Seen IRIS 860 Sensor Assembly instructions

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 1

Important warning

Please read this guide in full before starting. Incorrect

installation may void the warranty. If you need help

with anything please call the Seen Safety oice on

+64 4 381 4475

Seen IRIS 860 sensors can provide additional

information to the operator but are not intended to

provide active safety functions or control the machine.

Seen sensors do not replace the need for proper

operator training and best practice safe operating

procedure. The operator must always look to check

the way is clear before moving the vehicle. Detection

can never be guaranteed.

Seen sensors and cab boxes require a 12-24V DC

power supply. Voltages exceeding 24V may cause

damage and will not be covered by the warranty.

Caution Class I LASER PRODUCT. Disassembly or

modification of this device may result in hazardous

radiation exposure and will void the warranty.

This installation and set-up guide has been prepared

with all due care and attention, however, Seen Safety

Limited cannot be held responsible for any errors or

omissions in this guide or any consequences thereof.

Contact details

For technical support or questions please contact us.

Seen Safety Limited

Unit 4, 69 Kaiwharawhara Road

Wellington 6035, New Zealand

+64 4 381 4475

www.seensafety.com

info@seensafety.com

Contents

1. Overview 2

2. Mounting bracket 2

3. Sensor location 3

4. Weather shield installation 3

5. Sensor electrical connection 4

6. Cab box electrical connection 5

7. Trouble-shooting the reverse signal input into an

IRIS 860 sensor or cab box 6

8. Cab box sensor cable 7

9. Accessory port and cable 8

10. Sensor config settings 10

11. Self checking function 12

12. Sensor maintenance 12

13. Warranty 12

14. Sensor specifications 13

15. Connector pin-outs and electrical specs. 14

Seen IRIS 860 installation and set-up guide

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 2

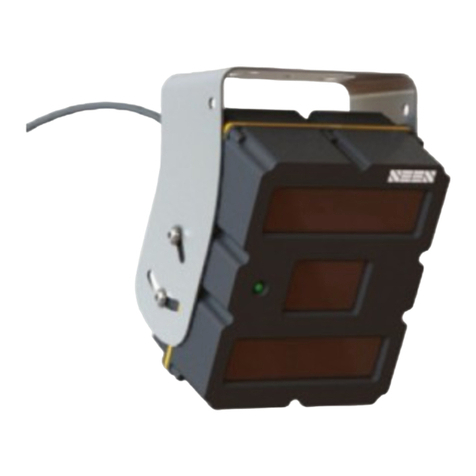

1. Overview

Seen IRIS 860 infrared laser sensors have a 60º horizontal x 45º

vertical detection area, and are designed to detect retroreflective

material such as the reflective tape on day/night high visibility

safety vests and markers.

The maximum detection range is 8 metres. The minimum

detection range is 1.2 metres. Detection is indicated by a loud

continuous-tone audible alert.

Sensor settings such as detection distance, volume, direction,

and test mode, can be configured using Seen’s simple PC

configuration app. Refer to Section 10.

IRIS 860 sensors are designed for use on industrial mobile

equipment in indoor and outdoor environments. They can also be

attached to fixed infrastructure to monitor exclusion zones.

2. Mounting bracket

The supplied stainless steel mounting bracket can be attached to

horizontal, vertical, or sloped surfaces. Securely bolt the bracket

to a solid surface using appropriate fasteners.

Once mounted, the sensor should be adjusted in the bracket so it

angles downwards by approximately 27º from horizontal (refer to

the diagrams below).

Tip: In mounting scenarios A and B, the front face of the sensor

should be parallel to the front edge of the bracket as shown by the

dashed lines.

Power or sensor

cable port

Vent

Sensor label

Green LED indicates

power. Red LED indicates

detection

Buzzer

Accessory port

Made in New Zealand

Seen Safety Limited

www.seensafety.com

SN-A00001

CLASS 1 LASER PRODUCT

Complies with FDA performance

standards for laser products except

for conformance with IEC 60825-1

Ed. 3 as described in Laser Notice

No. 56 dated May 8 2019

SEEN IRIS860 Sensor

Input power DC 12-24V 0.7A

Ingress protection IP67

Avoid high pressurewater jets

A. On top

B. Hung

underneath C. Vertical

27º

Correct mounting angle

Sensor front

Sensor back

Mounting bracket

Laser transmit window

LED

Logo

THIS WAY UP

Parallel

Parallel

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 3

3. Sensor location

IRIS 860 sensors should be mounted at head height or higher

with an unobstructed view of the desired detection area. If two

sensors are used to increase the overall detection area, they

can be mounted side-by-side or spaced apart in a cross-over

configuration. Refer to the diagram below.

