2 PN: 10410-00072 Revision: J 3670x50 Semi-Rigid Cables OMM

4. PRECAUTIONS

ANRITSU series 3670x50 cables are precision

laboratory items and should receive the same care

and respect afforded other such equipment.

Complying with the following precautions will

guarantee longer cable life and less equipment

downtime due to connector failure. Also, such

compliance will ensure that cable component failures

are not due to misuse or abuse—two failure modes

not covered under the ANRITSU warranty.

a. Bend Cables Carefully. Never bend the cable

sharply. Use gentle radius bends only. Place

bends in the center portion of cable; never bend

near the connectors. Avoid twisting cable; loosen

and re-tighten connectors, if necessary.

b. Beware of Destructive Pin Depth of Mating

Connectors. Measure the center conductor depth

of DUT connectors that mate with 3670x50 cable

connectors, before mating. Use an ANRITSU

Pin Depth Gauge (Figure 2), or equivalent. Based

on RF components returned for repair, destructive

center conductor depth of mating connectors is

the major cause of failure in the field. When a

3670x50 cable connector is mated with another

connector having a destructive pin depth,

damage will likely occur to the cable connector.

(A destructive pin depth has a center conductor

that is too long in respect to the reference plane of

the connector.)

The center conductor depth of 3670x50 cable

connectors have a tolerance measured in mils

(1/1000 inch). Test device connectors that mate

with these cables may not be precision types and

may not have the proper center conductor depth.

They must be measured before mating to ensure

suitability.

If the test device center conductor is too long, it

will measure out of tolerance in the “+” region

(Table 2). Mating under this condition will

possibly damage the cable center conductor.

If the test device center conductor is too short it

will measure out of tolerance in the “–” region.

This condition will not cause damage; however,

it may result in a poor connection and result in a

degradation of performance.

c. Avoid Over Torquing Connectors. Over

torquing connectors is destructive; it may damage

the connector center pins. Always use a connector

torque wrench when tightening GPC and other

precision type connectors. (The wrench should be

set to 8 inch-pounds maximum.) Never use pliers.

d. Avoid Mechanical Shock. Do not drop or other-

wise treat 3670x50 cables roughly. Mechanical

shock or rough handling will decrease the useful

life of these cables. Avoid introducing a bend

radius of less than 3 inches.

e. Keep Cable Connectors Clean. The precise

geometry of the precision connectors that makes

the high performance of these cables possible can

be easily disturbed by dirt and other contami-

nation adhering to connector interfaces. When not

in use, keep the connectors covered. Refer to

section 7 for cleaning instructions.

5. CONNECTING AND USING CABLES

Connect the female connector of one 3670x50 cable to

the Port 1 connector of the test set. Repeat for Port 2

with the second cable (if used). When connecting

cables, use a connector torque wrench and observe all

other precautions described above.

Figure 2. Pin Depth Gauge Scale

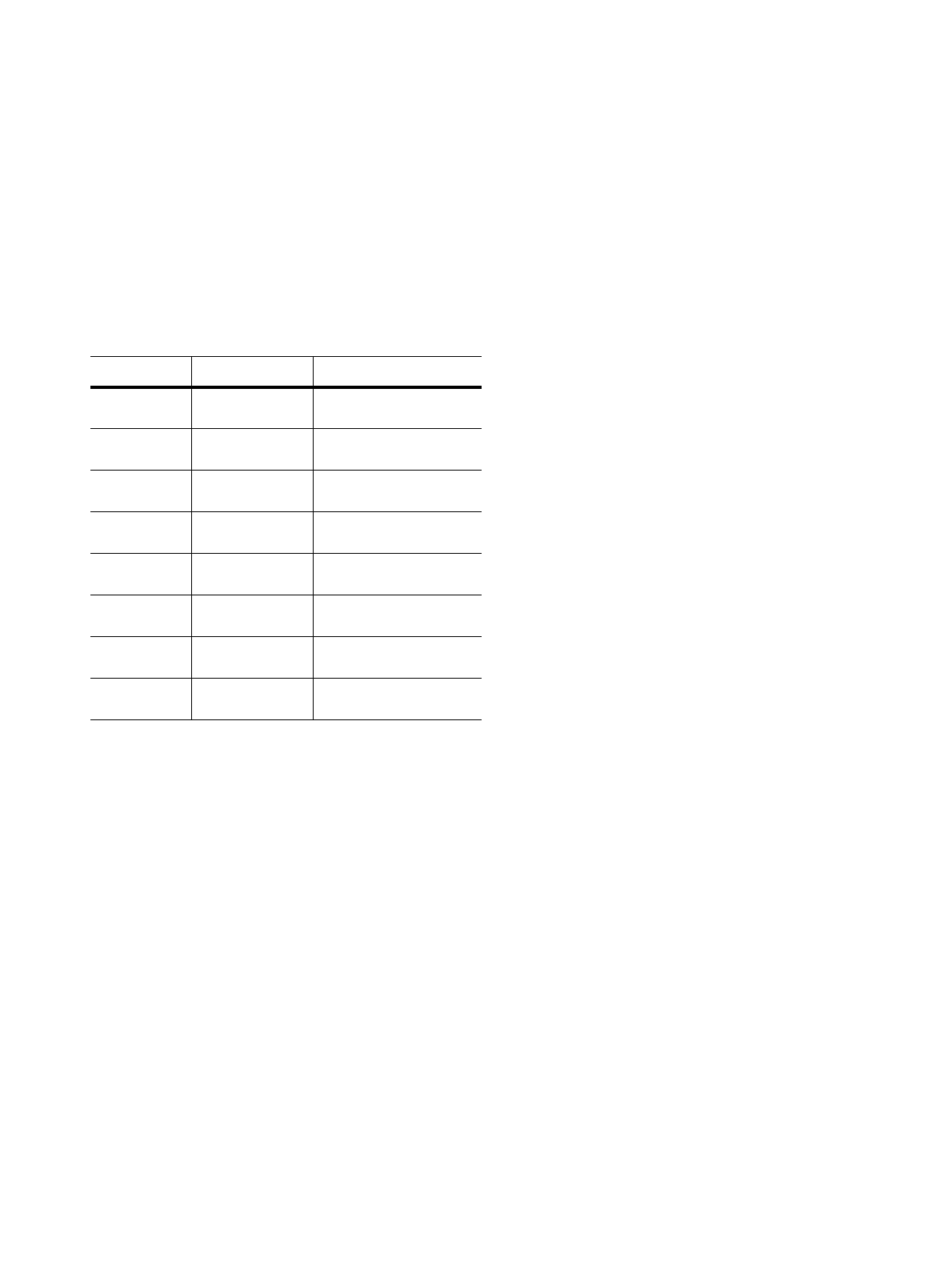

Table 2. Allowable Mating Connector Pin Depth

Connector Pin Depth Type (Inches)

GPC-7 +0.000 to –0.003

K +0.000 to –0.005

V +0.000 to –0.004

N Male –0.207 to –0.227

N Female +0.207 to +0.187