4

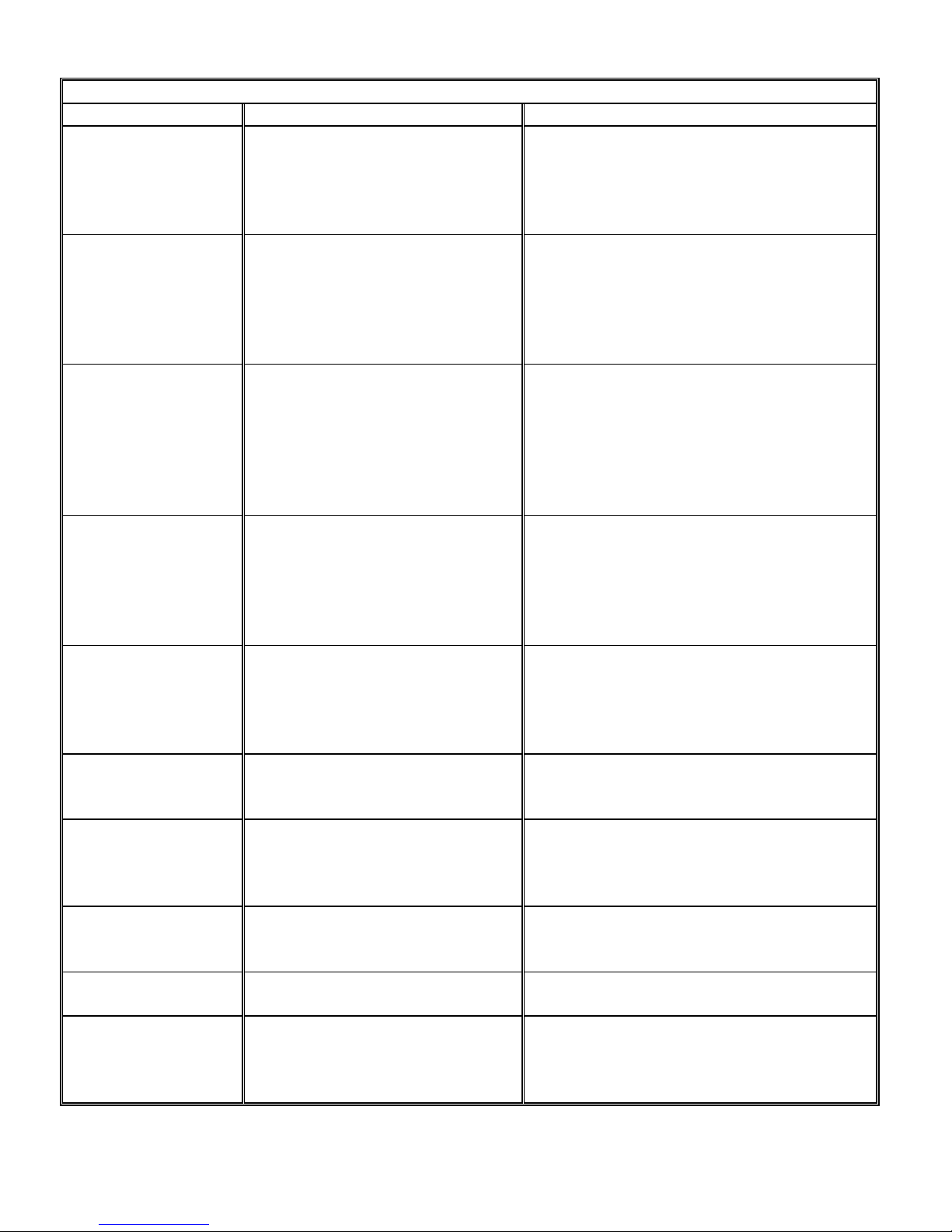

TROUBLE SHOOTING GUIDE

PROBLEM POSSIBLE CAUSE CORRECTION

Softener will not

regenerate.

A. Bad electrical connection.

B. Broken motor

C. Broken or stripped gears.

D. Gallon counter not counting

A. Check electrical connection.

B. Replace motor.

C. Replace gears.

D. Remove debris or replace part. (Located

on outlet port of control valve)

Drain opens but water

does not leave salt

tank.

A. Low inlet water pressure.

B. Broken or torn diaphragm.

C. Retaining ring missing.

D. Foreign material on stem or

internal seats.

E. Drain line kinked or restricted.

A. Increase inlet water pressure.

B. Replace diaphragm.

C. Add retaining ring.

D. Clean stem and seat on main

body.

E. Straighten or un restrict drain line.

Softener does not

draw brine.

A. Plugged injector screen.

B. Plugged or worn injector.

C. Inadequate backwash.

D. Low inlet water pressure.

E. Broken or plugged brine float

F. Kinked or restricted drain line.

A. Clean or replace.

B. Clean or replace.

C. Adjust backwash flow rate with

backwash adjuster.

D. Increase water pressure.

E. Clean or replace.

F. Straighten or unrestraint drain line.

Low or inadequate

capacity after

regeneration.

A. Plugged injector.

B. Plugged injector screen.

C. Increase in water consumption.

D. Insufficient quantity of brine.

E. Ran out of salt at one time.

F. Leaking toilets or faucets.

A. Clean or replace.

B. Clean or replace.

C. Increase frequency of regeneration.

D. Raise float level on brine valve.

E. Regenerate softener 3 nights in-a-row.

F. Repair leak.

Water chatter at unit

during regeneration

A. High backwash rate.

B. Low water pressure.

C. Diaphragm spring not properly

located on stem.

D. Restricted drain line.

A. Adjust backwash flow adjuster

B. Increase water pressure.

C. Locate spring on tip of stem assembly.

D. Straighten or un restrict drain line.

Water flows to drain

when not regenerating.

A. Foreign matter trapped in drain

valve.

B. Drain paddle out of adjustment.

A. Attempt to flush out by putting unit into

regeneration.

B. Replace drain paddle.

Salt in lines after

regeneration.

A. Rinse rate to low.

B. Excessive brine in salt tank.

C. Insufficient rinse time.

A. Change to larger injector disk.

B. Lower float setting or check for leak on

float.

C. Increase length of regeneration cycle.

Valve leaking between

body and head

assembly or back cap.

A. Torn diaphragm or pinched

outlet gasket.

A. Replace items.

Too much water brine

tank

A. Foreign matter in brine float.

B. Loose brine float fittings.

A. Clean or replace brine float.

B. Tighten or replace brine float fittings.

No water in brine tank A. Brine float set to low A. Adjust brine float to allow 1 ft. to 1½ ft.

of water into Round and 15x15 Square salt

tanks only. On 11x11 Square salt tanks, set

float to approximately fill tank half full.