8. Gradually decrease VIN1 and verify that VOUT voltage (J102) is restored back when the input voltage reaches

approximately 38.8V. Also check that UVOV1 status changes from 5V to 0V.

9. Reduce VIN1 to zero volts and verify that the output voltage goes down to zero volts.

10. Set the second 60V DC power supply (VIN2) to 5V and connect to VIN2 (J201). Verify that VOUT (J102) is 5V.

Repeat the steps 7-8 and verify the device U2 performance for OVLO operation.

Follow the steps (11-14) to test current-limit operation.

11. Set VIN1 to 24V and connect the adjustable load between VOUT and GND terminals and a multimeter in series

to measure the current. Gradually increase the load current and verify that VOUT (J102) goes down when the

load current increases above 0.3A. Also check that FLAG1 status changes from 5V to 0V.

12. Jumper JU103 can be configured to change the current limit as shown in Table 3. Verify various current-limit

settings by repeating Step 11.

13. Reduce VIN1 to zero volts and verify that the output voltage goes down to zero volts.

14. Set the second 60V DC power supply (VIN2) to 24V and connect to IN2 (J201). Verify that VOUT (J102) is 24V.

Repeat the steps 11-12 and verify the device U2 performance for different current-limit settings.

Follow the steps (15-20) to test ideal diode application.

15. Configure the jumpers JU103 and JU203 to current-limit setting = 3A as shown in Table 3 and connect 2.7A load

between VOUT and GND terminals.

16. Set VIN2 to 20V and connect to VIN2 (J201). Verify that VOUT (J102) is 20V.

17. Set VIN1 to 24V and connect to VIN1 (J101) to observe seamless switchover of VOUT voltage (J102) from VIN2

= 20V to VIN1 = 24V.

18. Observe that device U1 enters forward conduction state by verifying FLAG1 status change from 0V to 5V and

device U2 enters reverse blocking state by verifying FLAG2 status change from 5V to 0V.

19. Set the first DC power supply (VIN1) to 18V and observe seamless switchover of VOUT voltage (J102) from

VIN1 to 20V.

20. Observe that device U1 enters reverse blocking state by verifying FLAG1 status change from 5V to 0V and device

U2 enters forward conduction state by verifying FLAG2 status change from 0V to 5V.

Follow the steps (21-26) to test power source selector application.

21. Configure the jumpers JU103 and JU203 to current-limit setting = 3A as shown in Table 3 and connect 2.7A load

between VOUT and GND terminals.

22. Set VIN1 to 24V and connect to VIN1 (J101). Verify that VOUT (J102) is 24V. Verify that the load is supported

from VIN1.

23. Set VIN2 to 20V and connect to VIN2 (J201). Verify that VOUT (J102) is still 24V and the load is supported from

VIN1.

24. Set JU104, JU204 open and drive EN1 low with a waveform generator. Verify that VOUT (J102) switchover to

VIN2 (= 20V) and IIN1 is 0A, the load is supported from VIN2.

25. Drive EN1 high with a waveform generator. Verify that VOUT (J102) switchover to VIN1 (= 24V) and IIN2 = 0A,

the load is supported from VIN1.

26. To select/deselect the second power supply (VIN2), drive EN2 high and low with a waveform generator. Repeat

steps 21-25 to demonstrate power source selector application using EN2.

