User Guide

Thank you for choosing SGX Sensortech module. Before using it, please read this document in detail in order to use our

products correctly and eectively.

Storage

1. The best storage environment is: temperature (0-20) ℃, relative humidity 50% RH (non-condensing);

2. The storage environment should keep the air clean, no pollution gas, no acetone, no high concentration organic gas, no dust,

no smoke;

3. Avoid storage with alcohol (ethanol), perfume, sodium silicate and polyurethane liquids or solids;

4. Avoid high temperature and low humidity storage.

Packing and shipping

1. Avoid prolonged direct sunlight during transportation , prevent rainwater penetration;

2. Transport packaging should be protected with shock-proof bubble lm or non-odor environmentally friendly sponge;

3. During long-distance transportation, the temperature inside the sensor package should be kept within 40 ℃as much as

possible, and the maximum temperature should not exceed 55 ℃(can not be stored or used at this temperature for a long

time), and the humidity should not be less than 15% RH;

Steps for usage

1. Warm-up

• The ozone module is designed to have a plug-and-play function, but due to the electrochemical nature of the ozone sensor, after receiving the

calibrated product, it still takes about 10 minutes to warm up the machine when it is rst powered on. After the output signal is constant, the

warm-up is complete. (Note: under different storage and measurement environments, the rst electrode stabilization time is different)

• When warming up, it is recommended to rst warm the machine in clean air for about 10 minutes, observe whether the output of the ozone

module is 0ppm (due to storage and environmental differences, the indicated value

