APW9 Power Supply Maintenance Guide

2

2. Before the product is opened and the PCBA panel is repaired, the large capacitor must be

discharged, and the voltage must be measured with a multimeter (less than 5V discharge), and then

the soldering operation can be performed! Be sure to confirm to avoid electric shock.

3. Pay attention to the working method when judging the circuit components. After replacing any

device, the PCB panel has no obvious deformation, the soldering of bonding pad is reliable, and the

replacement parts and the surrounding area have no problem such as insufficient parts, open circuit

or short circuit.

4. After replacing the key components, the main circuit shall have no short circuit and other obvious

abnormalities before the AC voltage test, otherwise there is a hidden danger of explosion.

5. It needsAC220V voltage to judge the circuit signal; pay attention to operational protection.

The following: Notes, key slogans:

● Maintenance personnel qualifications must meet the specified requirements;

● Instruments and equipment used for maintenance must meet the specified

requirements;

● The instruments and equipment for maintenance must be effectively grounded, and

the maintenance environment must comply with anti-static requirements;

● Materials used for maintenance must meet the specified requirements; in order to

guarantee the accuracy and traceability of the materials used for maintenance, the

materials used for maintenance must be the production materials for the corresponding

models, and the material replacement must be confirmed;

1. In order to prevent possible electric shock hazard, non-professionals should not

disassemble the enclosure:

2. The maintenance personnel shall use a special enclosure opener to open the enclosure

of power adapter and repair, to avoid damage to the internal components of the product:

3. After the product is opened, it is required to discharge the high voltage capacitor;

4. E-waste waste generated during product maintenance cannot be arbitrarily dropped:

5. Bad products must have a repair process card and indicate the cause of the failure, and

placed separately;

6. The repaired products must be well marked to distinguish.

7. The repaired products must be placed in the repaired area and shall be systematically

tested before they can be stored.

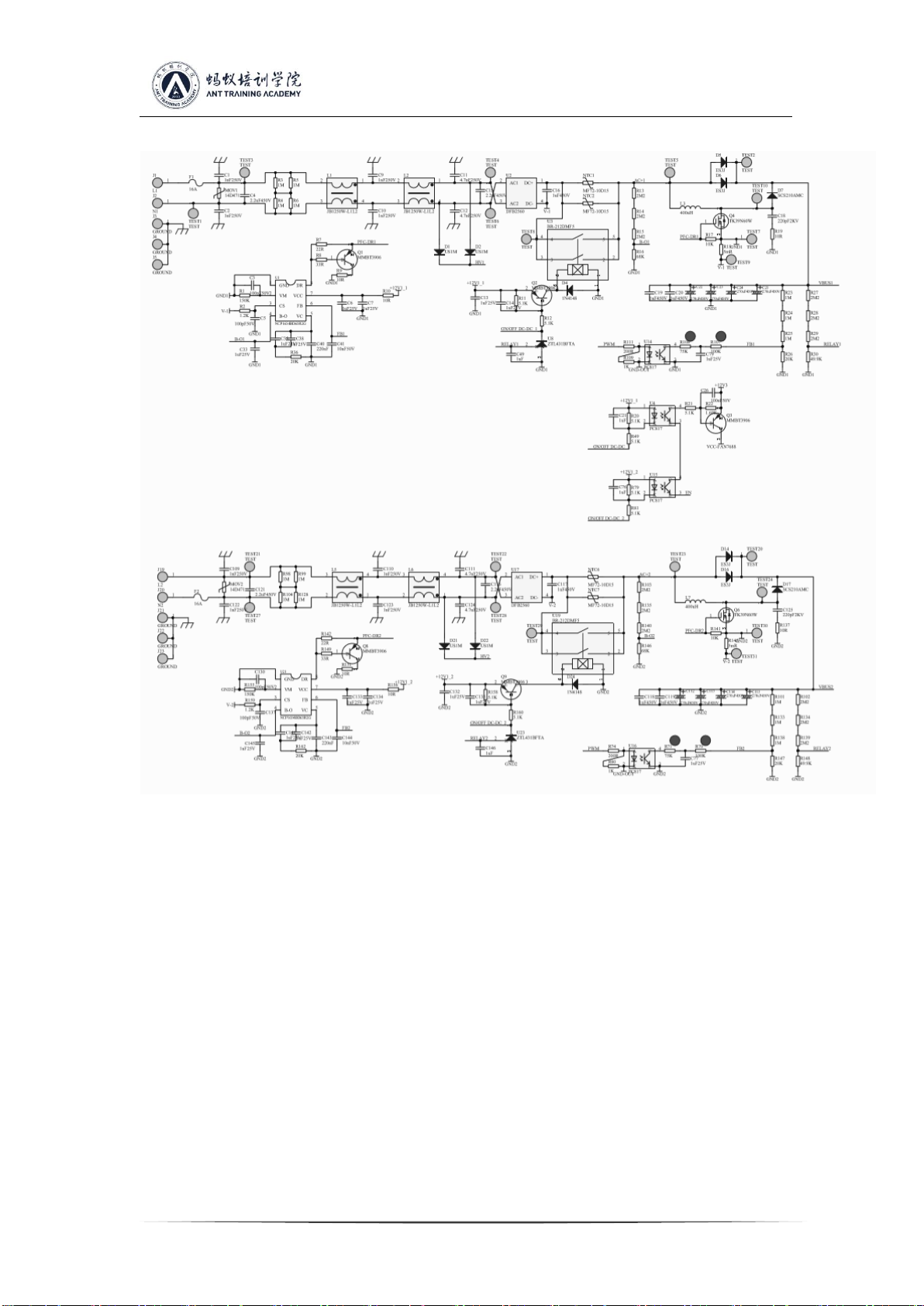

III. The Principle and Structure of the Power Supply

1. Principle overview

1. APW9 is composed of 1 large board, 3 fans and the upper and lower shell. The normal two input

channels are connected with AC220V and have two output voltages of DC, which are respectively

SB 12V. The main output voltage is 14.5v-21v, which is controlled by PIC port and communication

with the miner.

1.2 Performance characteristics and range of use are described below: