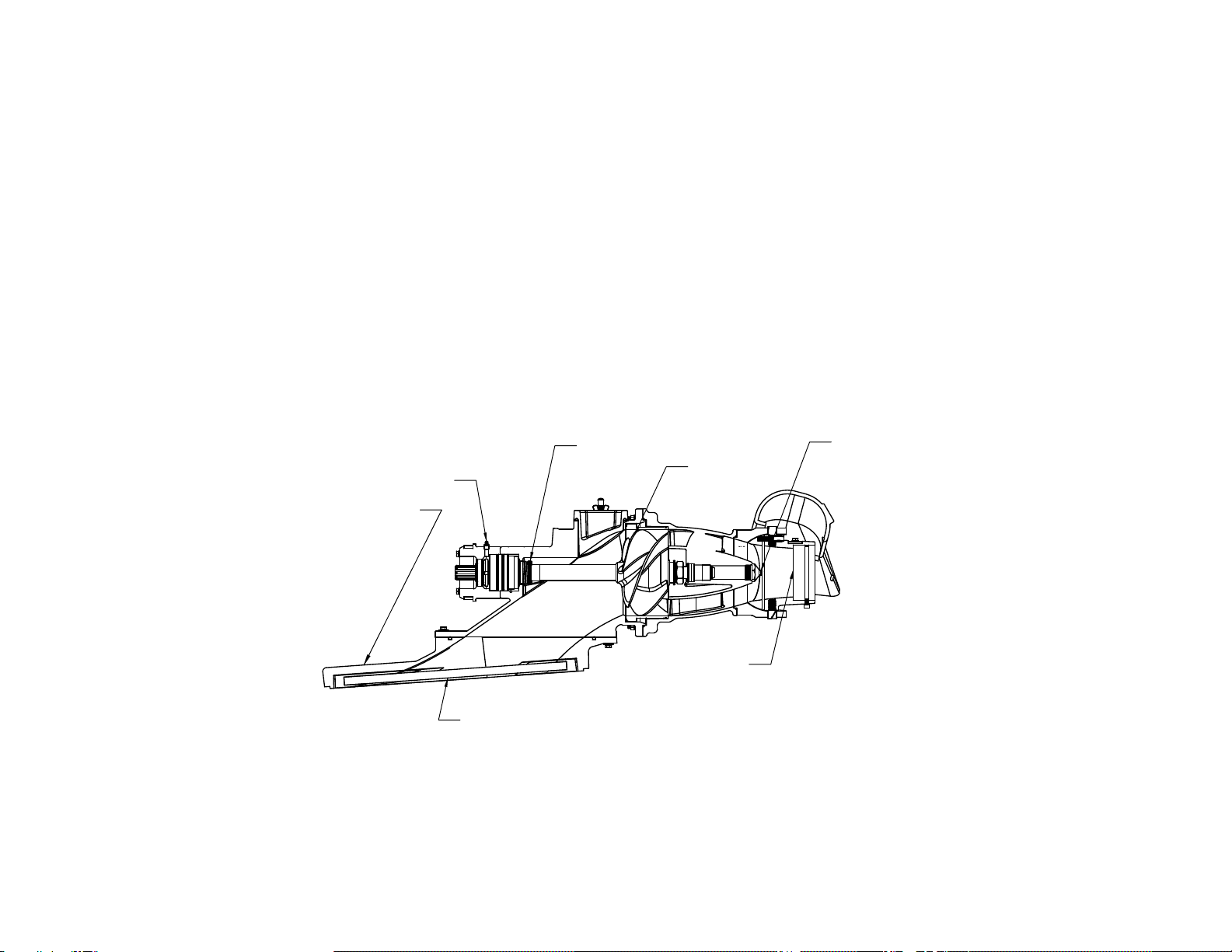

American Turbine

SD203

ITEM # DESCRIPTION PART # QTY.

