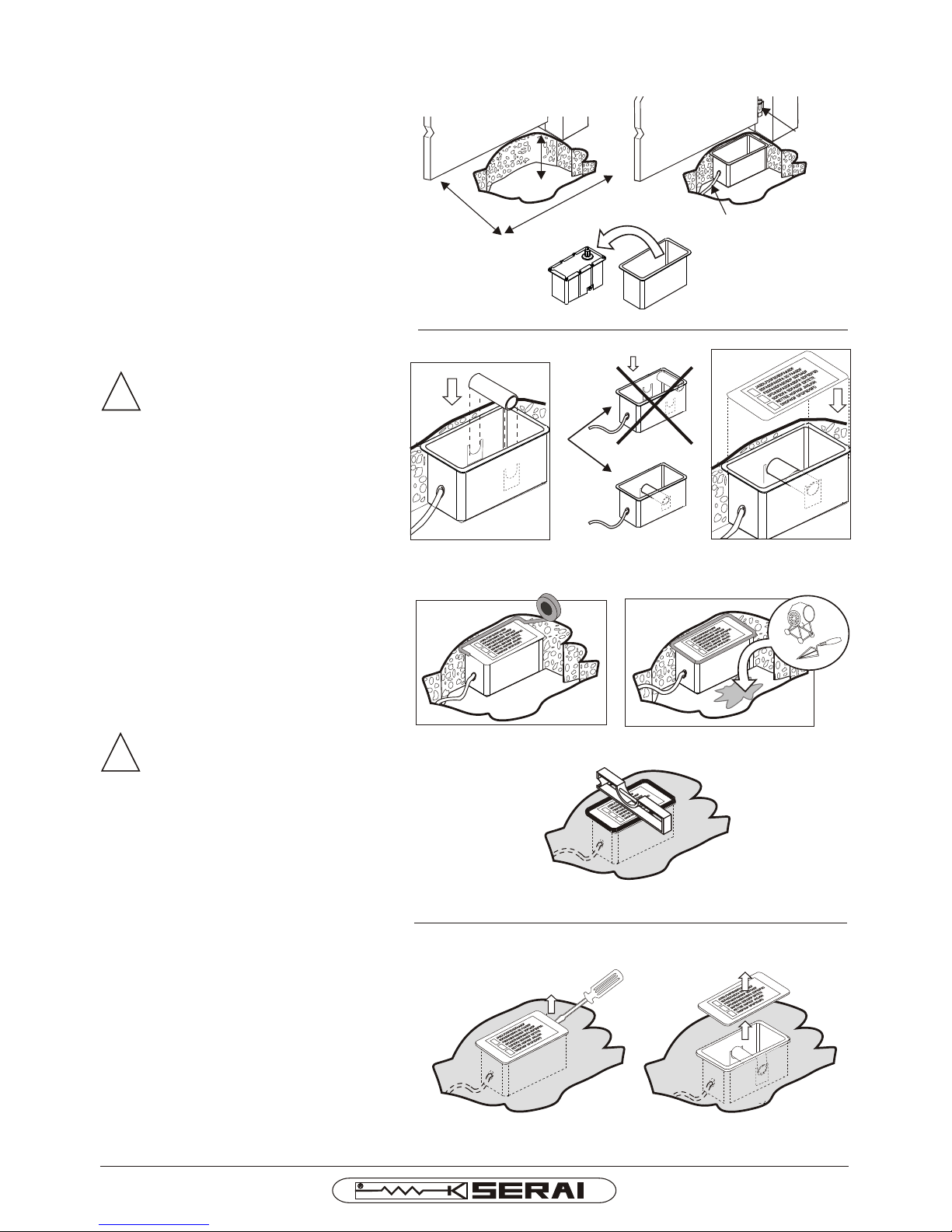

Fig 13

!

9- To make easy the eventual removal of the motor

and avoid any damage of the foundation box, insert

the 4 galvanized plates (which are supplied) in the

4 ends-inside the special circular places. See

picture no. 13.

10- Insert the motor, the telescopic arm and fix the

bracket on the gate. See Fig. 13.

IMPORTANT: lubricate the telescopic arm with

grease.

ATTENTION:

- Leave at least 35 cm of feeder under the

motor, for taking out the motor in case of

maintanance. Fig. 13

- The connection between the power supply

cable of the motor and the cable of the

control panel has to be carried out outside

the foundation box and inside a weather

proof housing. On the contrary a water

infiltration may be occur through the

power supply cable causing the motor

failure. See Fig. 13

11- Give power supply to the motor.

Weather proof

casing

35 cm of feeder

SKY BLUE =

OPEN/CLOSE

BROWN =

OPEN/CLOSE

ELECTRIC CONNECTIONS OF MOTOR

Connect the motors to the electronic control unit by means of cables

2

with a section of 2.5 mm .

SKY BLUE cable : Open/Close

BROWN cable: Open/Close

TURN OFF

POWER

SUPPLY

BEFORE

WIRING-UP

!

