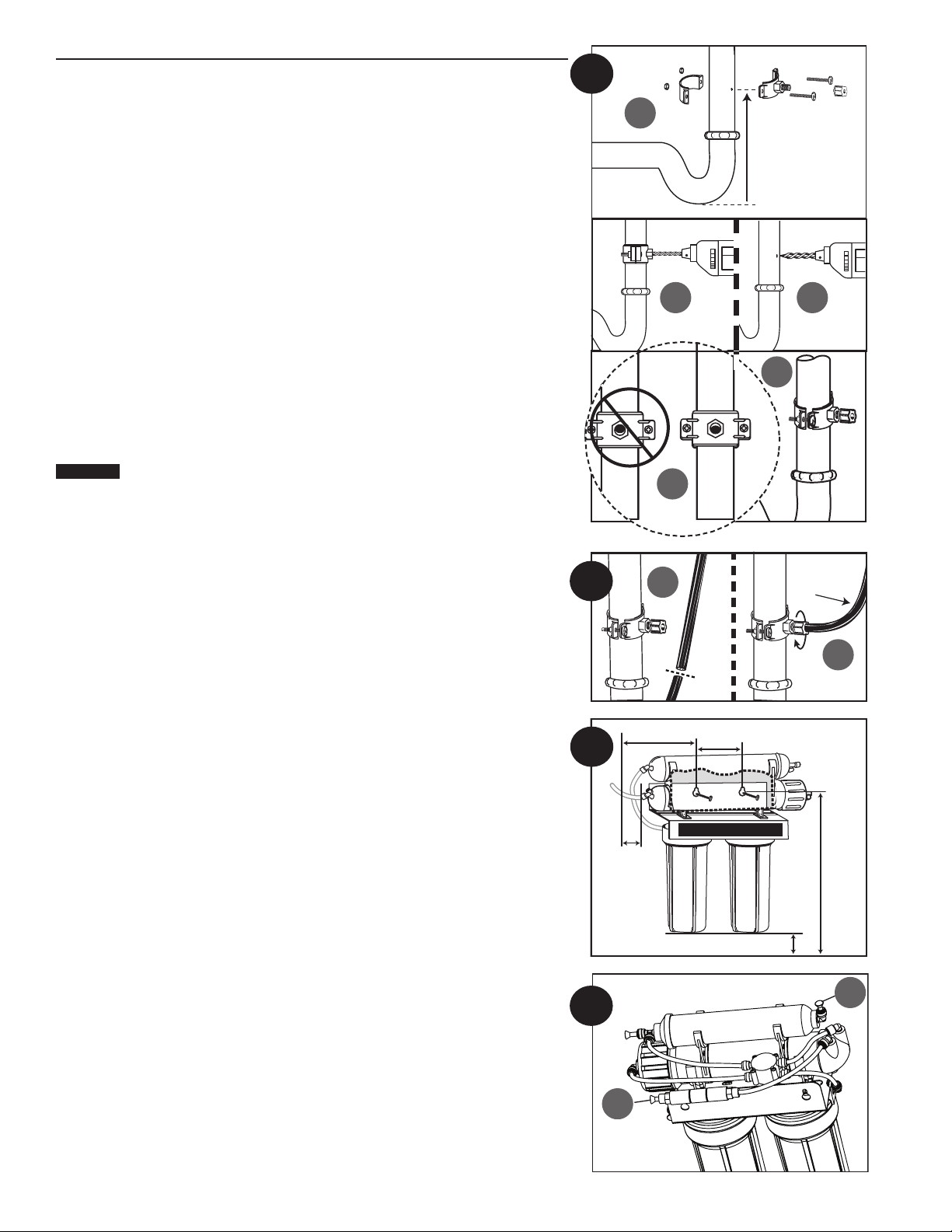

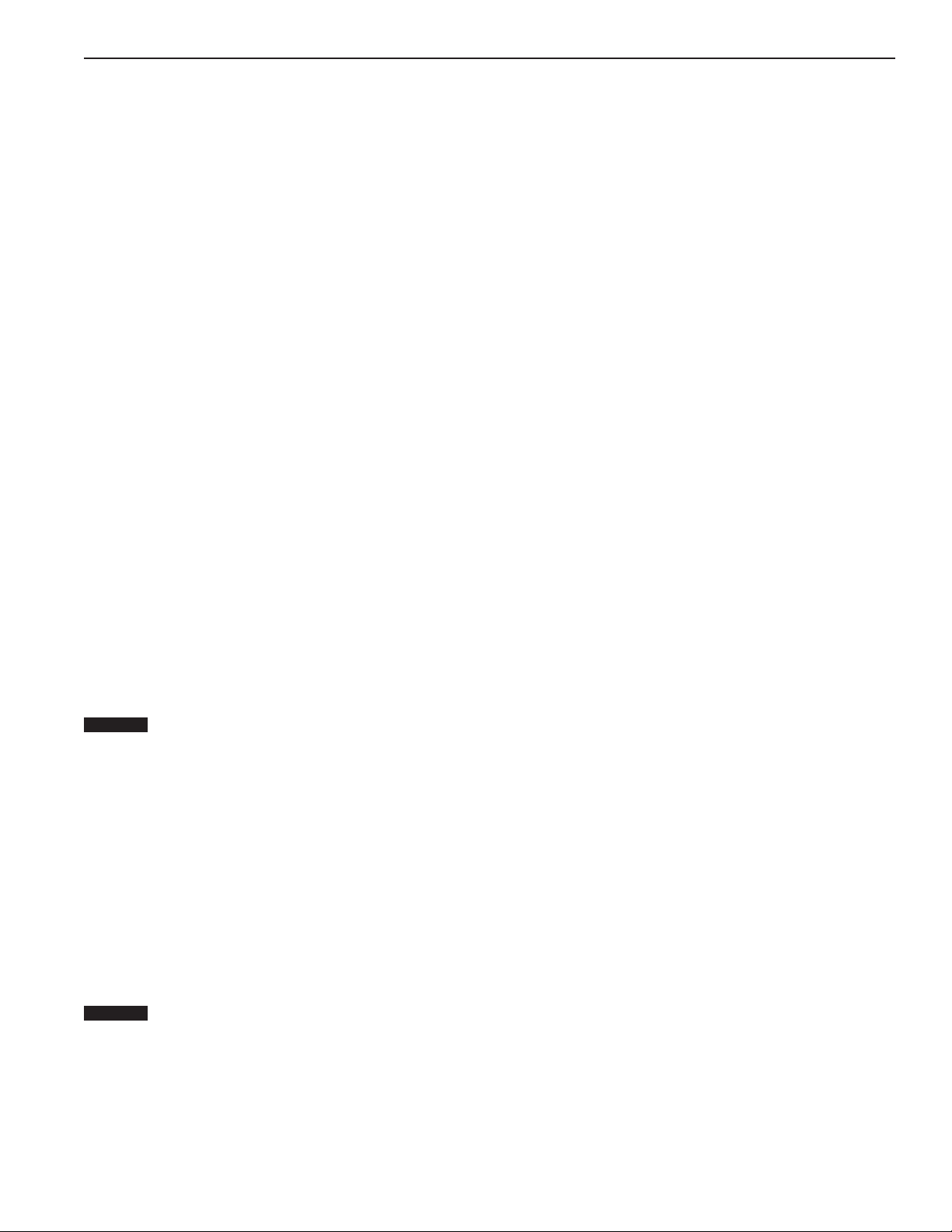

Leaks between bottom of housing and cap

1. Ensure sump is tightly screwed to cap. If it still leaks close the cold

water supply and tank valves.

2. Clean black rubber O-ring and lubricate with clean silicone grease.

With two fingers, insert O-ring in groove below threads of housing

and press into place. Tighten housing back onto cap.

3. Open the cold water supply and tank valve.

If leaks persist, call Technical Support.

Leaks on tank valve assembly

1. Open drinking water faucet to drain storage tank. Let drinking water

faucet run until it drips. Turn off cold water supply.

