2761-255-00

Self-Priming Centrifugal Pumps

High Volume Dewatering

Stainless Steel Models

Operating Instructions & Parts Manual XXXXX, XXXXX and XXXXX

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to

assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. The Safety

Instructions are contained in the General Operating Instructions. Failure to comply with the safety instructions accompanying this product

could result in personal injury and/or property damage! Retain instructions for future reference.

Specifications Information 2761-98 thru 282D-98 &

and Repair Parts Manual 2821-98 thru 282M-98

Refer to form 1808-634-00 for General Operating and Safety Instructions.

06/2001

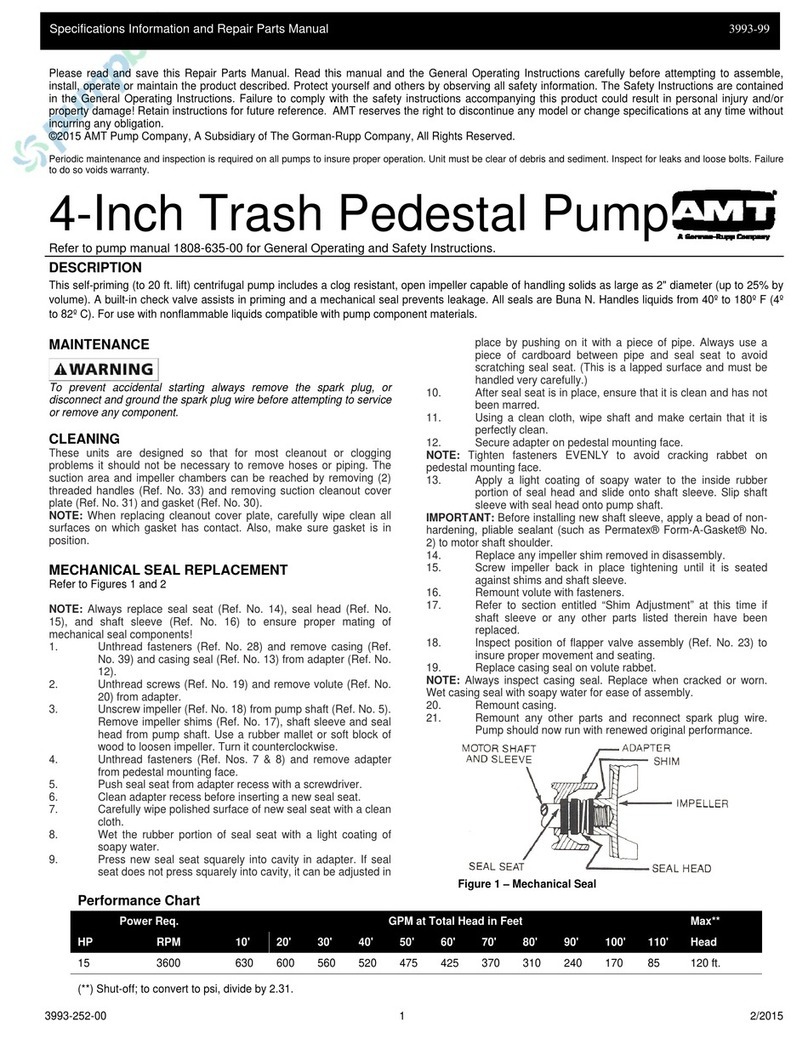

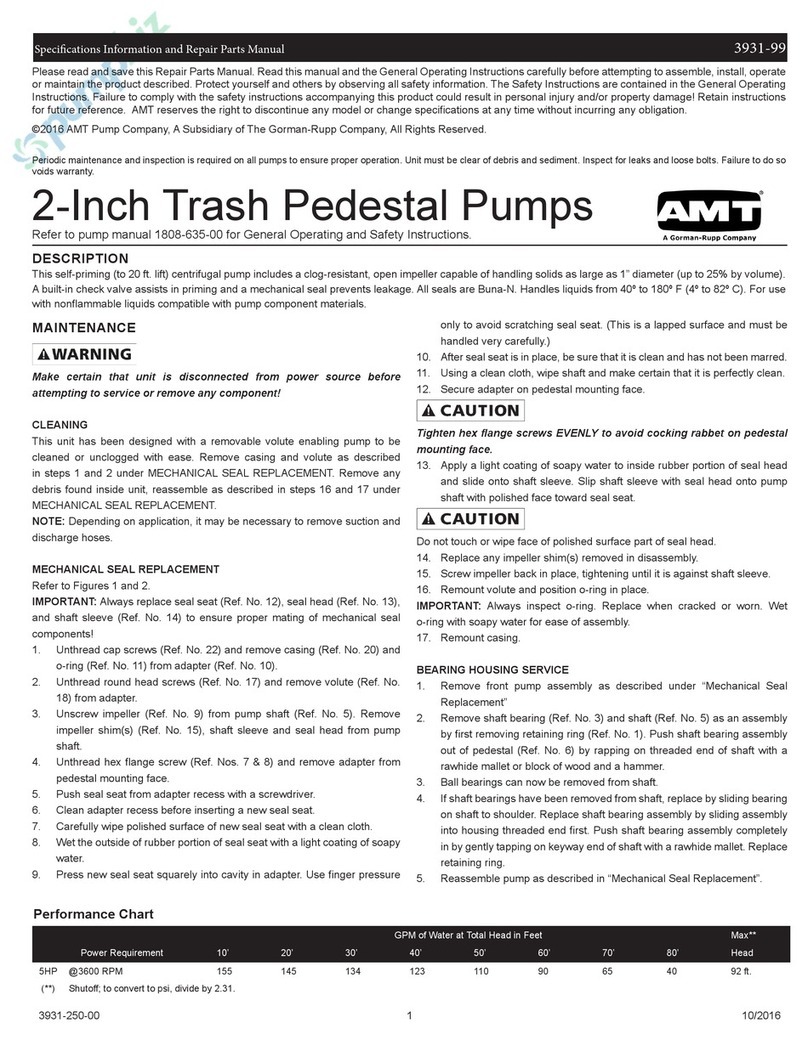

GPM of Water at Total Head in Feet Max.

Model 10’ 20’ 30’ 40’ 50’ 60’ 70’ 80’ 90’ Head*

2827, 282J, 282D, 282F 58 51 44 37 28 18 7 — — 74 ft.

2825, 2826, 282C, 282K 78 72 64 56 46 35 20 — — 78

2821, 2822, 282A, 282B 99 92 84 75 65 54 43 31 15 93

2828, 282L, 282E, 282M 117 112 102 92 82 70 56 42 24 95

2762, 2764, 276B, 276D 111 96 85 75 60 48 30 15 — 86

2761, 2763, 276A, 276C 127 115 103 90 76 60 40 20 — 93

2767, 2766 148 136 123 110 95 82 68 49 30 101

(*) Shut-off; To convert to psi, multiply by SG (specific gravity of liquid), then dived by 2.31.

Performance

Maintenance Make certain

that unit is

disconnected from power source before

attempting to service or remove any

component!

NOTE: The pump casing should be

removed and inspected periodically to

insure that any foreign material is not

clogging internal pump parts. This unit

is equipped with a dual volute pump

casing. One of the volutes runs 180°, all

the way from the side opposite the

discharge into the discharge through a

completely enclosed passageway. If

foreign material clogs this area, it can

be dislodged by using a wire or long

spring.