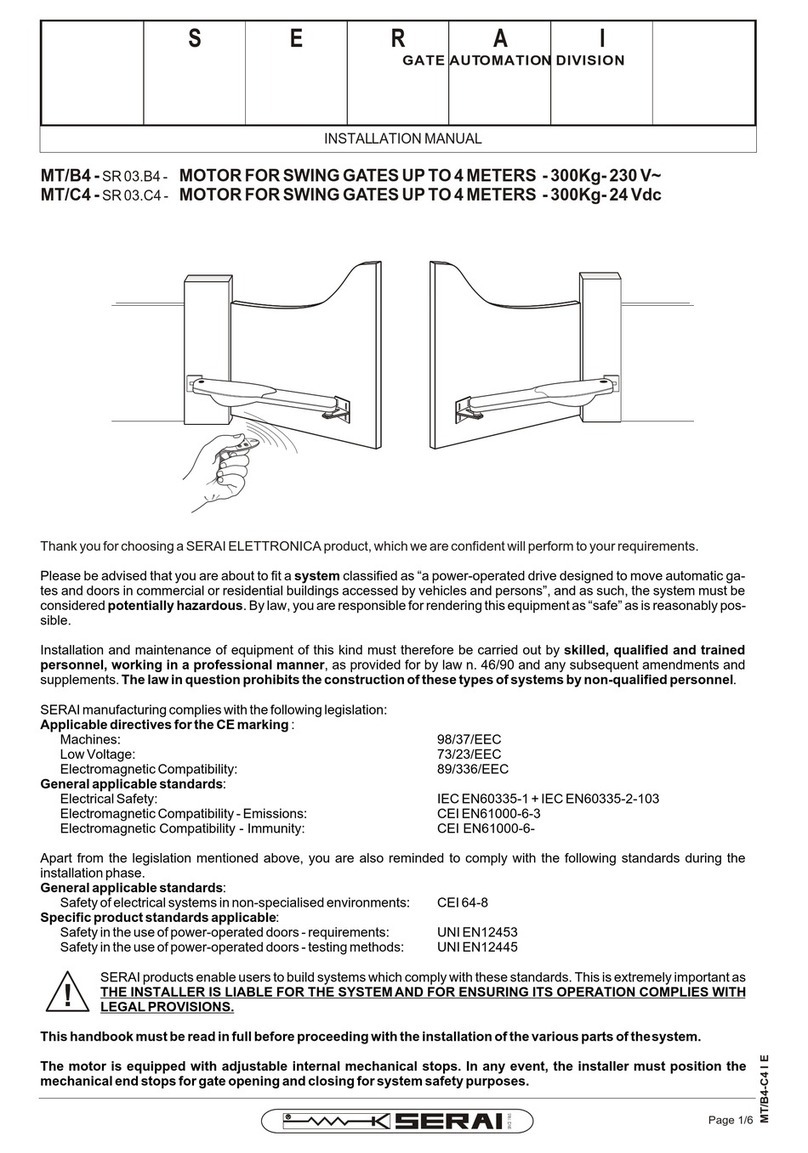

Reversing electromechanical motor for wing gates up to 2.20m each gate-wing and max. weight 250 kg.

Power supply..................................................24 V- ±25% Weight..............................................................10,7 kg

Max leaf lenght......................................................2,20 m Opening time for 90°.............................................13 s

Max leaf weight......................................................250 kg Protection rating...................................................IP67

Max opening angle.....................................................180° Operating temperature...........................-20° ¸+60°C

Max absorption..........................................................2,8A Dimensions......................................302x154x202mm

Power.......................................................................60 W

Max thrust............................................................175 Nm

Angular speed...................................................0,12 rad/s

GEARMOTOR TECHNICAL SPECIFICATIONS

MT/71 I E 01 05 080417 - A4Vf/r - IS MT71-IS-E

ELETTRONICA PADOVA

I

SINCE 1965

MADE IN ITALY

VIA ENRICO FERMI, 22

35020 LEGNARO - PADOVA

I T A L I A

PHONE +39 049 79 08 58

FAX +39 049 88 30 529

WEB www.serai.com

TERMS OF GUARANTEE

The company reserves the right to make modifications to the equipment without prior notice thereof. SERAI products are covered by a standard guarantee with a term of 24 months.

Coverage starts on the date on which the tax document constituting proof of purchase is issued and guarantee services shall be provided on the company's premises at Legnaro - PD -

or at the Authorised Service Centres. Carriage costs shall be borne by the Customer.

CE CONFORMITY DECLARATION

SERAI spa declares that the product MT/71 has been desifned and manufactured according to the above mentioned directives and standards

WEEE DIRECTIVE 2002/96/EC

This appliance was manufactured after 13/08/2005. To protect the environment: when the equipment is no longer needed, take it to a special WEEE (Waste Electric and

Electronic Equipment) collection centre. Do not dispose of it with normal household waste.

N.B. For stopping the gate-wings it is necessary to

install the electric lock -see the relevant

instructions-

Max. Working cycle: - opening.................................20s

- pause with opened gate........22s

- closing...................................20s

- pause with closed gate..........32s