Specications Information and Repair Parts Manual 5891-DC

5891-250-00 1 12/2019

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained in the General Operating

Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or property damage! Retain instructions

for future reference. AMT reserves the right to discontinue any model or change specications at any time without incurring any obligation.

©2019 AMT Pump Company, A Subsidiary of The Gorman-Rupp Company, All Rights Reserved.

Periodic maintenance and inspection is required on all pumps to ensure proper operation. Unit must be clear of debris and sediment. Inspect for leaks and loose bolts. Failure to do so

voids warranty.

Submersible Pump 12V DC Series

Refer to pump manual 1808-636-00 for General Operating and Safety Instructions.

DANGER: Not for use with uids that have a ash point below 100º F

(38º C) (Example: gasoline, alcohol). Sparking could result in death.

OPERATING AND INSTALLATION INSTRUCTIONS

Hose: Since the pump develops relatively low pressure, it is recommended

that non-collapsible hose be used for maximum pumping rates.

Hoisting and Lowering: Attach a line to the handle (Ref. 7) on the top of the

pump for hoisting or lowering the unit. Do not use power cable for handling

unit. LIFTING BY POWER CABLE VOIDS WARRANTY.

To Operate: Lower unit into liquid to be pumped and activate switch. Do not

run dry; damage to shaft seal will result.

RUNNING TIME: This unit draws about 30 amperes and can be operated about

1 hour on a fully charged 55 amp-hour battery and still permit starting of vehicle

under normal conditions. Caution should be used when running time exceeds

30 or 40 minutes without engine running to recharge battery, particularly in cold

weather when battery eciency is lowered. Battery size (amp-hour rating) and

the use of other accessories such as lights and radios, etc. must be taken into

consideration for practical running periods without engine running.

OVERLOAD PROTECTION is provided by means of a 40 amp automatic reset

circuit breaker located under top end cap (Ref. 9) on the back of the motor

(Ref. 13).

TROUBLE SHOOTING

NOTE: Most common cause of failure to run is due to hardened mud and sand

at impeller. Remove strainer (Ref. 26) to check.

Should unit not operate, always check freeness of rotation of impeller

by inserting screwdriver through hole in casing (Ref. 25) into slot in end

of shaft.

MOTOR WILL NOT RUN:

1. Poor connection at battery.

2. Impeller locked with foreign material.

3. Insucient impeller clearance.

4. Damaged power cable or loose connection internally in motor assembly.

5. Bad switch or circuit breaker. Connect power leads directly to motor leads

to check.

6. Worn motor brushes or out of position to make contact with armature.

PERFORMANCE LOW:

1. Strainer screen partially plugged.

2. Impeller rubbing. Check freeness of rotation with screwdriver inserted

through hole in casing into slotted end of shaft.

3. Battery not fully charged.

4. Discharge restriction such as kinked hose or excessive discharge head.

MOTOR RUNS BACKWARDS:

1. Check wiring for correct polarity.

SERVICE & REPAIR INSTRUCTIONS DISASSEMBLY:

Impeller and shaft seal can be inspected and serviced from lower end of pump

by removal of the casing via 4 screws (Ref. 19). Screwdriver slot is provided in

end of motor shaft to turn shaft while holding impeller for removal. This permits

removal of impeller without disassembly of upper motor housing to hold motor

shaft.

Alternately, there is a shaft extension with two ats on the rear of the motor for

use when the impeller is dicult to remove. The top end cap must be removed

to expose this shaft extension.

To replace power cord, remove 4 hex ange nuts (Ref. 15) and bump top

end cap free from cylinder (Ref. 14). Loosen the power cord grips (Ref. 5)

around the wires and raise top end cap suciently to disconnect power cable

connections. Slide cylinder up from adapter (Ref. 18) and motor will be exposed

for wiring of new cord.

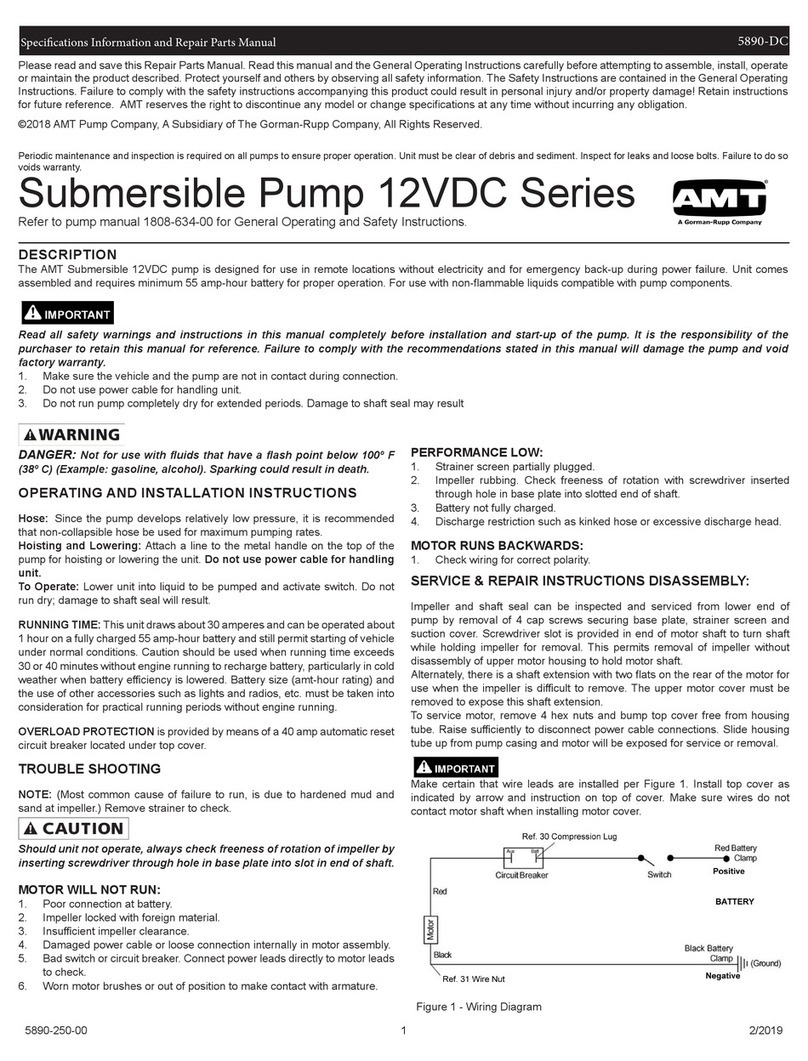

Make certain that wire leads are installed per Figure 1. Install top end cap

around cylinder. Use lubricant for easier installation with O-Ring (Ref. 12).

Make sure wires do not contact motor shaft when installing motor cover.

DESCRIPTION

The AMT Submersible 12V DC pump is designed for use in remote locations without electricity and for emergency back-up during power failure. Unit comes

assembled and requires minimum 55 amp-hour battery for proper operation. For use with non-ammable liquids compatible with pump components.

Read all safety warnings and instructions in this manual completely before installation and start-up of the pump. It is the responsibility of the

purchaser to retain this manual for reference. Failure to comply with the recommendations stated in this manual will damage the pump and void

factory warranty.

1. Make sure the vehicle and the pump are not in contact during connection.

2. Do not use power cable for handling unit.

3. Do not run pump completely dry for extended periods. Damage to shaft seal may result.

Figure 1 - Wiring Diagram