1 SUCTION PIECE, SD203-312 SC1401 1

2 PUMP SHAFT, SD203, 309, 312 SH1207 1

3 THRUST BEARING (SD & FW) B1101 1

4 BEARING SLEEVE, SD203, 309, 312 SH5001 1

5 NUT, BEARING SLEEVE, SD203, 309, 312 SH5101 1

6 SNAP RING, SHAFT SH1507 1

7 SEAL FACE HOUSING, SD203, 309, 312 SH5201 ALUM 1

8 SEAL, SEAL FACE HOUSING SL1201 1

9 SEAL, MECHANICAL (SD & YJ) SL4008 1

10 5/32 X 2 COTTER PIN F03 16 CP 1

11 O-RING, BEARING HOUSING, SD203, 309, 312 O3301 2

12 O-RING, SEAL FACE HOUSING, SD203, 309, 312 O3401 1

13 BEARING HOUSING, SD203, 309, 312 SC2101 1

14 ENGINE MOUNT RING (BEARING CAP) SC4007 1

15 GREASE ZERT SC8901 2

16 SEAL, BEARING HOUSING SD203, 309, 312 SL1101 1

17 5/16-18 X 4-1/2 HEX HEAD CAP SCREW F05 18 36 HH 6

18 5/16 LOCK WASHER F05 LW 24

19 HAND HOLE COVER, SD203, 312 SC1801 1

20 O-RING, HANDHOLE COVER, BERK, SD & FW O1002 1

21 WATER TUBE, (SD203, 312) SC4201 1

22 O-RING, WATER TUBE, SD203, 312 O3801 1

23 IMPELLER KEY SH3007 1

24 5/16 CLEVIS PIN F05 CL 2

25 7/64 X 3/4 COTTER PIN F02 04 CP 2

26 3/8 EYE BOLT F06 EB 2

27 3/8 THICK WASHER (SD HAND HOLE COVER) F06 TW 2

28 3/8 LOCK WASHER F06 LW 10

29 3/8 WING NUT F06 WN 2

30 VINYL CAP, 3/8 M5001 2

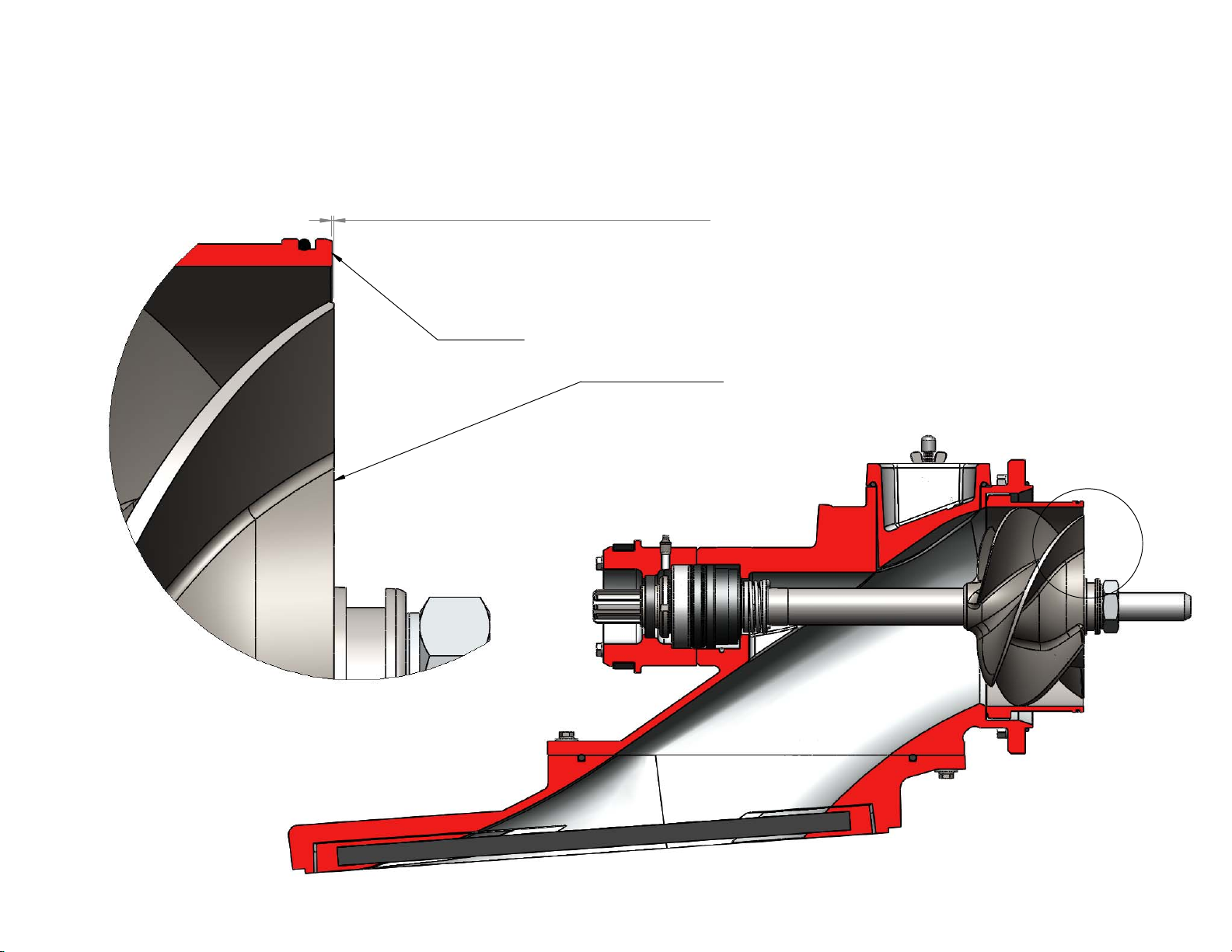

31 WEAR RING, SD203AF, STAINLESS STEEL WR203SS 1

32 3/8-16 HEX NUT F06 16 HN 8

33 O-RING, SD-312 BOWL O4001 1

34 WEAR RING INSULATOR (SD203, 312) WR6005 1

35 O-RING, WEAR PLATE, SD203AF O5172 1

36 INTAKE, WELD-IN, SD-312 I1401 1

37 GRATE, INTAKE, SD203, 312 I4401 1

38 5/16-18 X 1-1/2 SET SCREW F05 18 12 SS 8

39 5/16 AN FLAT WASHER F05 AN 4

ITEM # DESCRIPTION PART # QTY.

40 5/16 -18 LOCK NUT F05 18 LN 4

41 O-RING, INTAKE, SD-312 O3901 1

