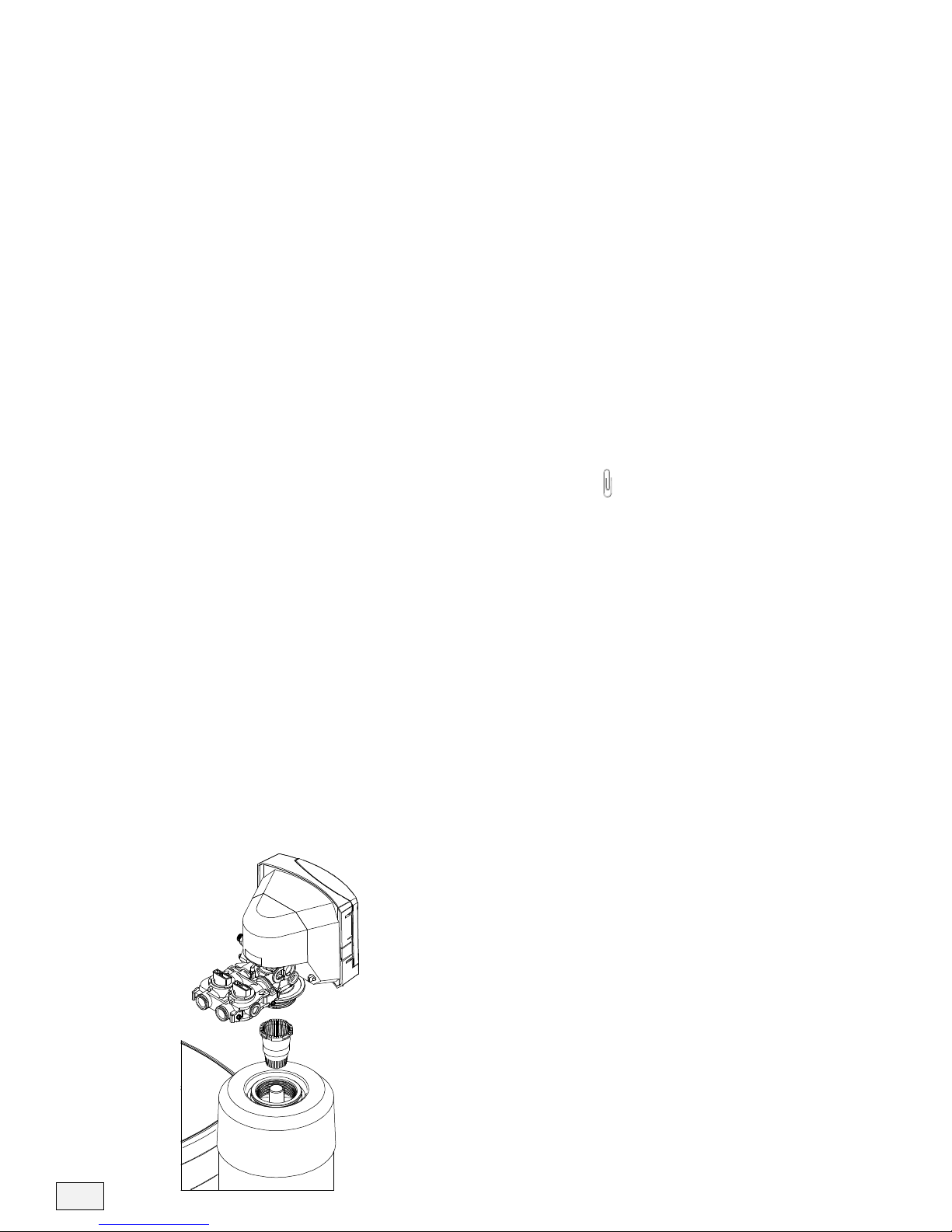

4. Flush the Hot Water Heater

• Run hot water in the bathtub until the water tests soft.

5. Add Salt to Brine Tank

Salt Recommendations

RainSoft Water conditioners use water softener Block Salt, Bag

Salt (Pellet), or Potassium Chloride. Go to the Main Menu, >

Configure Settings, >Salt Settings, to change Salt Type

(Sodium or Potassium) and Salt orm (Bag or Block)

Adding Salt to your Brine Tank

1) ill the Salt Tank with Block Salt, bag Salt (Pellet) or

Potassium Chloride. or maximum salt capacity of the

brine tank, see table on page 11 for the maximum setting

salt levels.

• Bag Salt and Potassium Chloride generally come in 40 lbs.

Pellet orm Bags. ill tank with pellets by empting contents

right into center of brine tank.

