AMPTech X User manual

AUTOMATIC FRUNK

MODEL X

INSTALLATION GUIDE

V. MX FNK20-MKIV

About this guide 3

Table of contents

2

Specifications 4

Technical data of the lifting arms 4

Technical data of the engine for automatic frunking 4

Preparations 5

List of tools needed for the installation 5

List about the scope of delivery 6

Installation guide 7

Remove cladding 7

Replace lifting arms 8

Modify clamping unit 10

Wiring 13

System test and system settings 17

Checklist 19

Deconstruction 21

3

About this guide

Product

descriptions

All specifications and descriptions of the products in this installation manual

have been verified and tested at the time of writing and are valid for the

respective version mentioned in the manual. We reserve the right to make

modifications and improvements to the products at any time.

Errors and inaccuracies

If you notice any errors or inaccuracies in this installation guide, or if you

notice that some descriptions are not complete, please use the following e-

We are open to your recommendations and suggestions and will gladly

accept them at the email

.

Copyright

This document is protected by copyright and is the intellectual property of

AMP Engineering GmbH. The contents of this manual may not be modified,

reproduced or copied in whole or in part without the express written

consent of AMP Engineering GmbH. Likewise, the commercial use of this

manual is prohibited.

Safety instructions

The automatic frunk control was designed to enable convenient and safe

opening and closing of the front cover (frunk). Nevertheless, as such it does

not replace the visual inspection. Therefore, always check that your frunk is

securely closed before starting a journey. In any case, the safety instructions

marked "🚫CAUTION:..." in these instructions must be observed. In case of

disregard of the safety instructions and resulting damages to the AMPTech

components or even vehicle parts, the warranty claim as well as any liability

for damages or consequential damages expires due to own fault (see GTC's

on www.amptech.store/agb/, V. Liability). If you have any questions or

problems with the Frunkautomatic, please contact AMPTech under the

4

Specifications

Below you will find more detailed information about the supplied components.

