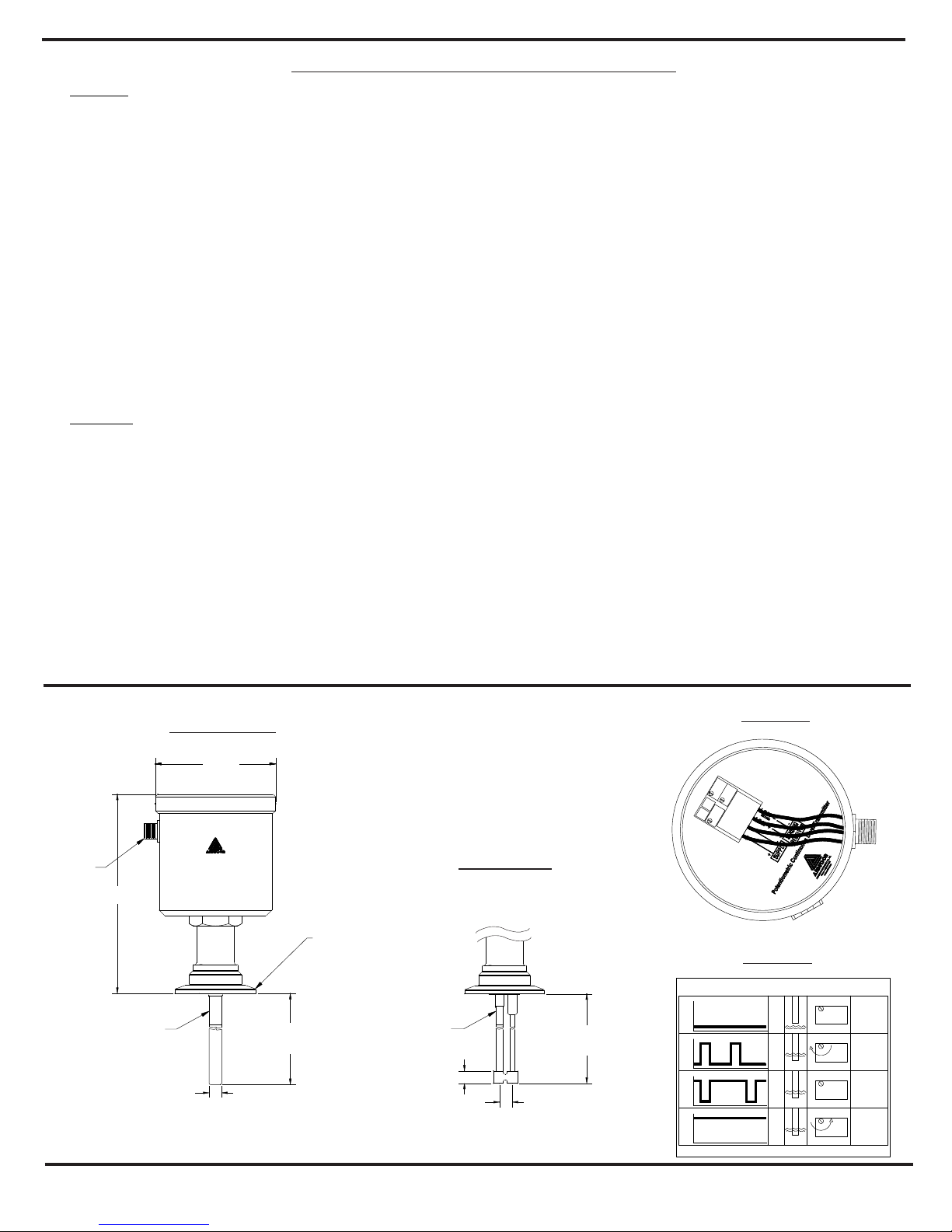

Figure 2

Figure 1

3.74”

INSERTION

LENGTH

6.1”

SHOWN WITH

2" TRI CLAMP

ANDERSON INSTRUMENT CO., INC.

WWW.ANDINST.COM

1-800-833-0081

MODELU

S/NU

INPUT 18-36 VDC

M12

CONNECTION

TEFLON COATING

2” for probe length < 20”

4” for probe length ≥ 20”

0.24” for probe length < 20”

0.39” for probe length ≥ 20” 0.59”

TEFLON COATING INSERTION

LENGTH

0.3”

2” for probe length < 20”

4” for probe length ≥ 20”

Rev. 2.1 Doc 1136 Page 2 of 2

Section 4 - Installation / Calibration Verification

Operation

• Probe may not be cut! Trimming the probe length will

disable the sensor and VOID warranty.

• The process connection must have electrical contact

with the tank, therefore LN’s must be clamped on

fitting for proper operation.

• Single probe LN's are suitable for installation in linear

metallic tanks with probe parallel to tank wall. Non-parallel

installation will increase reading error.

• Dual probe LN's are suitable for installation in

nonmetallic and/or non-linear tanks.

• Sensor probe must not touch tank wall.

• For accuracy and proper operation, measured media

should be homogeneous with respect to temperature

and conductivity. Media must have a conductivity of at

least 1 µS/cm.

• The LN is shipped calibrated to the bottom of the

Teflon® coating. Normally at installation, additional

adjustments are not required.

• A turndown of up to 30% below top of probe is possible

if 20mA output is desired at less than full rod height.

Follow SPAN ADJUST for this feature.

Calibration

Zero Adjust

1. Connect power supply as shown in Section 1.

2. Connect Digital MultiMeter to output. With empty

vessel (uncovered probe) signal output is 2.4mA.

