User Manual for AML Oceanographic’s Micro Pressure Sensor

AML OCEANOGRAPHIC

In-situ Real-time Detection Measurement

TABLE OF CONTENTS

1 – INTRODUCTION ................................................................................................................................................. 3

1.1 WARRANTY AND LIMITATION OF LIABILITY ......................................................................................................... 3

DISCLAIMER .............................................................................................................................................................. 3

1.2 INSTRUMENT SPECIFICATIONS .............................................................................................................................. 4

1.3 SYSTEM DESCRIPTION .......................................................................................................................................... 4

1.4 ABOUT THE USER ................................................................................................................................................ 5

2 GETTING STARTED .............................................................................................................................................. 6

2.1 INSPECTING THE INSTRUMENT ............................................................................................................................. 6

2.2 CONNECTING THE MICRO PRESSURE SENSOR TO A COMPUTER ........................................................................... 6

2.3 POWERING THE MICRO PRESSURE SENSOR .......................................................................................................... 6

3 COMMUNICATING WITH THE MICRO PRESSURE SENSOR .................................................................... 7

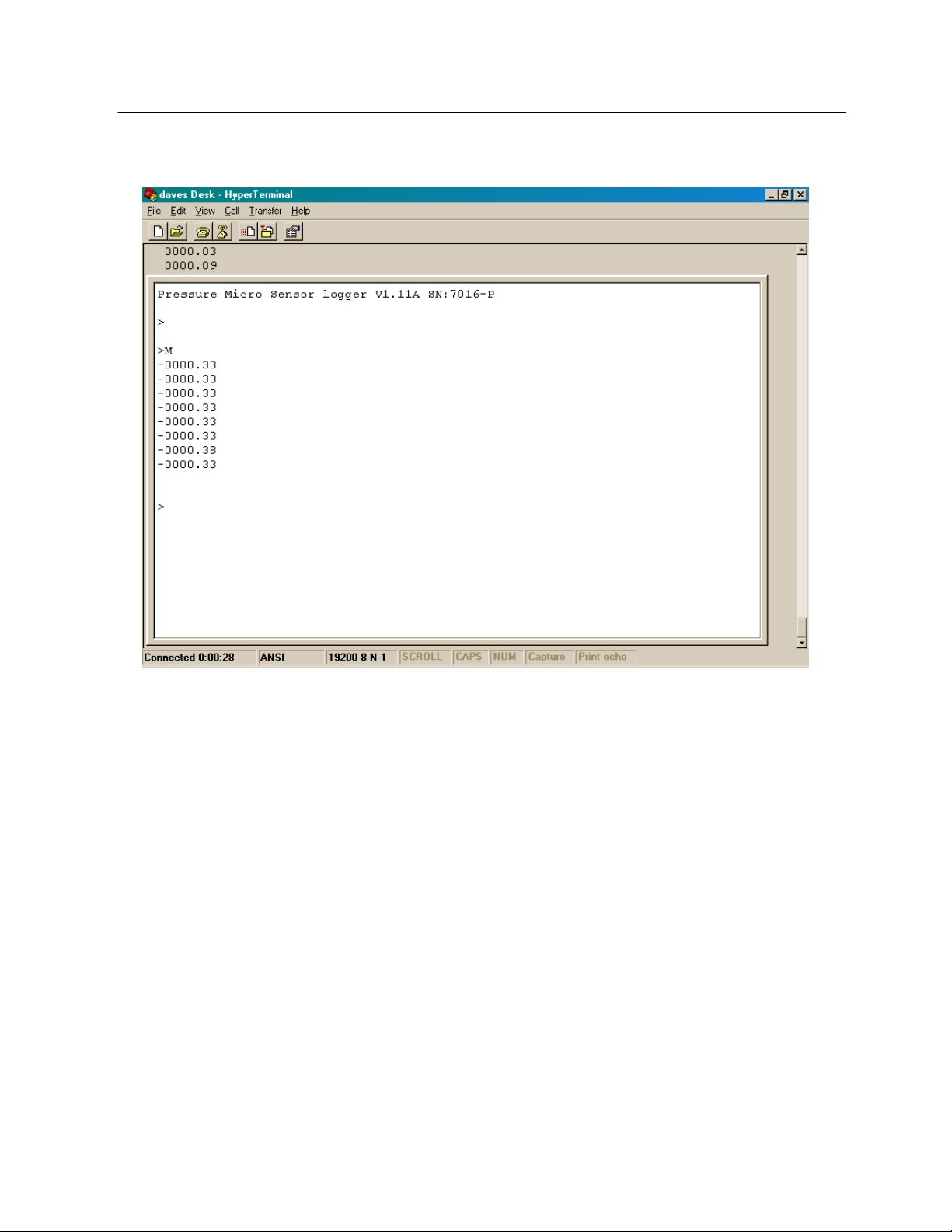

3.1 CONFIGURING HYPERTERMINAL FOR COMMUNICATIONS WITH THE MICRO PRESSURE SENSOR ............................ 7

3.2 RAW/REAL PARAMETER VALUES ...................................................................................................................... 9

3.2.1 RAW DATA FORMAT ......................................................................................................................................... 9

3.2.2 REAL DATA FORMAT ........................................................................................................................................ 9

3.3 COMMAND SUMMARY ................................................................................................................................ 10

4 MAINTENANCE .................................................................................................................................................... 13

4.2 MAIN O-RING MAINTENANCE ............................................................................................................................ 13

5 CALIBRATION ...................................................................................................................................................... 15

5.1 THEORY ............................................................................................................................................................. 15

APPENDIX `A': TROUBLESHOOTING GUIDE ................................................................................................ 16

APPENDIX `B': GENERAL LAYOUT ................................................... ERROR! BOOKMARK NOT DEFINED.

APPENDIX `C': WIRING DIAGRAM ................................................... ERROR! BOOKMARK NOT DEFINED.