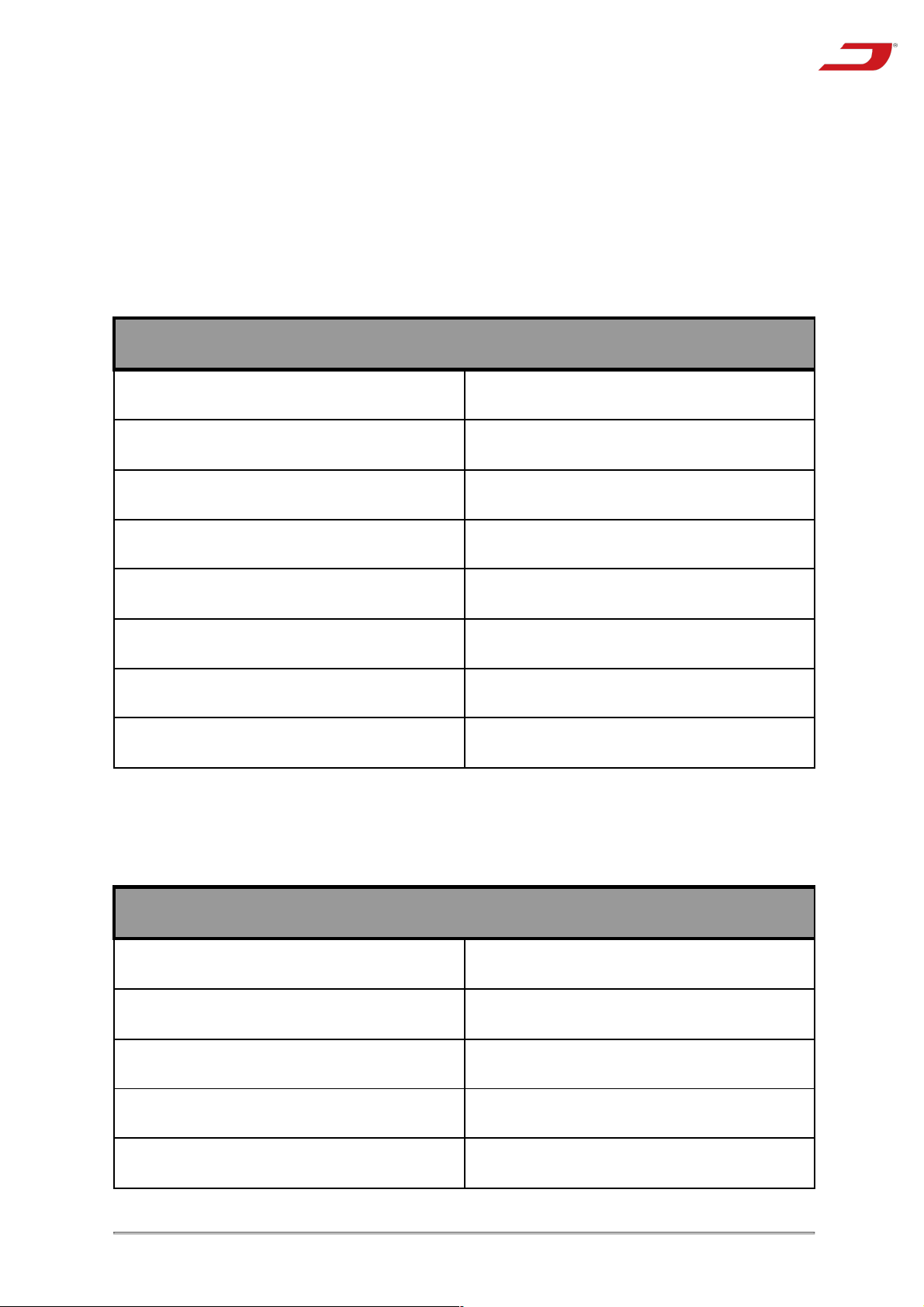

Technical data of the lifting arms

Lifting arms

Maximum lift arm length

360 mm

Minimum lifting arm length

112 mm

Highest diameter

32 mm

Maximum operating force

700 N

Operating voltage

12 V DC voltage

Operating current

5 A

Operating temperature

-30° Celsius −85° Celsius

Protection class

Static IP 67, on the move IP 65

Technical data of the engine for automatic frunking

Motor for automatic frunk

Operating voltage

12 V DC voltage

Operating current unloaded

≤1,1 A

Motor speed unloaded

280 - 360 rpm

Locking torque

≥4 Nm

Maximum current

20 A

5

Transmission ratio

26,4

Acoustic emission

≤60 dB

Preparations

To ensure that the installation can be carried out quickly, tools required for

the installation should be provided before starting. The required tools are

listed below.