Detection starts 1.2 m from the sensor face.

B

A

A

A

B

B

A

Detection area (45º)

Detection area (60º)

Side-by-side example Cross-over example

B

A

4. Weather shield installation

• Align the sensor to the correct angle then gently tighten screw

A on both sides.

• Place the weather shield over the bracket, so the round holes fit

around the screw-heads (A) on both sides.

• Insert screw B, check the alignment and evenly tighten all

screws.

Note. It is not possible to attach a weather shield to a sensor

mounted in the ‘hung underneath’ configuration.

B

A

Weather shield

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 4

5. Sensor electrical connection

If the sensor will be connected to a cab box, skip to section 6,

‘Cab box electrical connection’.

The supplied 2 metre power cable has a 5-pin M12 connector at one

end which attaches to the sensor, and bare wires at the other end

for connection to ignition power, ground, and reverse signal.

When powered up the sensor will beep once and the LED will flash

red then glow green. Detections are indicated by a continuous alert

tone and red LED.

Note: To minimise irrelevant detections, a connection to the reverse

signal allows sensors set to ‘R’ (reverse) to alert only while the

machine is reversing. A forward facing sensor can be set to ‘F’ and will

only alert when the machine is not reversing. Refer to section 10 for

more information about the config settings.

Note: If the BROWN (ignition) and BLACK (reverse) wires are twisted

together so they both receive 12-24V ignition power, an ‘R’ set sensor

will alert in any context.

TROUBLE SHOOTING. If an ‘R’ set sensor appears correctly

powered and connected to the reverse circuit but does not detect

as expected, please refer to section 7: Trouble-shooting the

reverse signal input into an IRIS 860 sensor or cab box.

Sensor power

cable

BLUE

Ground

Reverse (centre)

Ignition power

Orientation slot

Ground

Sensor power cable

BROWN

Input power (ignition)

DC 12-24V 0.7A

BLACK

Reverse signal

DC 12-100V 1mA

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 5

6. Cab box electrical connection

Seen’s cab box provides an audible detection alert and LED

indication to the driver inside the cab. Up to four sensors can be

connected to a cab box.

The cab box is powered by a 4-pin M12 power cable (supplied)

which is wired to the machine’s ignition power, ground, and

reverse signal (optional).

Note: To minimise irrelevant detections, a connection to the reverse

signal allows sensors set to ‘R’ (reverse) to alert only while the

machine is reversing. A forward facing sensor can be set to ‘F’ and

will only alert when the machine is not reversing. Refer to section 10

for more information about the config settings.

TROUBLE SHOOTING. If an ‘R’ set sensor attached to the cab

box appears correctly powered but does not detect as expected,

please refer to section 7: Trouble-shooting the reverse signal

input into an IRIS 860 sensor or cab box.

Cab box power cable

Cab box

Sensor cable

connectors

LED

Buzzer

BLUE

Ground

Ignition power

Orientation slot

Ground

Reverse

Cab box power cable

BROWN

Input power (ignition)

DC 12-24V 2.8A

BLACK

Reverse signal

DC 12-100V 1mA

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 6

7. Trouble-shooting the reverse

signal input into an IRIS 860 sensor

or cab box

Applies to: Sensors requiring a reverse signal input to indicate

when to alert. Cab boxes connected to the reverse signal.

Problem: The sensor / cab box appears correctly powered and

connected to the reverse signal, but the sensor does not alert

when the vehicle is in reverse.

Cause: The sensor’s reverse signal detection circuit is not

registering the reverse signal input. This is most likely caused by

a grounding issue.

