Recommendations for 12.5mm Solid Grade Laminate

Machining

• The machining of Compact laminate should be done using tungsten carbide tipped blade/ cutters or metal

cutting tools.

Cutting

• In order to obtain a clean cut, we suggest the use of carbide tipped saw blades with trapezoidal and as

many teeth as possible or a jigsaw with a metal cutting blade. However, alternating teeth can be equally

suitable, but the cut will not be as clean.

• Best r

Precision Cutting

y, sawing the

panel slightly oversize and then re-cutting the edge to the precise measurement using a tungsten carbide

tipped router cutter of the required pr

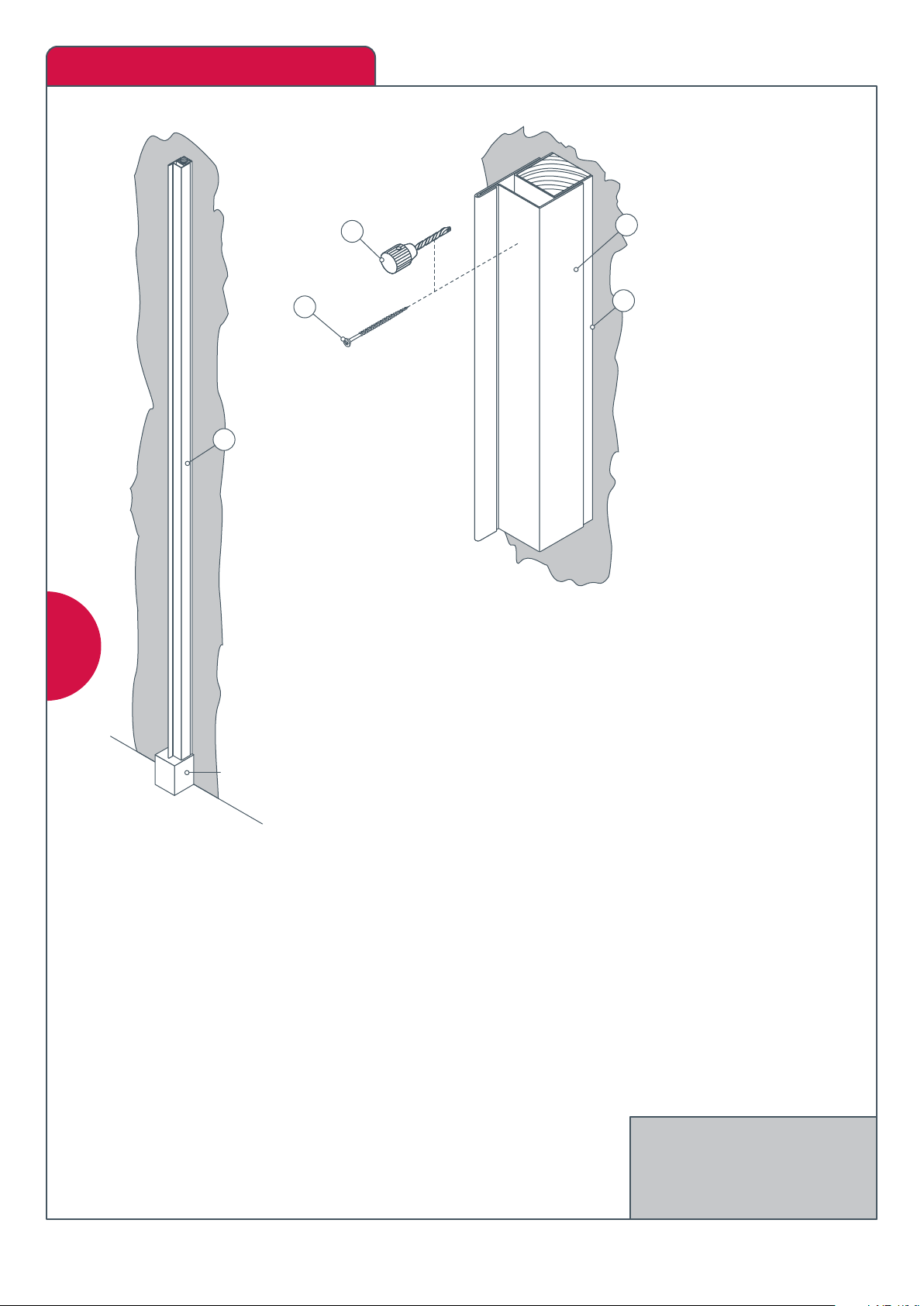

Grooving

• Compact can be grooved using a saw blade or router cutter with tungsten carbide tips.

• The depth of the groove must not exceed 1/3 of the Compact thickness.