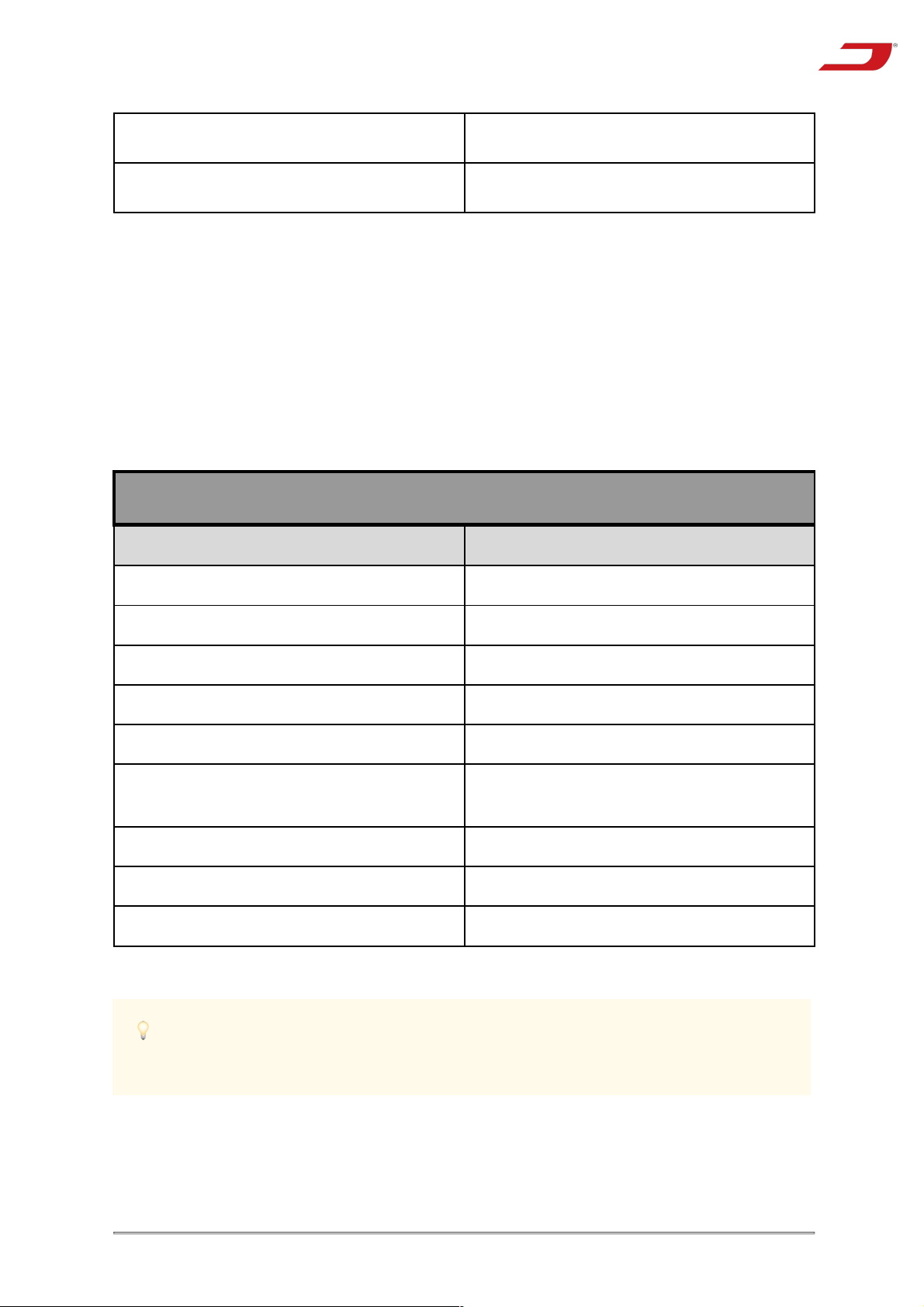

List of tools needed for the installation

Tool list

Position

Designation

1

Torx T20/T30

2

Needle nose pliers

4

Slotted screwdriver

5

Plastic mounting lever

7

Ratchet/Ratchet

8

Socket wrench set/nut (10mm,

13mm)

9

Cable ties in large and small

10

Adhesive tape

11

Cutting tool

💡Tip

A commercially available toolbox contains many of

the tools you need.

Preparations

6

Please check the scope of delivery of the order before starting the

installation.

List about the scope of delivery

Scope of delivery

Position

Designation

1

2 lifting arms

2

Softclose motor with emergency

release tab

3

Control unit

4

Cable tie

5

Power adapter plug with fuse

6

2 cable harnesses

7

2 adapter plates with ball joints

8

2 screws (hexagon socket)

9

Acoustic signal generator

10

Double-sided adhesive tape (3M)

After checking the scope of delivery and providing the tools, you can

proceed with the installation instructions.

Installation guide

Before proceeding to the removal of the inner lining, it is advisable to expose

storage areas for the parts removed in the course of the installation. In

addition, it is helpful to keep the clamps and screws that are removed

sorted.

Remove cladding

● Remove the four interior trim panels arranged around the front

storage compartment. To do this, pull the panels upwards with a jerk

(Figure 1).

Figure 1: Plastic cladding in the frunk

● Remove the front storage compartment carpet trim by reaching

under the rubber lip and separating the carpet trim from the rubber

lip

● Disconnect the two plugs for the storage compartment lighting and

the plug for the pushbutton. The plugs are locked according to the

barb principle

● Then lift out the carpet lining

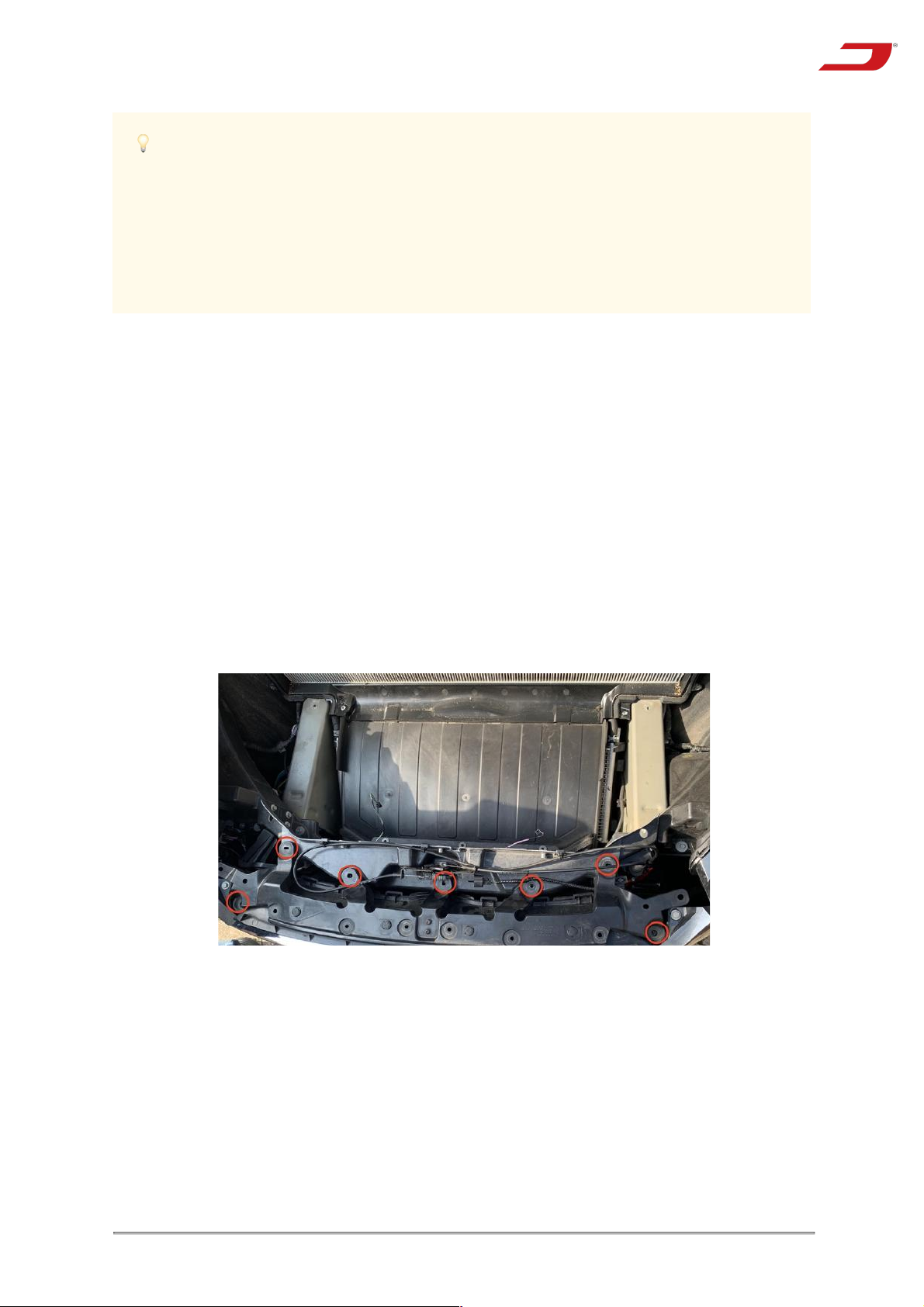

● The plastic tray under the fairing is fixed with 20 hexagonal screws

(10mm). Loosen the screws (Figure 2)

Installation guide

8

Figure 2: Screwing of the plastic tray

● Lift out the plastic tray

Replace lifting arms

● Remove the lift arms by levering the locking cotter pin with the

slotted screwdriver and pulling on the respective end of the lift arm

by hand until the lift arm releases at the attachment point (Figure 3)

Figure 3: Loosening the lifting arms

● Loosen the joints at the lower attachment points of the lifting arms

using a socket wrench (13mm) (Figure 4)

Installation guide

9

Figure 4: Lower attachment point

● Use the adapter plates included in the scope of delivery and screw

them to the lower attachment points of the lift arms using the screws

included in the scope of delivery. The adapter plates are marked with

"L" (left) and "R" (right) and refer to the left and right side of the vehicle

in the direction of travel. The arrows on the adapter plates indicate the

corner of the adapter plate that is further up when attached. The

curved part of the adapter plate is guided over the sheet metal edge

marked with the red arrow (Figure 5).

Figure 5: Attaching the adapter plates

Installation guide

10

💡Tip

Loosen one lift arm and attach the new lift arm to

the lower attachment point first. After the second

lift arm has been loosened, press both lift arms

against the joint at the upper attachment point so

that the lift arms engage. A second person should

be used to replace the lifting arms.

● The lifting arms for the automatic frunk are pressed against the ball

of the ball joint with the locking split pin until they engage. A "click"

sound is heard when they engage. The front hood must be held in

position for this if necessary.

● Test with both hands whether the front cover can be moved without

any problems

Modify clamping unit

● Loosen the 7 hex head screws (10mm, hex) that secure the plastic

cover above the Tesla emblem (Figure 6)

Figure 6: Screwing of the front plastic cover

● Loosen the two pin clips at the ends of the plastic cover. These are

located underneath the plastic cover (Figure 7)

Table of contents

Other AMPTech Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction