CONTENTS

Product Features and Specifications ..............................................1

Installation Requirement .............................................................3

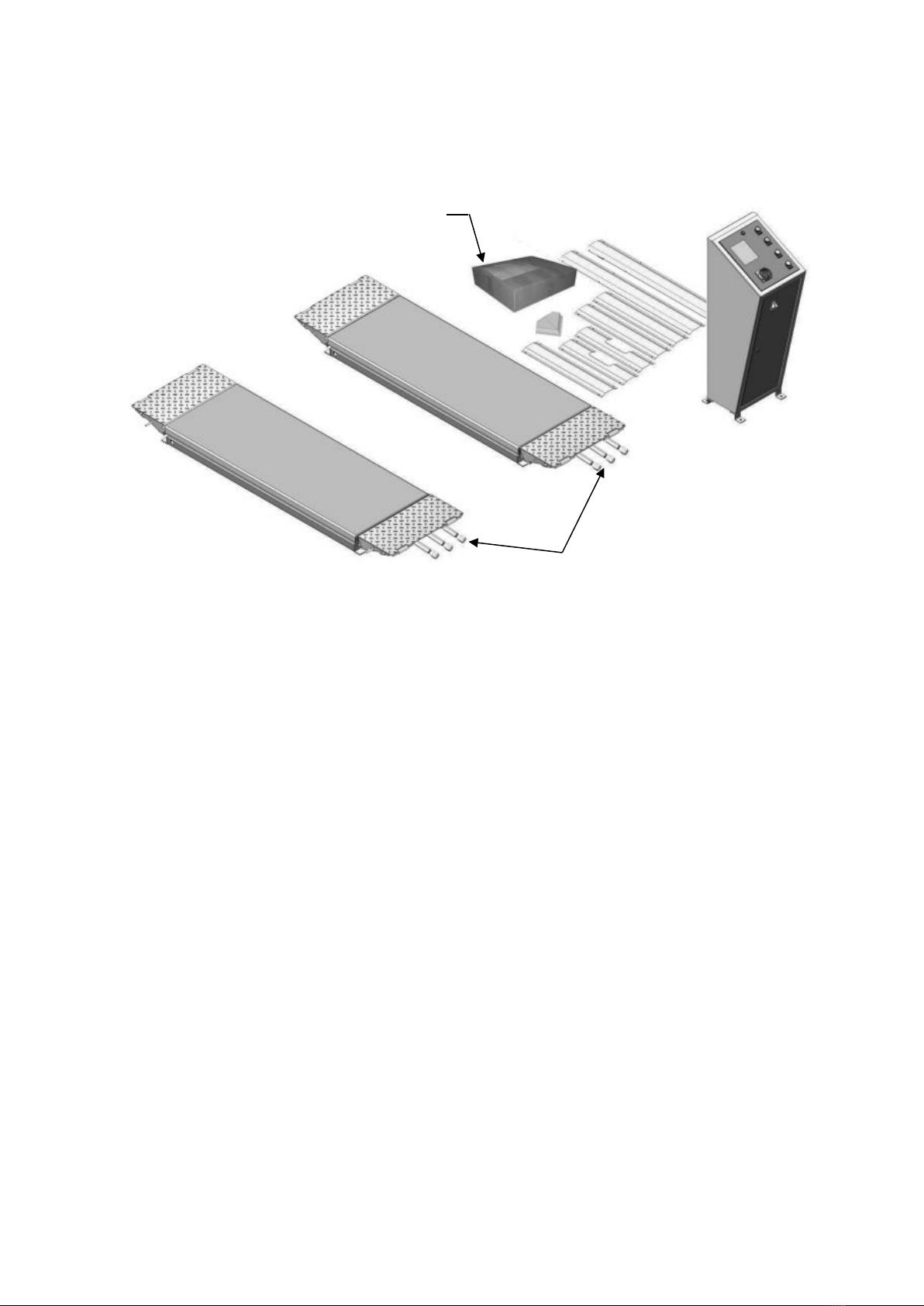

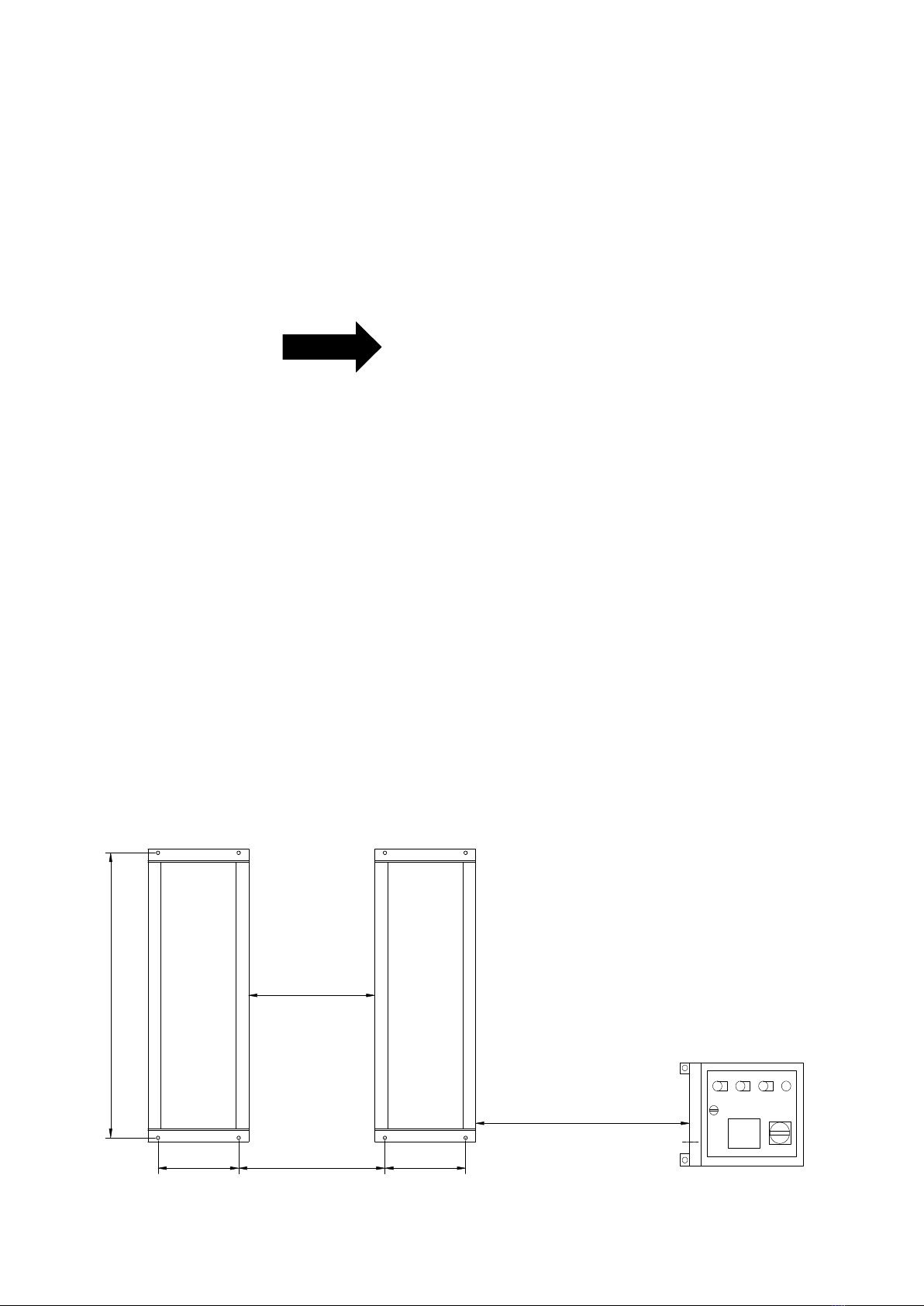

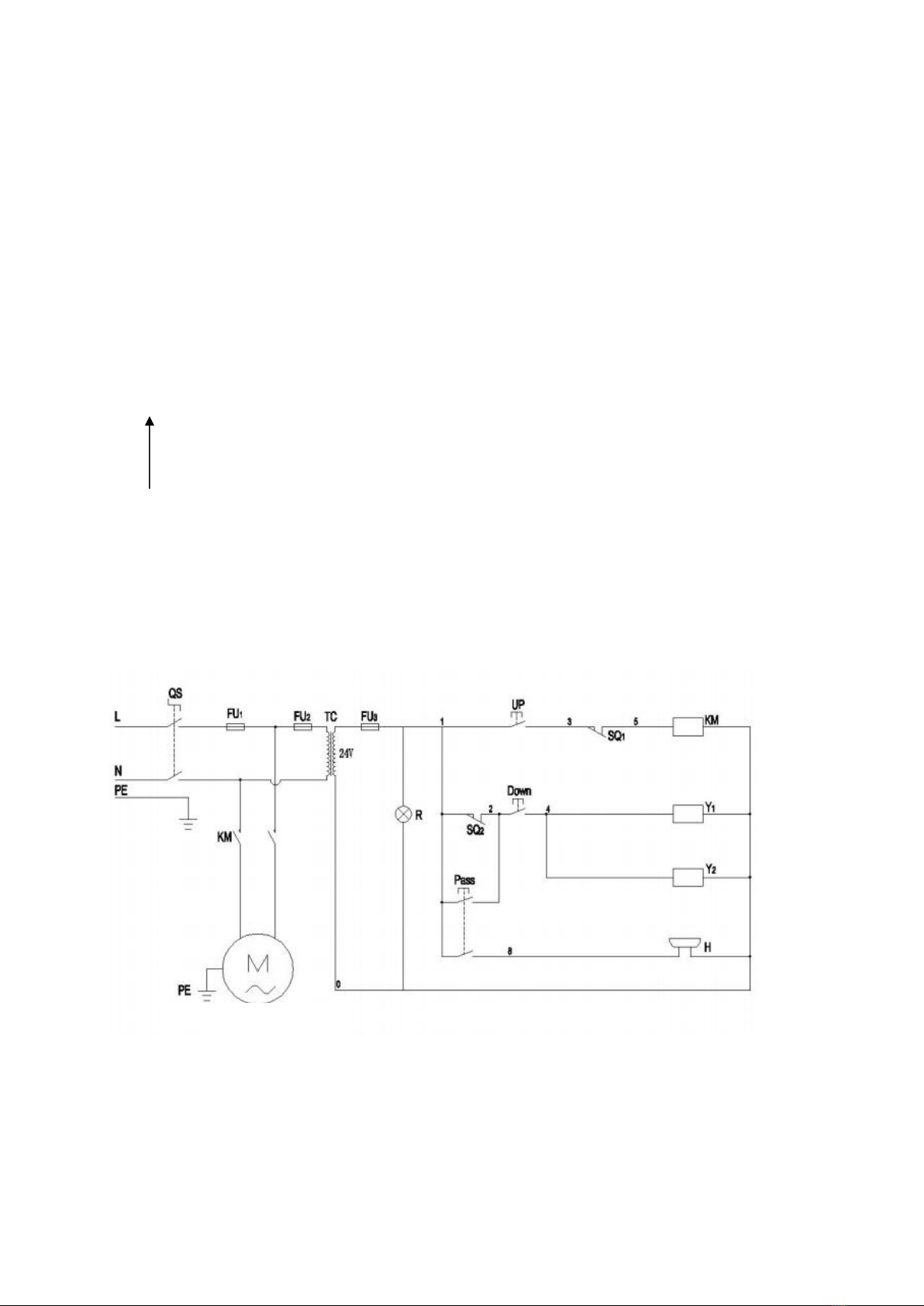

Steps of Installation ………………………………………………..…………………….…...4

Exploded View .........................................................................14

Test Run .................................................................................22

Operation Instruction ................................................................23

Maintenance ............................................................................24

Trouble Shooting ......................................................................25

Lift disposal .............................................................................25