PAGE 3

Section 1 General

1.1 INTRODUCTION1.1 INTRODUCTION

1.1 INTRODUCTION1.1 INTRODUCTION

1.1 INTRODUCTION

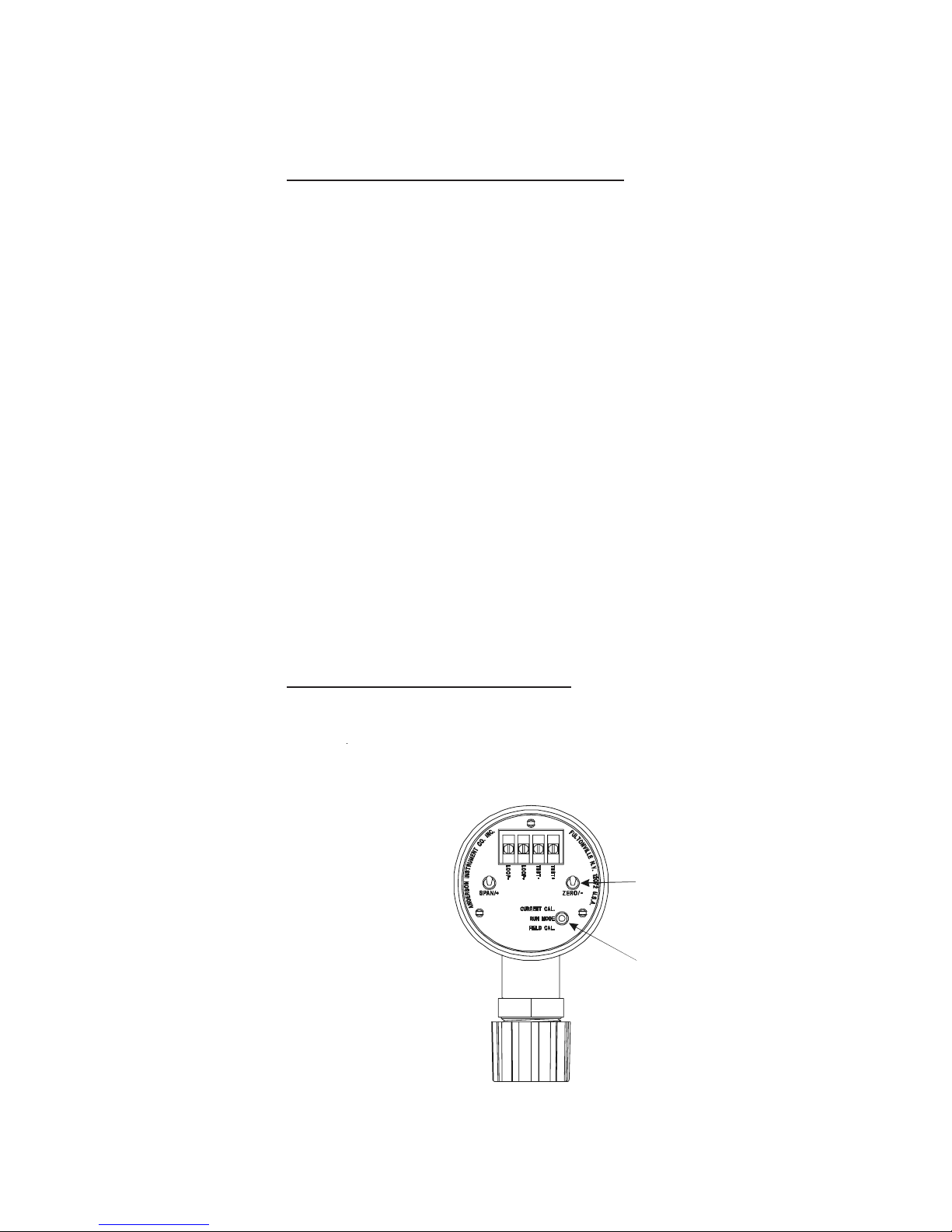

The Anderson “LD/LA” standard and pharmaceutical series level transmitters are unique

devices designed for level control applications where pressure based technology provides

the best overall solution, but where bottom access for the sensor is not available or prefer-

able. These sensors are designed to be mounted on the top of the vessel with the extension

tube positioning the sensing diaphragm near the bottom of the tank. Common applications

include rotary filler bowls, surge tanks and small processing storage vessels where bottom

access is impractical. With no moving parts, no air required, and wide compensated

temperature range the LD/LA provides accuracy and repeatability in applications where

other sensing technologies have been proven unreliable.

1.2 SPECIFICATIONS1.2 SPECIFICATIONS

1.2 SPECIFICATIONS1.2 SPECIFICATIONS

1.2 SPECIFICATIONS

Performance

Upper Range Limit (URL) 72" water column (w.c.)

Minimum Span: 30" w.c.

Over-Range Capacity: 2.5 times the URL (180" w.c.)

Accuracy: ± 0.75% of URL (± 0.5" w.c.)

Repeatability: within ±0.3% of URL (± 0.2" w.c.)

