SmartGyro SG80 User manual

Operation manual

GYRO STABILIZER

SG80

en English

SG80 Operation Manual

Disclaimers:

All information, illustrations and specications in this manual are based on the latest informa-

tion available at the time of publishing. The illustrations used in this manual are intended to be

representative reference views only. Moreover, because of our continuous product improvement

policy, we may modify information, illustrations and/or specications to explain and/or exemplify

a product, service or maintenance improvement. We reserve the right to make any change at any

time without notice. Smartgyro is a registered trademark of Smartgyro s.r.l. in the United States,

the European Union, and the United Kingdom.

All Rights Reserved:

No part of this publication may be reproduced or used in any form by any means - graphic, elec-

tronic, or mechanical, including photocopying, recording, taping, or information storage and re-

trieval systems - without the written permission of Smartgyro s.r.l.

Please review and comply with the applicable laws and regulations of the international export

control regimes at the territory or country where the product and manual are intended to be im-

ported and used.

OPERATION MANUAL MODEL SG80

CODE 108OM405

All Rights Reserved, Copyright Smartgyro s.r.l.

i

SG80 Operation Manual

Content

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before you operate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

During operation and maintenance . . . . . . . . . . . . . . . . . . . . . . 4

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

System description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Function of Gyro Stabilizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Component of SG80 Gyro Unit. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Description of SG80 Gyro Unit . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Description of control display. . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Home page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Setting the control display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Roll Angle Monitor Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Alarm Log Page. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Performance Monitor Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Gyro stabilizer operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Gyro Stabilizer Startup and Stabilization . . . . . . . . . . . . . . . . 27

Temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Gyro Stabilizer Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Emergency shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Periodic maintenance schedule. . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Safety precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Troubleshooting information . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Gyro system anomaly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

SG80 Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ii SG80 Operation Manual

1

SG80 Operation Manual

It isn’t easy to outsmart the most powerful ele-

ment on earth. In fact, it takes brazen courage.

At Smartgyro, we push the limits of technology

to elevate the entire boating experience. Our

gyro stabilizers eliminate boat roll to make life’s

richest moments more extraordinary.

We believe the ultimate luxury is uninterrupted

time on the water. That’s why Smartgyro SG80

is designed to minimize not only unwanted

movement but also downtime during mainte-

nance. We are leading the way and raising the

bar for onboard comfort, safety, reliability, and

convenience.

To help you use your Smartgyro products for

many years to come, please follow these rec-

ommendations:

- Read and understand this Operation Manu-

al before you operate the gyro stabilizer to

ensure that you follow safe operating prac-

tices and maintenance procedures.

- Keep this Operation Manual in a convenient

place for easy access.

- If this Operation Manual is lost or dam-

aged, order a new one from your authorized

Smartgyro dealer or distributor.

- Make sure this manual is transferred to sub-

sequent owners. This manual should be

considered a permanent part of the gyro

stabilizer and remain with it.

- Constant eorts are made to improve the

quality and performance of Smartgyro

products, so some details included in this

Operation Manual may dier slightly from

your gyro stabilizer. If you have any ques-

tions about these dierences, please con-

sult your authorized Smartgyro dealer or

distributor.

Introduction

2 SG80 Operation Manual

3

SG80 Operation Manual

SAFETY

Smartgyro SG80 considers safety of great im-

portance and recommends that anyone that

comes into close contact with its products,

such as those who install, operate, maintain or

service Smartgyro products, exercises care and

common sense and complies with the safety in-

formation in this manual and on the machine’s

safety decals. Keep the labels from becoming

dirty or torn and replace them if they are lost

or damaged. Also, if you need to replace a part

that has a label attached to it, make sure you

order the new part and label at the same time.

Safety symbols

These are the warning signs used in this manu-

al and on the product.

This safety alert symbol appears with most

safety statements. It means “attention, become

alert, your safety is involved!” Please read and

abide by the message that follows the safety

alert symbol.

DANGER

Indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not

avoided, could result in death or serious in-

jury.

CAUTION

Indicates a hazardous situation which, if not

avoided, could result in minor or moderate

injury.

