Angelus 4900 Pacific Blvd. Los Angeles, CA 90058-2214 Tel: (323) 583-2171 1/5

18014001 - 11/7/05

Service Notice

Subject:

180S Gravity Feed Lubricator for Can Feed Chain

Purpose:

Minimize expendable oil loss

Benefit:

The Gravity Feed Lubricator has substantial advantages over the existing sprocket lubricator.

The Gravity Feed Lubricator is a separate unit compared to the traditional chain sprocket lubri-

cator line fed by the automatic oil lubrication system. The Gravity Feed Lubricator does not

drain the oil recovery system, thus preventing oil loss. The Gravity Feed Lubricator can utilize a

lighter and less expensive oil.

Description:

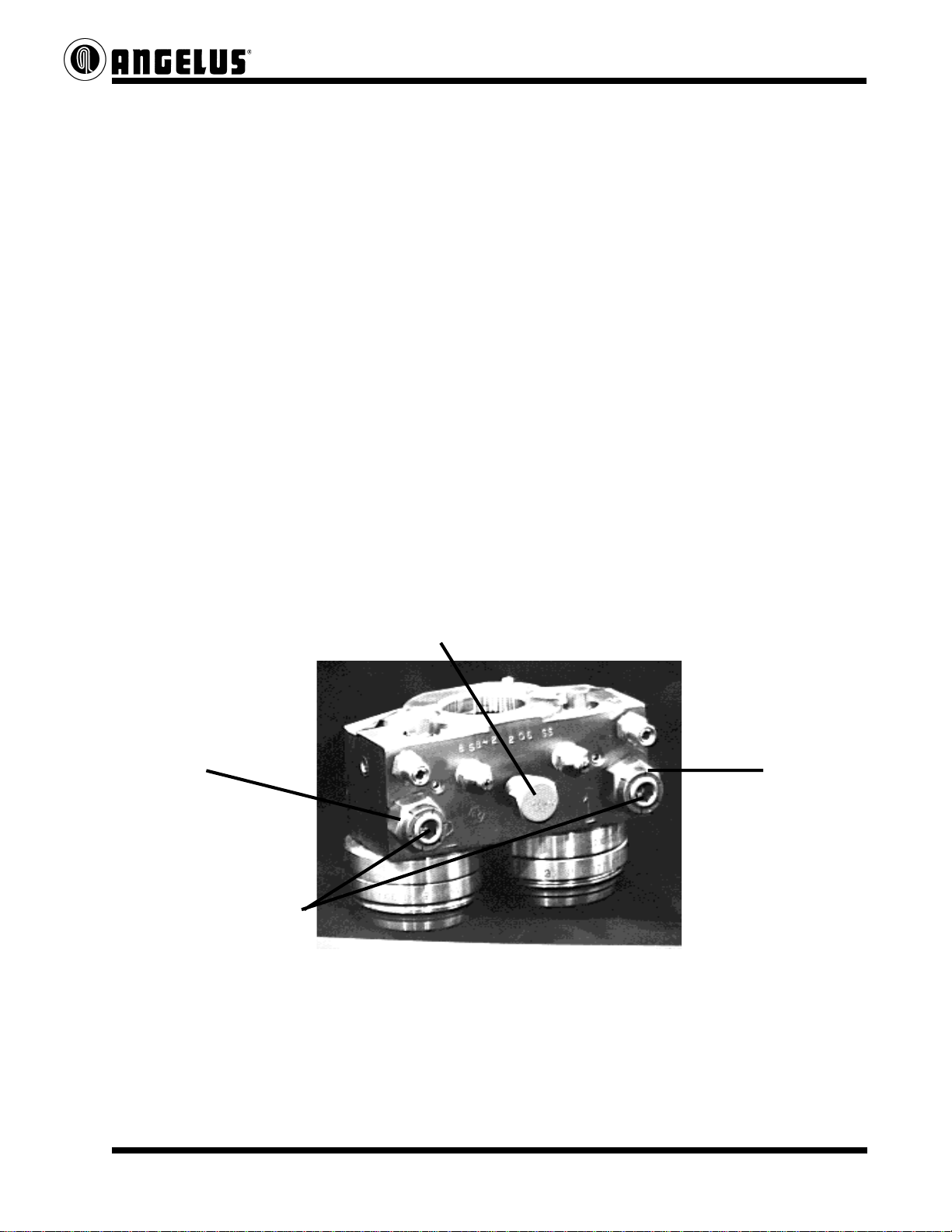

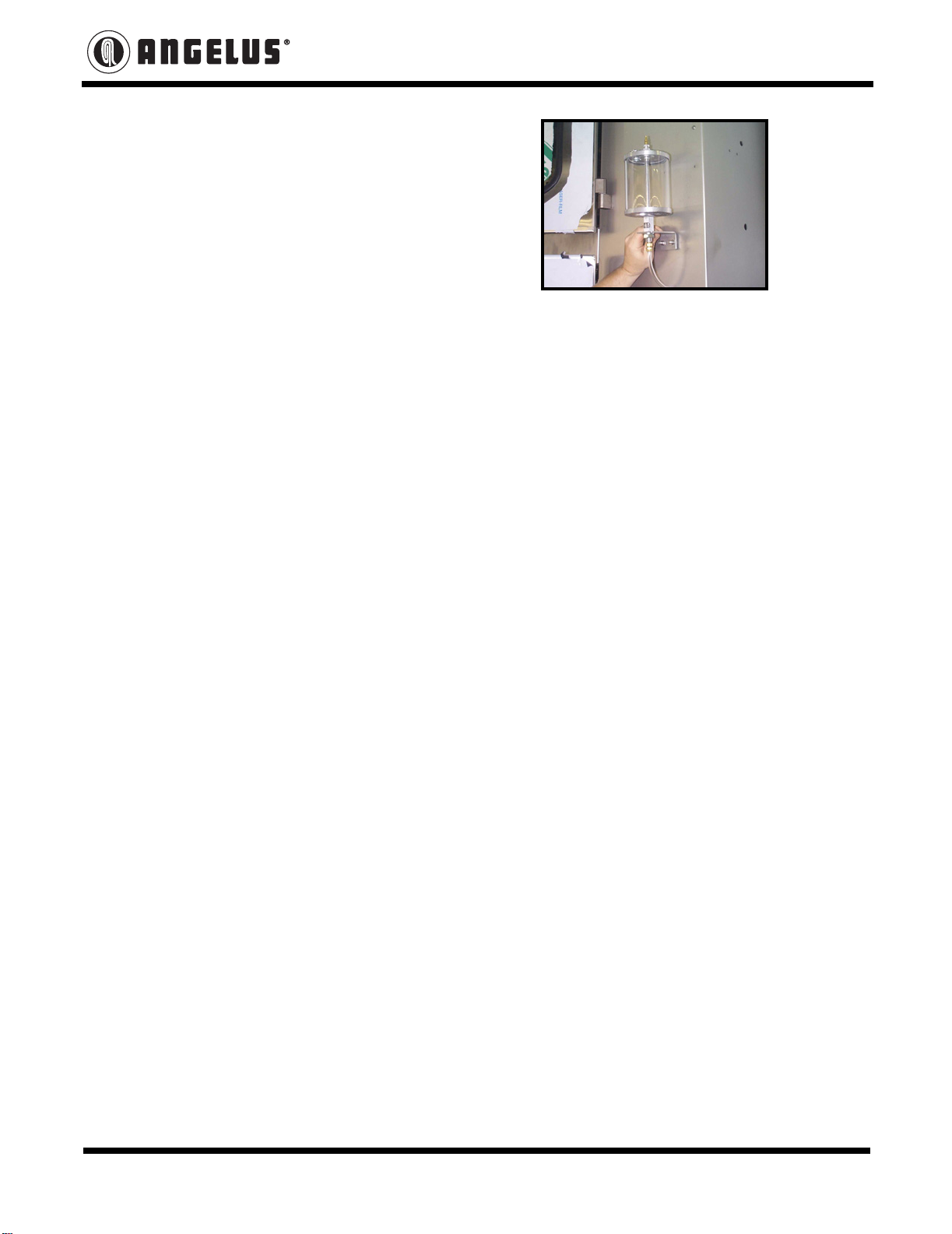

The Gravity Feed Lubricator consist of a oil canister with electrical solenoid mounted on the

outside top of enclosure for quick level visibility and plumbed by stainless steel line through

enclosure to the sprocket. The Gravity Feed Lubricator solenoid is programmed to operate

during “Jog” or “Run” commands only.

