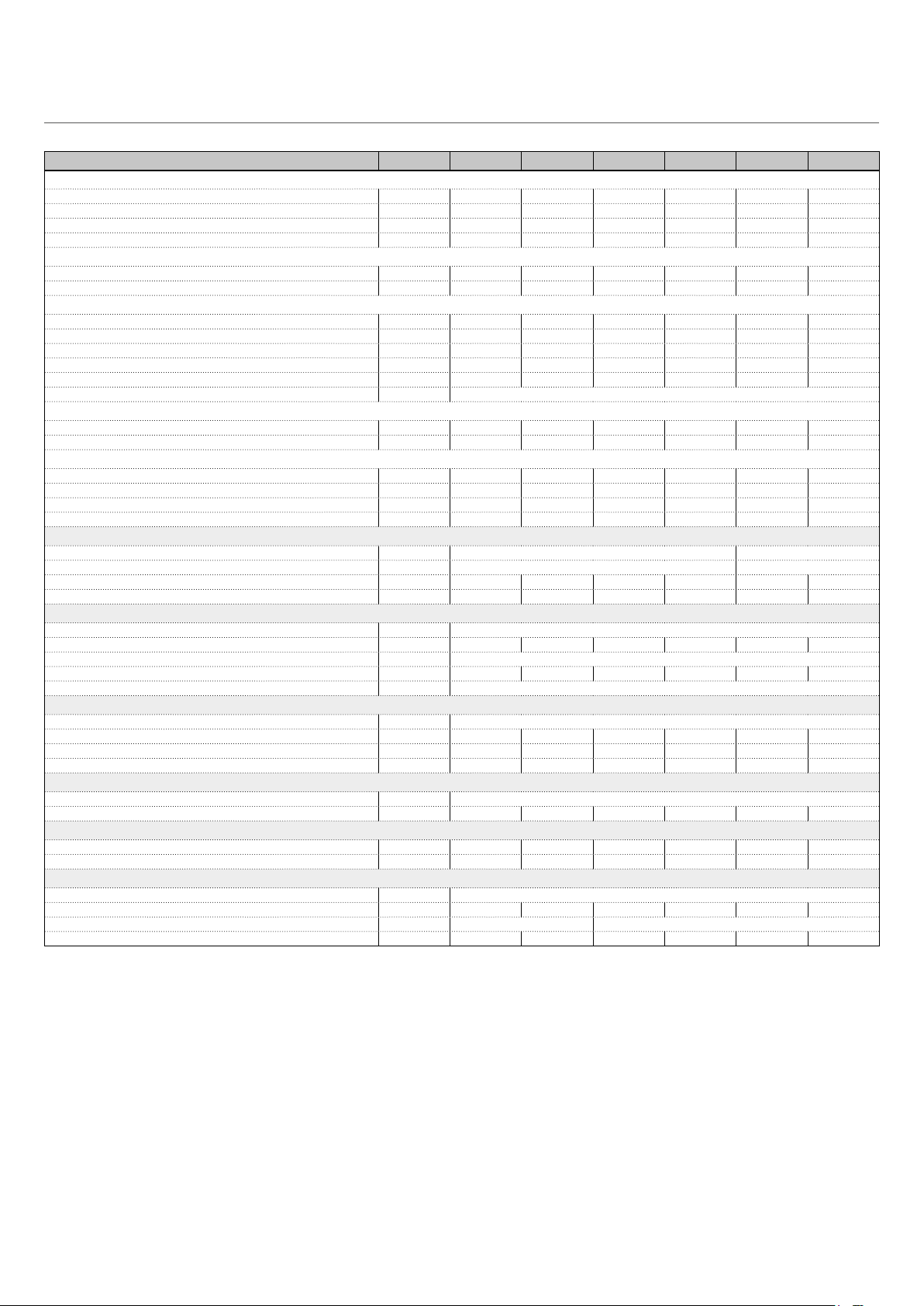

Performance based on the climatic zone

Model 5 7 11 15 11T 15T

Temperate zone - Average temperature [47 / 55 °C]