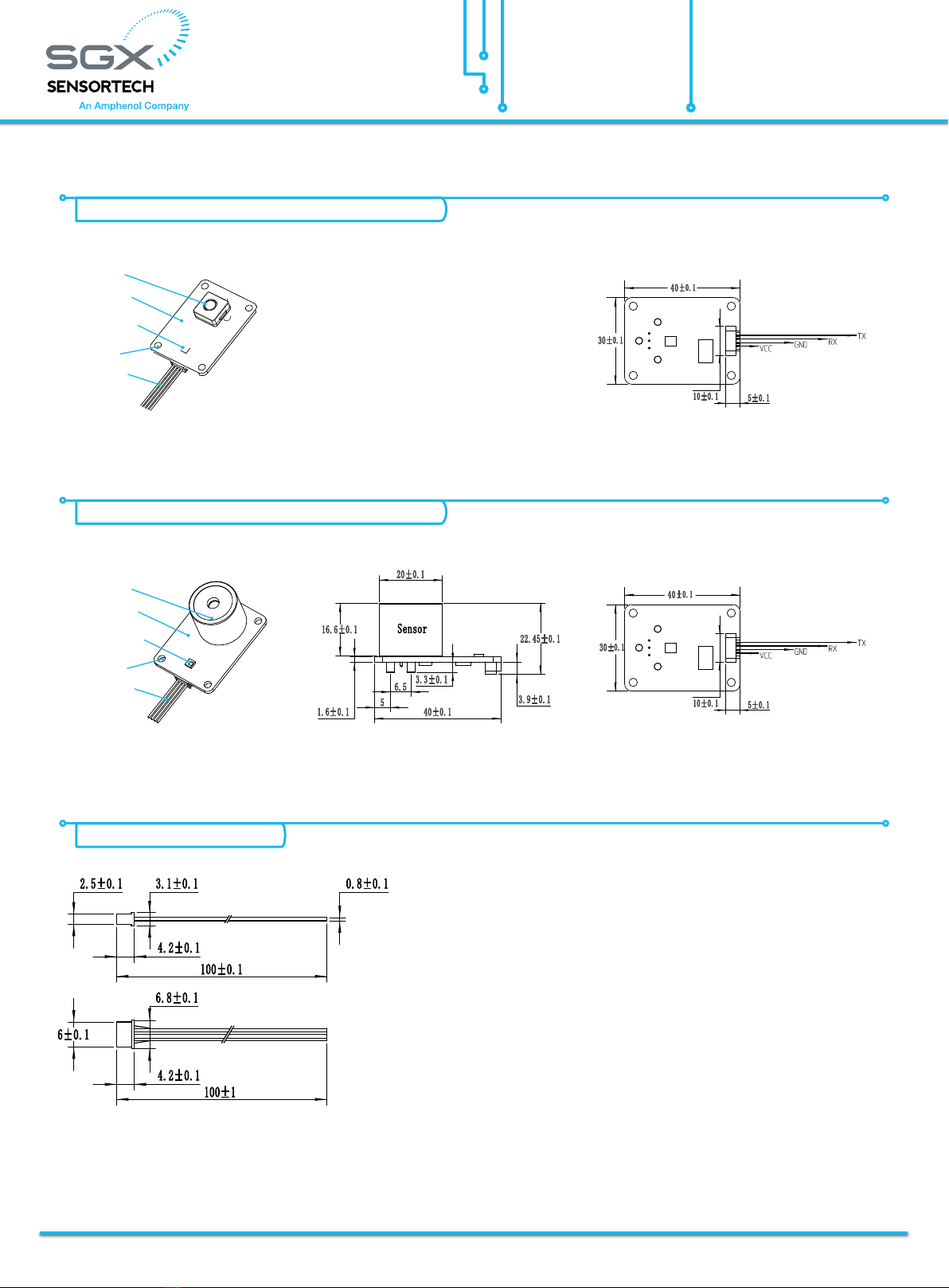

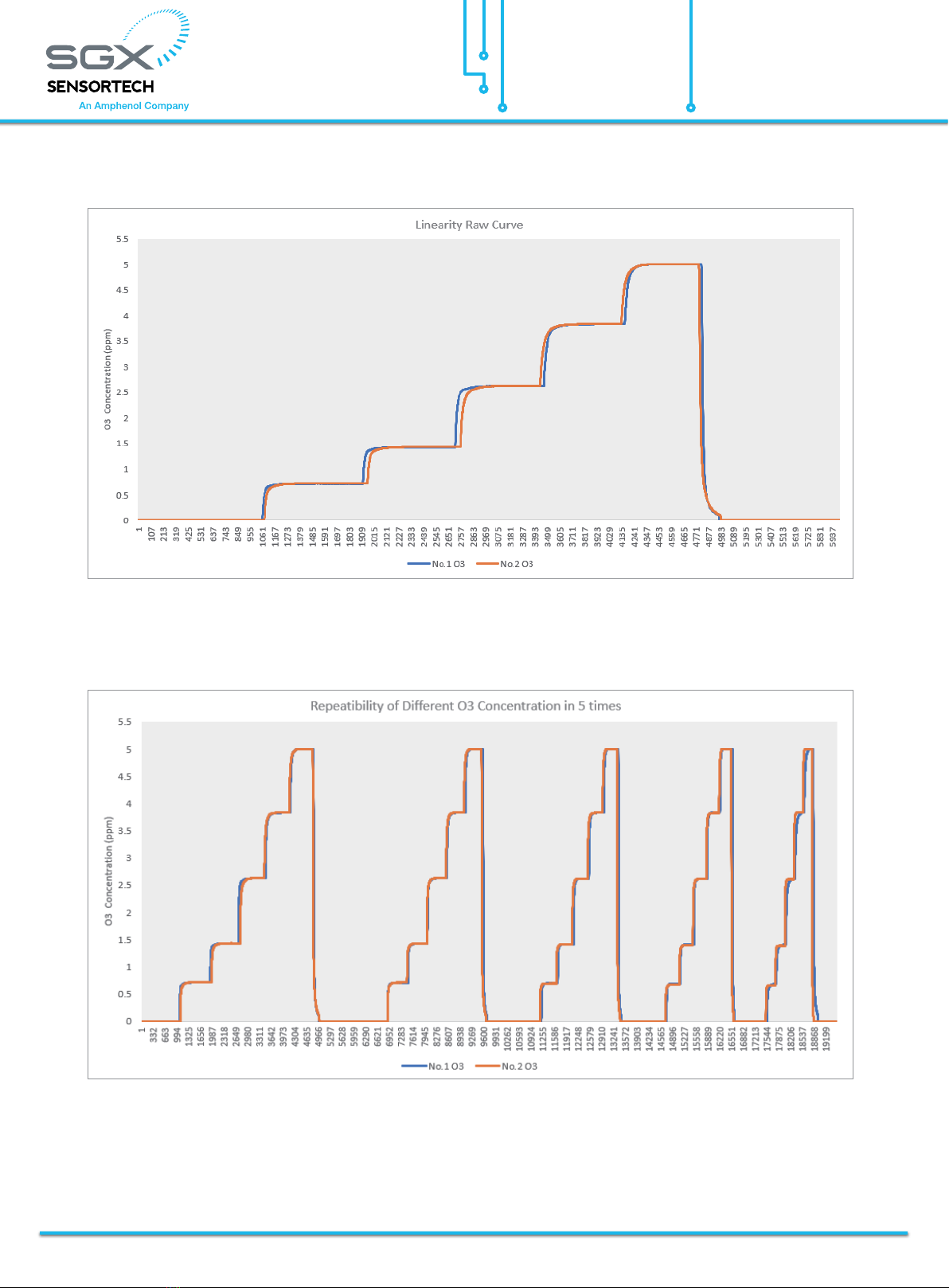

2. Connection

• Please refer to the 4Pin cablel in the “Structure Diagram” above. For the power supply, see the voltage and current ranges marked in the

performance indicators. Note: incorrect wiring will cause the module to malfunction or damage the module.

3. Diffusion use

• When using in a closed environment, it is necessary to ensure a constant pressure and the working pressure range is within ± 10% of atmospheric

pressure. to ensure accurate measurement data, when using under different pressure environments, re-sen sitivity calibration should be

performed according to the pressure of the use environment.

• Usually the change of pressure will cause the output signal to change.if The pressure increase, the signal will increase, the pressure change

suddenly, and the sensor signal will have a sudden change in peak value.

4. Pump suction use

• When using the sensor in the pumping detection mode, the gas ow rate must be controlled within 500ml per minute, and the ow rate must be

stable. The change of ow will cause the signal to uctuate. When the ow is large, it will bring the change of pressure, which will cause the

sensor signal value to change.

• When using the pump suction mode, it is best to add a ow sensor or an air pump control according to the product design to avoid negative

pressure and physical damage to the sensor that cannot be recovered.

• The design of the gas path should avoid direct gas ow to the front of the sensor. An optional ow cap should be used, while the air is inlet and

the air is outlet (normally small in and large out). The inlet and outlet gas is designed to be 90 degrees or straight-through with a barrier type to

ensure that the gas can fully contact the ozone sensor.

5. Temperature and humidity effects

• The ozone gas module has been corrected for temperature compensation through an intelligent algorithm, which is suitable for the detection

environment of -40 ~ 55 ℃.

• The ozone sensor module must not be used and stored for a long time in a high-temperature and low-humidity environment with a humidity

below 10% or a temperature above 55 ℃. Failure to do so will result in reduced sensor life,Either failure or test data is invalid.

• The frequent and rapid changes in temperature or humidity will affect the chemical material and cause an unexpected decrease in the sensor

life.

• Ozone sensors are generally not affected by humidity, but during use, it is necessary to avoid condensation blocking the air inlet holes on the

surface of the lter membrane, resulting in the inability of ozone to diffuse into the sensor and no signal output.

