INSTALLATION OF STANDARD LIFT ARM ASSEMBLY

®is designed to pick up your POV using a lift arm attached to the seat post (Figure7)

Make sure your seat post is securely mounted to your vehicle platform.

A support collar has been added to the lift arm bracket over the seat post. You must fasten the support

collar rst by inserting both 1/4-20 x 5/16 (#5379) long set screws into the support collar and using a 1/8” Allen

wrench to tighten down the set screws securely against the seat post. Resume with the following

instructions to tighten down the spacers.

Provided are two spacers, two bolts, two nuts, two washers, and two set screws that are

®Parts Diagram.

Permanently secure the lift arm (#7545 STD) one inch below the top of the seat post (Figure 7), extending toward the front of

the vehicle. Insert both set screws (#5379) into the rear of the lift arm and tighten the set screws against the seat post. Place

one spacer (#7238) inside the lift arm bracket, aligning the center with the rst mounting hole. Insert one of the bolts (#1344)

through the bracket and spacer and fasten with one of the nuts (#3083) (#1, Figure 7a). If you have a power seat lift which

electronically raises and lowers your seat, be sure the lift arm assembly (#7544) is mounted on the outer tube, NOT on the

inner moveable tube, and the top of the bracket is 3/8 inch (.95 cm) above the outer tube (Figure 7b).

After installing the lift arm on the seat post, take the second bolt (#1344) and place a washer (#5893) on it. Place your second

spacer inside the lift arm aligning the center with the adjustment slot. Thread the bolt through the arm and spacer, and then

place the second washer over the bolt. Fasten the bolt with the second nut.

Adjust this second spacer over the estimated center of the weight of the vehicle and tighten securely (#2, Figure 7a). Next,

®

boom to the operating position, and swing out over the rear trunk opening. (Refer to section “Operating

®

”, on page 9.)

Lower the boom S-hook and attach it to the lift arm assembly (#2, Figure 7a). Raise your POV o the ground 2-3

inches (5.08 - 7.62 cm) and observe whether it is level. If not, lower the POV and relocate the second spacer along the

adjustment slot until the POV is level.

LIFT BRACKET INSTALLATION OPTIONAL

The optional lift bracket can be used in vans or SUVs to lift the entire POV without

removing the seat and/or

handle. It is installed in place of the standard S-hook.

To attach the lift bracket to the lift webbing, remove the button head screw and one retaining collar from the tube.

Place the tube through the loop in the webbing directly over the J-hook on the other end of the lift bracket.

Reinstall the set collar and the button head screw and tighten the screws securely.

operAting Your Lift•ALL®

Upon raising your lift strap, make sure that the top of the S-hook does not go past the bottom of the strap enclosure. Keep

strap twisting to a minimum. Before lifting your mobility aid, make sure the end of the S-hook is completely engaged around

adjustment spacer. (Figure 7a, No. 2 adjustment spacer.)

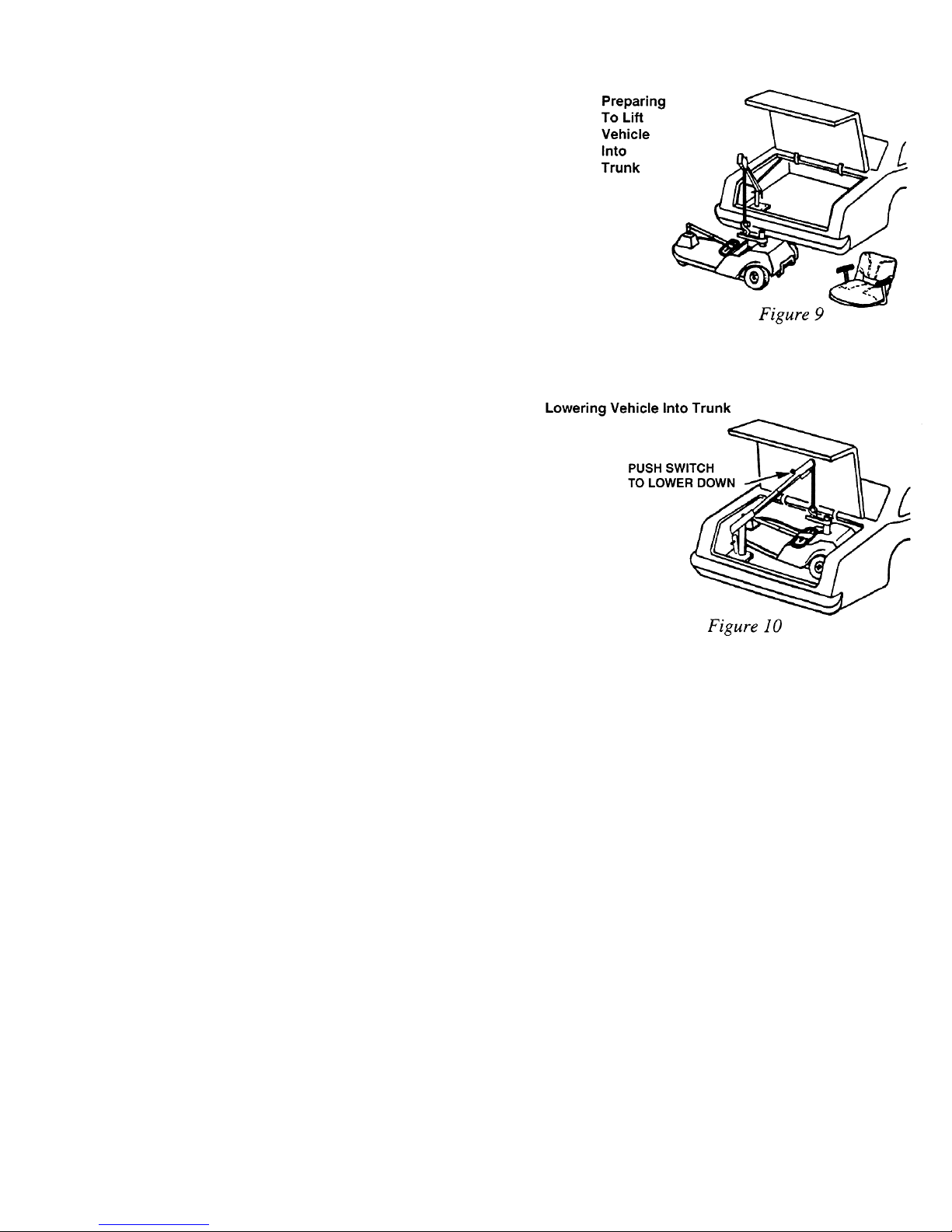

STEPS TO LOADING POV INTO TRUNK

1)

Unhook the shock cord from the end of the boom. Lift the boom until you can latch the S-hook over the 1/2-inch

(1.27 cm) diameter bolt at the boom inner end using the black handle (Figure 8).

2)

Park your POV close to the car, parallel to the rear bumper. Remove the seat from the POV. Remove or fold down the drive

handle of the POV.

www.myamigo.com 9