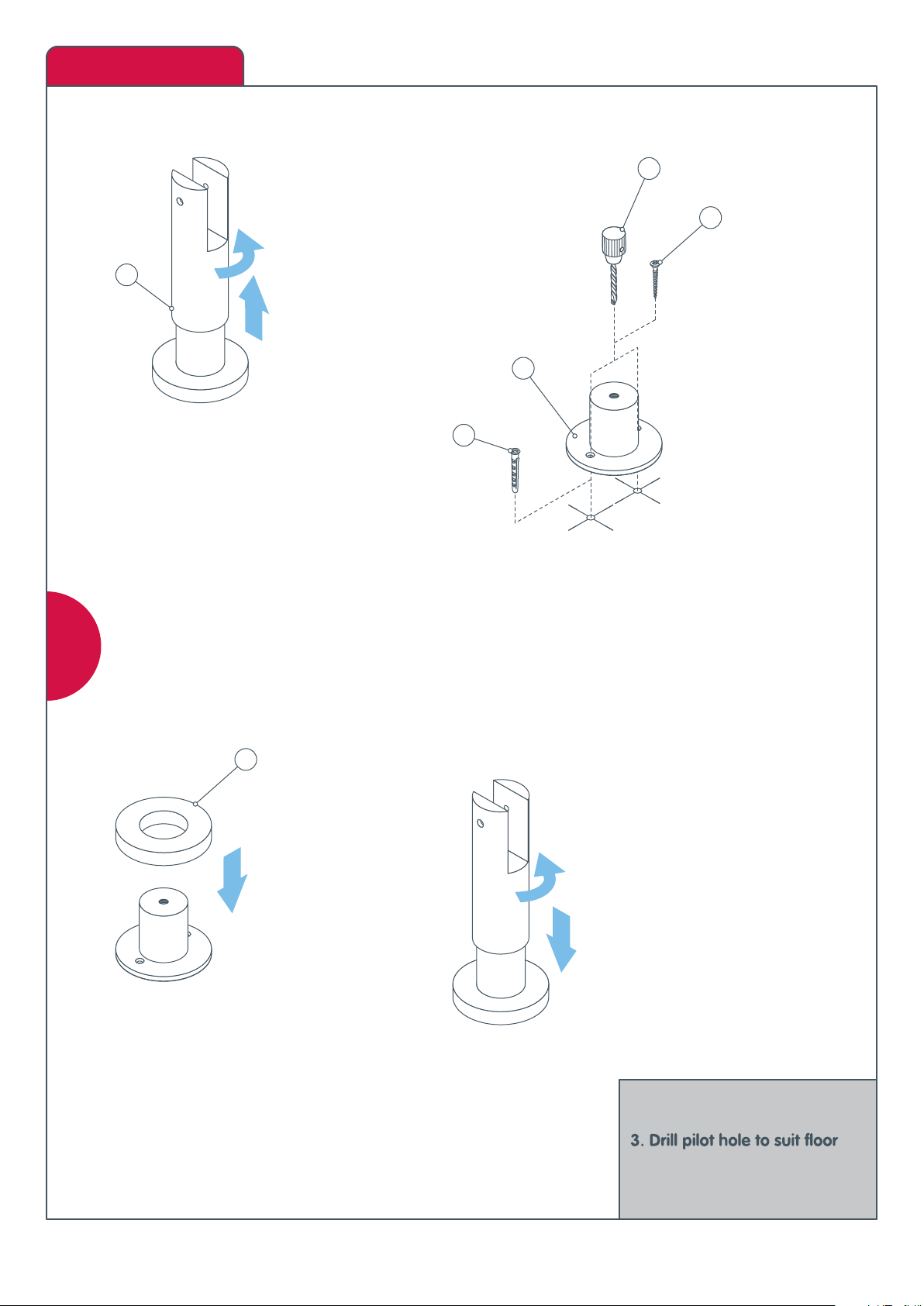

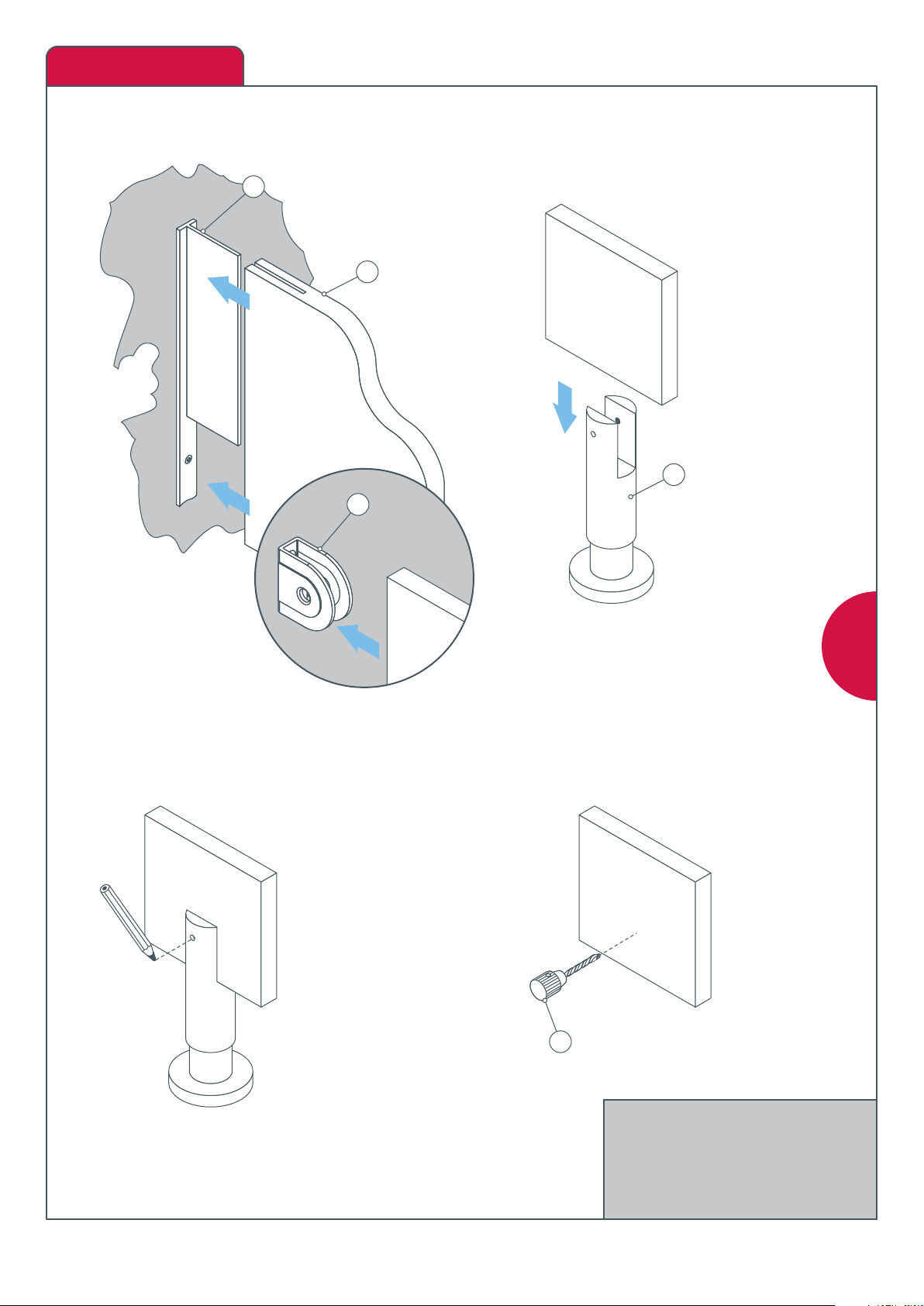

Drilling

• Carbide bits with 3 prongs give best results (helicoidal bits) and can be used in preference to high-speed

steel drills.

• Holes can be drilled through part of the thickness or through the whole. In the case of stopped holes, a

minimum thickness of 1.5mm to 2mm of the laminate must remain (i.e. maximum depth of hole = 11mm). A

minimum of 1mm of space must remain between the tenon, screw tip or insert and the bottom of the hole

(otherwise ther

• Pilot hole diameters for self tapping screws are: 3.5mm - No.6 screw; 3.5mm - No.8 screw; 4.5mm - No.10

screw; 5mm - No.12 screw.

Cut-Outs

• Square Cut-outs:- Drill the four corners with at least a 10mm diameter hole and, starting from one of the

holes, use a jigsaw with a metal cutting blade, cutting in straight lines, join the holes and square into the

cor re removed to avoid injury.

• Oval or Circular Cut-outs:- For example, cutting a basin hole into a vanity top. Drill a single 10mm diameter

hole and, starting from the hole, cut according to template using a jigsaw with a metal cutting blade. Finish

re removed to avoid injury.

Resizing and re-edging pr

• We would recommend that you cut the panel as previously described and trim to size using a ‘TREND’ Sunk

th a 300 grit sand paper.

• Polish as described below.

Finishing edges

• In order to eliminate machine-cutting imperfections created at the edges of the Compact, sand with a 300

• To obtain darker edges, rub the edge with a cloth soaked in linseed oil or wax. Leave to dry for 30 minutes

and wipe off. Sharp edges must be smoothed to avoid injury.

Minima Page 3