How to check the reverse signal

• Unplug the sensor / cab box from its power cable

• Switch the vehicle ignition to ON (preferably without starting

the vehicle for safety)

• Attach a voltmeter across the Ignition power pin (+) and the

Ground pin (–) of the power cable. The voltage should be

between +10V and +30V. Refer to the Sensor / Cab box power

cable diagram (opposite)

• Next, attach the voltmeter across the Reverse pin and the

Ground pin (–). When the vehicle is NOT in reverse the voltage

should measure between 0V and +1V. When the vehicle IS in

reverse it should measure between +3V to +100V.

If the vehicle is in reverse and the voltage is not 3-100V between

the Ground pin (–) and the Reverse pin, there may be a grounding

issue.

DC/DC converter grounding issue

Some installations (typically electric machines) require a DC/DC

converter to reduce the supply voltage to 12 or 24V. If the DC/

DC converter is an isolated type, the ground reference for the

sensor’s power supply can be dierent from the ground reference

for the reverse circuit.

The DC/DC converter circuit diagram (opposite) will not work

because the reverse signal input is isolated from the IRIS 860

sensor ground (-Vin on the IRIS 860 sensor)

Making a connection across the DC/DC converter isolation barrier

(shown as the dashed ‘jumper’ line) means all the circuits now

have a common ground. HOWEVER this is not advisable if other

accessories also use the DC/DC converter because the isolation

barrier may be required for safety. In this case the best solution is

to use a separate DC/DC converter for the IRIS 860 sensor with

the jumper line connected as shown.

Note. To check if an ‘R’ set sensor is working correctly, supply 12-

24V to both the ignition wire (brown) and reverse wire (black). A

properly functioning sensor wired in this way will always be active

and trigger o a reflective vest. (Note the 1.2m minimum operating

range when testing).

Isolated DC/DC

converter

High voltage

DC supply

Reverse

signal

Chassis

ground

IRIS 860 Sensor

Other accessory

+Vin

+30V to

+100V

+3V to +100V

+24V

+Vout

+Vin

+Vin

–Vin

–Vout

–Vin

–Vin

Reverse in

Jumper line

Sensor / Cab box power cable

Reverse (Sensor

power cable)

Reverse (Cab Box

power cable)

Ignition power (+)

Orientation slot

Ground (–)

DC/DC converter circuit

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 7

5. Grey (Centre)

4. Black

Screw-block

3. Blue2. White

1. Brown

Re-wireable connector

9mm16mm

Cable

Wire stripping guide

Grey wire (centre)

Other wires

8mm 9mm

8. Cab box sensor cable

A cab box sensor cable is required to connect each sensor to the

cab box. This cable supplies power to the sensor, and transmits

the detection signal back to the cab box.

To facilitate cable threading, or to shorten the cable, the larger

black plastic connector can be removed and re-wired.

IMPORTANT

When re-wiring the connector, the wire colours must exactly

match the diagram opposite. Use the screw-block as a reference.

Unscrew first

Unscrew second

Re-wireable connector

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 8

9. Accessory port and cable

The IRIS 860 sensor features an 8-pin M12 accessory port. Seen’s

accessory cable can be used to attach and trigger third-party

accessories such as cameras, data-loggers, alarms etc.

Pin no. Wire colour Description

1 Brown 12V accessory power supply

2 White Ground / Earth

3 Blue Detection NPN

4 Black Detection 3V6 logic output

5Grey Do not connect

6 Pink Detection 12V logic output

Accessory use-case examples

12V external buzzer or light

IRIS 860 sensor

12V accessory

GND

NPN switch

connects to ground

during detection

1

2

3

4

5

6

7

8

12V power supply (BROWN)

IRIS 860 ground (WHITE)

Detection NPN (BLUE)

Detection 3V6 (BLACK)

Do not connect (GREY)

Detection 12V (PINK)

–

+

Accessory port / cable

• On detection the NPN transistor switch closes, putting 12V

across the connected accessory

• Maximum supply current 500mA.

12V external relay

IRIS 860 sensor

12V relay

GND

NPN switch

connects to ground

during detection

1

2

3

4

5

6

7

8

12V power supply (BROWN)

IRIS 860 ground (WHITE)

Detection NPN (BLUE)

Detection 3V6 (BLACK)

Do not connect (GREY)

Detection 12V (PINK)

–

+

Accessory port / cable

• On detection, the NPN transistor switch closes, putting 12V

across the relay

• A flywheel diode is required across the relay coil to protect the

NPN transistor against the coil transient when the detection

event ends and the coil is switched o

• Maximum supply current 500mA.