Stability: Within published specification for one

(1) year minimum

Compensated Temp. Range: 30°F to 220°F (-1°C to 104°C)

(process)

Compensated Temp. Range: 30°F to 120°F (-1°C to 49°C)

(ambient)

Effect of Process/Ambient

Temperature Change: ± 0.40% of URL per 10°F

Humidity: 0-100% RH, Condensing

Response Time: 526 mSec

Power Signal

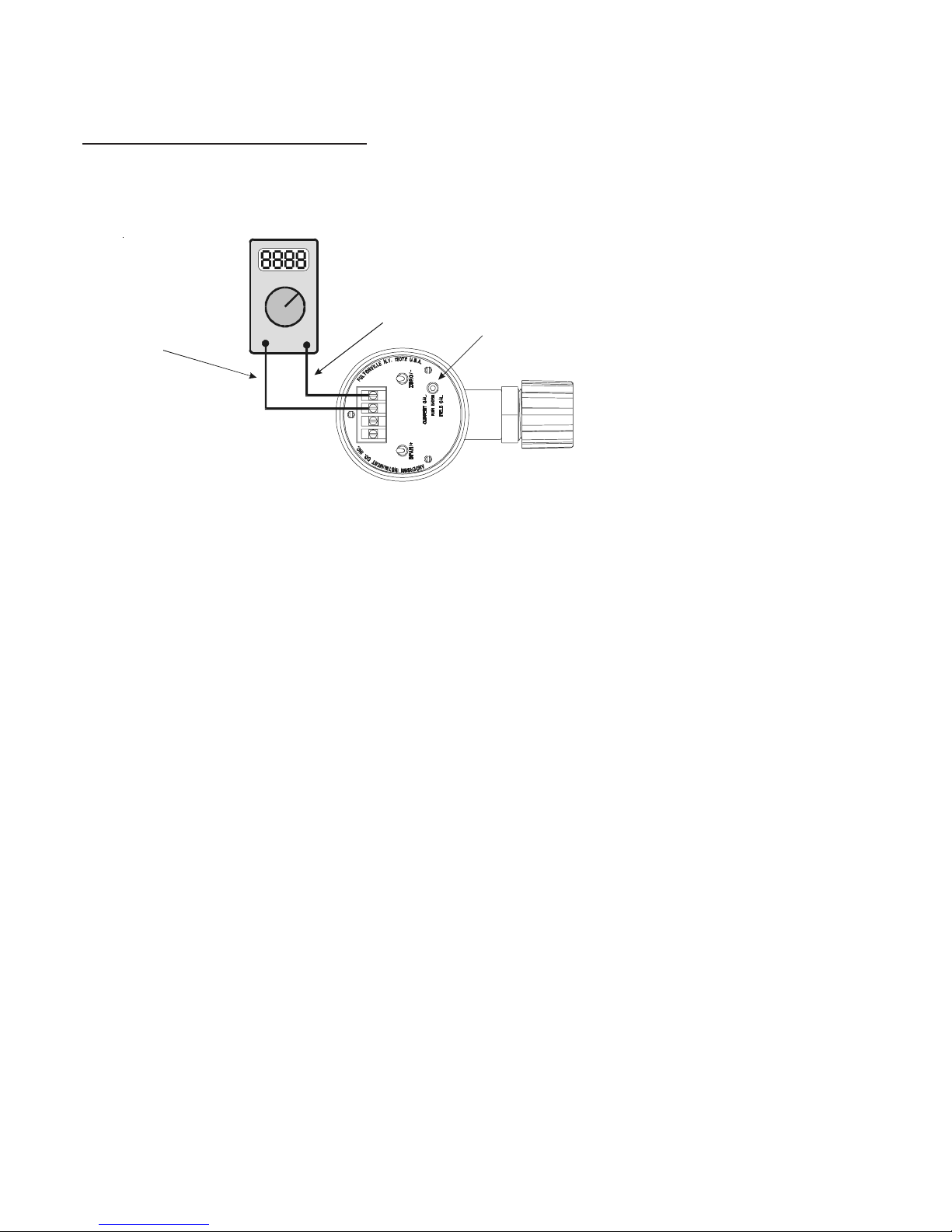

Output: 4-20mA dc

Loop Power required: 12-40 Vdc

Effect of Voltage Change: ± 0.05% of URL per 30 volts

Load Impedance: 1550 Ohms at 40 VDC

Cable Recommended: 18-24 AWG, .169" to .209" diameter,

stranded, 2 conductor with ground,

shielded and PVC coated for use with

seal-tight wire grommet

Materials/Construction

Housing /Wiring Head: 304 stainless steel

Wetted Parts: 316L stainless steel

Surface Finish (LD): Ra=25 microinches or better (wettedparts)

Surface Finish (LA - Pharm.) Ra=15 microinches or better (wetted parts)

Housing Rating: NEMA 4X, IP-65

Agency Approvals

Electronic "Noise" Designed to meet IEC 801-2, -3 and -4,

Immunity: Level 3, CE Compliant

Sanitary Standards: Complies with all applicable provisions

of 3-A Sanitary Standards (74-00).

Hazardous Locations: For LA only: UL, Intrinsically safe for use in CLass 1, Div. 1 Groups A-D.

Warranty: All units are covered by a two (2) year warranty against defects in material

and workmanship when installed and maintained according to the instruction

manual provided.