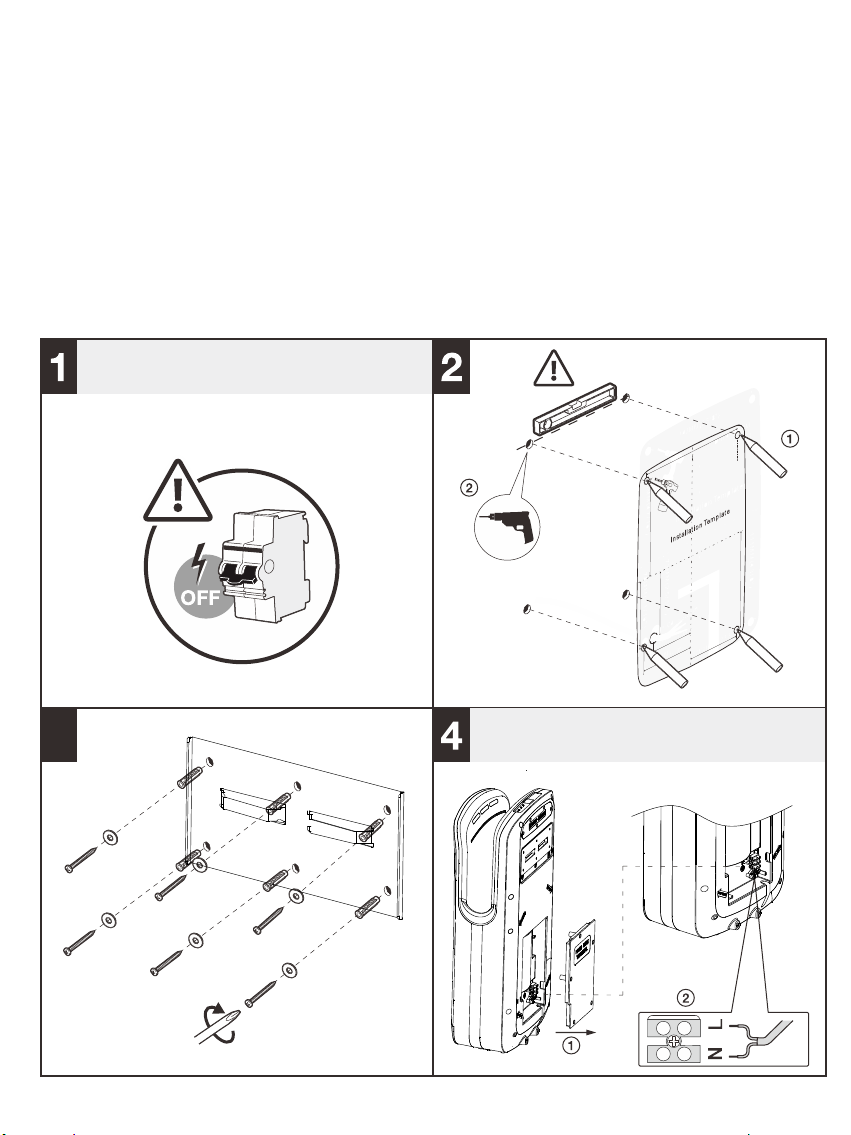

Before installing, be sure to read this installation manual and retain for future reference.

This product must be installed by qualified personnel in accordance with the instructions given

in this manual and installation must comply with all applicable regulations, national security

standards and laws in force in the country where the product is installed.

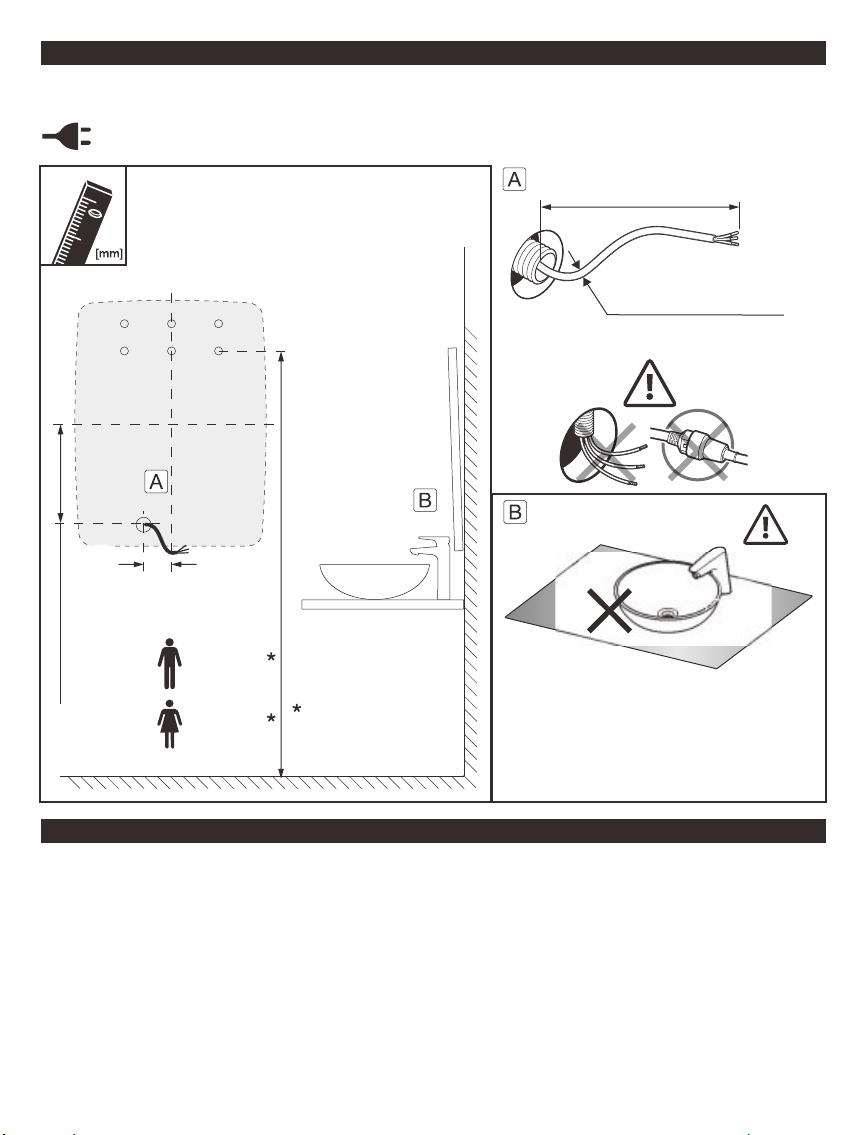

Turn off the power at the main switch before installing or servicing the dryer unit

The dryer must not be installed on a flammable surface. Do not damage any parts of

the electrical connections.

Pre-arrange an appropriate power outlet and a system of disconnection in accordance with

current local regulations. Make sure the product is properly connected to ground. If there is

no ground connection, there is a risk of an electrical shock.

Do not install the dryer over a washbasin. If the power cord is damaged, it must be repaired

by qualified personnel to avoid any type of risk.

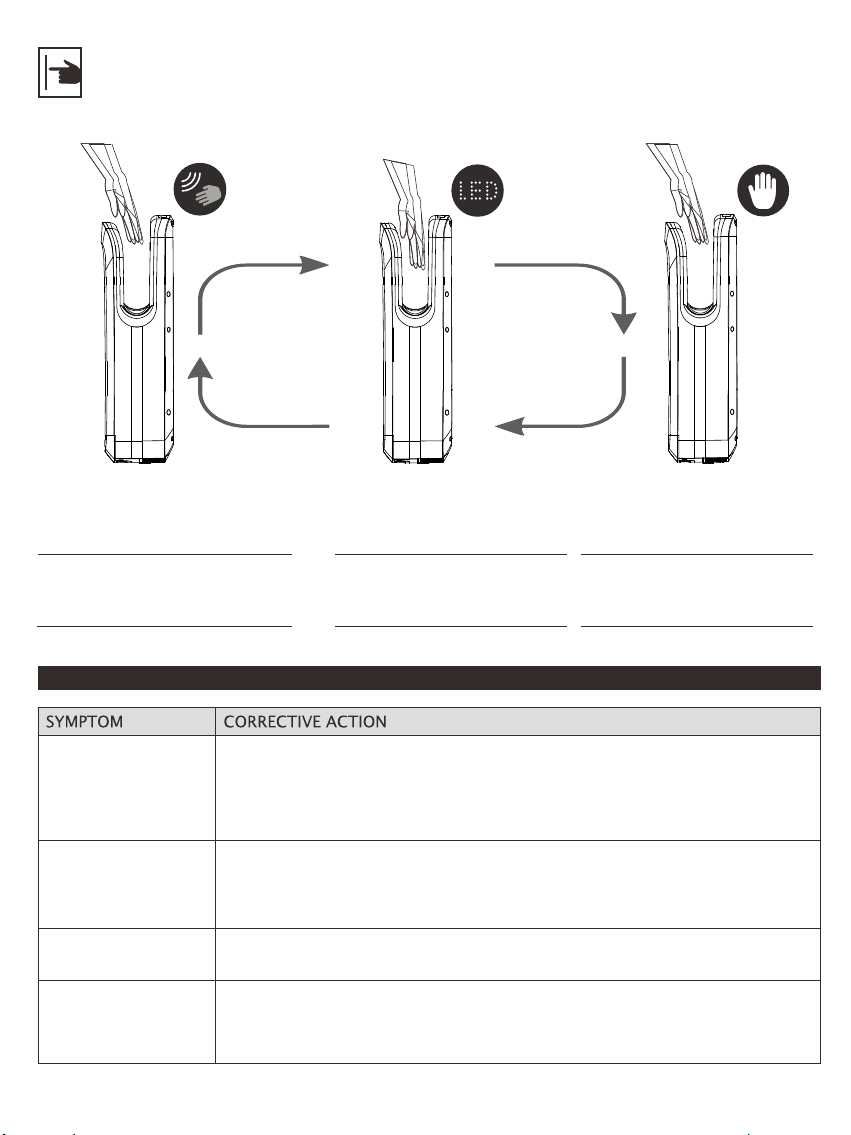

This dryer can be used by children aged 8 years and above. People with reduced physical,