Accessory port

Made in New Zealand

Seen Safety Limited

www.seensafety.com

SN-A00001

CLASS 1 LASER PRODUCT

Complies with FDA performance

standards for laser products except

for conformance with IEC 60825-1

Ed. 3 as described in Laser Notice

No. 56 dated May 8 2019

SEEN IRIS860 Sensor

Input power DC 12-24V 0.7A

Ingress protection IP67

Avoid high pressurewater jets

Flywheel diode

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 9

12V camera with digital input

IRIS 860 sensor

GND

1

2

3

4

5

6

7

8

12V power supply (BROWN)

IRIS 860 ground (WHITE)

Detection NPN (BLUE)

Detection 3V6 (BLACK)

Do not connect (GREY)

Detection 12V (PINK)

12V camera accessory

Output high during detection

12V trigger input

–

+

12V power supply

Accessory port / cable

• The IRIS 860 accessory power supply is used to power the camera

accessory (maximum supply current 500mA)

• Detection 12V puts 12V on the camera trigger during detection (this is a

low power output and can only sink/source a few milliamps of current).

• If required, add an external regulator to limit the 12V detection logic

output voltage (e.g. down to 5V or 3.3V) or use Detection 3V6 (black) for a

3.6V detection output.

Also refer to section 15 for the Accessory Port PIN-out diagram for full

electrical specifications.

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 10

10. Sensor config settings

IRIS 860 sensors are supplied with a default setting which is

indicated on the config sticker on the back of each sensor.

These settings can changed using a simple PC desktop software

application which can be downloaded for free at

www.seensafety.com/download

An IRIS 860 USB config cable is needed to connect the sensor’s

power port to the computer’s USB port.

Instructions

• Launch the IRIS 860 software app (Windows PC required)

• Connect the config cable USB plug directly to the computer

USB port, THEN connect it to the sensor power port

• The sensor will power up (indicated by green LED). Wait a few

seconds for the sensor to boot (indicated by a brief change to

red LED) and once booted, click “Connect”

• Update the settings then click “Apply New Settings”

• Check the new settings are correct, then unplug the sensor and

repeat for the next sensor.

TROUBLE SHOOTING.

• Make sure the sensor finishes booting (red LED followed by

steady green LED) before clicking “Connect”.

• If the sensor is powered on (green LED) but fails to connect,

try installing the Windows drivers included with the software.

Range setting

The detection range can be set in 0.5 metre steps up to 8.0

metres. Select Custom Range to individually change the range of

each channel (see examples on the following page).

Direction setting

A Reverse (R) set sensor will only alert in the presence of a 12-

100v reverse signal from the machine. A Forward (F) set sensor

will only alert when a reverse signal is not present. An Always

(A) set sensor will alert even if it is connected to a reverse signal

input.

Test Mode setting

A Test Mode enabled sensor can be temporarily toggled to test

mode using a simple ignition on-o-on sequence. When test mode

is active, the reverse direction (R) setting is ignored for 2 minutes.

This allows an operator to walk behind the machine to test the

sensor/s function without the machine needing to be in reverse

gear.

Test procedure:

• Turn the ignition on (to power the sensor), wait 2 to 5 seconds,

then turn the ignition o. The next time the ignition is turned

on the sensor will be in test mode indicated by a flashing green

LED on the sensor and cab-box (if used).

• Test mode lasts 2 minutes. The green LED on the sensor and

cab box (if used) flashes during this period indicating test mode

is active.

• Check the sensors are working by walking into the detection

zone behind the machine wearing a reflective safety vest.

Detection is indicated by an audible alarm and red LED.

Custom Range

Sensor config sticker, indicating the sensor is

set to 4 metres, reverse mode.

Power port

Made in New Zealand

Seen Safety Limited

www.seensafety.com

SN-A00001

CLASS 1 LASER PRODUCT

Complies with FDA performance

standards for laser products except

for conformance with IEC 60825-1

Ed. 3 as described in Laser Notice

No. 56 dated May 8 2019

SEEN IRIS860 Sensor

Input power DC 12-24V 0.7A

Ingress protection IP67

Avoid high pressurewater jets

Sensor config. application

Sensor connected

Custom range setting panel*

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 11

• Return to the cab and engage reverse gear to test the reverse

signal. The audible alarm should sound when the reverse signal

is detected.

