instructions can result in serious injury,

including death.

WARNING!To reduce the risk of

electrocution, keep all connections dry and

off the ground. Do not touch plug with wet

hands.

This machine is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless

they have been given supervision or

instruction concerning use of the machine

by a person responsible for their safety.

Children should be supervised to ensure

that they do not play with the machine.

WARNING! This machine has been

designed for use with the cleaning agent

supplied or recommended by the

manufacturer. The use of other cleaning

agents or chemicals may adversely affect

the safety of the machine.

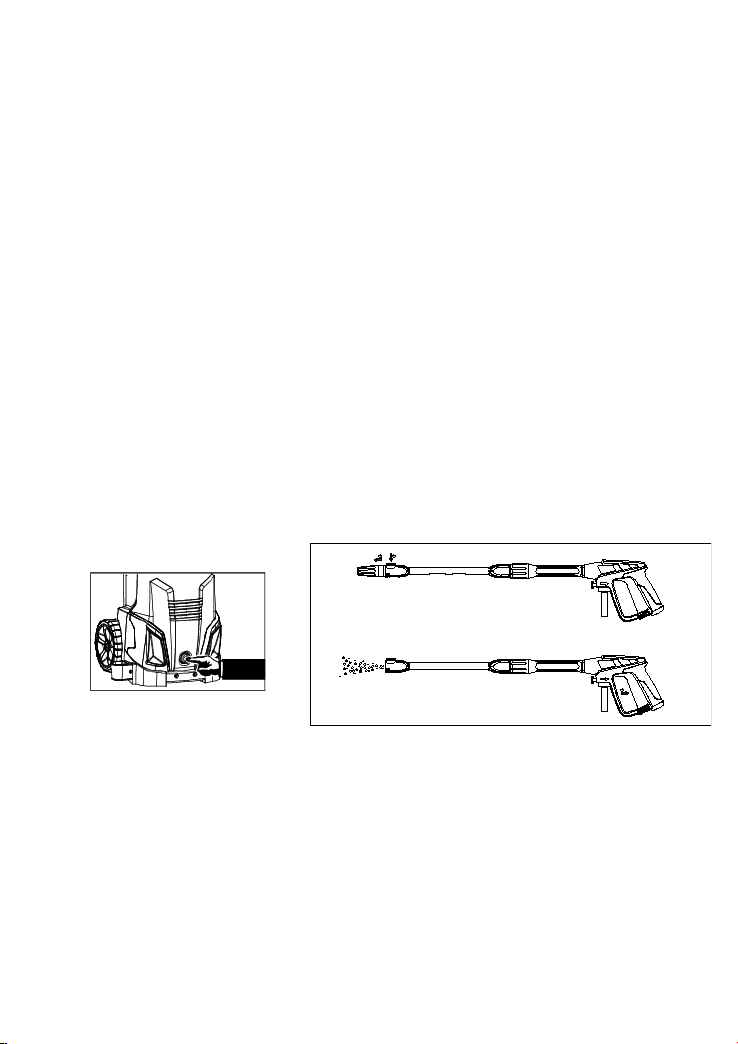

WARNING! High pressure jets can be

dangerous if subject to misuse. The jet

must not be directed at persons, live

electrical equipment or the machine itself.

WARNING! Do not use the machine

within range of persons unless they wear

protective clothing.

WARNING! Do not direct the jet against

yourself or others in order to clean clothes

or foot-wear.

WARNING! Risk of explosion-Do not

spray flammable liquids.

WARNING! High pressure cleaners shall

not be used by children or untrained

personnel.

WARNING! High pressure hoses, fittings

and couplings are important for the safety of

the machine. Use only hosed, fittings and

couplings recommended by the

manufacturer.

WARNING! To ensure machine safety,

use only original spare parts from the

manufacturer or approved by the

manufacturer.

WARNING! Water that has flown through

backflow preventers is considered to the

non-potable.

WARNING! The machine shall be

disconnected from its power source by

removing the plug from the socket-outlet

during cleaning or maintenance and when

replacing the machine to another function.

WARNING! Do not use the machine if a

supply cord or important parts of the

machine are damaged, e.g. safety devices,

high pressure hoses, trigger gun.

WARNING! If an extension cord is used,

the plug and socket must be of watertight

construction.