4

6.3 FUSES .............................................................................................................................................30

7ORDINARY MAINTENANCE..............................................................................................................31

7.1 FILTER MAINTENANCE..................................................................................................................31

7.1.1 Washing the filters ....................................................................................................................32

7.2 GENERAL INSPECTION OF THE FILTERS...................................................................................33

7.3 CLEANING THE MACHINE.............................................................................................................33

8EXTRAORDINARY MAINTENANCE..................................................................................................34

8.1 SOSTITUTION OF ION EMITTER NEEDLES.................................................................................34

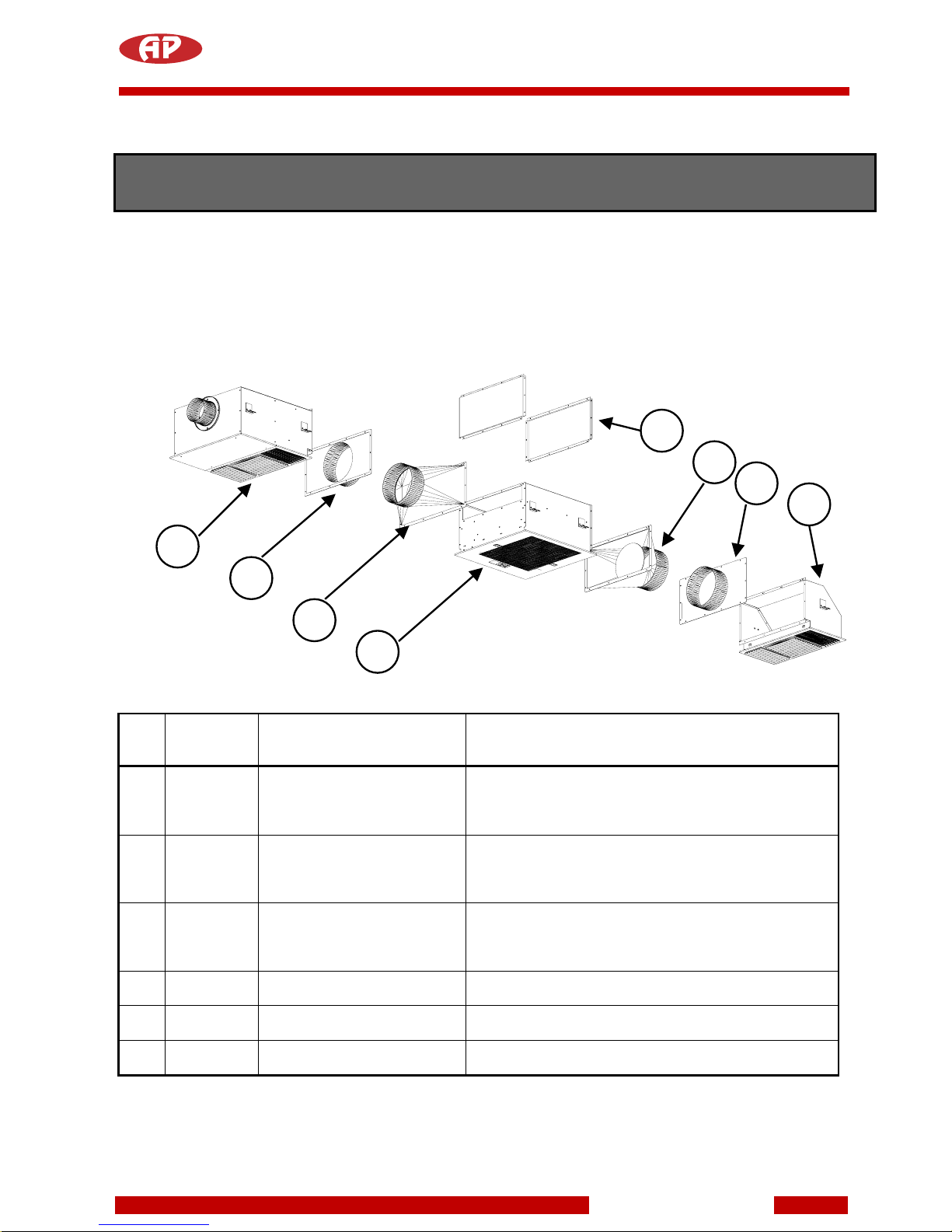

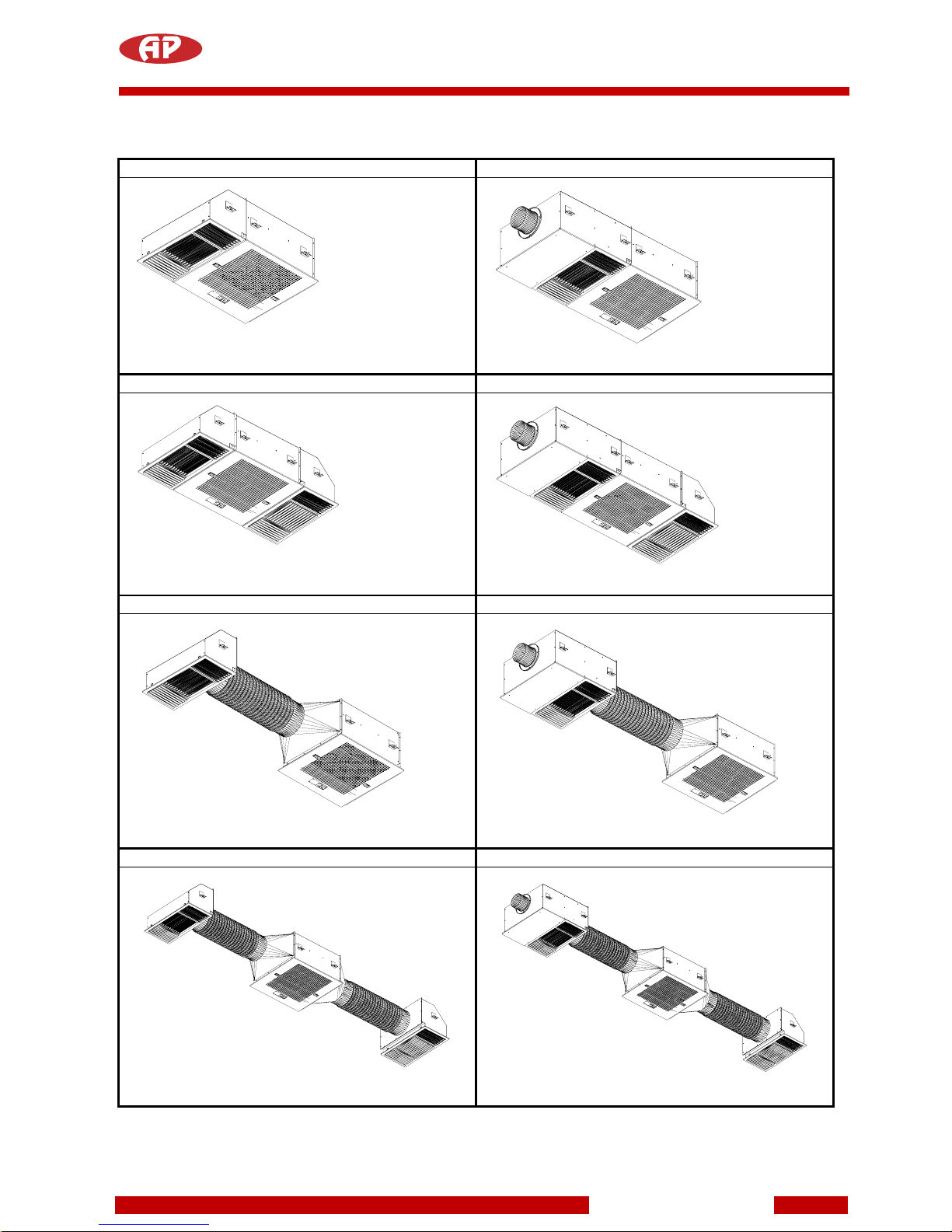

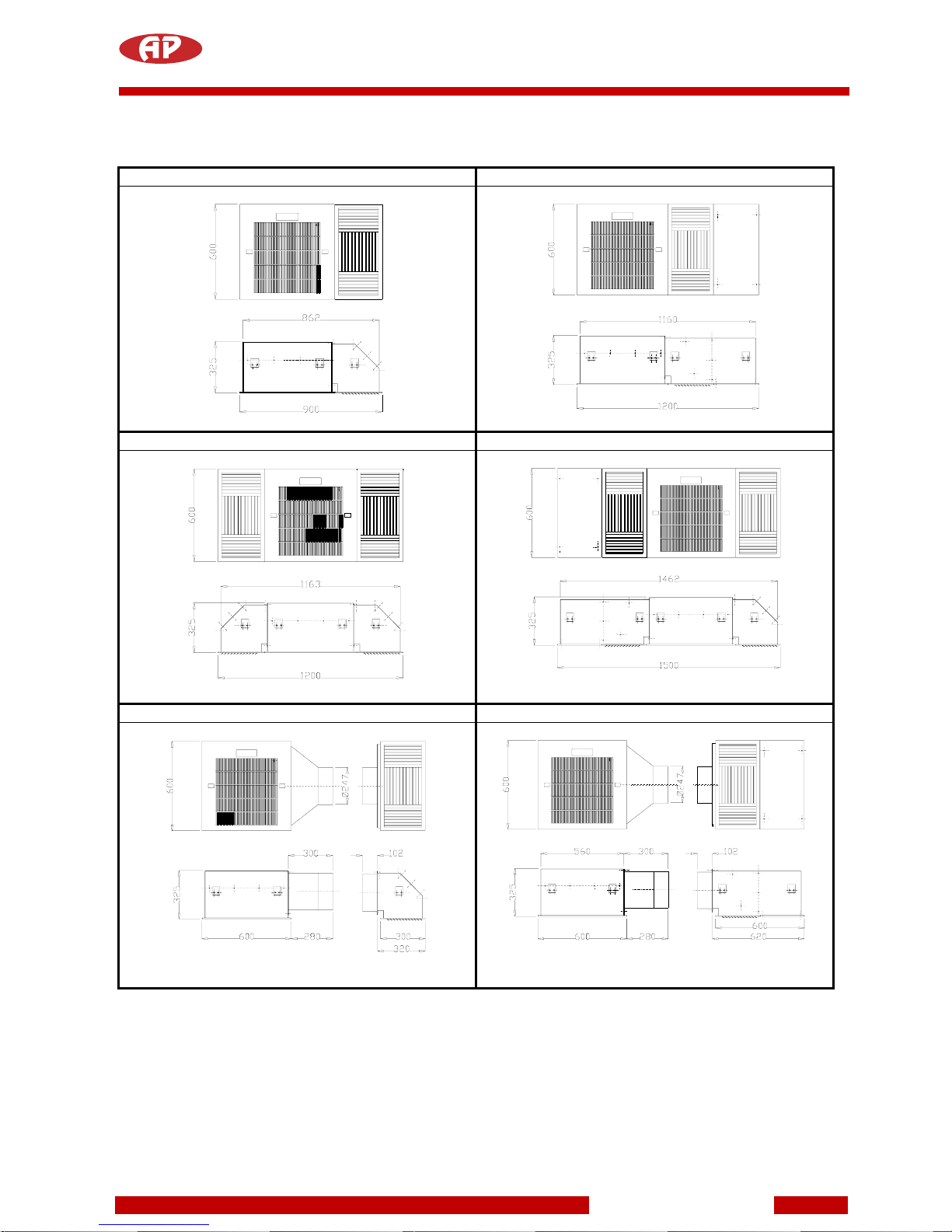

9AVAILABLE VERSIONS.....................................................................................................................35

10 NATURE SYSTEM ........................................................................................................................37

10.1 CONTROL PANEL .......................................................................................................................38

10.1.1 DISPLAY...................................................................................................................................38

10.1.2 RECEIVER................................................................................................................................38

10.1.3 MANUAL, TEST, ON-OFF FILTER AND RESET BUTTONS ..................................................39

10.1.4 OPERATION OF THE MACHINE.............................................................................................39

10.1.5 FILTERING STATUS ................................................................................................................40

10.2 INFRARED REMOTE CONTROL UNIT.......................................................................................40

10.3 POWER SUPPLY AND ANTI BLACK-OUT SYSTEM .................................................................40

10.4 ENVIRONMENTAL REVITALISATION (RIVITALIZZAZIONE AMBIENTALE®) ..........................41

10.5 PURIFICATION ............................................................................................................................41

10.6 NORMAL CONDITIONS OF OPERATION ..................................................................................41

10.7 NIGHT-TIME REVITALISATION WITH ENVIRONMENTAL DEODORIZATION ........................42

10.8 SIGNALS ......................................................................................................................................42

10.9 STATE OF FILTRATION EFFICIENCY .......................................................................................42

10.10 OPTIMAL APPLICATION OF THE REVITALIZER ......................................................................43

10.11 ELECTRONIC CIRCUIT ALARM SIGNALS ................................................................................44

10.12 ELECTRONIC CIRCUIT ANOMALOUS SIGNALS......................................................................45

11 AFC SYSTEM................................................................................................................................46

11.1 CONTROL PANEL .......................................................................................................................47

11.1.1 DISPLAY...................................................................................................................................47

11.1.2 (RECEIVER) .............................................................................................................................47

11.1.3 MANUAL, TEST, ON-OFF FILTER AND RESET BUTTONS ..................................................48

11.2 OPERATION OF THE MACHINE ................................................................................................48

11.3 FILTERING STATUS....................................................................................................................49

11.4 INFRARED REMOTE CONTROL UNIT.......................................................................................49

11.5 POWER SUPPLY AND ANTI BLACK-OUT SYSTEM .................................................................49

11.6 PURIFICATION ............................................................................................................................50

11.7 SIGNALS ......................................................................................................................................50

11.8 STATE OF FILTRATION EFFICIENCY .......................................................................................50

11.9 ELECTRONIC CIRCUIT ALARM SIGNALS ................................................................................51

11.10 ELECTRONIC CIRCUIT ANOMALOUS SIGNALS......................................................................52

12 BASIC SYSTEM ..............................................................................................................................53

12.1 CONTROL PANEL .......................................................................................................................54

12.2 VISUALISATION OF SPEED .......................................................................................................54

12.2.1 RECEIVER................................................................................................................................54

12.2.2 MANUAL AND ON-OFF FILTER BUTTONS............................................................................55

Feb. 12

Automatikprodukter