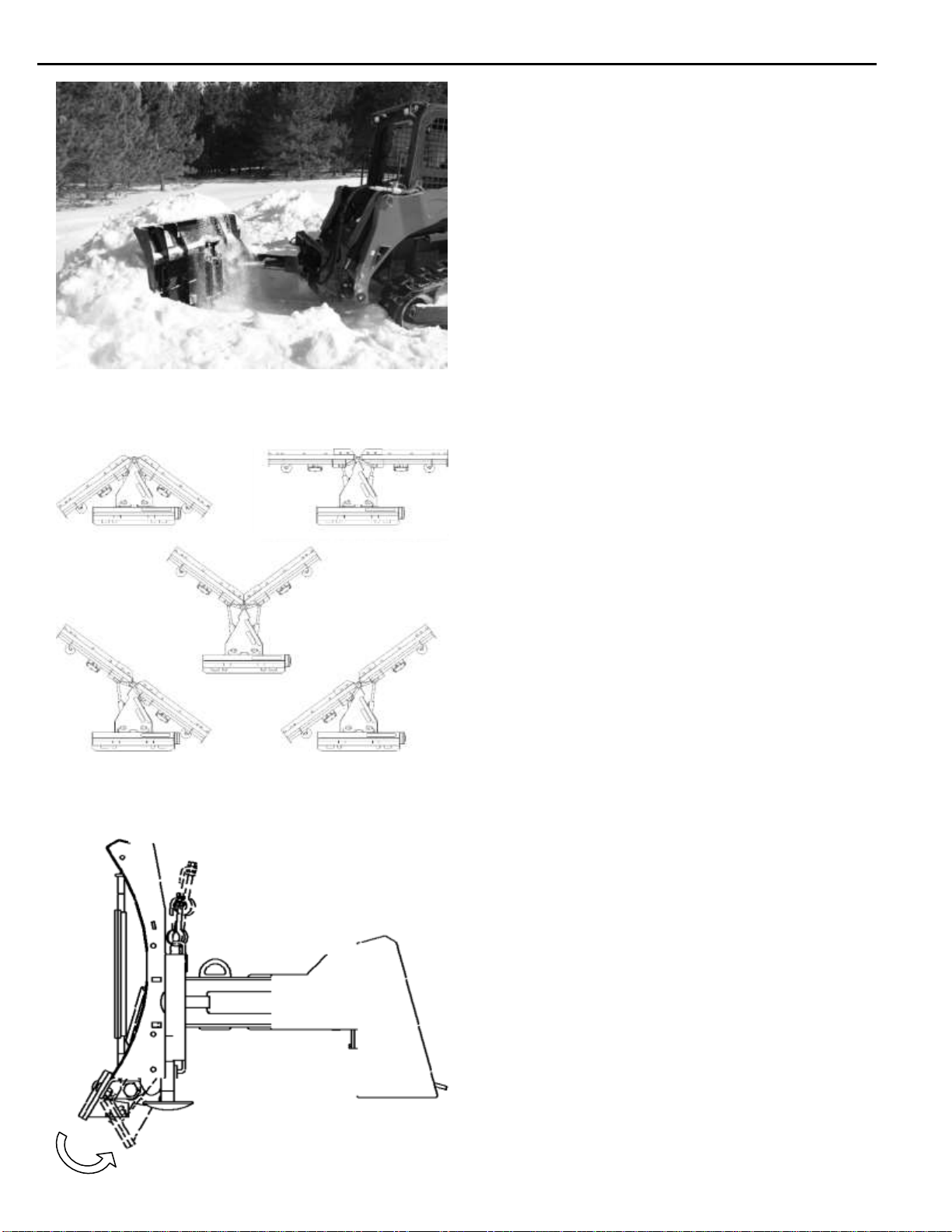

IMPORTANT: The v-plow is designed for snow

removal only. It is not designed for moving or grading

soil.

1. With the operator in the seat of the loader, the seat

belt fastened, and the seat bar lowered (if so

equipped), start the engine.

2. With the loader lift arms fully lowered, tilt the

attachment forward to rest on the skid shoes.

3. Drive the loader forward to push snow.

4. Use the loader lift and tilt functions to increase

traction and adjust the pitch of the v-plow.

Blade Angle

The v-plow utilizes a specially designed valve block to

change the blade orientation without the requirement

of an electrical attachment control system. The valve

block isolates one side of the attachment as the

priority side, with the secondary side moving once the

priority side has reached the end of its stroke.