42 5/16-18 X 1 HEX HEAD CAP SCREW F05 18 08 HH 2

43 5/16 FLAT WASHER F05 FW 10

44 5/16-18 X 1-1/4 HEX HEAD CAP SCREW F05 18 10 HH 8

45 STATOR, SD203 SC9312 1

46 BOWL, SNAP RING SC9201 1

47 BOWL PLUG SC9001 1

48 O-RING, BOWL PLUG O2203 1

49 BOWL BEARING, GREASE LUBE 3/4 B1502 2

50 SEAL, BOWL (AT, BERK, LATE DOM) SL2003 2

51 5/16-18 X 3/4 HEX HEAD CAP SCREW F05 18 06 HH 4

52 3/8-16 X 2 SET SCREW F06 16 16 SS 8

53 NIPPLE, WATER COOLING TUBE (SD203, 312) SC4101 1

54 IMPELLER, STAINLESS, AXIAL, SD203AF, 2.8KW IMX203-280 1

55 NOZZLE HOUSING, SDR (SD203) SR1007 1

56 NYLINER BUSHING, SPLIT (3/4) (WJ STR, HVR) B2007 4

57 SDR, NOZZLE, (AXIAL FLOW) SR1009 1

58 NOZZLE INSERT, AXIAL, SIZE 4.200 SR7420 1

59 5/16-18 X 1/2 SOCKET HEAD CAP SCREW F05 18 04 SH 1

60 5/8-11 X 1 SOCKET HEAD CAP SCREW W/ 5/8

PIVOT HEAD - TYP 304 R3702 2

61 SDR, TILLER ARM, (AXIAL) SR3009 1

62 BUCKET STOP, SDR REVERSE BUCKET SR5101 1

63 1/4-20 X 3/4 SOCKET HEAD CAP SCREW F04 20 06 SH 1

64 SDR, REVERSE BUCKET SR2101 1

65 5/8-11 X 5/8 SOCKET HEAD CAP SCREW W/

3/4 PIVOT HEAD - TYP 304 R3703 2

66 1/4-28 STAINLESS FEMALE ROD END (BEST, JET

TRIM) F04 28 FRE 1

67 1/4 CLEVIS PIN F04 CL 1

68 5/64 X 3/4 COTTER PIN F01 06 CP 1

69 3/8-24 X 1-1/4 HEX HEAD CAP SCREW F06 24 10 HH 2

70 3/8-24 LOCK NUT F06 24 LN 2

71 3/8-24 HEX NUT F06 24 HN 1

72 SDR OFF-SET STEERING EXTENSION, SS TUBING SR6101 1

73 O-RING, NOZZLE HOUSING, SD191, SD203,

TJ191 O5001 1

74 5/16-18 HEX NUT F05 18 HN 4

75 3/8-24 MALE ROD END F06 24 MRE 1

76 O-RING, TEFLON, NOZZLE, SD203 O5363T 1

77 IMPELLER NUT SH3507 1

78 SDR REVERSE CABLE BRACKET, AXIAL FLOW SR2009 REV 3 1

79 IMPELLER SHIMS SHK4007 1