BMK-30

A. Getting started

1. Check all parts against the parts list and inspect for damage.

2. Make sure you have the tools needed for the job.

Recommended tool list

Adjustable wrench Torque Wrench Drill

5

⁄

8

⬙wrench (2) Side Cutter

7

⁄

16

⬙drill bit

13

⁄

16

⬙wrench

15

⁄

16

⬙wrench Utility knife

Center punch

7

⁄

8

⬙wrench (2) Adjustable filter wrench

Hammer Oil drain pan Vice

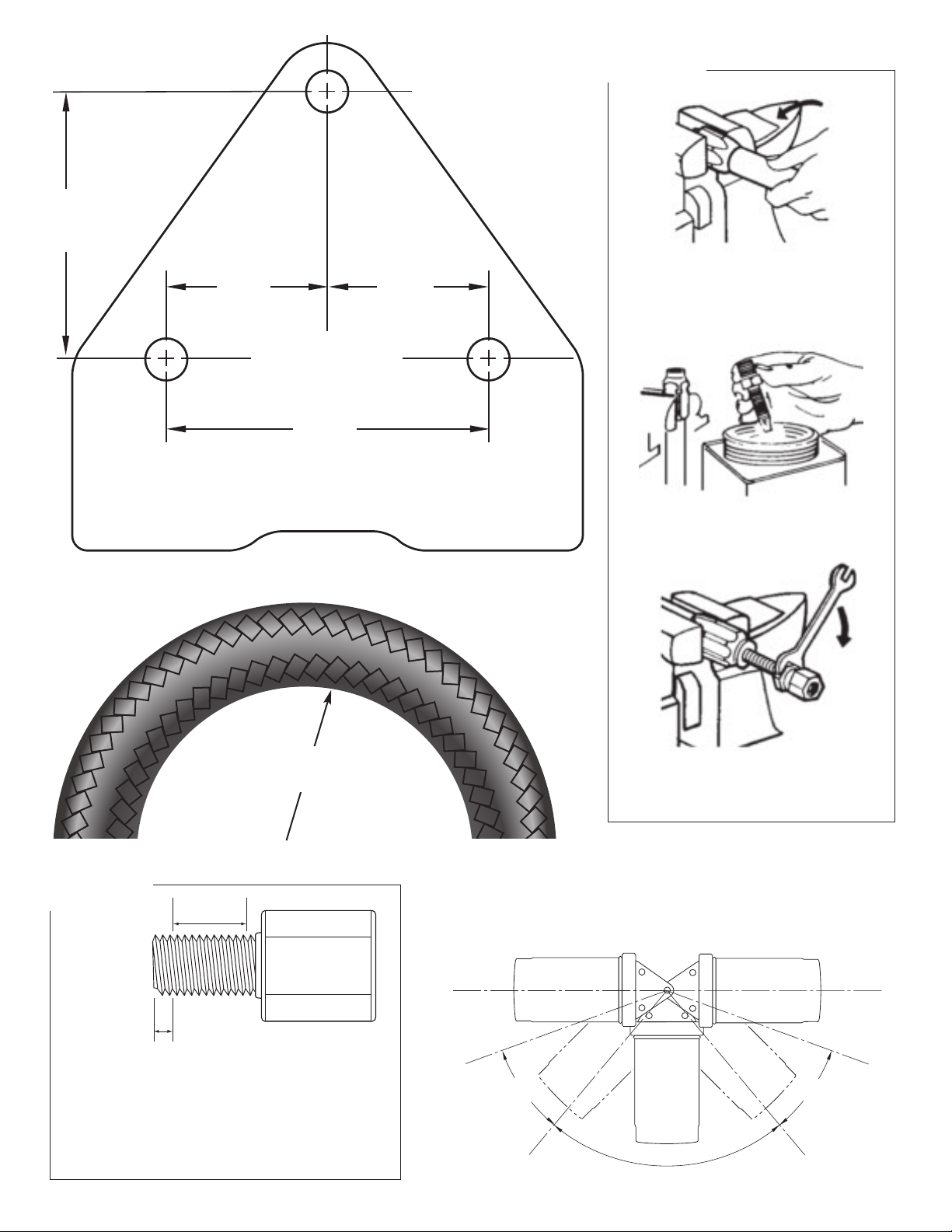

B. Attaching the filter mount

1. Survey the engine compartment for possible mounting locations. Solid

structures such as the firewall, fender well, radiator support or frame are

normal locations. (Do not mount on engine.) See diagrams A and G

2. This filter system must be mounted vertically to operate properly.

3. When the location has been determined, mark the area using the filter

mount as a template and mark the holes with a center punch and hammer.

See diagram B

4. Install adapter fittings (BP-190) on filter mount (BK-305) using PST or

thread tape. Using a

13

⁄

16

⬙wrench, tighten fittings 2-3 turns beyond

finger tight.

5. With a

7

⁄

16

⬙drill bit, drill out the previously marked mounting holes and

attach the filter mount using the

7

⁄

16

⬙bolts, nuts, small washers and fender

washers provided. The bolts should be tightened to 20 foot pounds.

5

⁄

8

⬙

wrenches or socket will be required for this operation.

6. Fill the By-Pass Filter element (EaBP-120) with the same motor oil being

used in the vehicle. Lubricate the filter gasket with oil and spin filter onto

mount. Tighten per instructions on the filter.

C. Oil Supply

1. Locate a pressurized oil port such as a gallery port, pressure sender port,

etc. Note: AMSOIL recommends adapting off of the pressurized oil port

using a fitting(s) to accept the

1

⁄

2

⬙JIC female hose end provided in this

kit. Purchase of adapters for your specific application is required.

2. Measure the amount of hose (BP-250, Purchased Separately) needed to

run from the pressurized oil port. Using a utility knife, squarely cut the hose

to the proper length.

3. Install hose fittings (BP-260) on both ends of the hose following the

instructions noted in diagram F. Tools required are one

7

⁄

8

⬙and one

15

⁄

16

⬙

wrench or vise.

Note: The hose and fittings supplied with this kit have been matched to

provide maximum performance and life expectancy. Interchanging with

other types or brands is not recommended and should be avoided.

Should additional hose be required, it may be obtained from AMSOIL by

ordering part number BP-250. Do not use any form of thread sealant any-

where on the BP-260 hose fittings.

