804053UK CS Res Quick Start Guide June 2016 - V3.01

Command-CentreTM installation

CO2Cylinder

Example

HydroTap®G4 Classic model

Arc / Cube

Elite Classic

Step 4-

Installing the Command-CentreTM. Also refer to 803341UK Tap installation instructions

(for Arc / Cube also refer to the tube kit assembly instructions) supplied with the tap.

GAS IN

WHITE

POWER

CABLE

USBMAINS IN SPARKLING

OUTLET

CO2

IN

BLUE

CHILLED

OUTLET

BRAIDED

Cold isolation valve

(not supplied)

Clearance

Envelope

535mm

Note All plastic / silicon tubes must be trimmed to size. They must have a constant

fall to the Command-CentreTM.

Note Mains hose length is 750mm.

Electrical power cable length is 3.0m nom.

Position the Command-CentreTM according to the hose and cable lengths supplied.

280mm 50mm50mm

Braided hose fitting

Install the mains water braided hoses to the Command-CentreTM before locating in place.

Note Neither the braided hoses or the tubes supplied can be lengthened.

Note Chilled and sparkling outlet tubes must be insulated with the foam insulation

provided.

Commissioning

OPEN Position

CLOSED Position

ON

OFF

Stop cock

operation

Have a bucket or similar container (not

supplied) at the ready to hold a

quantity of water that will be ejected

while the filter flush mode is in

operation. Open the filter access

door on the front of the Command-

CentreTM and the filter cartridge will

be exposed. Located to the rear right

hand side of the cartridge is a flush

line, approx 600mm long, and the

flush line stop cock. Place the free

end of the flush line into the bucket

or container (not supplied).

Note

At first commissioning, the system will select filter flush screen

automatically.

• Press the [MENU] button for main menu.

• Press the [Install] button.

• Press the [Purge CO] button.

• In the next screen, press the [START] button

to commence the purging process.

• You will hear the CO2gas running through

the tap.

• Run for 10 seconds to fully purge the CO2.

• Press the STOP button to stop the purge.

• Press [NEXT] for filter flush screen.

CO2Purge

Step 5-

Commissioning.

• Open the flush line stop cock.

• Press [START] button to start filter flush.

• Allow at least 10 litres of water to flush

through the filter.

• Once the filter flush is finished, close the

flush line stop cock, then press [STOP] to

end filter flush mode.

Filter flush

The HydroTap®G4 is now ready to be commissioned.

• Turn on the power, gas and water and check for any leaks.

• Familiarise yourself with the operation of the HydroTap®G4 in preparation

for use (see User manual).

• Follow the installation instructions below (and review section C of the User

manual).

• Initially you will be prompted to select the language.

• After commissioning, the system may be customised by selecting further

options in section G - Settings, of the User manual.