• The test is now complete. Turn the ignition o, restart the

vehicle and operate as normal.

• To clear test mode at any time simply switch the ignition o,

then re-start the machine.

Sensitivity setting

Reduced sensitivity mode may help in environments where

false detections are occurring. False detections are defined as

detections which do not come from a retroreflector. Although

uncommon, the sensor may occasionally be triggered by plastic

stretch-wrap in certain conditions, and from certain metallic

surfaces which create a retroreflective type eect. Low sensitivity

mode slightly increases the amount of retro-reflective tape

required to enable detection, and may prevent some false

detections.

Volume reduction

This setting reduces the alert tone from very loud to loud. It can

be used in situations where the sensor is close to the operator

and the alert tone is uncomfortably loud. The 3.5kHz alert tone is

94dB at 1 metre.

Default detection area

Custom detection

area examples

Two sensors with mirrored

custom shaped detection area

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 12

SI860-1119

SN-A01000

11. Self checking function

IRIS 860 sensors have an automatic self checking function that

can alert the operator of an internal fault, or if the laser transmit

window becomes excessively contaminated and needs cleaning.

If the sensor LED (and cab box if used) repeatedly flashes red

and beeps, the sensor is indicating a fault. Stop the machine.

Try cleaning the sensor windows (see below) but if this does not

correct the issue, please contact your Reseller/Supplier or Seen

Safety to arrange repair or replacement.

12. Sensor maintenance

There are no user-serviceable parts in the sensor. Other than

keeping the windows and buzzer free from dust and dirt build-

up, no scheduled maintenance is required. Remove dust and dirt

using clean water and a clean non-abrasive cloth. The sensor and

buzzer are rated IP67 (protected from dust ingress and water

ingress at 1 metre submersion for 30 minutes). Do not use high

pressure water jets to clean.

13. Warranty

Seen IRIS 860 sensors have been designed for reliable long-term

use on industrial vehicles in both indoor and outdoor applications.

Seen oer a 1-year repair or replacement warranty on materials

and workmanship. The warranty excludes general wear and tear,

physical damage caused by direct impact to the sensor, damage

to the windows, damage caused by high-pressure water jets, or

incorrect electrical connection. There are no user serviceable

parts. Opening the sensor will void the warranty.

Sensor label

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 13

14. Sensor specifications

Input power (ignition) DC 12-24 V 0.7A

Reverse signal input DC 3.5-100V 1mA

Power consumption 1.5W max (sensor only)

8.4W max (with attached accessories)

Detection range 1.2 - 8.0 metres

Detection area 60 degrees horizontal x 45 degrees vertical

Detection target Class II day/night high visibility safety

apparel / vest and other retroreflective

material

Latency Up to 250ms

Maintenance No scheduled maintenance required

Buzzer 94dB at 1m 3500Hz

Connectors M12 5-pin and M12 8-pin auxiliary port

Laser type Pulsed infrared 905nm non-visible

Safety Caution Class I LASER PRODUCT.

Disassembly or modification of this device

may result in hazardous radiation exposure.

Standards IEC 61000-6-4 (EMC emissions)

IEC 61000-4-2 (EMC immunity)

IEC 60825-1:2014 (Laser eye safety)

IEC 61010-2-201:2017 (Electrical equipment

safety)

Lighting Immune from sunlight interference or

ambient lighting conditions.

Ingress protection IP67. Protected from dust ingress and

water ingress at 1 metre submersion for 30

minutes. Avoid high pressure water jets

Enclosure ASA injection moulded plastic

Mounting 4 x M6 brass inserts

Windows Hard coated IR filtered PMMA

Weight 0.48 kg

Dimensions 125W x 160H x 85D

Operating temperature: -20 to +60 degrees C ambient

Product specifications are subject to change without notice to improve reliability, function, design or

otherwise.