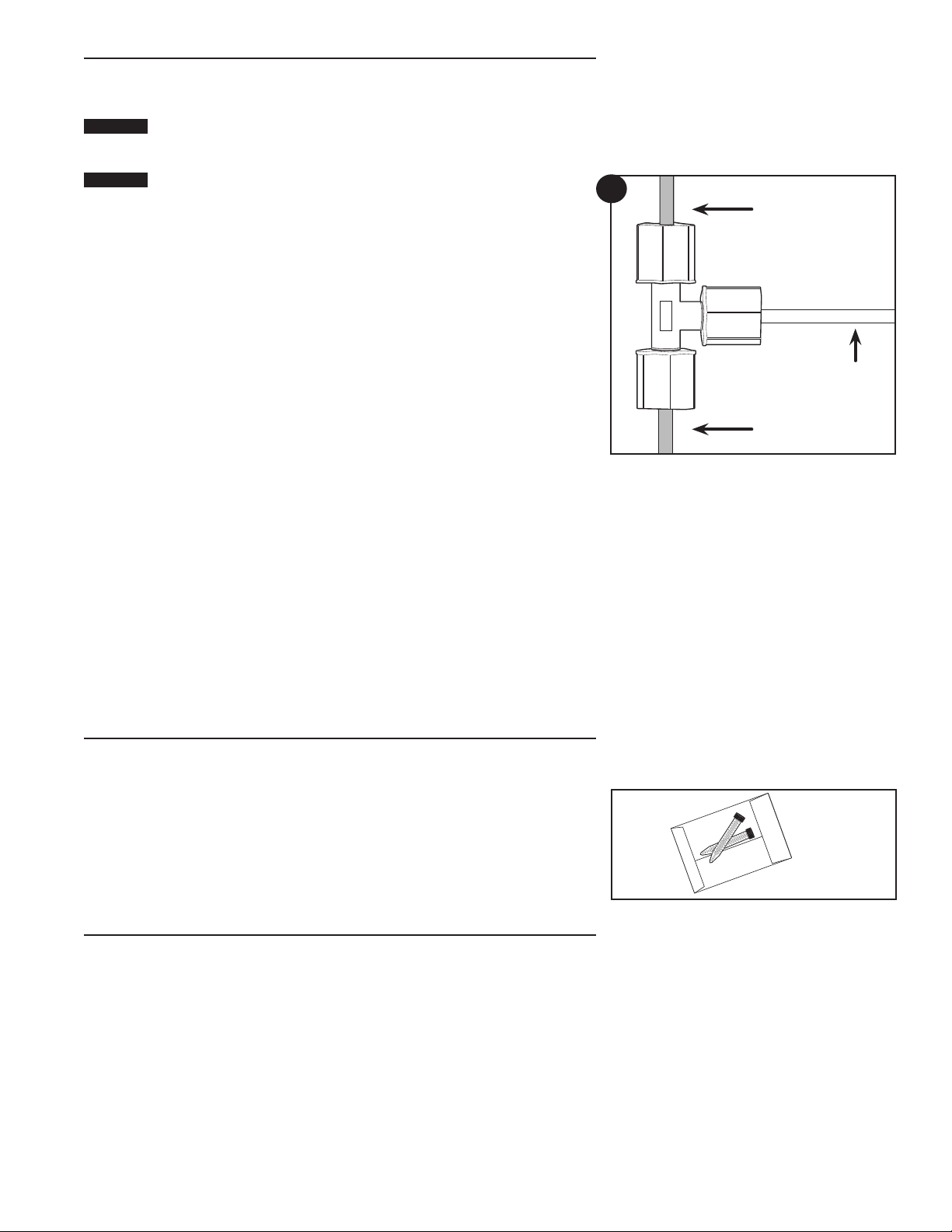

2. Push in on white collar of tank valve fitting and pull out tubing.

Unscrew the tank valve from the storage tank. Rewrap threads on

top of the tank with Teflon®tape. Screw tank valve back onto tank.

Trim 1/2-inch from end of tubing and reinsert 5/8-inch into tank

valve fitting.

3. Open the cold water supply and shut off the reverse osmosis

faucet. Let the system pressurize for several hours and check for

leaks. Check again after tank is fully pressurized.

