Specications Information and Repair Parts Manual 3670-94

3670-253-00 1 4/2015

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained in the General Operating

Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or property damage! Retain instructions

for future reference. AMT reserves the right to discontinue any model or change specications at any time without incurring any obligation.

©2015 AMT Pump Company, A Subsidiary of The Gorman-Rupp Company, All Rights Reserved.

Periodic maintenance and inspection is required on all pumps to ensure proper operation. Unit must be clear of debris and sediment. Inspect for leaks and loose bolts. Failure to do so

voids warranty.

Bronze Marine Pump

Refer to pump manual 1808-634-00 for General Operating and Safety Instructions.

INSTALLATION

Because of crystallization and erosive material on shaft seal (Ref. No. 11),

installation of a seal wash is recommended to avoid premature leaks. Two

types may be used, a recirculated liquid type or a clean liquid type. Sometimes

a periodic seal cleaning is unavoidable.

Use pipe or hose to connect drain port on front of casing (Ref. No. 15) to seal

ush port on side of adapter (Ref. No. 9). Whenever pump is running, this re-

circulation line will ush seal.

Or, connect a line supplying clean liquid to seal ush port on adapter. Always

use an in-line check valve on this line. Flush as required.

MAINTENANCE

Disconnect from power source before servicing or inspecting the pump

for any reason. Failure to do so could result in fatal electrical shock!