© Copyright 2020 Seen Safety Limited. All rights reserved. Patents and trademarks granted and pending. Version 1.71 14

15. Connector pin-outs and electrical specs.

Power connector (M12 5-PIN)

5

4

1 2

3

Pin Name Description Direction Max.

input

voltage

Min.

input

voltage

Input

high

voltage

Input

low

voltage

Output

high

voltage

Output

low

voltage

Conditions Notes

1 Vin + Supply positive Input 30v 10.8v - - - - - 8W maximum power

draw (with attached

accessory). 2W maxi-

mum for sensor only.

2 Vin – Supply nega-

tive (ground)

- - - - - - - - System / chassis

ground

3 System

status

High when sys-

tem operating

Output - - - - 5.2v max.

4.5v min.

0.1v max. 1K Ohm load

to ground

PNP output

4 Detection High when tar-

get detected

Output - - - - 5.2v max.

4.5v min.

0.1v max. 1K Ohm load

to ground

PNP output

5 Reverse in Reverse input Input 100v 0v 3.5v min. 1v max. - - - Input current is less

than 0.5 mA

Accessory connector (M12 8-PIN)

6

12

3

4

5

Pin Name Description Direction Max.

input

voltage

Min.

input

voltage

Input

high

voltage

Input

low

voltage

Output

high

voltage

Output

low

voltage

Conditions Notes

1 12V out Accessory supply Output - - - - 12.1v max.

10v min.

- Supply

voltage 12v

and drawing

500mA from

accessory

supply pin

Accessory supply,

eg external alert or

camera

2 Vin – Supply negative

(ground)

- - - - - - - - System / chassis

ground

3 Detection

NPN

Detection output Output - - - - 30v max. 0.8v

max.

0.8v output

low max when

sinking 500

mA

NPN output, max

blocking voltage

30v

4 Detection

3V6

Low voltage logic

detection output

Output - - - - 3.6v max.

2.0v min.

- Source / sink

100 uA max.

-

5 Do not connect

6 Detection

12V

High voltage logic

detection output

Output - - - - 11v max.

9.3v min.