Availability:

Available for purchase per Parts List 121LM158.03.

Installation Procedure:

Divert the existing “Y” Feed Sprocket Line into “P” Lower Chuck Cam Line. Use Pipe Thread

Compound (PST) on all connections.

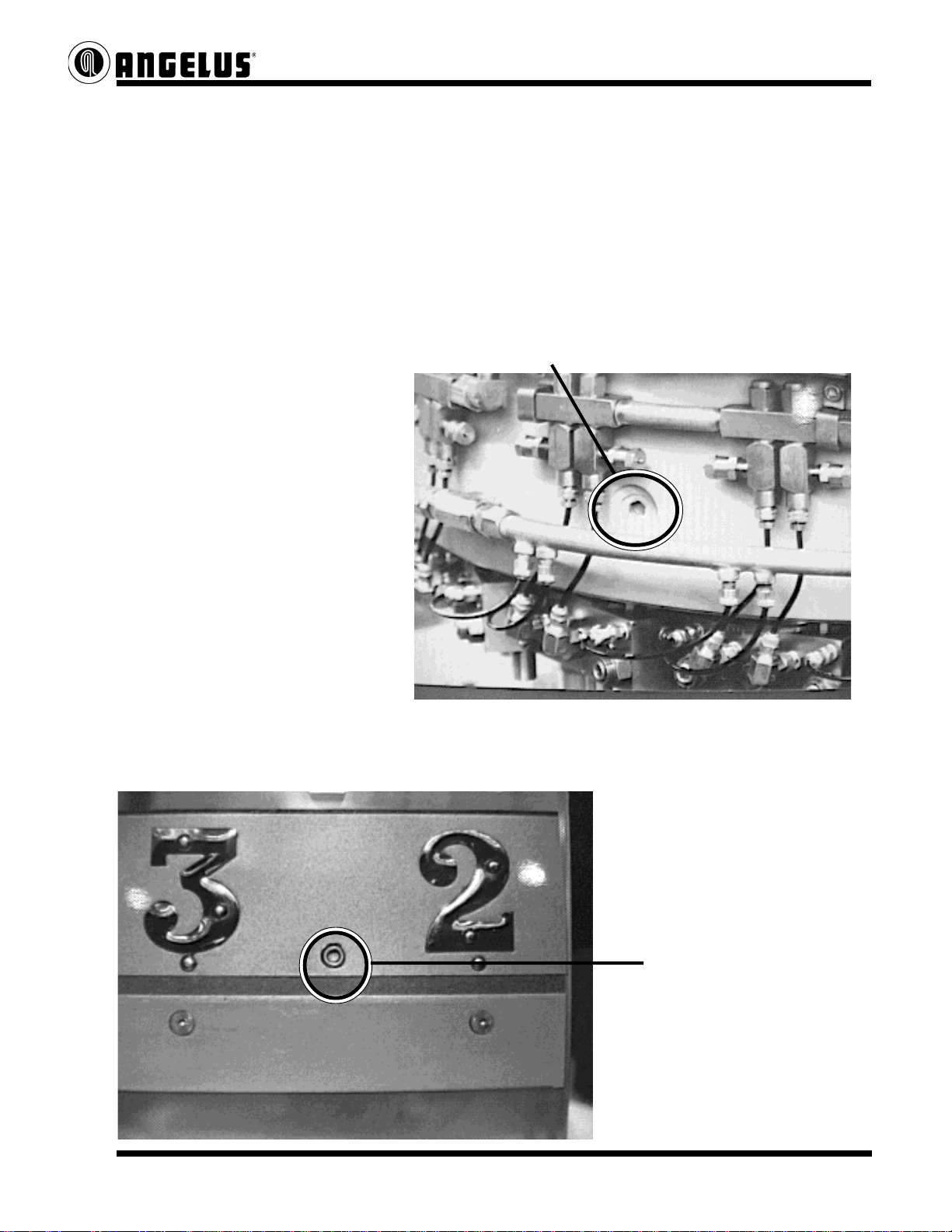

• Remove lines “Y” and “P” and temporary identify lines “Y” or “P” (See Fig. 1)

