FILTER TYPE 2" AAF 000616-101019 /07.2017 Page 3of 28

Table of Contents

1. Introduction........................................................................................................................... 4

2. Safety Instructions.................................................................................................................. 4

2.1 General Safety Instructions:..................................................................................................... 4

2.2 General Installation:................................................................................................................4

2.3 Shipment and transporting: .....................................................................................................5

2.4 Electricity: .............................................................................................................................. 5

2.5 Pneumatics:............................................................................................................................5

2.6 Hydraulics:.............................................................................................................................. 5

2.7 Civil Engineering:..................................................................................................................... 6

2.8 Commissioning: ...................................................................................................................... 6

2.9 Operation and Control:............................................................................................................ 6

2.10 Maintenance:........................................................................................................................6

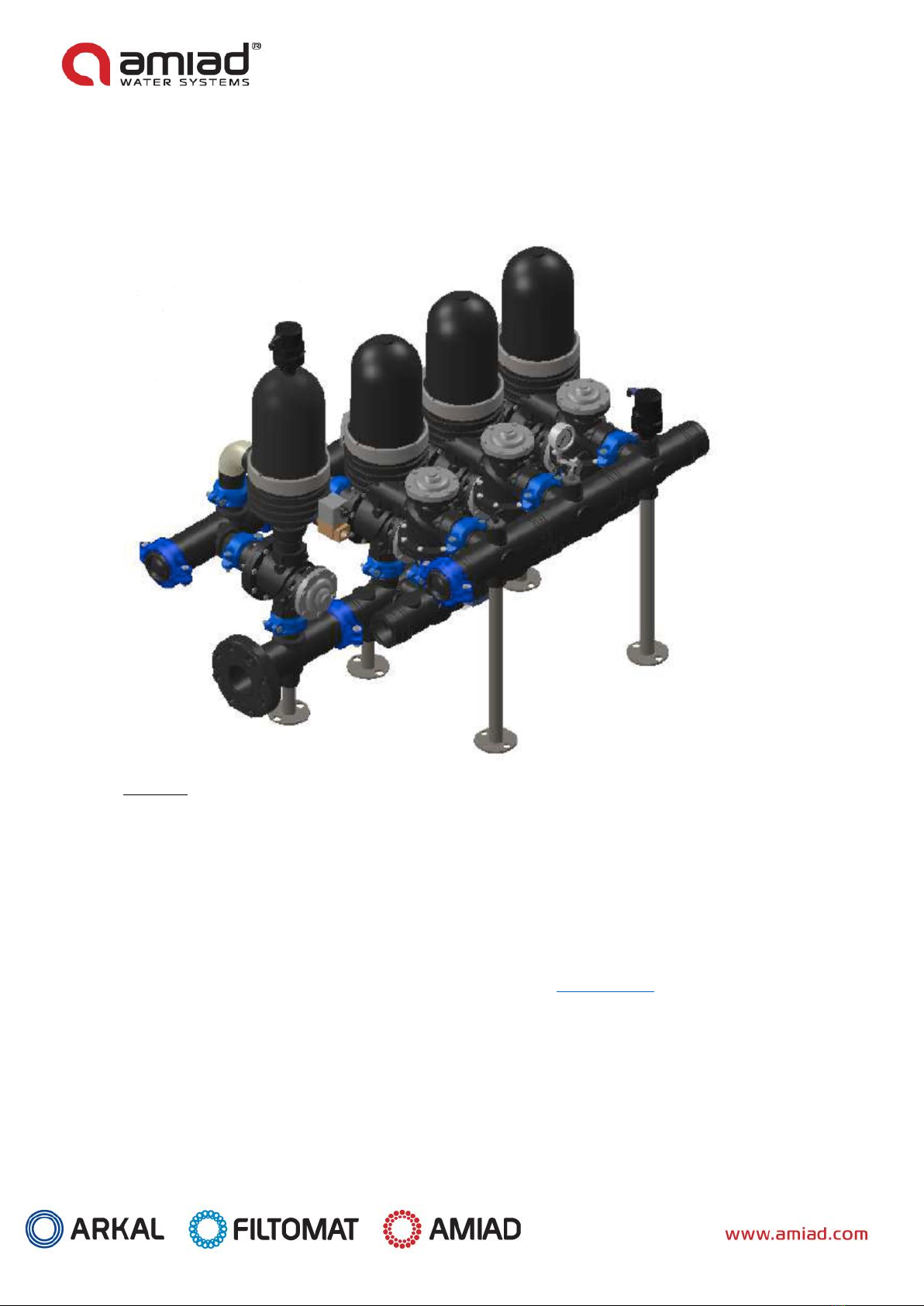

3. Description & Operation ......................................................................................................... 7