- Supply

voltage 12v,

2K Ohm load

to ground

-

Other manuals for IRIS 860 Sensor

3

Table of contents

Other Seen Accessories manuals

Popular Accessories manuals by other brands

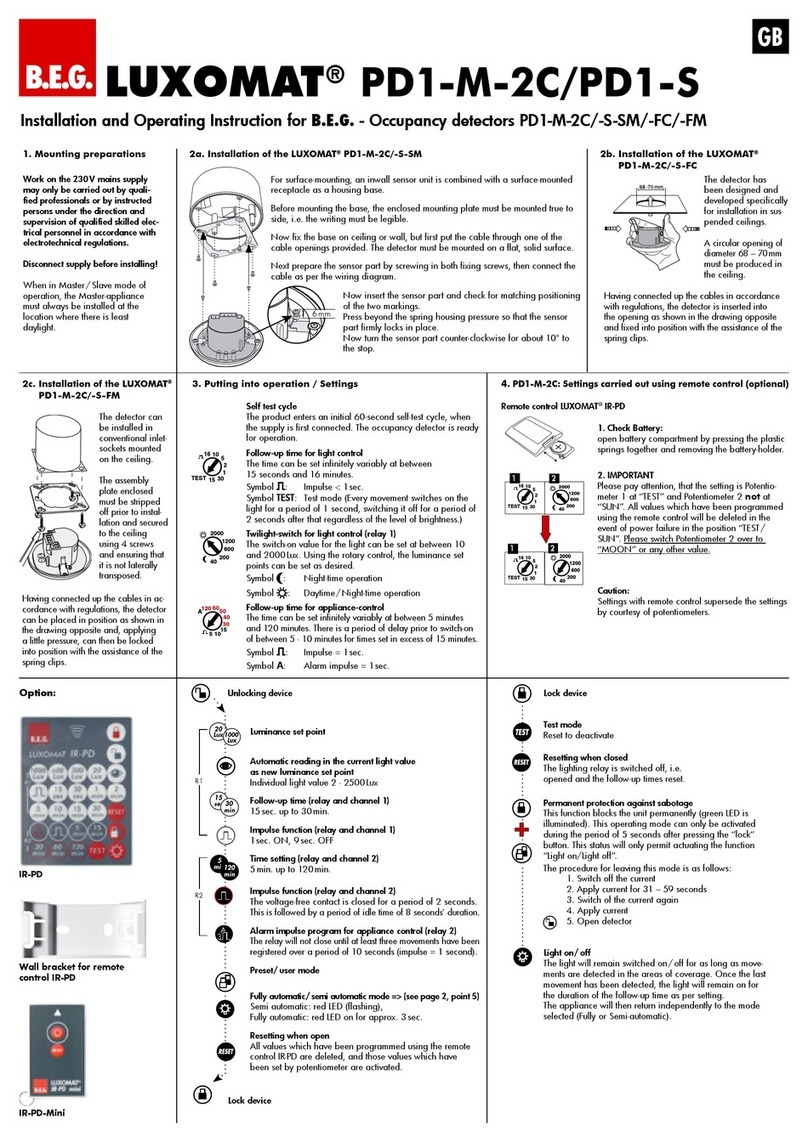

B.E.G. LUXOMAT

B.E.G. LUXOMAT PD1-M-2C Installation and operating instruction manual

PCB Piezotronics

PCB Piezotronics 117B67 Installation and operating manual

Crown

Crown PIP-FTE reference guide

Powerfix Profi

Powerfix Profi 292045 Operation and safety notes

SICK

SICK PowerProx WTT12L-A Series operating instructions

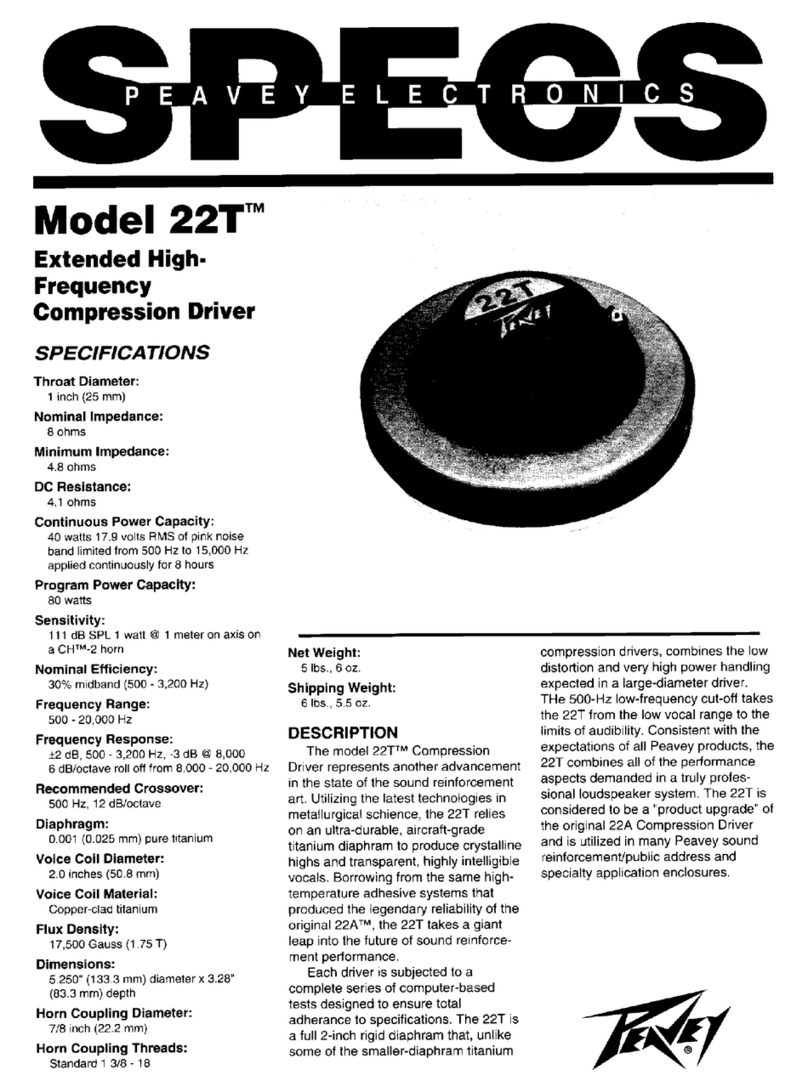

Peavey

Peavey Model 22T user guide