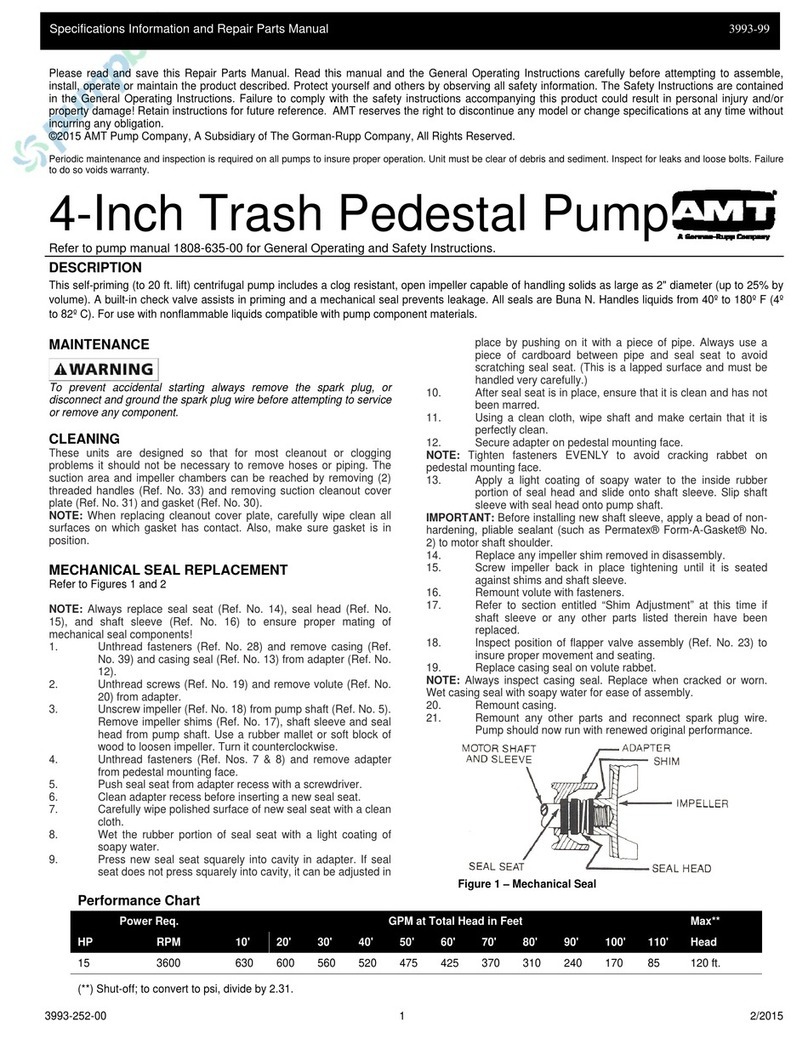

MECHANICAL SEAL REPLACEMENT

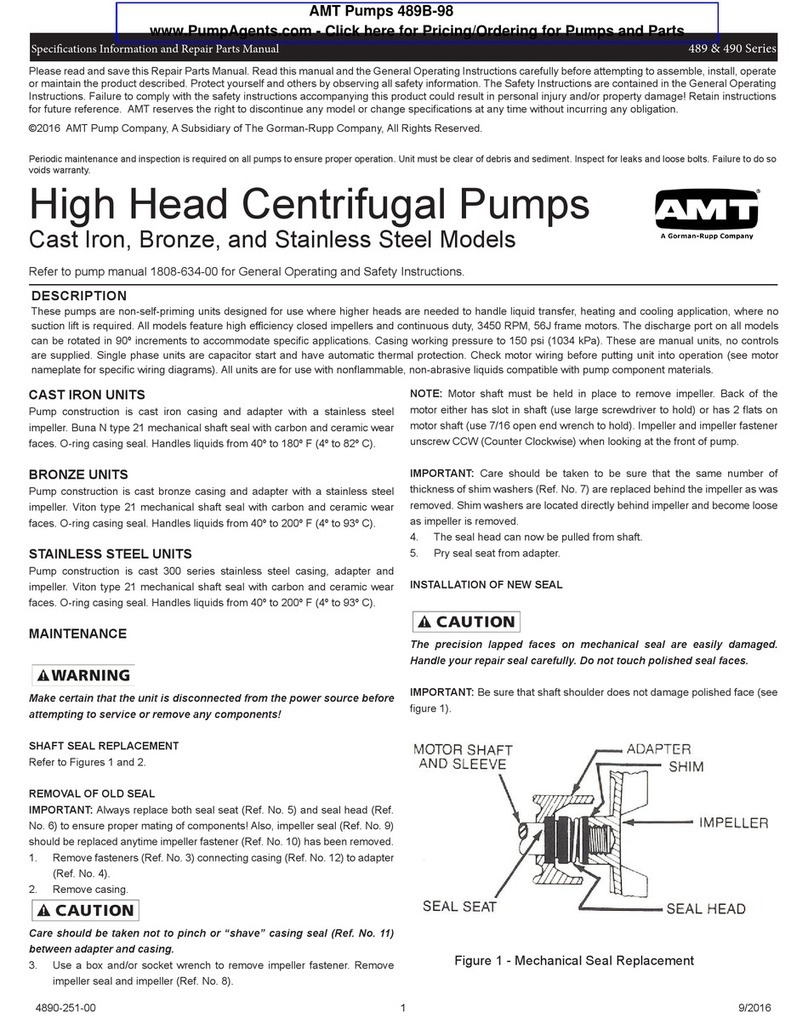

Refer to Figures 1, 2 and 3.

IMPORTANT: Always replace both the seal seat and the seal head (Ref. No.

11) to ensure proper matching of components!

1. Unthread cap screws (Ref. No. 2) and remove casing (Ref. No. 15) and

o-ring (Ref. No. 14).

2. Unscrew impeller (Ref. No. 13) from shaft (Ref. No. 7). To keep the shaft

from turning, remove three screws holding the motor fan guard and

remove the guard. Loosen the screw clamping the fan to the motor shaft

and remove the fan. When the fan is removed, the shaft can be held using

vise grip pliers or other suitable means.

3. Remove the three hex nuts (Ref. No. 8) and remove the adapter (Ref.

No. 9).

4. Lay the adapter face down on a at stable surface and press the seal

cartridge from the adapter.

5. Pry the seal seat from the rear of the impeller with a screwdriver or other

suitable means.

6. Clean the recess in the adapter for the seal cartridge and the recess in the

impeller for the seal seat before inserting any new parts.

7. Inspect the ceramic face of the seal seat and carbon face of the cartridge

to insure they are clean and not marred.

DESCRIPTION

This non self-priming, low pressure, centrifugal pump is intended for liquid transfer, re-circulation and wash down applications in marine environments where no

suction lift is required. Pump is sized for saltwater (1.03 specic gravity) and features provisions for the installation of an automatic seal wash. This may extend

shaft seal life by retarding salt crystallization on seal wear face. Seal wash hose not included. For use with nonammable, non-abrasive liquids compatible with

pump component materials. Units are equipped with a TEFC (Totally Enclosed Fan Cooled), ball bearing, splash protected, capacitor start, 4 pole motor. Thermal

protection not provided. The motor has ON/OFF switch, standard plug and six foot cord.

Figure 1 - Mechanical Seal Replacement

Figure 2 - Mechanical Seal Replacement