NOTICE

Indicates a situation which can cause damage

to the machine, personal property and/or the

environment, or cause the equipment to oper-

ate improperly.

Safety

4 SG80 Operation Manual

SAFETY

WARNING

The safety messages that follow have WARN-

ING level hazards.

Explosion Hazard

Keep ammable materials such

as gasoline out of the area

where the gyro stabilizer is in-

stalled.

Before operating the gyro sta-

bilizer, conrm that there are no ammable

materials such as gasoline around the gyro

stabilizer.

Fire Hazard

Undersized wiring systems can

cause an electrical re.

Sever Hazard

The gyro stabilizer may poten-

tially cause mechanical and

electrical hazards. For this rea-

son, never stay in close proximi-

ty to the gyro unit, and never

service it when electrical power is applied or

when the ywheel is running.

General information

There is no substitute for common sense and

careful practices. Improper practices or care-

lessness can cause burns, cuts, mutilation, as-

phyxiation, other bodily injury or death. This

information contains general safety precau-

tions and guidelines that must be followed to

reduce risk to personal safety. Special safety

precautions are listed in specic procedures.

Read and understand all of the safety precau-

tions before operation or performing repairs or

maintenance.

Before you operate

DANGER

The safety messages that follow have DANGER

level hazards.

Never permit anyone to perform

maintenance or operate the

gyro stabilizer without proper

training.

- Read and understand this Operation Man-

ual before you operate or service the gyro

stabilizer to ensure that you follow safe op-

erating practices and maintenance proce-

dures.

- Safety signs and labels are additional re-

minders for safe operating and mainte-

nance techniques.

- Consult an authorized Smartgyro dealer or

distributor for additional training.

Safety precautions

During operation and

maintenance

5

SG80 Operation Manual

SAFETY

WARNING

- Never remove the protection panels that

cover the gyro unit when the gyro stabilizer

is running.

- Maintenance activities must always be per-

formed by qualied technicians only when

power is disconnected and the ywheel is

stopped.

Alcohol and Drug Hazard

Never service the gyro stabilizer

while under the inuence of al-

cohol or drugs, or when feeling

ill.

Exposure Hazard

Always wear personal protective

equipment including appropri-

ate clothing, gloves, work shoes,

and eye and hearing protection

as required by the task at hand.

WARNING

Entanglement Hazard

When servicing the gyro stabi-

lizer, make sure that the gyro

system is not powered. It is pos-

sible for someone to activate the

gyro system without realizing

that someone is working on the gyro unit.

Never operate or service the gyro stabilizer

while wearing a headset to listen to music or

the radio because it will be dicult to hear the

warning signals.

Burn Hazard

Some of the gyro unit surfaces

can become very hot during op-

eration and shortly after shut-

down. Keep your hands and

other body parts

6 SG80 Operation Manual

SAFETY

CAUTION

Poor Lighting Hazard

Ensure that the work area is adequately illumi-

nated. Always install wire cages on portable

safety lamps.

Tool Hazard

Always use tools appropriate for the task at

hand and use the correct size tool for loosen-

ing or tightening machine parts.

Flying Object Hazard

Always wear eye protection

when servicing the gyro stabi-

lizer or when using compressed

air or high-pressure water. Dust,

ying debris, compressed air,

pressurized water or steam may injure your

eyes.

Coolant Hazard

Wear eye protection and rubber

gloves when you handle coolant

or hydraulic oil. If contact with

your eyes or skin occurs, clean

and wash it o immediately with clean water.

WARNING

Electrical Shock Hazard

- Inside the gyro unit

hazardous voltages are

present. For this reason the

cover must not be opened

when the gyro system is

running and AC power is connected. Also,

never disconnect the yellow/green

earthing/grounding cable, connected to

the ground stud.

- Before opening the cover be sure that the

AC mains supply is disconnected from the

gyro unit.

- Before operating the gyro stabilizer ALWAYS

ensure that the safety ground cable is se-

curely connected to the gyro base frame.

- The inverter box contains hazardous volt-

ages derived from the AC power line. When

inspecting the inside of the inverter box, be

sure to turn o the AC power supply.

- A potentially dangerous voltage is present

even if AC power is disconnected but the

ywheel is still rotating. Therefore, service

work on the inverter box is only permitted

when power is disconnected and the y-

wheel has come to a complete stop.

7

SG80 Operation Manual

SAFETY

NOTICE

The safety messages that follow have NOTICE

level hazards.

Periodic maintenance prevents unexpected

downtime and helps extend the life of the gyro

stabilizer.

Always be environmentally re-

sponsible.

Follow the guidelines of the EPA or other gov-

ernmental agencies for the proper disposal of

hazardous materials such as coolant and hy-

draulic oil. Consult the local authorities or rec-

lamation facility.

Never dispose of hazardous materials by

dumping them into a sewer, on the ground, or

into groundwater or waterways.

Do not shut o the power or short the cables

while the gyro system is running. Damage to

the electrical system will result.

8 SG80 Operation Manual

PRODUCT OVERVIEW

Overview

Smartgyro SG80 is the gyro stabilizer of choice

for boats from 60–70 ft.

Ideal for both new builds and ret installations,

the stabilizer can be fully serviced on-board

the vessel without the need to lift it out for

maintenance, ensuring signicant savings in

time and cost.

For larger vessels, in order to increase the anti-

roll torque, more than one Smartgyro SG80 can

operate in parallel on the same boat. These

units work autonomously and there is no need

to synchronize them.

This manual, therefore, only outlines a single

unit installation, where the gyro stabilizer is

controlled by its own control device (the “Con-

trol display”).

Product overview

9

SG80 Operation Manual

PRODUCT OVERVIEW

System description

This gyro stabilizer contains the following units.

- SG80 gyro unit

- Control display

5

DC 24 V

6

64

3

1

4

2

5

AC 230 V 50-60 Hz

7

Figure 1

1. SG80 gyro unit

2. Control display

3. See water pump *1

4. Electrical connections (electronic control)

5. Electrical connections (power)

6. Hydraulic connections *1

7. Sea water intake

*1. Item not included in the scope of supply.

10 SG80 Operation Manual

PRODUCT OVERVIEW

Figure 2

1. Boat tilt

2. Precession angle

Function of Gyro Stabilizer

This gyro stabilizer is a device that creates an

anti-roll torque that reduces the tilting of the

boat using the gyroscopic principle.

Anti-roll torque is generated by the combined

eect of having a high-inertia ywheel rotat-

ing inside the gyro sphere and the sphere

tilting around the precession axis. The preces-

sion movement is automatically created by

the gyro, when subjected to the sea roll, and is

dynamically adjusted by the control unit, that

regulates the braking eect of two hydrau-

lic cylinders, to transmit the optimal anti-roll

torque to the boat.

1

3

33

3

2

44

2

1

1

3

33

3

2

44

2

1

3. Anti-roll torque

4. Bow

11

SG80 Operation Manual

PRODUCT OVERVIEW

Component of SG80 Gyro Unit

1. Heat exchanger

2. Vacuum pump

3. Pressure sensors

4. Accumulators

5. Manifold

6. Vacuum sensor

7. Gyro sphere and ywheel

8. Hydraulic cylinders

9. Precession angle sensor

10. Base frame

11. Lower bearing

12. Inverter box

13. Upper bearing

14. Glycol pump

15. Control box

16. Motor sealed sleeve

17. IR sensor (upper) sealed sleeve

18. IR sensor (lower) sealed sleeve

Figure 3

1234

9

11

12

17

18

16 6

7

13

14

15

10

5

6

7

8

12 SG80 Operation Manual

PRODUCT OVERVIEW

Description of SG80 Gyro Unit

The control unit monitors the system components and displays the information obtained on the

control display.

The following components are monitored by the control unit.

Name of component Description

Flywheel The ywheel rotates inside the gyro sphere.

It takes the ywheel about 45 minutes to accelerate from a stand-

still and reach top speed. It also takes about 120 minutes to decel-

erate from top speed to a complete halt.

Upper and lower bearings Because the upper and lower bearings support the ywheel rotat-

ing at high speed, they are subjected to heavy loads and high tem-

peratures. Therefore, the glycol pump circulates coolant to reduce

the temperature of these bearings.