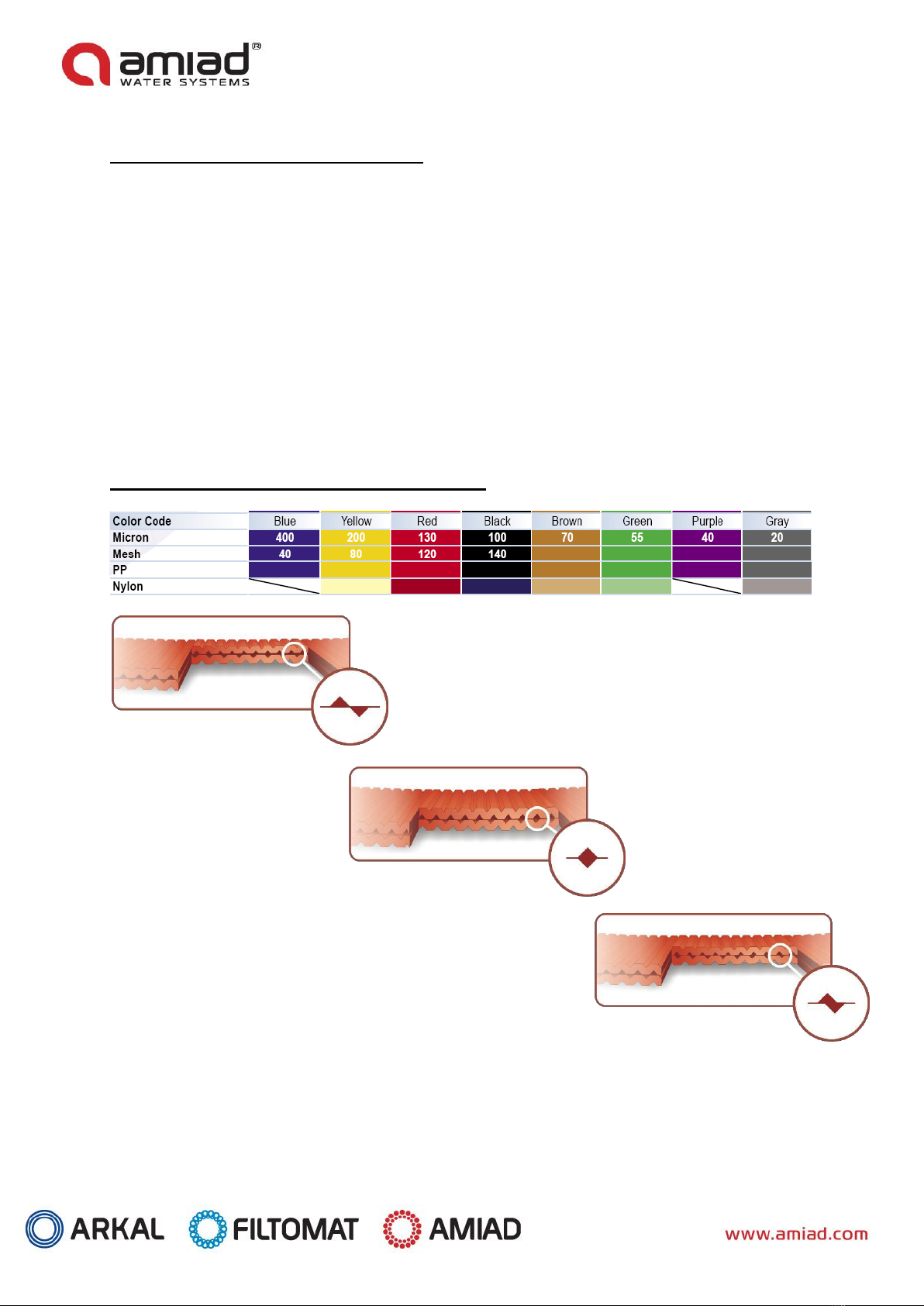

3.1 Disc Filtration Technology:.......................................................................................................7

