ANTTI MOBILE DRYER VACBOOST M13 ............................................................................................................ 4

SELECTING LOCATION FOR THE DRYER.......................................................................................................... 4

FOUNDATION ........................................................................................................................................................4

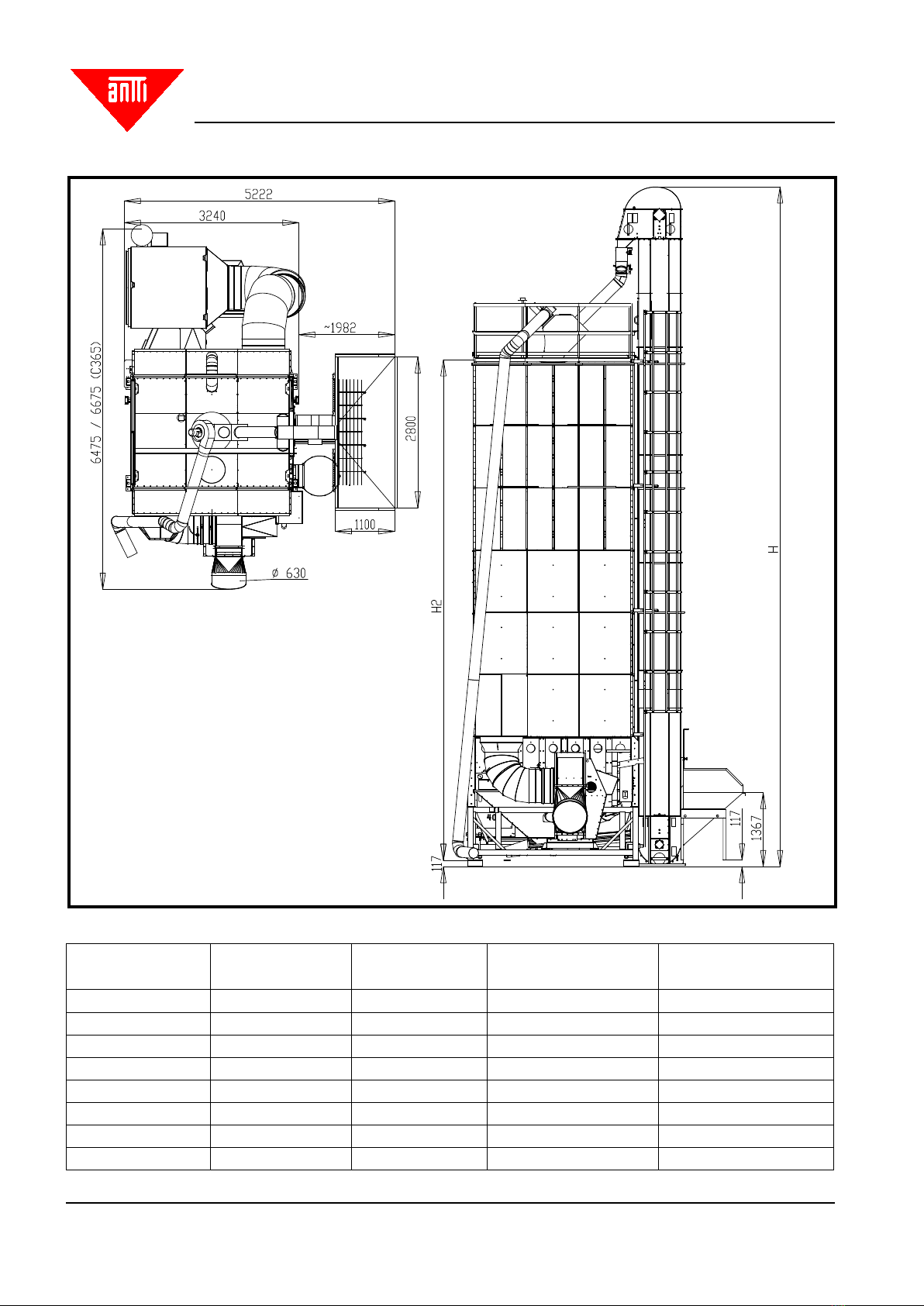

THE SPACE REQUIRED FOR THE INSTALLATION............................................................................................. 5

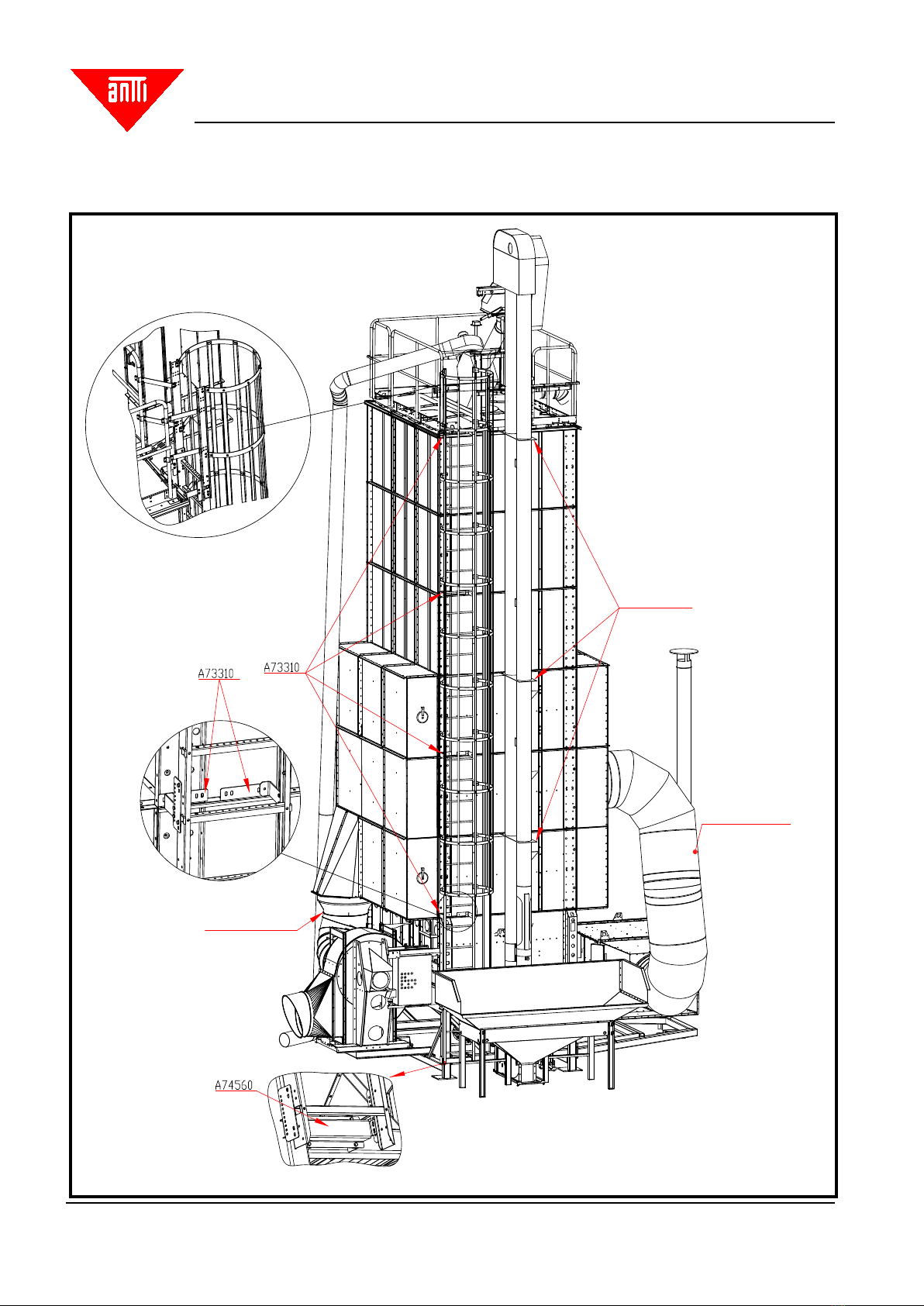

PRESENTATION OF THE MACHINE .................................................................................................................... 5

SAFETY..................................................................................................................................................................6

Follow the local instructions for occupational safety............................................................................................... 6

INSTALLATION OF THE ANTTI VACBOOST MOBILE DRYER ............................................................................ 6

Principle drawings of dierent dryer types with accessories .................................................................................. 8

Base with frame....................................................................................................................................................26

Sections, air channel ends ................................................................................................................................... 26

Top tanks and cover with handrails ...................................................................................................................... 26

Installing the upper limit sensor............................................................................................................................ 27

(Capacitive, adjustable)........................................................................................................................................27

Installing the elevator............................................................................................................................................27

Large bolt-assembled hopper .............................................................................................................................. 27

The intake pit with Skandia conveyor................................................................................................................... 27

Wire control of the 3-way divider and the circulation pipes .................................................................................. 28

Installing the blower stand....................................................................................................................................34

Fuel pipes.............................................................................................................................................................36

Installing the debris piping for the pre-cleaner......................................................................................................36

Electric installations..............................................................................................................................................37

1. Installation ........................................................................................................................................................39

1.1 Installing the LTM thermostat ......................................................................................................................... 39

1.2 Installing the re thermostat ........................................................................................................................... 40

1.3 Installing the temperature sensors ................................................................................................................. 41

1.4 Installing the upper limit sensor...................................................................................................................... 41

2. STARTING UP................................................................................................................................................. 42

2.1 Elevator .......................................................................................................................................................... 42

2.2 Pre-cleaner.....................................................................................................................................................42

2.3 Feeder ........................................................................................................................................................... 43

2.4 Blower.............................................................................................................................................................43

2.5 Burner.............................................................................................................................................................43

2.6 LTM thermostat............................................................................................................................................... 43

3. Functions of the control centre ........................................................................................................................ 44

3.1 Switches and buttons ..................................................................................................................................... 44

3.1.1 Operation switch..........................................................................................................................................44

3.1.2 Operating switch for the elevator................................................................................................................. 45

3.1.3 Operating switches for other appliances ..................................................................................................... 45

3.1.4 Bypass button..............................................................................................................................................46

3.1.5 Start button..................................................................................................................................................46

3.2 Operating hour counter .................................................................................................................................. 46

3. 3 Outlet air and drying temperature thermostats.............................................................................................. 46

3. 4 Cooling timer ................................................................................................................................................. 47

3.4.1 Display.........................................................................................................................................................47

3.4.2 Setting the cooling time ............................................................................................................................... 47

3.4.3 Interrupting the cooling................................................................................................................................47

3.5 Frequency converter controlled feeder........................................................................................................... 48

3.6 Signal lights .................................................................................................................................................... 49

CONTENTS

Translation of original