sensory or mental abilities or lack of experience and knowledge, if they have been given

supervision and appropriate training regarding the use of the dryer in a safe manner, can use

it with no restriction. Children should not play with the apparatus. Cleaning and

maintenance performed by the owner should not be done without the children having

supervision.

During use, temperatures above 158℉ [70℃] may develop in the parts near the hot air nozzle.

Do not touch or cover the dryer during use or when finished using it.

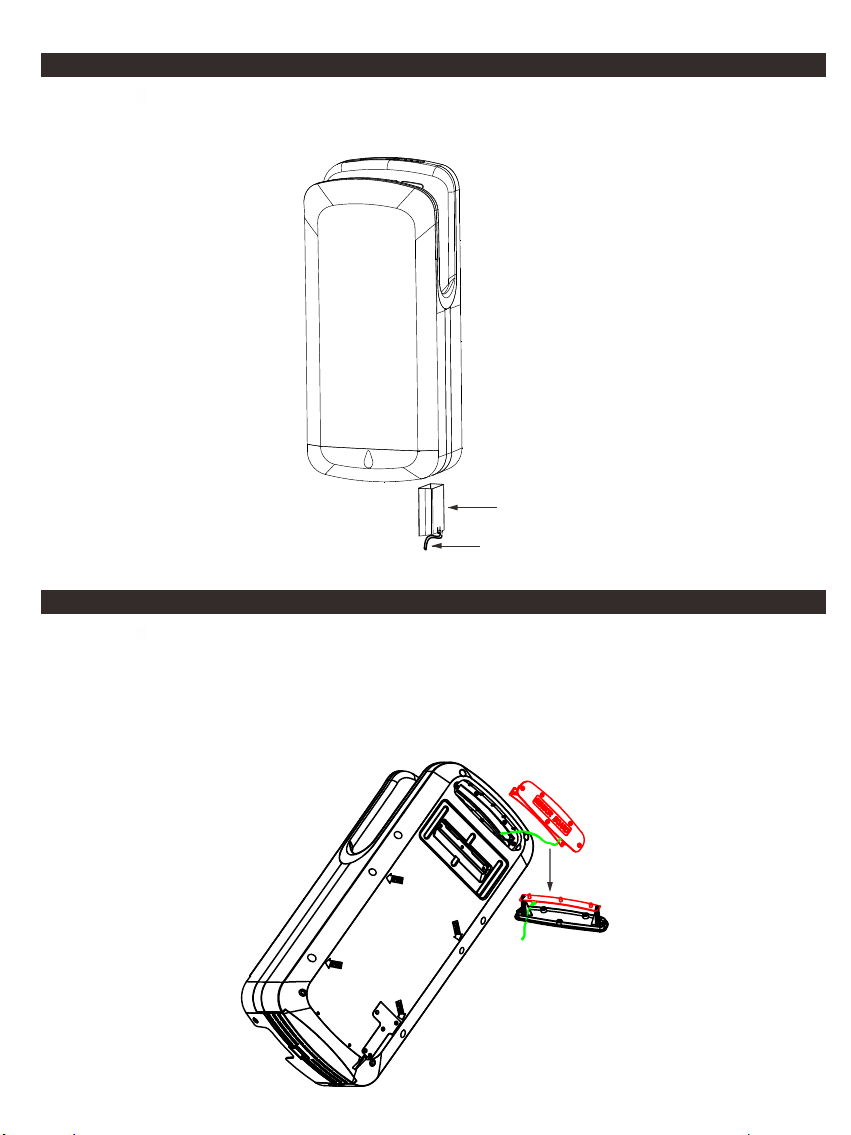

General safety information:

WARNING

WARNING

WAR NI NG

WAR NI NG

WARNING

DANGER

WARNING

WARNING

This product is intended

Failure to properly ground

Disconnect power at the

All units must be suppllied

for installation by a qualified service person.

Use AWG NO.12 solid conductor for wiring.

unit could result in service electrical shock

and/or death.

service breaker before installing or servicing.

with a 3-wire service. The ground wire must

be connected to the dryer’s backplate.

--NOTE: Do not install dryer over washbasin --

SAFETY WARNINGS