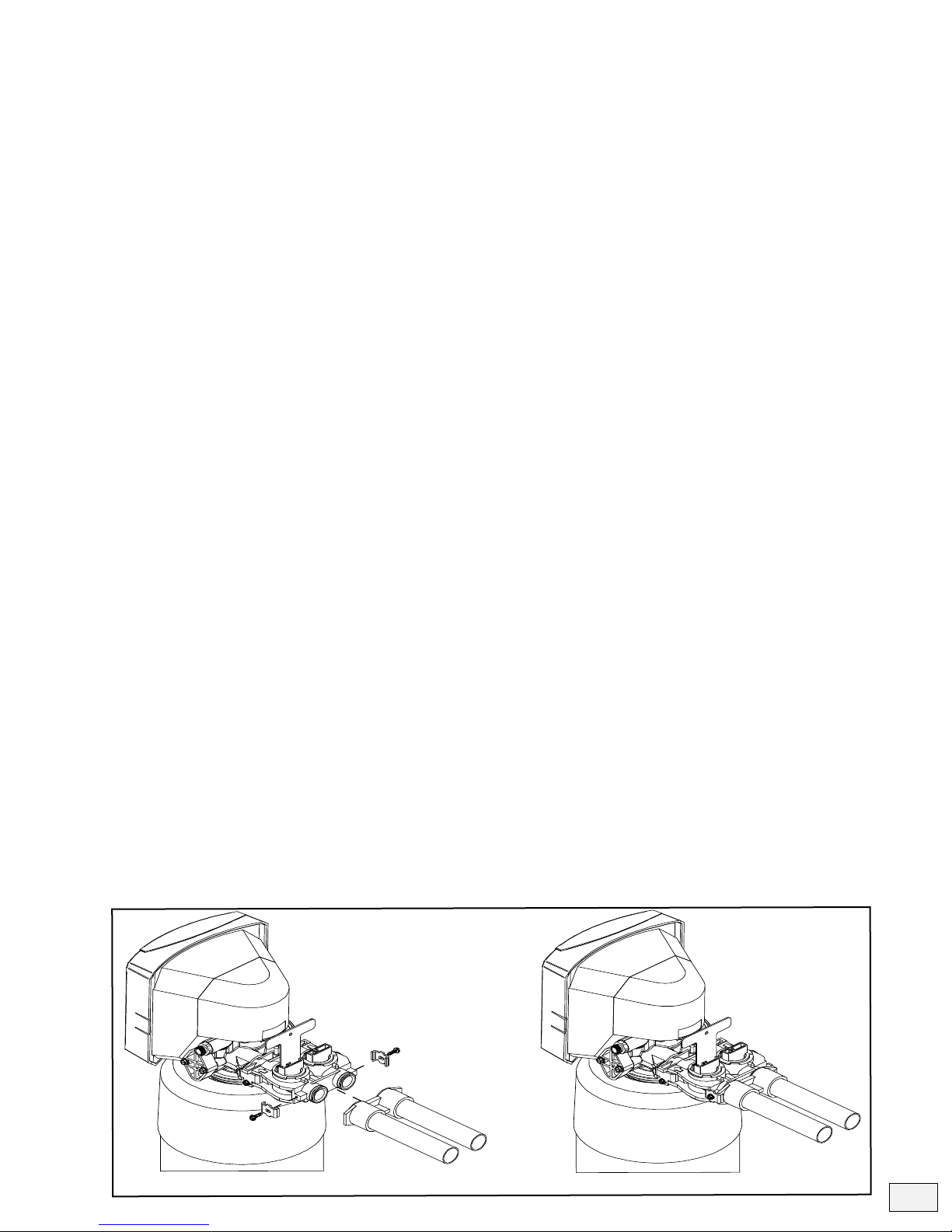

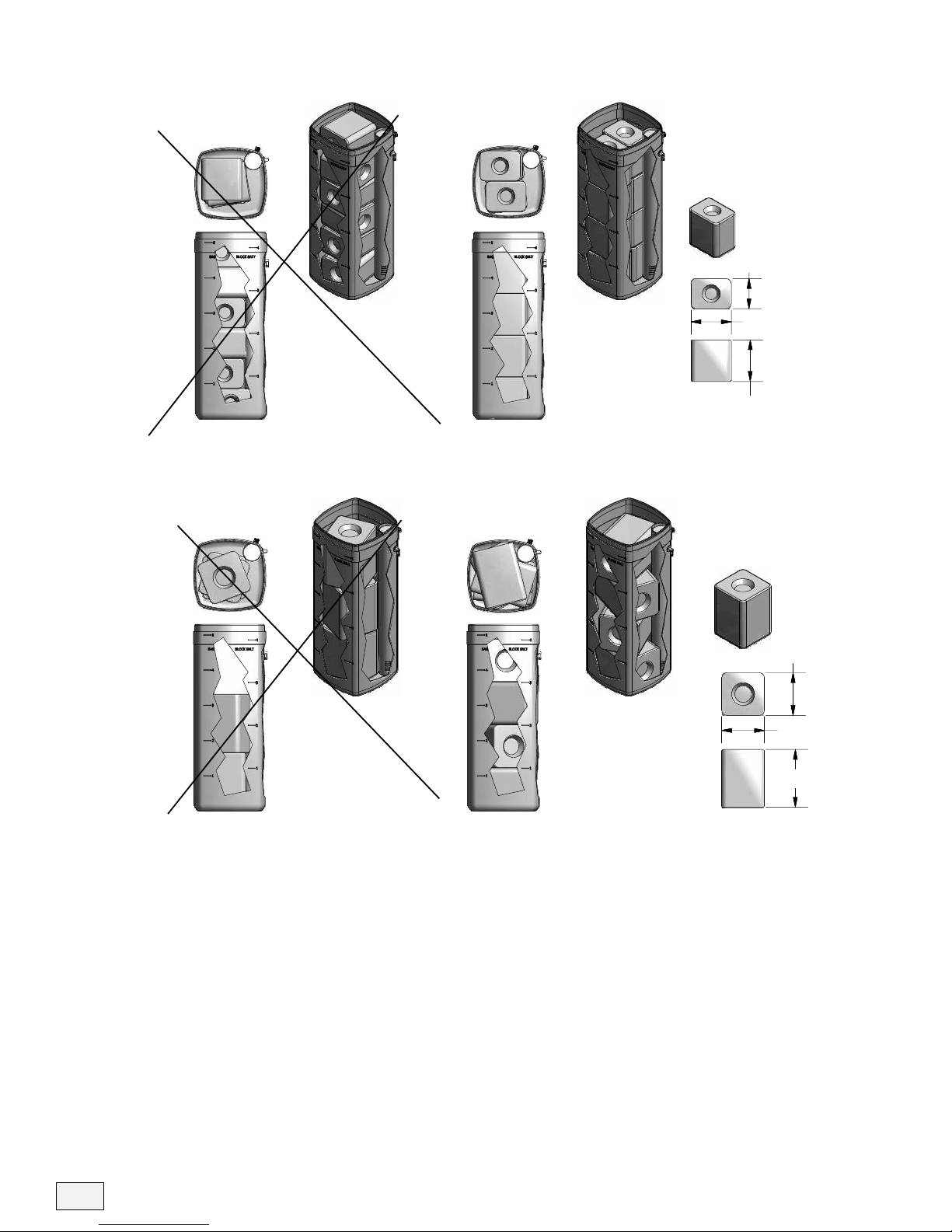

• Block Salt comes in 25 lbs. blocks or 50 lbs. blocks. See Block

Stacking igures on page 14 for correct and incorrect stacking

of block salt.

2) On the EC5, press any button from the home screen to enter

the Main Menu, then select >SALT LEVEL, Press Enter or

Right Arrow button. Using the Up and Down Arrows, set the

Salt Level to the level of salt that is filled in the brine tank. You

can reference the weight of salt you entered for more precise

entering of amount of salt used. Level of 1.0 is equal to 50 lbs.

22kg] of salt.

3) Press Enter Button to save new salt level and exit salt level

screen. Press the Left Arrow button to exit the Main Menu and

return to the Home Screen.

Note: Exiting Salt Level screen with the Left Arrow button will

NOT save new salt settings.

9

Important Note: It is important to main-

tain at least 15 lbs. to 30 lbs. of salt in

your brine tank to correctly regenerate

your System and to continue to enjoy soft

water. LOW SALT ALERTS will activate

for salt levels under 30 lbs.

Recommendations: If choosing to use

both Block and ellet form of salt when

filling the brine tank, we recommend

you maintain your settings on ellet

Form. We do not recommend this

method of filling your brine tank for

system sizes of EC5 150 and higher. The

total volume of salt in the full brine tank

will not allow enough room for water to

make the appropriate amount of brine

solution to regenerate the system fully.

Important Note: Salt for your water

conditioner can be readily purchased in

either bag or block form. Bagged salt

(sodium chloride) may be described on

the packaging as pellet, flake, crystal, or

solar salt. Any of these are fine, with the

most important point being that the salt

is clean, high purity, or labeled specically

as suitable for water softeners. Salt used

for melting ice, such as rock salt, is

typically high in impurities and should not

be used, since dirt can clog the brine

system. Very fine, granulated salt is also

not recommended.The use of granulated

salt may cause service problems.

Salt in block form should also be labeled

as high purity, solar or suitable for water

softeners. Blocks sold as cattle licks

should not be used, since these may be

high in impurities.

You can also use potassium chloride

instead of sodium chloride. otassium

chloride is usually available only in bags

and sold specifically for this purpose.