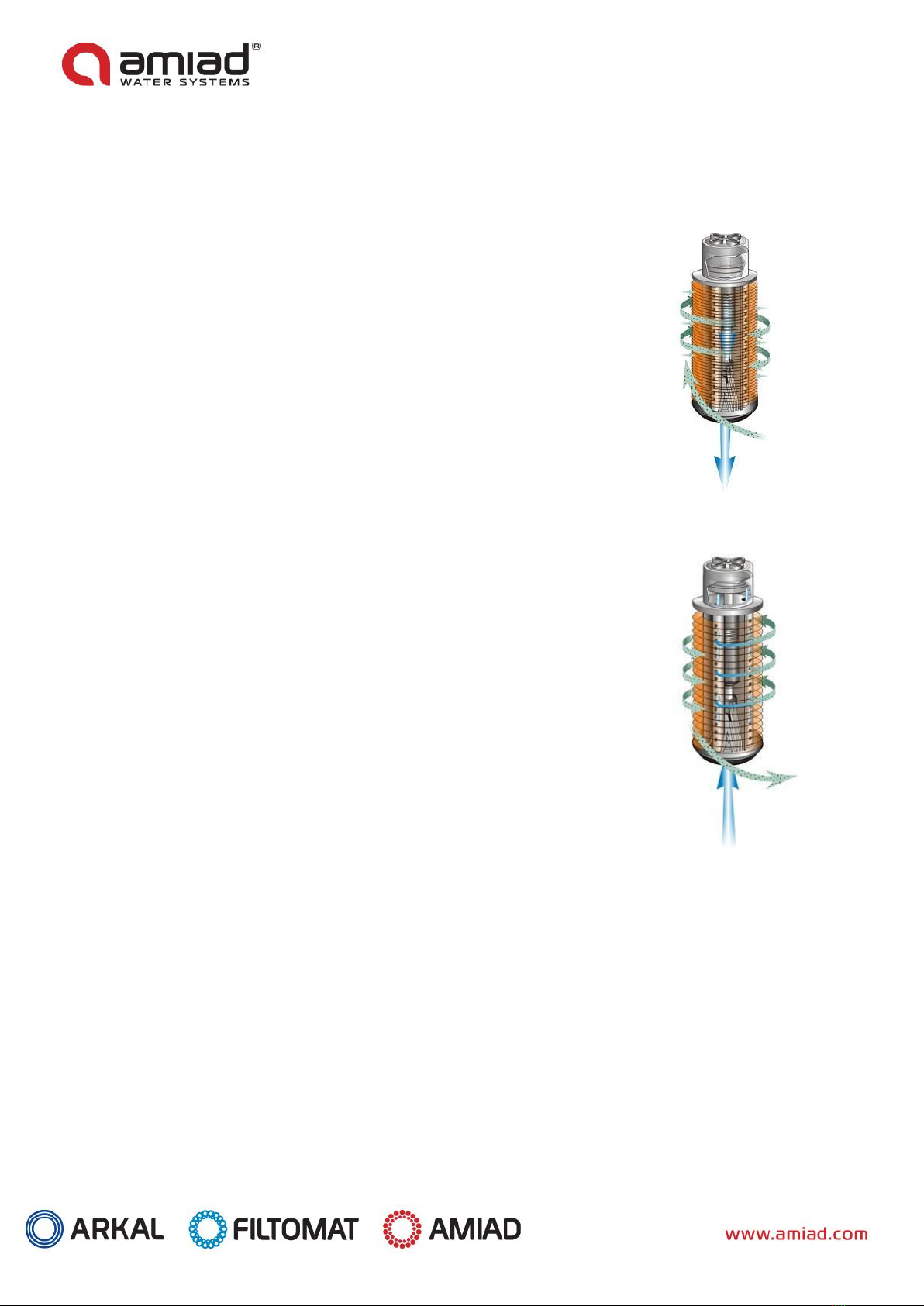

3.2 Spin Klin Technology: .............................................................................................................. 8