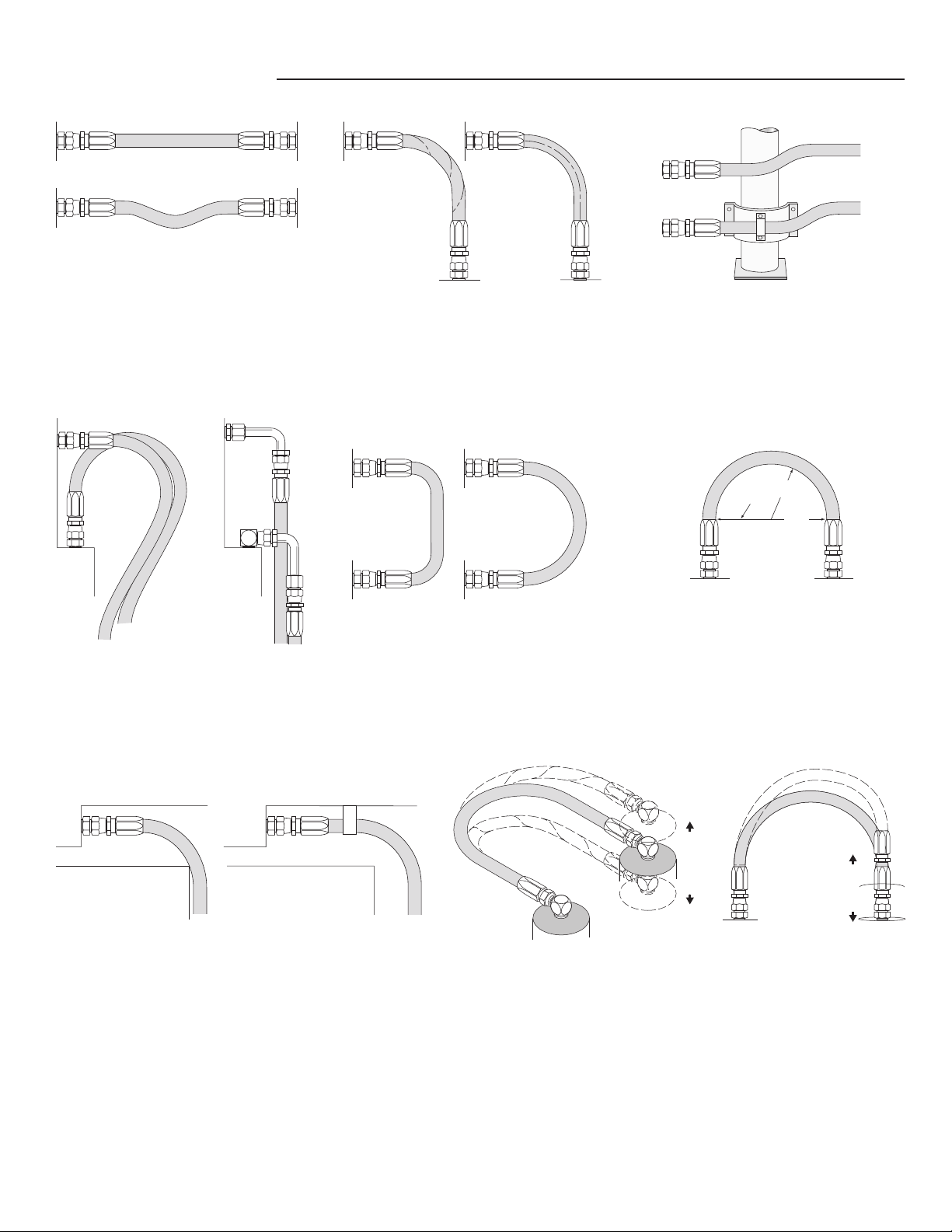

4. Route and connect the hose assembly to the filter mount (BK-305) at the

IN port see diagram C and to the

1

⁄

2

⬙JIC male fitting at the pressurized

oil port, making sure the hose does not contact any hot or moving sur-

faces or sharp edges. Ensure a minimum of a

3

⁄

4

⬙bend radius is main-

tained at all corners. Also, bends in hose should not begin at hose

fittings. See diagrams D and H

5. Using two

7

⁄

8

⬙wrenches, tighten hose fitting swivel nuts to 525-575

inch pounds or from finger tight, rotate an additional 60° or

1

⁄

6

of a turn.

Note: Do not use any form of thread sealant anywhere on the hose fittings.

D. Oil Return

1. The outlet of the by-pass unit (BK-305) should be connected to a low pres-

sure or free oil return to the crankcase or sump of the engine. Many heavy

duty diesels have access ports on the side of the oil pan or at the oil fill

tube.

2. Measure the amount of hose (BP-250, Purchased Separately) you will

need to run from the filter mount (BK-305) to the low pressure oil outlet

on the engine.

Note: AMSOIL recommends adapting off of the crankcase or sump port

using a fitting to accept the

1

⁄

2

⬙JIC female hose end provided in this kit.

Purchase of adapters for your specific application is required.

3. Using a utility knife, squarely cut the hose to the proper length.

4. Install hose fittings (BP-260) on both ends of the hose following the

instructions noted in diagram F. Tools required are one

7

⁄

8

⬙and one

15

⁄

16

⬙wrench or vise.

5. Route and connect the hose assembly to the filter mount (BK-305) at the

OUT port see diagram C and to the

1

⁄

2

⬙JIC male fitting at the low pres-

sure oil port, making sure the hose does not contact any hot or moving sur-

faces or sharp edges. Ensure a minimum of a

3

⁄

4

⬙bend radius is maintained

at all corners. Also, bends in hose should not begin at hose fittings.

6. Using two

7

⁄

8

⬙wrenches, tighten hose fitting swivel nuts to 525-575

inch pounds or from finger tight, rotate an additional 60° or

1

⁄

6

of a turn.

Note: Do not use any form of thread sealant anywhere on the hose fittings.

7. Use plastic ties (BP-46) to secure hose in position and away from

damage. Trim ties using side cutter.

Note: Over tightening the plastic ties can restrict oil flow.

5. Record vehicle mileage/operating hours and date of installation.

E. Start up procedures

1. Check that all fittings and hoses are securely attached, and that the

hoses are routed properly.

2. Check engine oil level. Fill to full mark if necessary.

3. Set vehicle parking brake. With transmission in park/neutral start the engine

and immediately check oil pressure. Note: Pressure may initially take a

moment or two to rise. Caution: Carefully check for leaks at fittings, hoses

and mount. If leaks are observed,

STOP ENGINE IMMEDIATELY,

repair

leaks and continue.

IMPORTANT NOTICE

Read all instructions completely before attempting to install this unit.

Improper installation could result in serious system and/or equipment

damage. The installation of this system is not difficult, however, some

mechanical ability is necessary. If you are not comfortable with the

instructions or have questions, do not attempt the installation. Consult

a mechanic or contact AMSOIL INC. for further instructions or assistance.

If installing on a Japanese- or European-built vehicle utilizing Metric or

B.S.P. threads, additional parts may be required. Consult step D.1

before you continue.

WWAARRNNIINNGG::This filter system is not designed to replace the engine’s

normal full-flow filter. Do not attempt to install a by-pass filter element

in place of the existing full-flow filter.

WWAARRNNIINNGG::Extreme care should be taken to avoid bodily harm during

installation. Before starting, ensure the engine is cool to avoid burns and

never work in the engine compartment area with the engine running.

Heavy-Duty By-Pass Filtration System

Installation and Servicing Instructions

BMK30_90358 6/6/08 7:50 AM Page 1