Leaks on quick-connect fittings

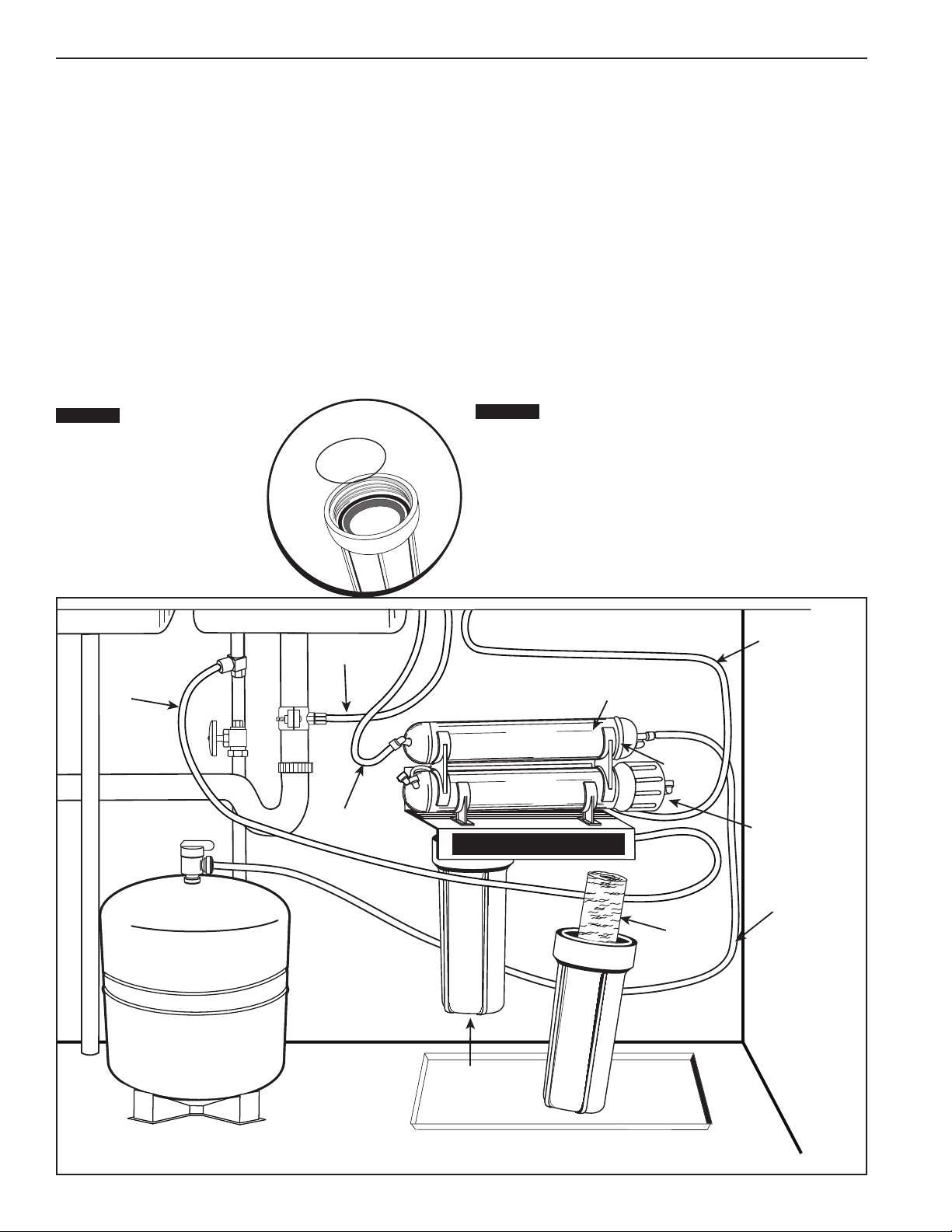

1. Close the cold water supply and tank valve.

2. Depress plastic collar and pull out tubing.

3. Cut off 1 inch of tubing and place a mark 5/8-inch from end of

tubing. Tubing should be cut squarely. The internal and external

burrs should be removed.

