Table of Contents

Section 1: Introduction........................................................................................................................... 6

1.1 Introduction...................................................................................................................................... 6

1.2 About This Guide.............................................................................................................................7

1.3 Terminology.....................................................................................................................................7

Section 2: C21 Overview .......................................................................................................................8

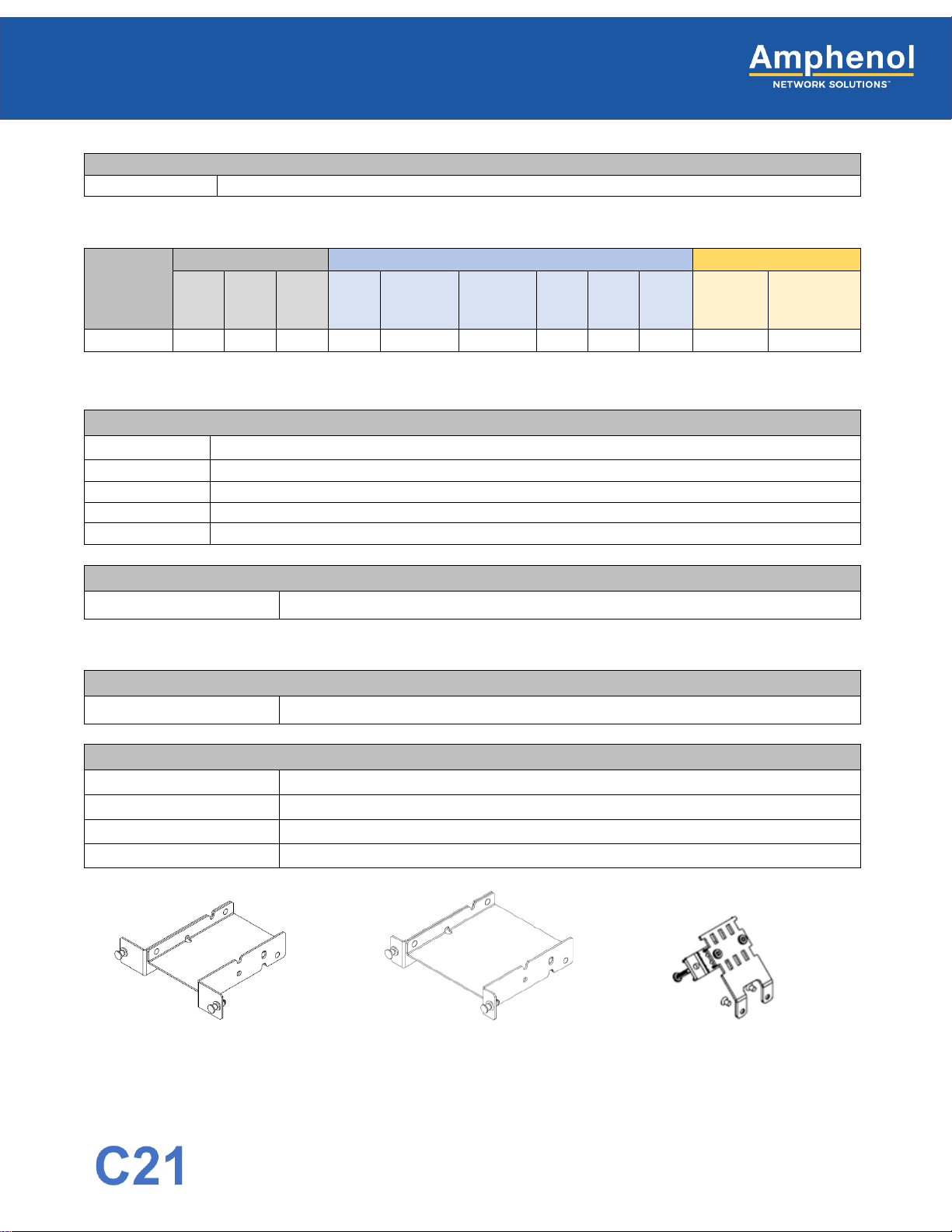

2.1 General Description.........................................................................................................................8

2.1.1 Chassis Attributes 9

2.1.2 Chassis Density ................................................................................................................. 9

2.1.3 Specifications/Compliance ................................................................................................. 9

2.1.4 Parts List............................................................................................................................ 9

Section 3: Installation Considerations.................................................................................................. 10

3.1 Unpacking...................................................................................................................................... 11

3.1.1 Standard Chassis Contents ................................................................................................. 11

3.1.2 Optional Module Configurations........................................................................................... 11

3.2 Inspection...................................................................................................................................... 12

3.3 Installation Guidelines.................................................................................................................... 12

3.4 Location and Space Planning ........................................................................................................ 12

3.5 Tools and Equipment..................................................................................................................... 12

Section 4: General C21 Installation Instructions................................................................................... 13

4.1 Dimensions.................................................................................................................................... 13

4.2 Removing the C21 Front and Rear Access Panels ........................................................................ 13

4.3 C21 Mounting Bracket Options ...................................................................................................... 14

4.4 Mounting the C21 Chassis on the Rack......................................................................................... 14

4.6 C21 Fiber Cable Routing................................................................................................................ 15

4.6.1 Cable routing to the C21 Chassis......................................................................................... 15

4.6.1.1 Top-down Fed Fiber Cable:........................................................................................... 15

4.6.1.2 Bottom-Up Fed Fiber Cable:.......................................................................................... 15

4.6.2 Cable routing within the C21 Chassis................................................................................... 16

4.6.2.1 Routing Fiber Direct to Patch Plates.............................................................................. 16

4.6.2.2 Routing Fiber to Modules .............................................................................................. 17

4.6.2.3 Routing/Terminating Fiber to Splice Tray....................................................................... 17

4.7 Grounding and Bonding................................................................................................................. 19

4.7.1 Bonding ............................................................................................................................... 19

4.7.2 Grounding to B-Bond........................................................................................................... 19