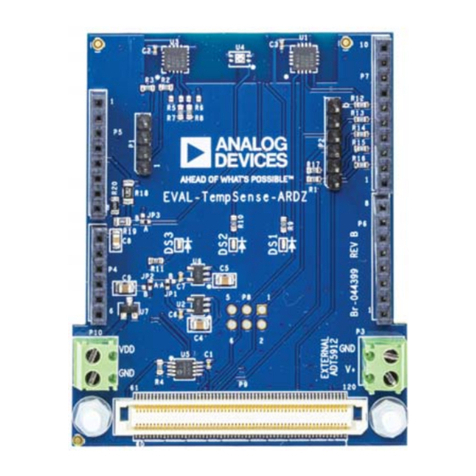

Detailed Description of Hardware

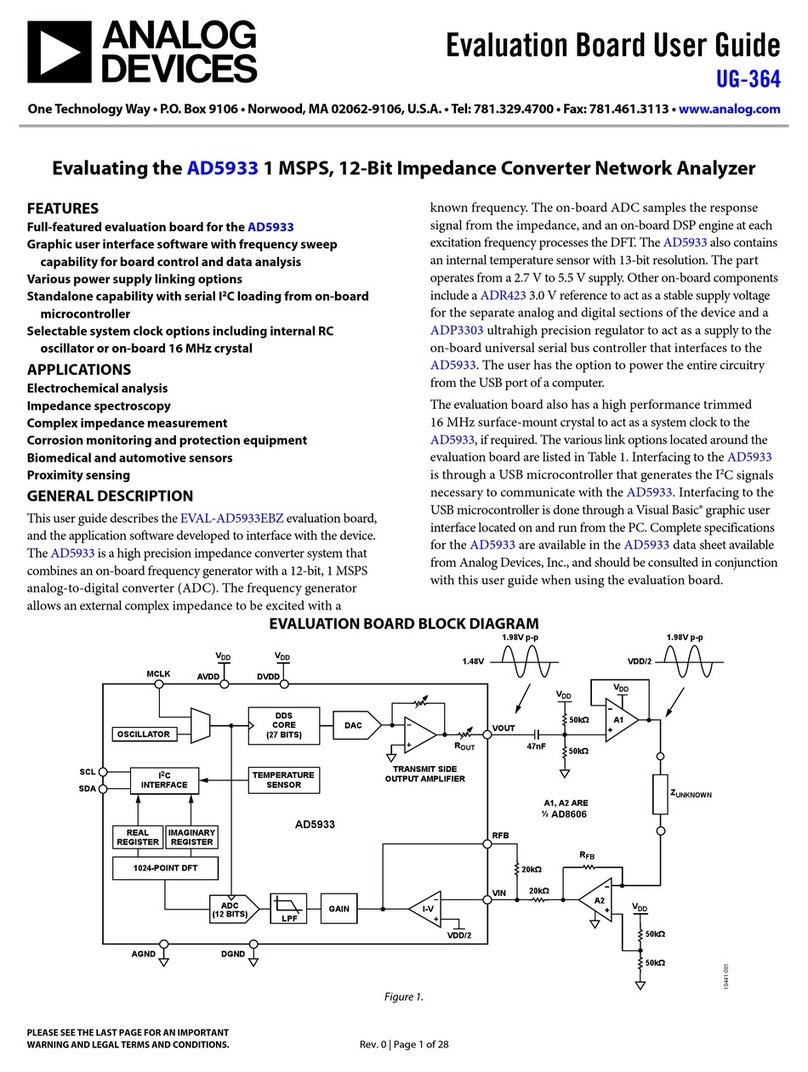

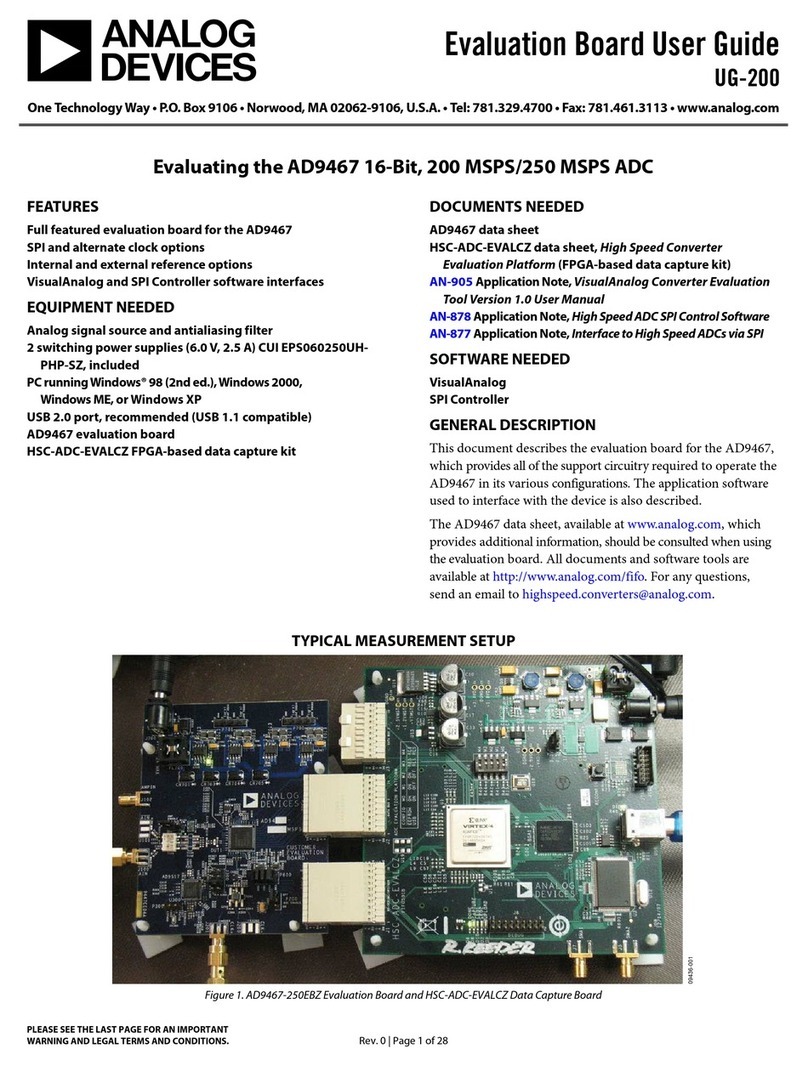

The conventional redundant power architecture solution to support a critical load is to OR two power sources using

Schottky diodes. In this scheme, if one of the power sources were to fail, switchover to the other source occurs smoothly

without interruption of power to the load. However, the Schottky-based solution suffers from power loss and higher

temperature rise while also requiring a large number of discrete components for implementation of other important

protection features such as current limit, UVLO, and OVLO.