Seasonal energy efciency (ns) % 130 131 131 135 139 133

SCOP kW/kW 3,32 3,36 3,35 3,45 3,34 3,40

Pdesignh -7 °C kW 3,09 3,83 7,69 9,11 7,69 9,81

Pdesign at +2 °C kW 1,88 2,37 5,42 5,55 5,36 5,13

Pdesignh +7 °C kW 1,21 1,42 3,66 3,63 3,63 3,99

Pdesignh +12 °C kW 1,12 0,94 4,22 4,15 4,14 4,01

Annual energy cons. kWh/annum 2170 2651 5349 6159 5358 6734

Energy class A++

Sound power level dB(A) 64 65 68 69 69 69

Cold zone - Average temperature [30 / 35 °C]

Seasonal energy efciency (ns) % 186 184 173 173 167 171

Sound power level dB(A) 64 65 68 69 69 69

SCOP kW/kW 4,73 4,68 4,39 4,41 4,26 4,35

Pdesignh -7 °C kW 3,55 4,57 8,43 9,40 8,27 9,07

Pdesign at +2 °C kW 2,16 2,72 5,39 5,28 4,97 4,97

Pdesignh +7 °C kW 1,40 1,84 3,56 3,77 2,99 3,54

Pdesignh +12 °C kW 1,30 1,12 4,11 4,26 4,17 2,79

Annual energy cons. kWh/annum 1747 2273 4469 4967 4528 4858

Energy class A+++ A++

Warm zone - Average temperature [47 / 55 °C]

Seasonal energy efciency (ns) % 163 152 164 156 178 162

SCOP kW/kW 4,15 3,87 4,17 3,98 4,51 4,13

Pdesignh -7 °C kW - - - - - -

Pdesign at +2 °C kW 3,30 3,83 7,59 7,59 9,43 10,24

Pdesignh +7 °C kW 2,15 3,36 3,42 6,12 5,39 6,18

Pdesignh +12 °C kW 1,01 1,51 4,28 3,93 4,33 10,24

Annual energy cons. kWh/annum 1055 1317 2423 2539 2780 3300

Warm zone - Low temperature [30 / 35 °C]

Seasonal energy efciency (ns) % 230 259 230 225 232 225

SCOP kW/kW 5,83 6,54 5,83 5,73 5,87 5,71

Pdesignh -7 °C kW - - - - - -

Pdesign at +2 °C kW 3,60 5,00 8,70 10,20 8,40 9,80

Pdesignh +7 °C kW 2,33 3,86 5,53 7,24 5,61 7,32

Pdesignh +12 °C kW 1,15 1,77 4,23 4,19 4,27 4,23

Annual energy cons. kWh/annum 817 1013 1983 2376 1899 2283

Cold zone - Average temperature [47 / 55 °C]

Seasonal energy efciency (ns) % 100 111 109 107 112 108

SCOP kW/kW 2,57 2,84 2,80 2,75 2,86 2,78

Pdesignh -7 °C kW 3,35 5,06 7,85 8,32 8,06 8,51

Pdesign at +2 °C kW 2,04 3,08 5,55 5,27 5,60 5,32

Pdesignh +7 °C kW 1,33 1,99 3,39 3,41 3,42 3,45

Pdesignh +12 °C kW 1,14 1,43 4,23 4,13 4,28 4,17

Annual energy cons. kWh/annum 5078 6930 10922 11771 10951 11924

Cold zone - Low temperature [30 / 35 °C]

Seasonal energy efciency (ns) % 148 153 140 138 136 135

SCOP kW/kW 3,77 3,89 3,57 3,53 3,48 3,45

Pdesignh -7 °C kW 3,65 5,57 8,42 9,18 8,65 9,33

Pdesign at +2 °C kW 2,22 3,39 5,65 5,65 5,21 5,21

Pdesignh +7 °C kW 1,44 2,18 3,40 3,58 3,43 3,62

Pdesignh +12 °C kW 1,26 1,56 4,24 4,21 4,28 4,26

Annual energy cons. kWh/annum 3769 5566 9186 10118 9665 10527

9

Performance are declared according to standards EN

14511:2018 and EN 14825:2016