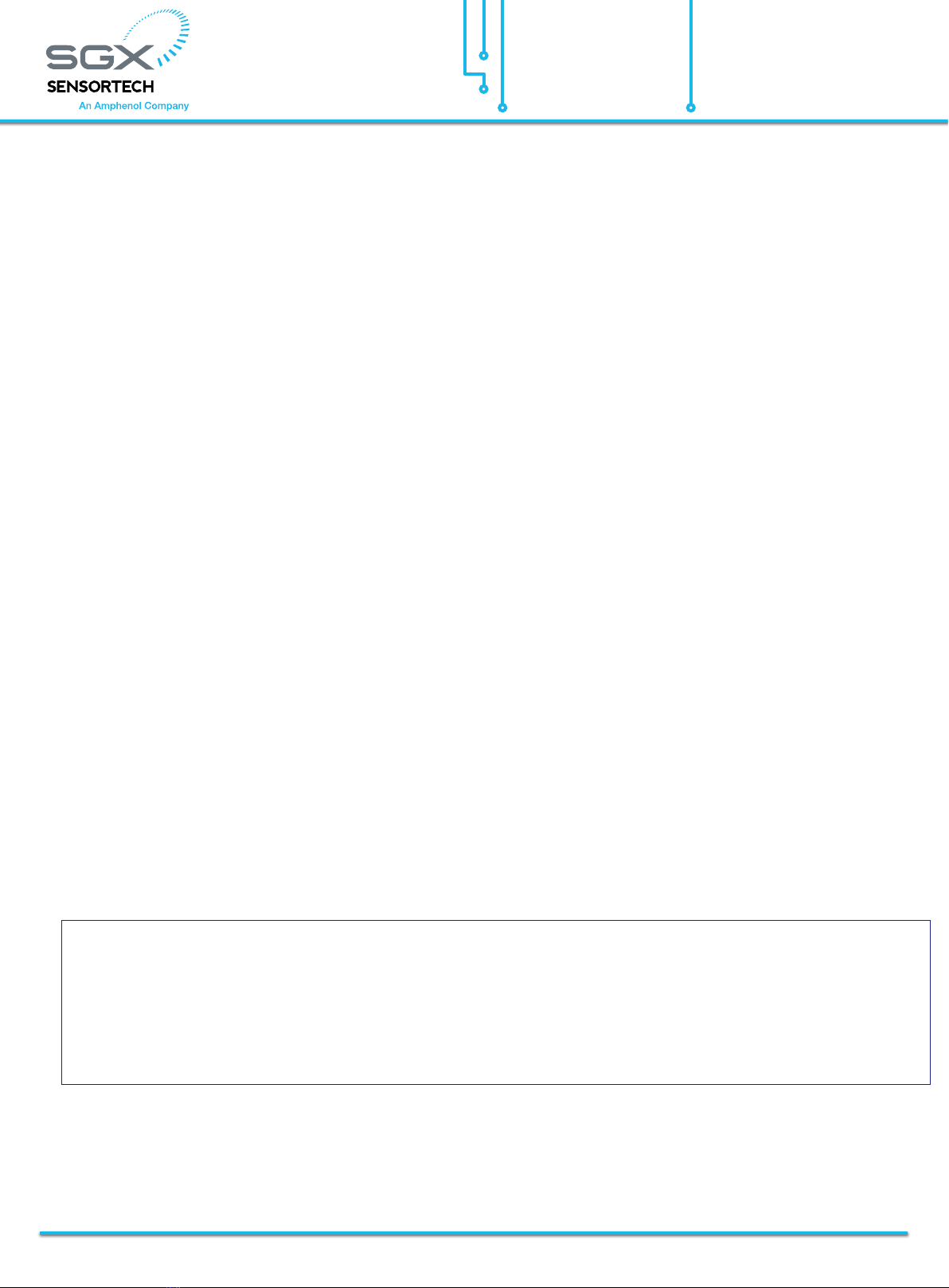

• Impact of environmental changes on sensors: Due to the principle and characteristics of electrochemical sensors, environmental changes have

varying degrees of inuence on the chemical electrolytes inside the sensors.The TB200B ozone detection module analyzes the changes in the

current data of the sensor in detail through different environmental temperature and humidity effects tests, and combines the temperature and

humidity sensor data to perform algorithmic compensation to correct the resulting deviations. Sudden changes in temperature and humidity

will cause abnormal uctuations in the trace data of the sensor, but generally it can fully adapt to the new environment and be stable within

5-10 minutes.

6. Maintain

• The maintenance of the ozone detection module is mainly for accuracy calibration. Generally, the solid polymer ozone sensor does not

consume chemical electrolyte, but it can be affected by temperature, humidity, dust, and other gases used in the environment. The sensitivity

of the sensor will shift, and the ozone sensor needs to be re-calibrated. The better the use environment, the longer the maintenance cycle and

less maintenance workload.

• In case a calibration is needed the user may make sure that clean air is available or the module can be sent back to the factory for

recalibration.

SGX Europe Sp. z o.o.

Building 11

Ligocka St. 103,

40-568 Katowice,

Poland

T: +48 (0) 32 438 4778

www.sgxsensortech.com

© SGX Sensortech 2012-2022 DS-0452-PS1&PS4-O3-5-MOD, Issue 1, 10-Feb-2022, Page 7/14