3. Fill vessel until level contacts probe. Adjust OFFSET

until signal output is 4.0mA (see Fig. 1).

Span Adjust

1. Connect power supply as shown in Section 1.

2. Connect Digital MultiMeter to output.

3. Fill vessel until maximum level desired. Adjust SPAN

until signal output is 20.0mA (see Fig. 1).

Note:

• Probe will not measure in Teflon® coated zone. Maximum

level must be below the Teflon® zone.

• Max turn down is 30% of full probe length (including

Teflon® coated area) from the top e.g. 30” rod length

with 4” Teflon® coating may adjusted from 26” down to

21”.

• Span and Zero are normally non interactive however

significant turndown adjustment may require an

additional Re-Zero step.

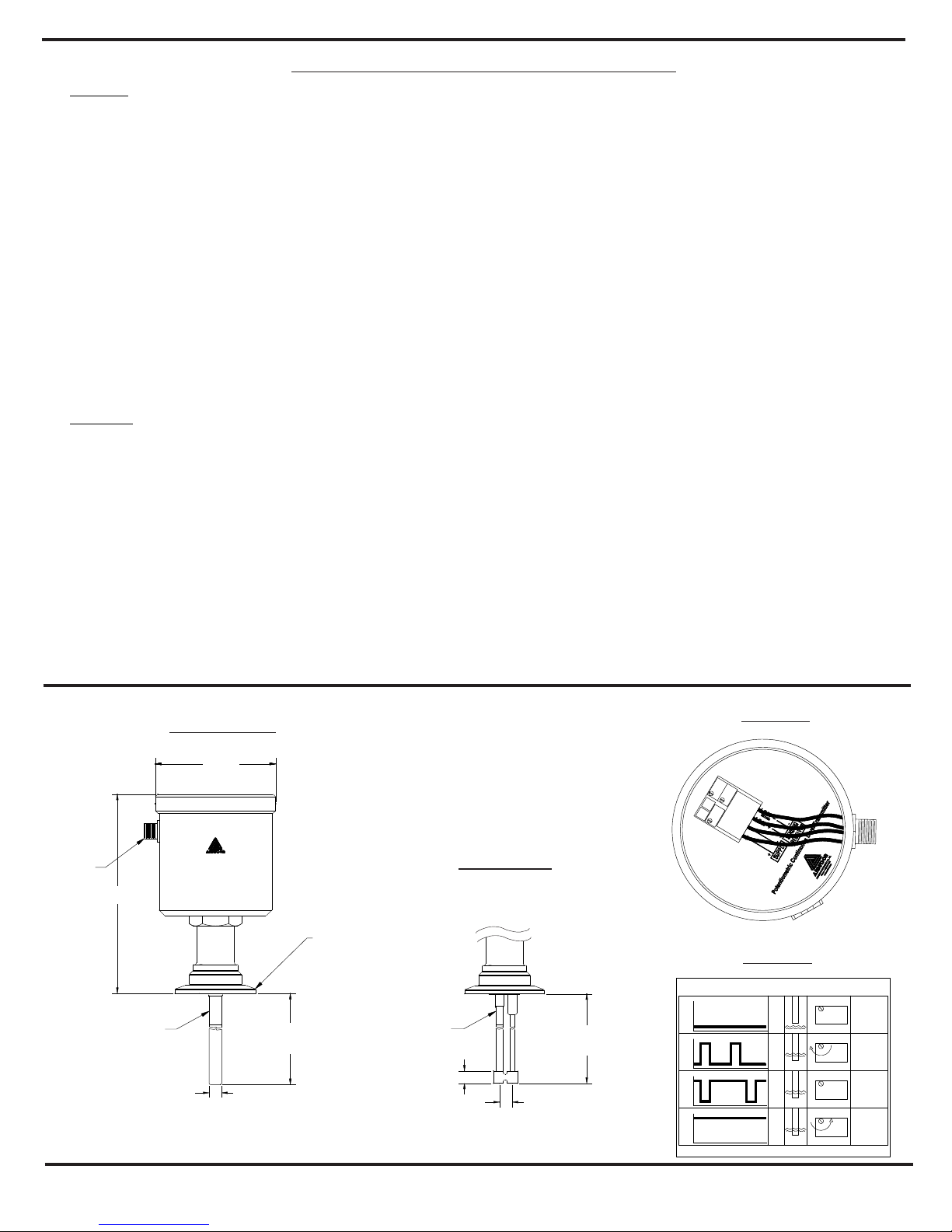

Sensitivity

Typically adjustment is not required. If calibration is needed, perform

the following with the least conductive media:

1. Connect power supply as shown in Section 1.

2. Fill vessel until media level contacts probe.

3. Observe red LED labeled SENSITIVITY (see Fig. 2 LN

Sensitivity Table).

• If the LED remains off or only blinks on briefly, turn

SENSITIVITY clockwise.

• If the LED remains on continuously, turn

SENSITIVITY counterclockwise.

Note:

The objective is to achieve state 3 on the LN

Sensitivity Table. The red LED should be lit with a brief

off blink.

Single Probe

Dual Probe

Sensitivity Offset

Span

Sensitivity Power

OUTPUT PROBE

ON

OFF

ON

OFF

ON

OFF

ON

OFF

2.4

mA

4-20

mA

4-20

mA DO NOT

ADJUST

4-20

mA

LED

SENSITIVITY

ADJUSTMENT

DO NOT

ADJUST

EXPECTED

WITH NO

LIQUID

INCREASE

SENSITIVITY

TOO

SENSITIVE

OPTIMAL

State

1

2

3

4

LN Sensitivity Table