Specications Information and Repair Parts Manual 489 & 490 Series

4890-251-00 1 9/2016

Please read and save this Repair Parts Manual. Read this manual and the General Operating Instructions carefully before attempting to assemble, install, operate

or maintain the product described. Protect yourself and others by observing all safety information. The Safety Instructions are contained in the General Operating

Instructions. Failure to comply with the safety instructions accompanying this product could result in personal injury and/or property damage! Retain instructions

for future reference. AMT reserves the right to discontinue any model or change specications at any time without incurring any obligation.

©2016 AMT Pump Company, A Subsidiary of The Gorman-Rupp Company, All Rights Reserved.

Periodic maintenance and inspection is required on all pumps to ensure proper operation. Unit must be clear of debris and sediment. Inspect for leaks and loose bolts. Failure to do so

voids warranty.

High Head Centrifugal Pumps

Cast Iron, Bronze, and Stainless Steel Models

Refer to pump manual 1808-634-00 for General Operating and Safety Instructions.

CAST IRON UNITS

Pump construction is cast iron casing and adapter with a stainless steel

impeller. Buna N type 21 mechanical shaft seal with carbon and ceramic wear

faces. O-ring casing seal. Handles liquids from 40º to 180º F (4º to 82º C).

BRONZE UNITS

Pump construction is cast bronze casing and adapter with a stainless steel

impeller. Viton type 21 mechanical shaft seal with carbon and ceramic wear

faces. O-ring casing seal. Handles liquids from 40º to 200º F (4º to 93º C).

STAINLESS STEEL UNITS

Pump construction is cast 300 series stainless steel casing, adapter and

impeller. Viton type 21 mechanical shaft seal with carbon and ceramic wear

faces. O-ring casing seal. Handles liquids from 40º to 200º F (4º to 93º C).

MAINTENANCE

Make certain that the unit is disconnected from the power source before

attempting to service or remove any components!

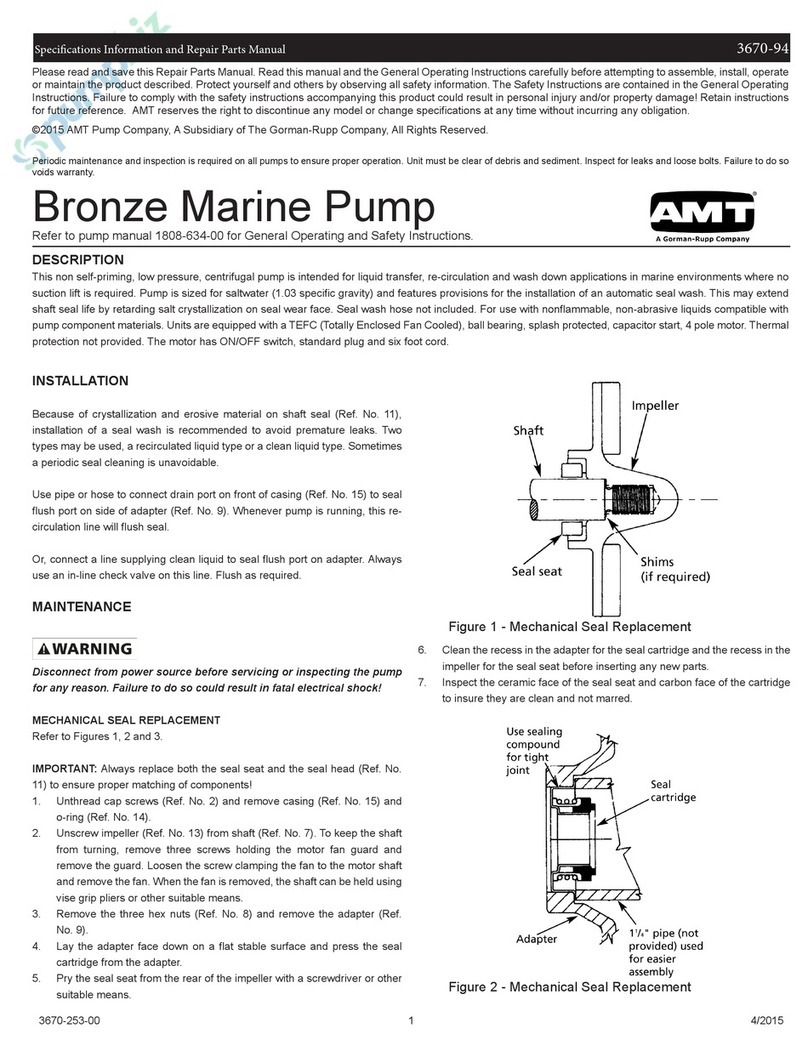

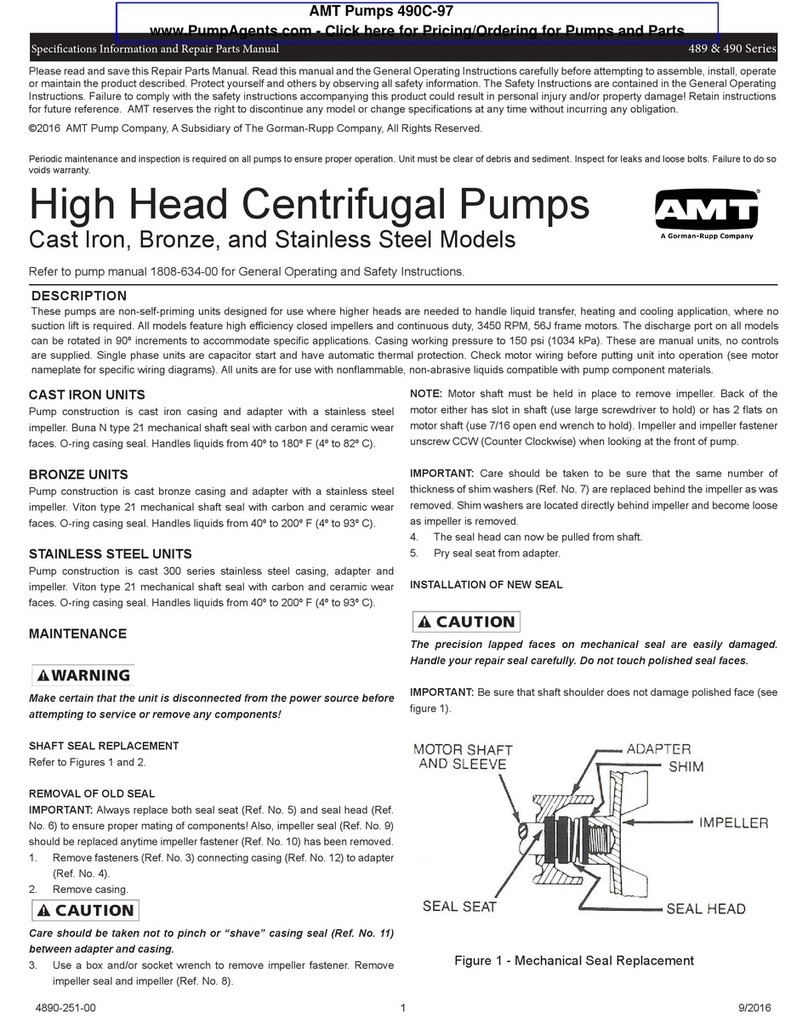

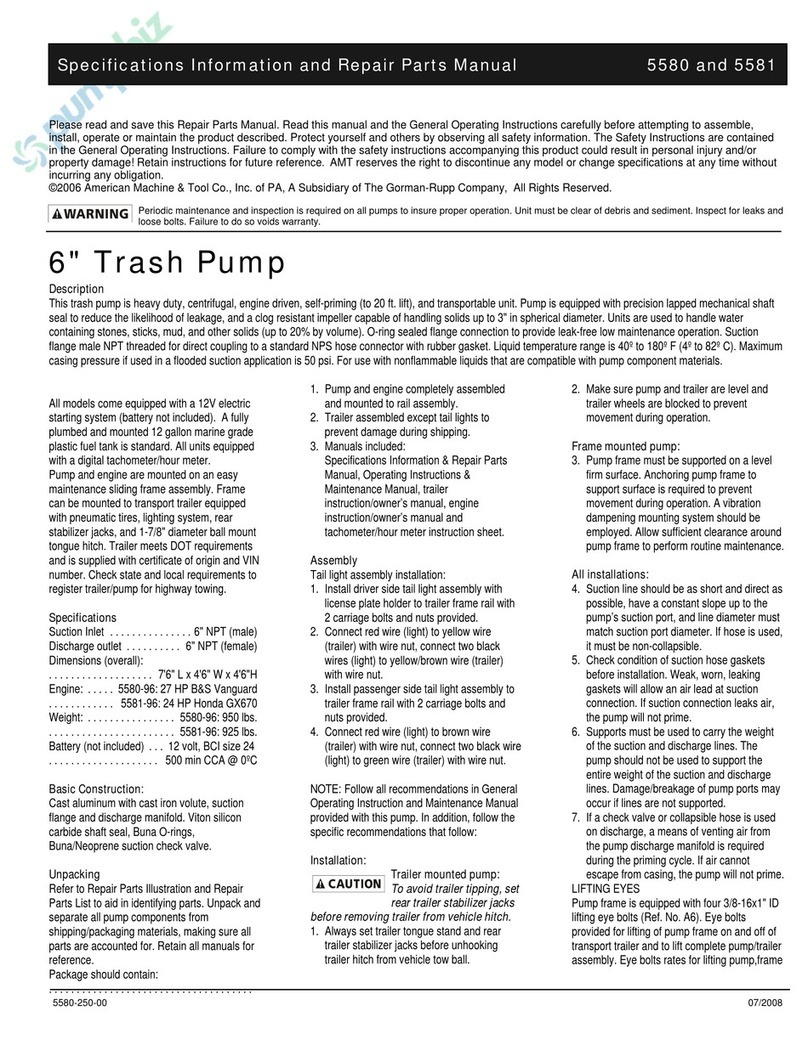

SHAFT SEAL REPLACEMENT

Refer to Figures 1 and 2.

REMOVAL OF OLD SEAL

IMPORTANT: Always replace both seal seat (Ref. No. 5) and seal head (Ref.

No. 6) to ensure proper mating of components! Also, impeller seal (Ref. No. 9)

should be replaced anytime impeller fastener (Ref. No. 10) has been removed.

1. Remove fasteners (Ref. No. 3) connecting casing (Ref. No. 12) to adapter

(Ref. No. 4).

2. Remove casing.

Care should be taken not to pinch or “shave” casing seal (Ref. No. 11)

between adapter and casing.

3. Use a box and/or socket wrench to remove impeller fastener. Remove

impeller seal and impeller (Ref. No. 8).

NOTE: Motor shaft must be held in place to remove impeller. Back of the

motor either has slot in shaft (use large screwdriver to hold) or has 2 ats on

motor shaft (use 7/16 open end wrench to hold). Impeller and impeller fastener

unscrew CCW (Counter Clockwise) when looking at the front of pump.

IMPORTANT: Care should be taken to be sure that the same number of

thickness of shim washers (Ref. No. 7) are replaced behind the impeller as was

removed. Shim washers are located directly behind impeller and become loose

as impeller is removed.

4. The seal head can now be pulled from shaft.

5. Pry seal seat from adapter.

INSTALLATION OF NEW SEAL

The precision lapped faces on mechanical seal are easily damaged.

Handle your repair seal carefully. Do not touch polished seal faces.

IMPORTANT: Be sure that shaft shoulder does not damage polished face (see

gure 1).

DESCRIPTION

These pumps are non-self-priming units designed for use where higher heads are needed to handle liquid transfer, heating and cooling application, where no

suction lift is required. All models feature high eciency closed impellers and continuous duty, 3450 RPM, 56J frame motors. The discharge port on all models

can be rotated in 90º increments to accommodate specic applications. Casing working pressure to 150 psi (1034 kPa). These are manual units, no controls

are supplied. Single phase units are capacitor start and have automatic thermal protection. Check motor wiring before putting unit into operation (see motor

nameplate for specic wiring diagrams). All units are for use with nonammable, non-abrasive liquids compatible with pump component materials.

Figure 1 - Mechanical Seal Replacement

www.PumpAgents.com - Click here for Pricing/Ordering for Pumps and Parts

AMT Pumps 489B-98