Vacuum pump The vacuum pump creates a specic grade of vacuum state inside

the gyro sphere to minimize air resistance generated when the y-

wheel rotates.

Hydraulic cylinders Two hydraulic cylinders are used to brake and control the preces-

sion movement of the sphere.

When the user wants to lock precession, the system applies a brake

to the gyro sphere by blocking oil ow within the cylinders. In this

condition no antiroll torque is generated by the gyro.

13

SG80 Operation Manual

PRODUCT OVERVIEW

Description of control display

The control display is the interface between

the user and the operation of the gyro unit. It

is typically installed on the boat’s helm station.

When the system is powered (DC 24 V), the dis-

play turns on and the splash screen is displayed

(Smartgyro logo). After about 40 seconds since

power on, the Home page (Figure 5) appears.

The home page groups and displays the most

important parameters of the gyro unit.

Figure 4

The main purpose of the display is to activate,

control and monitor the gyroscope during its

operation.

In the case of an anomaly, the display unit au-

tomatically warns the operator of the failure

which has occurred, showing an anomaly mes-

sage on a dedicated alarm log page.

The control display is a touchscreen device

and can be operated by pressing the icons dis-

played on it.

Figure 5

14 SG80 Operation Manual

PRODUCT OVERVIEW

Figure 6

Home page

The following information elds are presented on the home page.

3

9

5

6

2

11

1

7

8

4 10

Display item Description

1 Power (ON/OFF)

icon

When the gyro system is powered, the outer circle of this icon is gray; when the

icon is pressed, the circle turns green, indicating that the system is powered (basi-

cally that the motor drive is on) and running. If for any reason the stabilizer unit

cannot be turned on, the circle remains gray.

2 Precession

lock toggle icon

When the ywheel is accelerating and has not reached a minimum velocity (set

at 55 % of top speed), the precession lock toggle icon has no eect on preces-

sion, which remains locked; this condition is signalled by the presence of yellow

circle around the icon. Once the ywheel rotation speed has reached 55 % of top

speed, the circle goes blue, and the functionality of the icon is enabled.

A red circle indicates that precession is locked and no antiroll torque is generated.

By pressing the icon, the circle is red and precession is locked.

Pressing the icon again, the outer ring becomes blue, precession is unlocked and

antiroll torque is generated (and so on, thereby toggling functionality).

3 Menu icon By pressing this icon, it is possible to log into the various pages of the menu.

See gure 17.

15

SG80 Operation Manual

PRODUCT OVERVIEW

Display item Description

4 Identication

number

Displays the identication number of the gyro currently selected. The stabilizer

identication number can be set in a password protected page of the Settings

menu.

In general, data presented on the various pages of the display refer to the gyro

whose ID is selected (and displayed) on this page.

5 Roll angle This information is derived from the IMU (Inertial Measurement Unit) inside the

control box and is presented in both digital and analogue form; digital data is in a

“two digits + sign” format. See“Indication of roll and pitch angles on page 16.

6 Precession angle

(gyro sphere

angular position)

Precession angle given in both digital and analogue.

In digital form, it is presented as the actual angle (in degrees) of the gyro sphere

with respect to the vertical.

In analogue form, it is represented by a blue bar that originates from the center

and goes to the left or the right depending on the angle of the sphere. See“Indi-

cation of precession angle” on page 17.

7 Speed indication Flywheel rotation speed given in both digital and analogue.

In digital form, it is shown as a percentage of top speed (“day” speed); when the

system is accelerating, this indication goes from 0 % to 100 % (if the system is in

“day” mode) or to 65 % (if in“night” mode).

In analogue form, it is shown as a circular dial, whose red pointer indicates the

actual speed, expressed as percentage of top speed.

8 Bearing

temperatures

The temperatures of both upper and lower bearing packs are presented in the

form of two curved segments whose length increases proportionally to the meas-

ured temperature.

9 Pressure of

hydraulic circuits

The two pressure values are presented here in the form of two curved segments

whose length is proportional to the pressure itself.

10 Local time

(hours, minutes,

seconds)

Hour information is stored in the battery-powered real-time clock inside the gyro’s

Control Unit. The local time can be set reaching the “Set time”option described on

page 18.