• Remove straight fittings from the base (See Fig. 1)

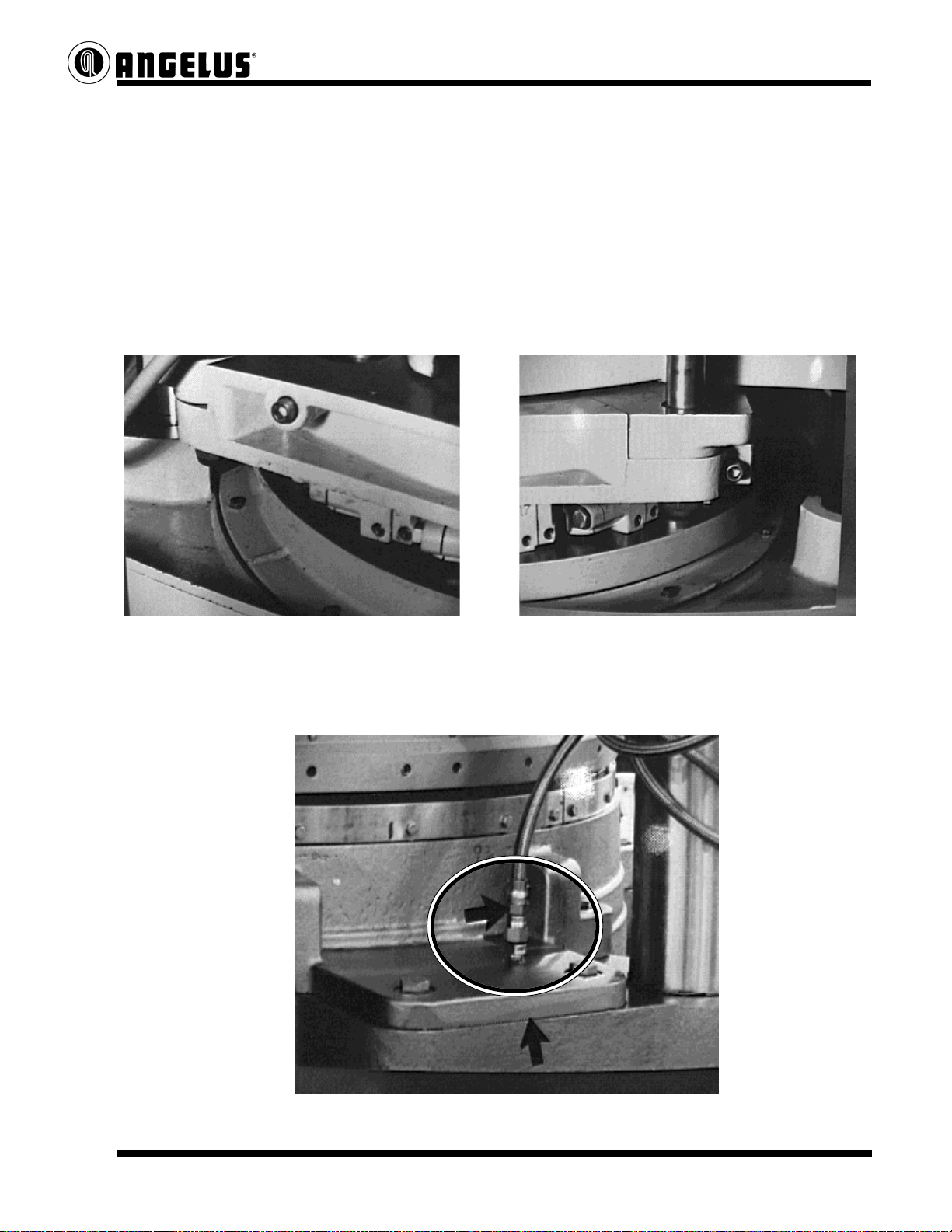

• Install 1/8 close nipple, 1/8 tee, and straight fitting into “P” designate in base (See Fig. 3)

• Install 1/8 close nipple and 1/8 elbow into tee (See Fig. 3)

• Install 1/8 plug in “Y” designate in base (See Fig. 3)

• Reinstall lines by cutting to fit. (See Fig. 3)

