Ampex 400 Series User manual

Other Ampex Recording Equipment manuals

Ampex

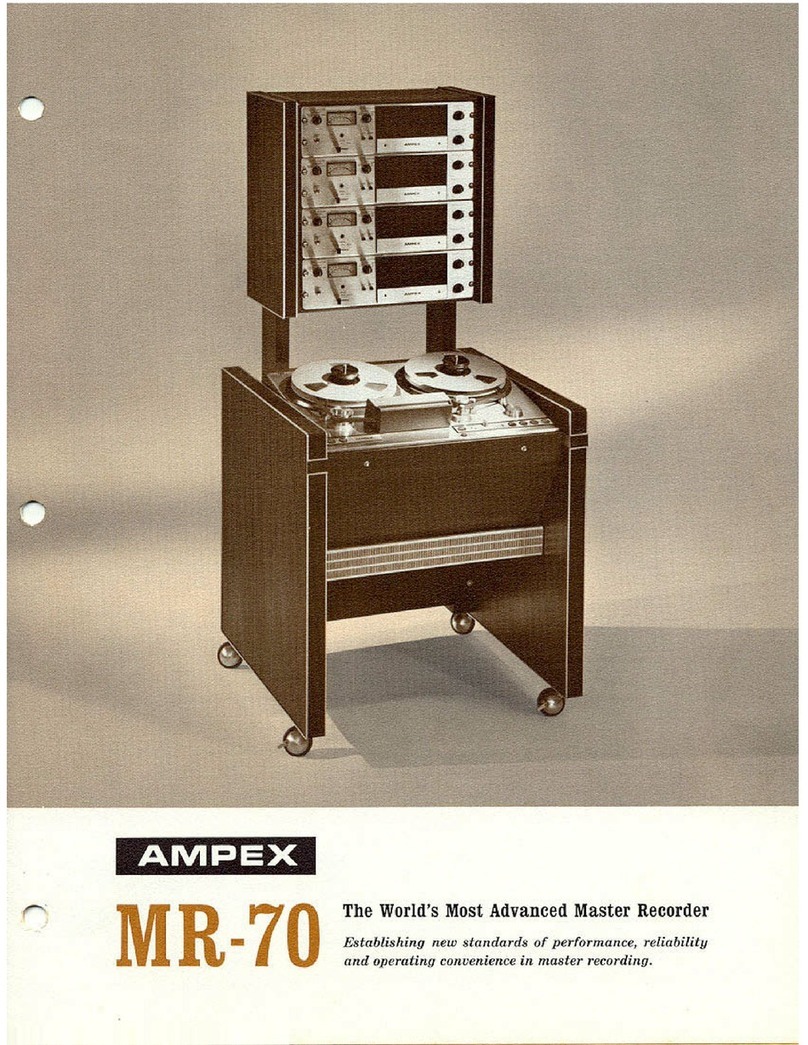

Ampex MR-70 User manual

Ampex

Ampex 300 Owner's manual

Ampex

Ampex AG-440 B User manual

Ampex

Ampex ATR-700 Installation guide

Ampex

Ampex AG-440 B User manual

Ampex

Ampex 350-2 Reference manual

Ampex

Ampex 300 User manual

Ampex

Ampex 351 Series User manual

Ampex

Ampex ATR-700 User manual

Ampex

Ampex AG500 User manual