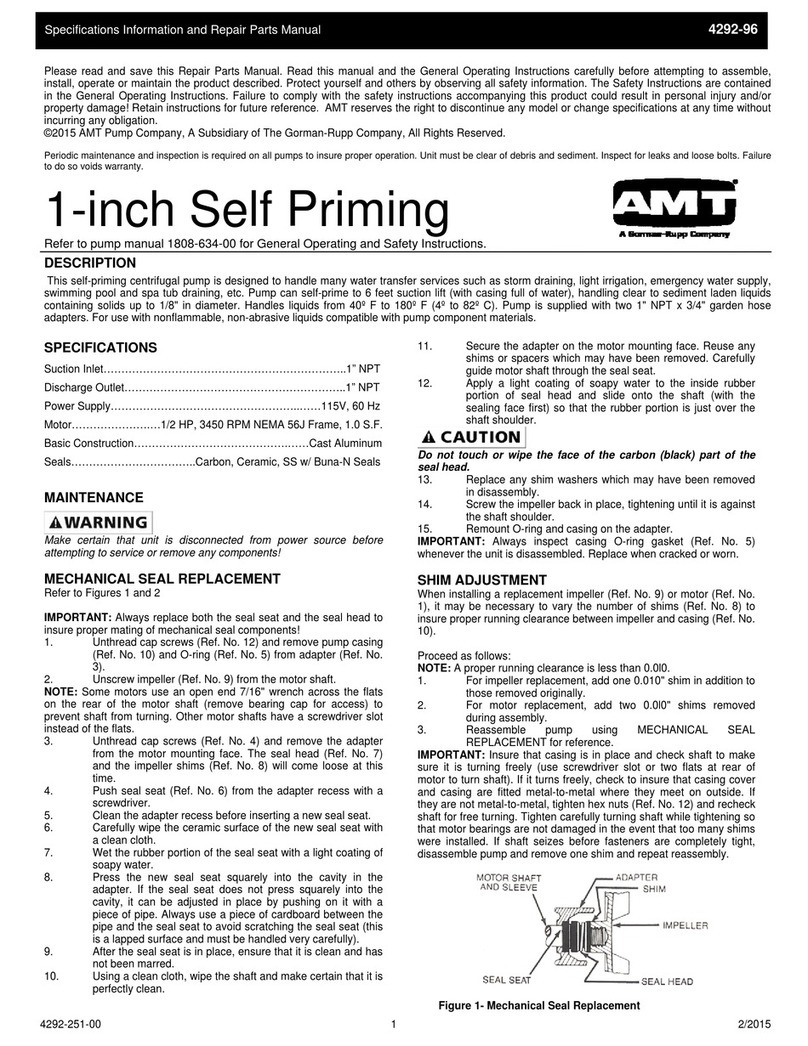

MECHANICAL SEAL REPLACEMENT

Refer to Figure 1

IMPORTANT: Always replace both seal

seat (Ref. No. 8) and seal head (Ref. No.

9) to ensure proper mating of

components!

1. Unthread fasteners (Ref. No. 6) and

remove casing (Ref. No. 14) and

casing seal (Ref. No. 7) from adapter

(Ref. No. 5).

2. Unscrew impeller fastener (Ref. No.

13), and impeller (Ref. No. 11)

separately by turning each

counterclockwise.

NOTE: Most motors use an open end

7/16” wrench across flats on rear of

motor shaft (remove bearing cap for

access) to prevent shaft from turning.

Other motor shafts have a screwdriver

slot instead of flats.

3. Unscrew fasteners (Ref. Nos. 4 & 18)

and remove adapter, foot (Ref. No.

19), and handle (Ref. No. 3) from

motor (Ref. No.1) mounting face.

Seal head will come loose at this

time.

4. Push seal seat from adapter recess

with a screwdriver.

5. Clean adapter recess before

inserting new seal seat.

6. Carefully wipe polished surface

of new seal seat with a clean cloth.

7. Wet rubber portion of seal seat with

a light coating of soapy water.

8. Press new seal seat squarely into

cavity in adapter. If seal seat does

not press squarely into cavity, it can

be adjusted in place by pushing on

it with a piece of pipe. Always use a

piece of cardboard between pipe

and seal seat to avoid scratching

seal seat. (This is a lapped surface

and must be handled very carefully.)

9. After seal seat is in place, insure

that it is clean and has not been

marred.

10. Using a clean cloth, wipe shaft and

make certain that it is perfectly

clean.

NOTE: If removed, slide slinger washer

(Ref. No. 2) onto shaft until it is located

approximately 1/8” from face of motor

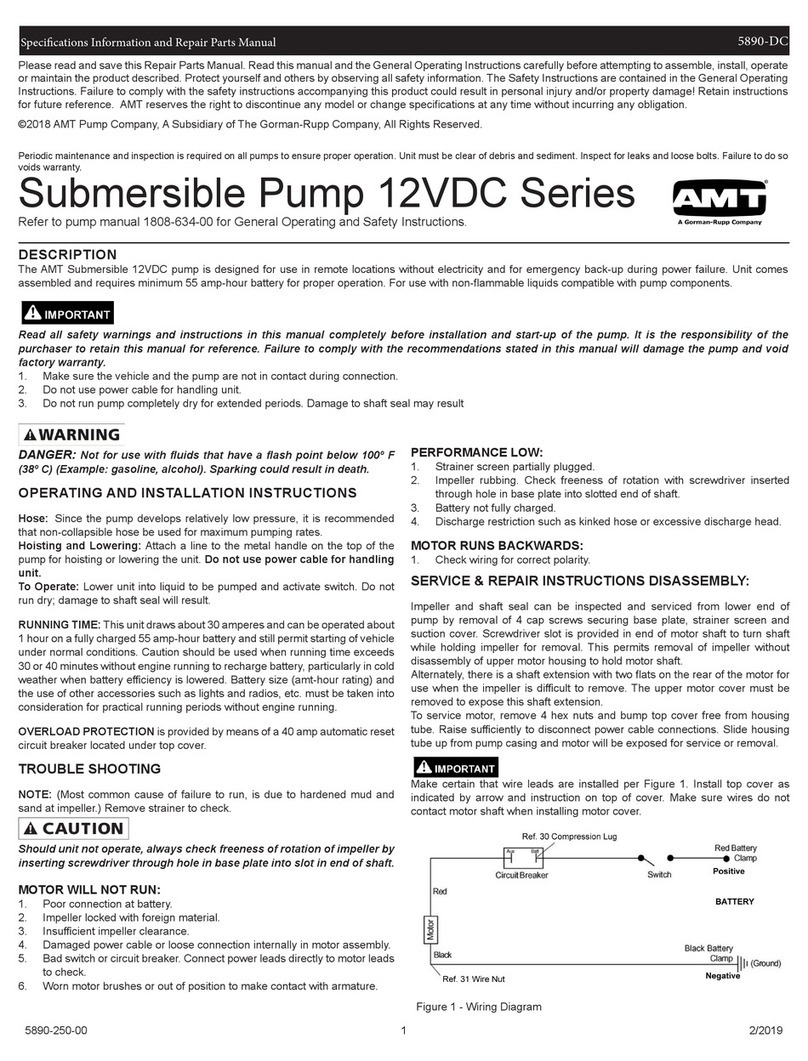

Description

These centrifugal pumps are self-priming (to 20 ft. lift) units designed for high

volume liquid transfer - irrigation, de-watering, lawn sprinkling, etc. They can also

accommodate semi-solids (up to 3/8” dia.), sediment laden liquids, and liquids

with entrained air or gases. Units are constructed of 316 stainless steel and include

Viton elstomers. They are direct coupled to NEMA 56J frame, 3450 RPM motors

which require field wiring, no controls are supplied. Each pump is equipped with

a flapper valve to shorten re-prime time. Handles liquids from 40º to 200º F (4º to

93º C). For use with non-flammable, non-abrasive liquids compatible with pump

component materials.