11 Gyro working state Indicates the current operating state (“mode”) of the stabilizer.

See table on page 25.

16 SG80 Operation Manual

PRODUCT OVERVIEW

Indication of roll and pitch angles

A positive roll is observed when the starboard

side of the vessel is angled upward (starboard

up) (Figure 7).

A positive pitch is observed when the bow of

the vessel is angled downward (bow down)

(Figure 8).

If the roll is positive, the semi-circular bar on the

Home page moves to the right (Figure 9).

Figure 9

A negative roll is observed when the port side of

the vessel is angled upward (port up) (Figure 10).

A negative pitch is observed when the bow of

the vessel is angled upward (bow up) (Figure 11).

If the roll is negative, the semi-circular bar on the

Home page moves to the left (Figure 12).

Figure 12

Figure 7

Figure 8

Figure 10

Figure 11

This manual suits for next models

1

Table of contents

Other SmartGyro Boating Equipment manuals

Popular Boating Equipment manuals by other brands

Zattini Group

Zattini Group bamar BTM 08 Use and maintenance instruction manual

Muir

Muir STORM VR 2500 manual

Attwood

Attwood 11930-4 Owner's instructions

SureShade

SureShade Power Bimini Installation and owner's manual

bamar

bamar PE instruction manual

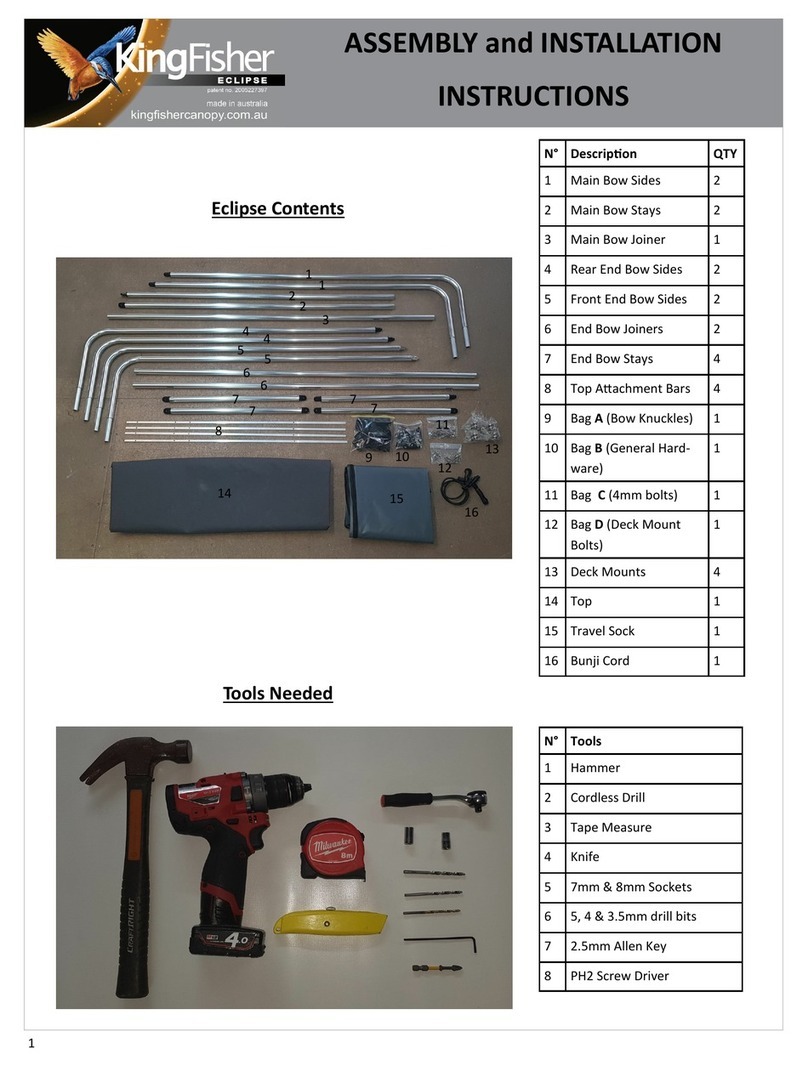

Kingfisher

Kingfisher ECLIPSE Assembly and installation instructions