4. Push tubing 5/8-inch into fitting.

5. Open the cold water supply and tank valve. If leaks persist, call

Technical Support.

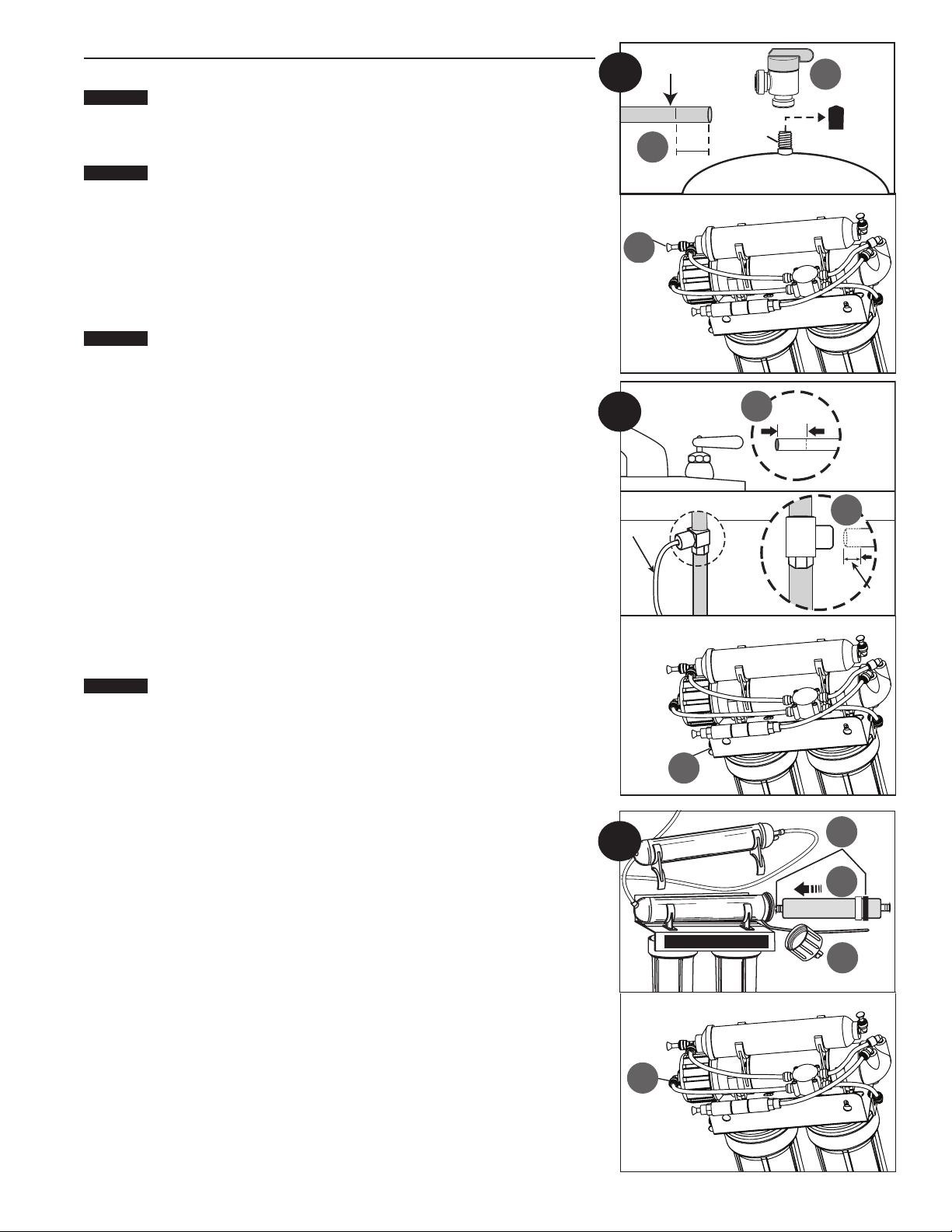

No flow or slow flow from the brine (drain) line

Less than 1½ cups per minute

NOTE: Before checking brine (or reject) flow, make sure the system

is producing water by turning off the valve on the storage tank

and opening the faucet. Water should drip from faucet.