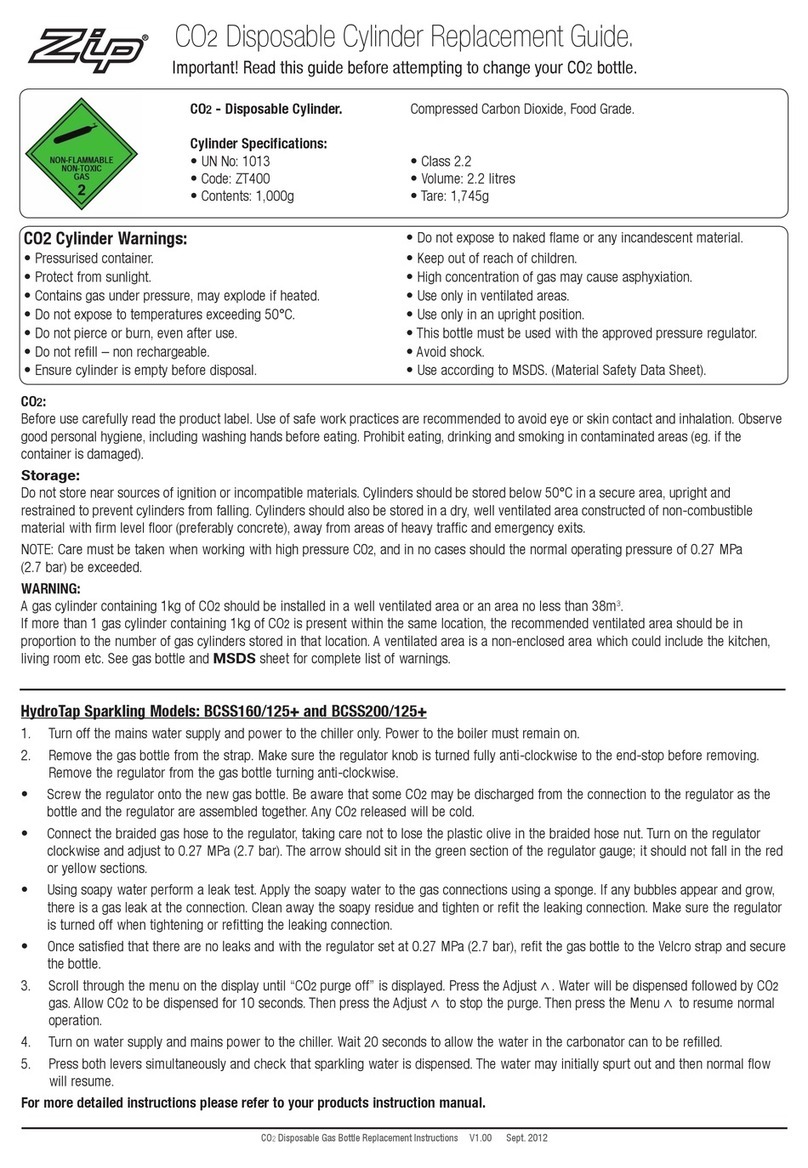

WARNING! The cylinder ( containing 1kg of CO2) should be installed in a

well ventilated area of area no less than 38m3.

If more than 1 gas cylinder containing 1kg of CO2is present within the same

location, the recommended ventilation area should be in proportion to the

number of gas cylinders stored in that location.

A ventilated area in a non-enclosed area which could include the kitchen, living room etc.

See gas cylinder and MSDS sheet for complete list of warnings.

Secure the cylinder

Secure the gas cylinder supplied to a suitable wall, within 1 metre of the Command-

CentreTM, in an upright position. This is undertaken by screwing the metal bar holding the

Velcro strap to a cupboard wall, 200mm above the floor or base of the cupboard. Make

sure the gas cylinder can stand in place before securing to the wall. Due to regulatory

requirements the gas cylinder must be stored securely and in an upright position.

Connect the regulator

Remove the gas cylinder from the strap. Make sure the regulator knob is turned fully

anti-clockwise to the end-stop before fitting. Screw on the regulator (clockwise). Be aware

that some CO2may be discharged from the connection to the regulator as the cylinder

and the regulator are be assembled together. Any CO2released will be cold. Screw on the

regulator to stop this leakage.

Note the leaking CO2will be cold.

Note Two plastic seals are supplied with a new regulator. Only one is required, the other

is supplied as a spare part.

Connect the gas hose

Connect the threaded end of the braided gas hose to the regulator, then connect the push

fit fitting to the top of the Command-CentreTM via connection marked ‘CO2IN’ .

To turn the gas on, rotate the black knob on top of the cylinder clockwise. Then adjust the

outlet pressure, by rotating the regulator knob clockwise to between 2.7- 3.0 bar (green

zone).

Note The arrow should sit in the green zone of the regulator gauge; it should not fall in

the red or yellow zones.

CO2Regulator

ON - OFF knob

Note When removing hose, take

care not to lose plastic olive from

the fitting.

Green indicator

Leak test

Faulty seal joint

Good seal joint

After replacing a cylinder or after making

a gas connection, perform a leak test

Stage 1

• Turn the gas off.

• Using soapy water applied with a sponge, or with a

brush, cover all of the gas joints with a liberal amount

of suds.

Stage 2

• Turn the gas on.

• Adjust the pressure to between 2.7- 3.0 bar.

• Inspect the joints for leaks.

• If any bubbles appear to grow, the joint will need

to be resealed and tested again.