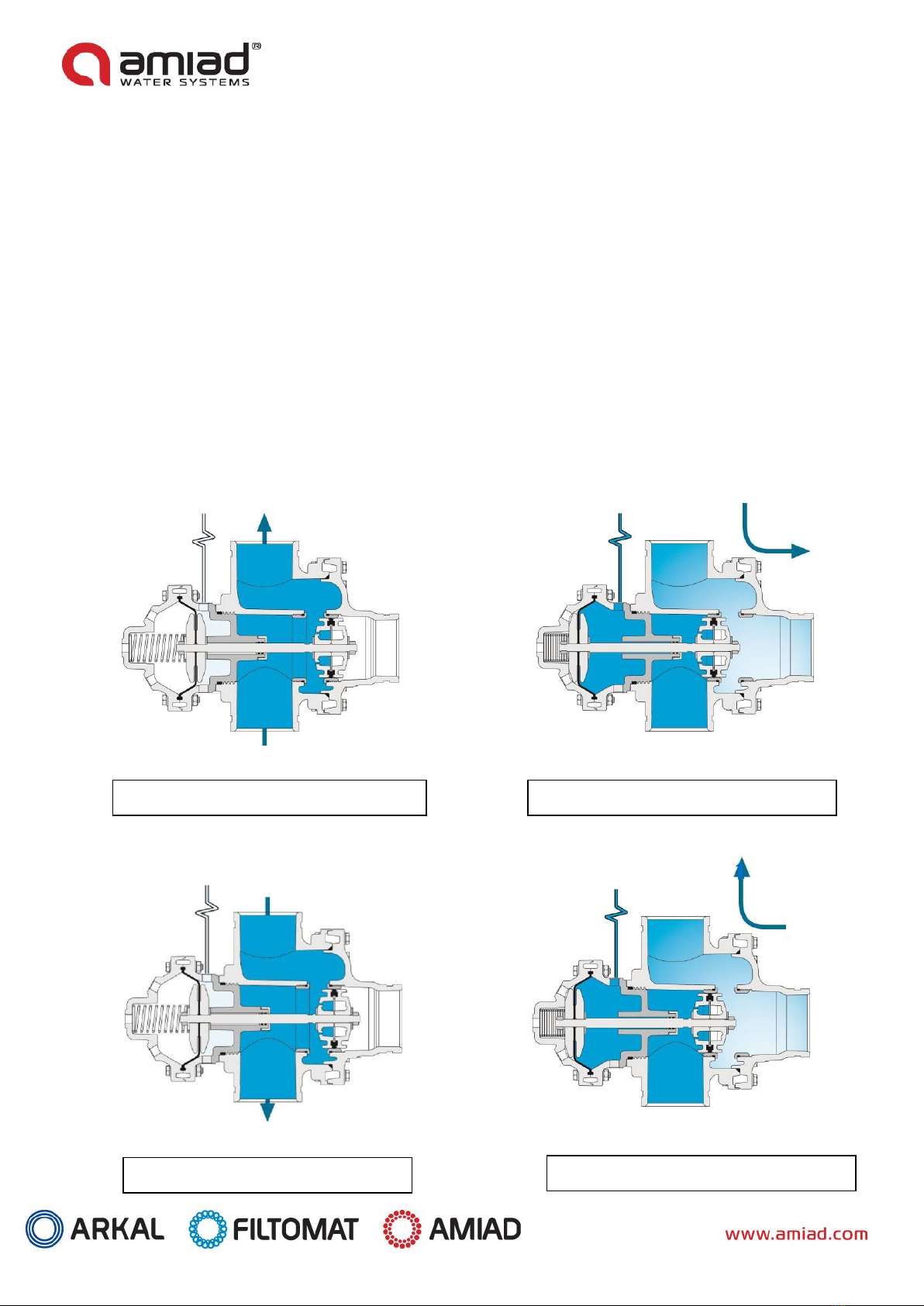

3.3 Back-flush Valves Operation Mode:..........................................................................................9

Filtration Process .................................................................................................................. 10

Back-flushing Process............................................................................................................ 10

4. Technical Data...................................................................................................................... 11

5. Dimensional Drawing............................................................................................................ 12

6. Installation & Start-up ......................................................................................................... 13

7. System Maintenance ............................................................................................................ 14

7.1 General inspection of the filter module operation:.................................................................. 14

7.2 Weekly maintenance:............................................................................................................ 14

7.3 Maintenance prior to long term cessation of filter operation: .................................................. 14

7.4 Maintenance prior to re-operation:........................................................................................ 14

7.5 Periodical: ............................................................................................................................ 15

7.6 Service & Opening the Filter Lid: ............................................................................................ 15

7.7 Cleaning Recommendations:.................................................................................................. 17

8. Troubleshooting ................................................................................................................... 19

9. Control Scheme .................................................................................................................... 21

11. FILTER PARTS SCHEDULE AND PARTS LIST............................................................................. 22

12. VALVES - PARTS SCHEDULE AND PARTS LIST ......................................................................... 23

12.1 STANDARD VALVES PARTS LIST ............................................................................................ 24

12.2 AW VALVES PARTS LIST........................................................................................................ 25

12.3 SW VALVES PARTS LIST ........................................................................................................ 26

13. SYSTEM DRAWINGS (to be amended per each specific ordered) ............................................ 27

14. AMIAD LIMITED WARRANTY ............................................................................................... 28