3

Parts & Service: 020 8988 7400 / E-mail: Parts@clarkeinternational.com or Service@clarkeinternational.com

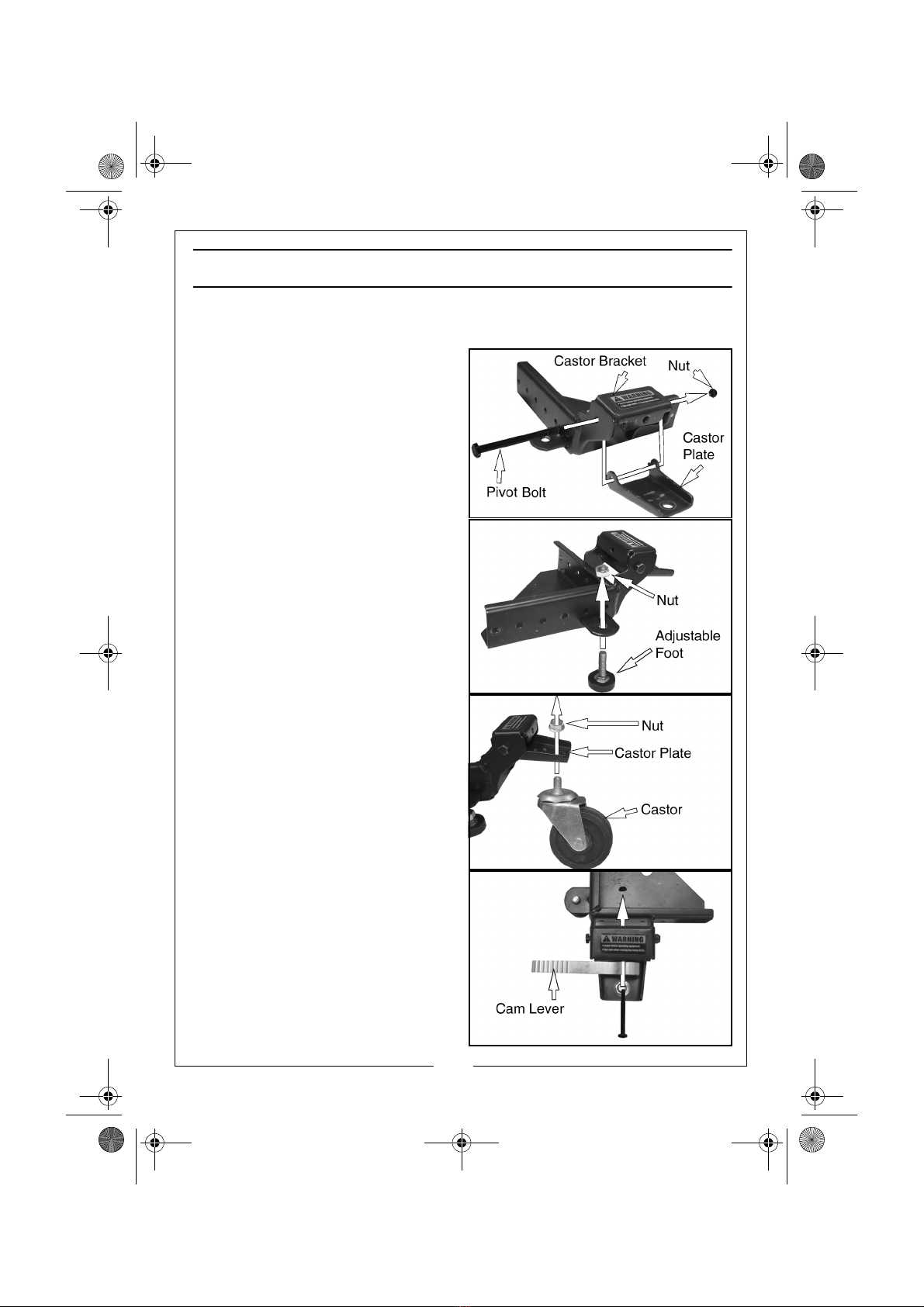

SAFETY INSTRUCTIONS FOR MOBILE BASES

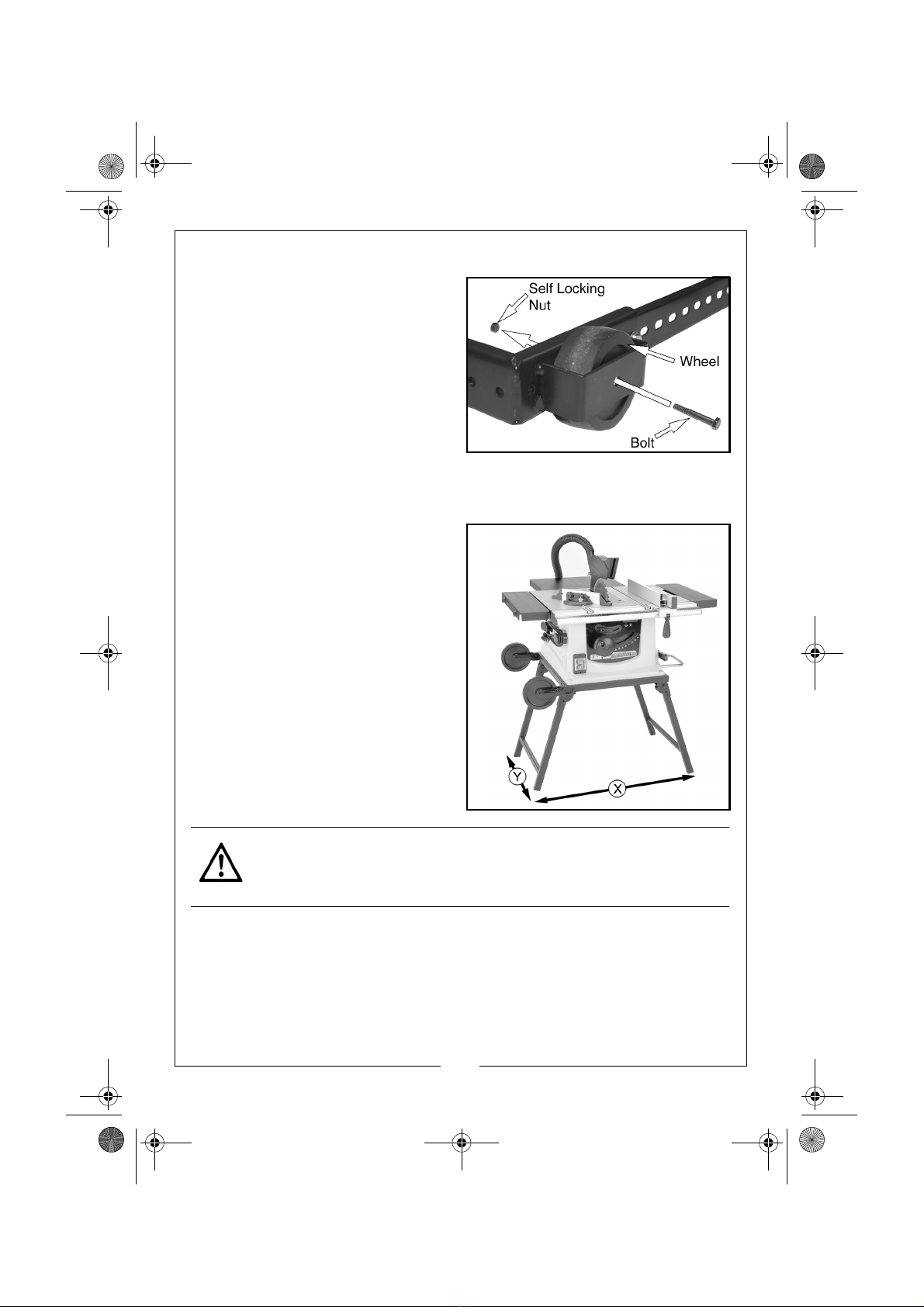

1. Place the mobile base on a level surface and adjust the feet before

placing the machine in position. This should stop the machine rocking,

while testing it for stability. Test for stability in both the up (on the castors)

and the down positions.

2. Exercise caution when testing the stability of top heavy machines.

3. Unplug any power tool before moving or repositioning the mobile base.

4. Always check stability for safety after repositioning.

5. Care should be taken when planning the orientation of the machine on

the universal mobile base. When the weight is on the castors the machine

will tilt 1/2'' toward the fixed wheels. When positioning top heavy tools such

as a drill press or band saw, take advantage of the center of gravity, and

position it so that it will remain stable while on castors.

6. Never use your machine while it is supported on the two swivel castors.

Always lower the machine onto the adjustable feet before operating.

7. When moving, always push the base, not the machine. take care not to tilt

the machine over when moving.

8. SECURE ALL FASTENERS - Make sure that all nuts & bolts on the mobile base

are fully tightened before installing a machine.

9. RESPECT THE RATED WEIGHT LIMIT - Do not install machines exceeding the

rated weight capacity of the mobile base. (See Page 7)

10. SELECT AN APPROPRIATE LOCATION FOR USE - Use only on flat, smooth,

sturdy surfaces, that are free of debris and able to support the weight of

the machine and the operator.

11. DISENGAGE CAM LEVERS - Verify that all cam levers are disengaged before

turning on your machine. Failure to ensure that your machine is completely

immobile may cause serious injury if the machine begins to move across

the floor when in use or as the workpiece is fed into the blade(s) or cutting

tool.

12. LOOK BEFORE YOU MOVE THE MACHINE - Ensure that there is a clear path

to the destination before moving it. Avoid rolling over any power cords or

debris, clutter or obstructions.

13. DO NOT OVERLOAD - The mobile base is designed to roll smoothly when

operating within its rated weight capacity and requires only steady

pressure to move around. If you find that excessive force is needed, STOP

and check for obstructions or damage to the wheels before proceeding.

CUMB1 - Universal Mobile Base.fm Page 3 Thursday, March 28, 2013 12:34 PM