• Remove existing sprocket lubricator line and install 1/8 plug. (See Fig. 4)

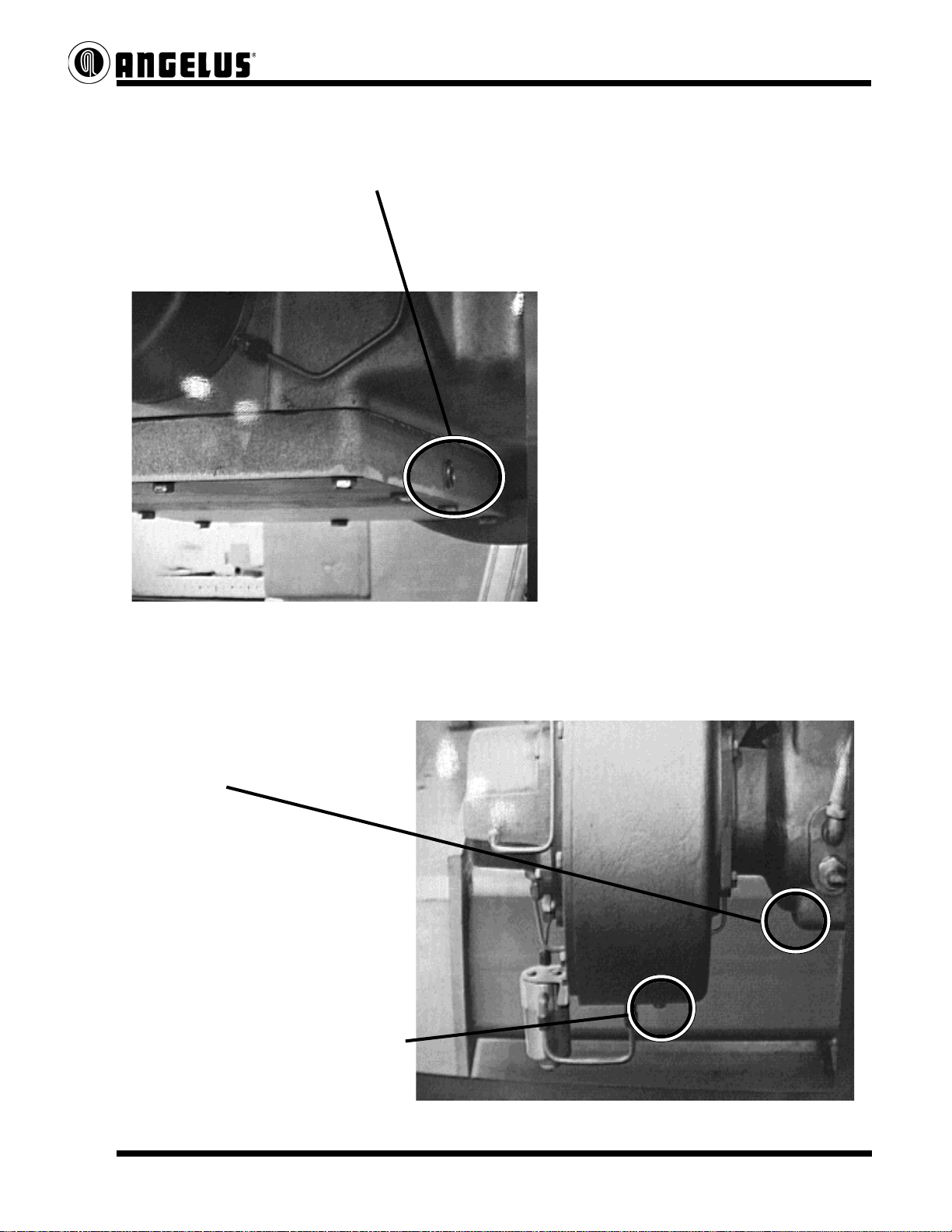

• Install Gravity Feed Lubricator (See Fig. 6)

• Modify 262S854 feed sprocket guard per the following illustrations. (See Fig. 7)

• Electrical Programming Changes - Connect chain oiler solenoid to a unused 24VDC output.

In PLC program add a line of logic. Program “Jog Command” bit parallel with “Run

Command” bit to energize Gravity Feed Lubricator.