1. Examine the P5 and EPM10 pre-filters. If clogged, replace (see

Replacing the Pre-Filter and Post-Filter on page 8) and recheck the

brine (or reject) flow rate.

2. If the pre-filters are not at fault, the brine (or drain) flow controller is

probably clogged. Call Technical Support.

High TDS in Product Water

1. If high TDS (Total Dissolved Solids) is detected in the product water,

the RO Cartridge may need to be replaced or the reject flow control

tubing may be clogged. If this is a new installation, call Technical

Support.

2. Otherwise, draw 1 gallon of water from the unit. After 10 minutes,

then run water from the faucet and test the water again.

3. Determine when you last changed the RO Filter Cartridge and call

Technical Support.

Reduced production

Slow or no product water flow usually indicates either a clogged pre-

filter or an exhausted membrane. First, replace the pre-filters. If the

production rate is not improved, replace membrane.

Gradual return of taste and odor

Gradual return of unpleasant taste and odor over a period of time may

indicate that your filter cartridges and/or RO membrane need to be

replaced.

See Replacing the Pre-Filters on page 8

and Replacing the

Reverse Osmosis Membrane”on page 9.

Sudden return of taste and odor

If shortly after complete servicing noticeable taste and odors return

contact Technical Support.

No water pressure from the drinking water faucet or

low volume in storage tank

1. Close the cold water supply to system.

2. Lift storage tank to see if it is empty. If not, open the drinking water

faucet to empty water from tank.

NOTE: It may be necessary to pump a small amount of air into the tank

with a bicycle pump to remove all the water from the tank.

3. When tank is empty, use a pressure gauge to check tank pressure.

An empty tank should contain 5 to 7 psi pressure. Increase or

decrease the air pressure in the tank accordingly.

4. Open cold water supply. Let system run for

3 hours to fill tank, then check system performance. If performance

has not improved, call Technical Support.

Performance Data

Important Notice: Read this performance data and compare the

capabilities of this system with your actual water treatment needs. It is

recommended that before installing a water treatment system, you have

your water supply tested to determine your actual water treatment needs.

This system has been tested according to NSF/ANSI 58 for the reduction

of the substances listed below. The concentration for the indicated

substances in water entering the system was reduced to a concentration

less than or equal to the permissible limit for water leaving the system, as

specified in NSF/ANSI 58.

NOTE:

Substances reduced are not necessarily in your water. Filter

must be maintained according to manufacturer’s instructions,

including replacement of filter cartridges.

The tested efficiency rating for this system is 7.68%. Efficiency

rating means the percentage of the influent water to the system

that is available to the user as reverse osmosis treated water under

operating conditions that approximate typical daily usage. The tested

recovery rating is 20.1%. Recovery rating means the percentage

of the influent water to the membrane portion of the system that is

available to the user as reverse osmosis treated water when the

system is operated without a storage tank or when the storage tank is

bypassed

Model WRO-2550

Substance

Average Influent

Concentration

Maximum

Permissible

Product Water

Concentration

Reduction

Requirements

Average

Reduction

Standard 58

Barium 10.0 mg/L ± 10% 2.0 mg/L 98.3%

Cadmium 0.03 mg/L ± 10% 0.005 mg/L 98.7%

Chromium

(Hexavalent) 0.3 mg/L ± 10% 0.1 mg/L 91.2%

Chromium

(Trivalent) 0.3 mg/L ± 10% 0.1 mg/L 94.8%

Copper 3.0 mg/L ± 10% 1.3 mg/L 98.9%

Cysts Min. 50,000 /mL 99.95% 99.99%

Fluoride 8.0 mg/L ± 10% 1.5 mg/L 95.6%

Lead 0.15 mg/L ± 10% 0.010 mg/L 98.7%

Radium

226/228 25 pCi/L ± 10% 5 pCi/L 80.0%

Selenium 0.10 mg/L ± 10% 0.05 mg/L 96.0%

Turbidity 11 NTU ± 1 NTU 0.5 NTU 99.0%

Total

Dissolved

Solids

750 mg/L ± 40

mg/L 187 mg/L 96.2%

Troubleshooting Guide

10