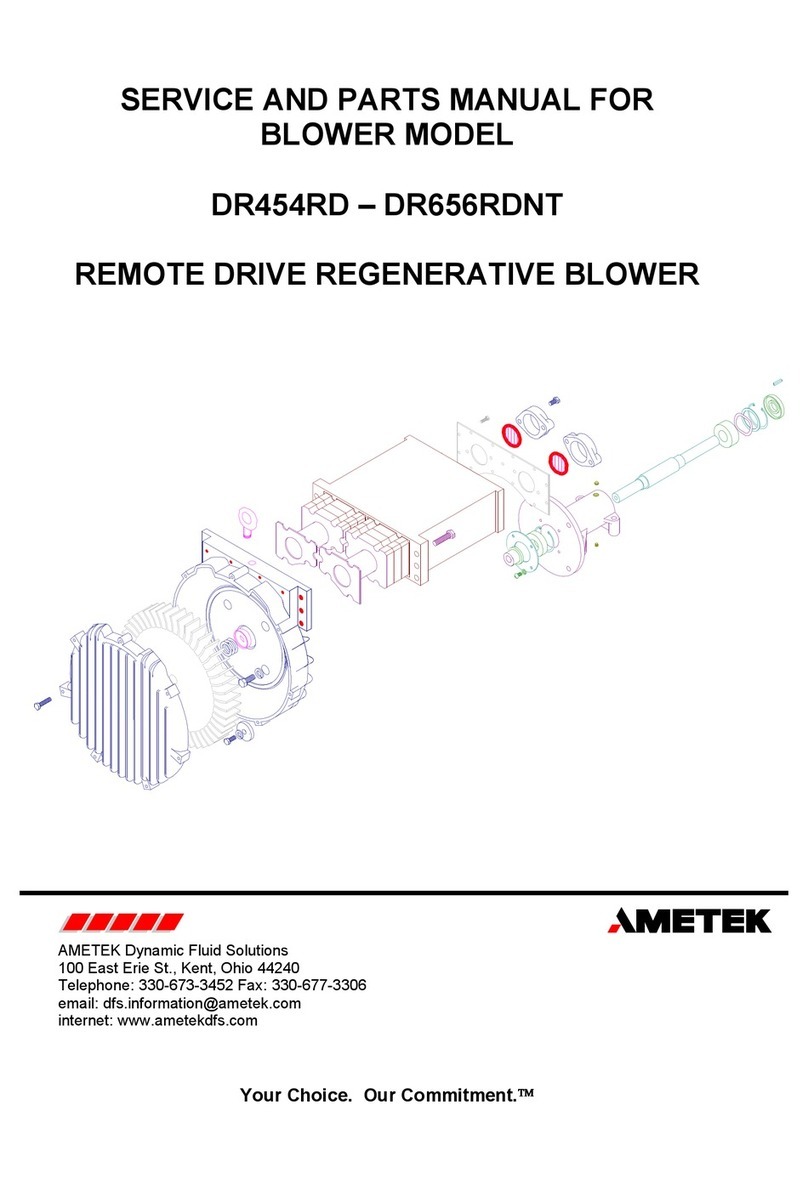

1 Revised – June 2016

AMETEK Dynamic Fluid Solutions

100 East Erie St., Kent, Ohio 44240

Telephone: 330-673-3452 Fax: 330-677-3306

email: dfs.information@ametek.com

internet: www.ametekdfs.com

1. AMETEK Rotron DR, EN and HiE regenerative direct drive blowers are guaranteed for one full

year from the date of installation (limited to 18 months from the date of shipment) to the original

purchaser only. Should the blower fail we will evaluate the failure If failure is determined to be

workmanship or material defect related, we will at our option repair or replace the blower.

2. AMETEK Rotron Minispiral, Revaflow, Multiflow, Nautilair, remote drive blowers, moisture

separators, packaged units, CP blowers, Nasty Gas™ models and special built (EO) products are

guaranteed for one full year from date of shipment for workmanship and material defect to the

original purchaser only. Should the blower fail, If failure is determined to be workmanship or

material defect related, we will at our option repair or replace the blower.

3. Parts Policy - AMETEK Rotron spare parts and accessories are guaranteed for three months from

date of shipment for workmanship and material defect to the original purchaser only. If failure is

determined to be workmanship or material defect related we will at our option repair or replace the

part.

Corrective Action - A written report will be provided indicating reason(s) for failure, with suggestions

for corrective action. Subsequent customer failures due to abuse, misuse, misapplication or repeat

offense will not be covered. AMETEK Rotron will then notify you of your options. Any failed unit that is

tampered with by attempting repair or diagnosis will void the warranty, unless authorized by the

factory.

Terms and Conditions - Our warranty covers repairs or replacement of regenerative blowers only,

and will not cover labor for installation, outbound and inbound shipping costs, accessories or other

items not considered integral blower parts. Charges may be incurred on products returned for reasons

other than failures covered by their appropriate warranty. Out-of-warranty product and in warranty

product returned for failures determined to be caused by abuse, misuse, or repeat offense will be

subject to an evaluation charge. Maximum liability will in no case exceed the value of the product

purchased. Damage resulting from mishandling during shipment is not covered by this warranty. It is

the responsibility of the purchaser to file claims with the carrier. Other terms and conditions of sale are

stated on the back of the order acknowledgement.

Installation Instructions for SL, DR, EN, CP, and HiE Series Blowers

1. Bolt It Down - Any blower must be secured against movement prior to starting or testing to

prevent injury or damage. The blower does not vibrate much more than a standard electric motor.

2. Filtration - All blowers should be filtered prior to starting. Care must be taken so that no foreign

material enters the blower. If foreign material does enter the blower, it could cause internal

damage or may exit at extremely high velocity.

Should excessive amounts of material pass through the blower, it is suggested that the cover(s)

and impeller(s) be removed periodically and cleaned to avoid impeller imbalance. Impeller