1. Activate the auxiliary hydraulic circuit to move the

priority side to the desired position and keep it

activated until the secondary side has moved to

the desired configuration.

2. To move the blades into a position other than the

end of the stroke, activate the auxiliary hydraulic

circuit until the secondary side is in the desired

position, then reverse the hydraulic flow until the

priority side in in the desired position.

NOTE: The blades may have to be repositioned after

hard contact with a solid object. This is normal due to

the design of the valve block.

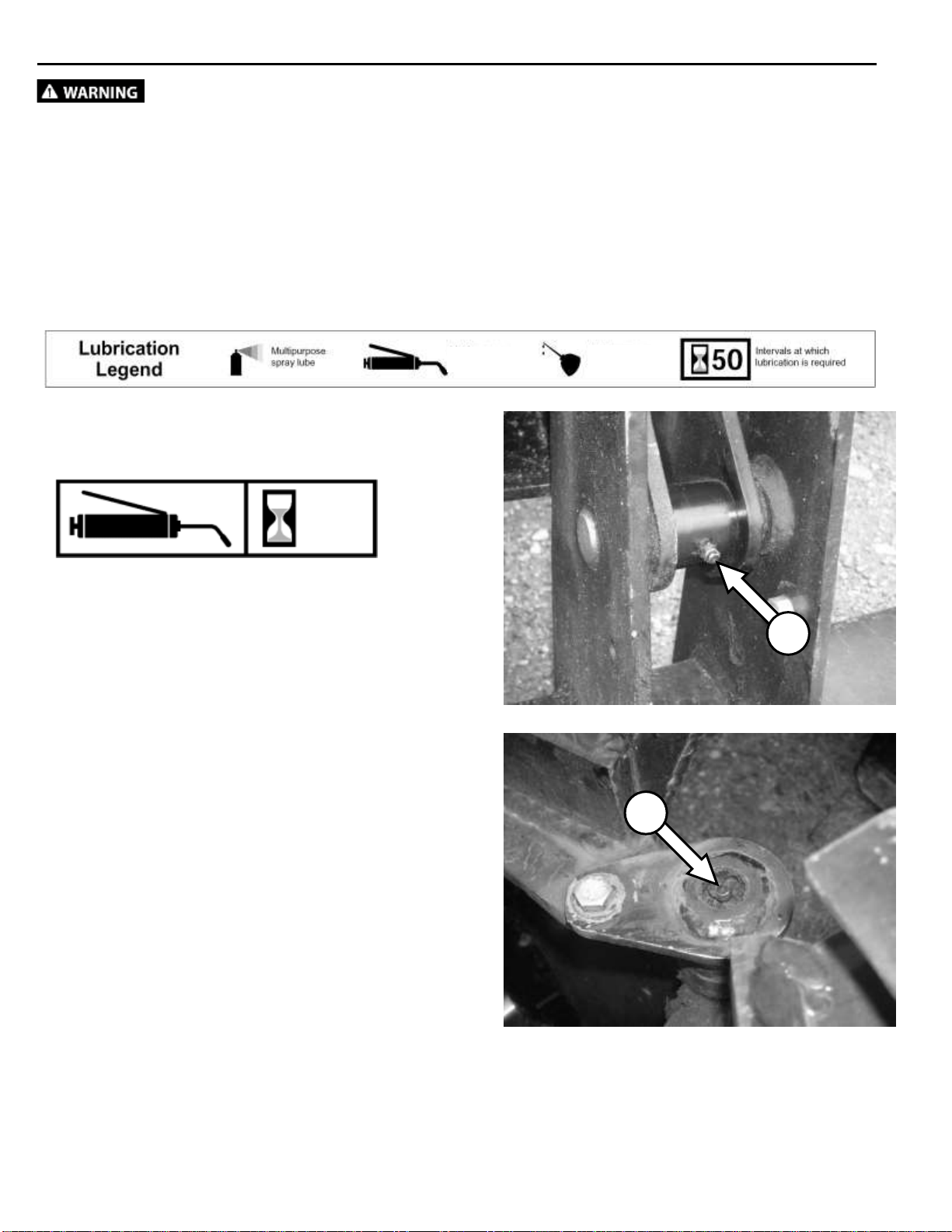

Trip Springs

The v-plow is equipped with trip springs which allow

the cutting edge to trip when it strikes an obstruction.

This helps to protect the attachment and the

obstruction from damage.

To reset the trip springs after striking an obstruction,

raise the loader lift arms to lift the attachment slightly

off of the ground, or slowly drive the loader backward

a few feet.