Automatikprodukter

SUMMARY

1 GENERAL...................................................................................................................................................5

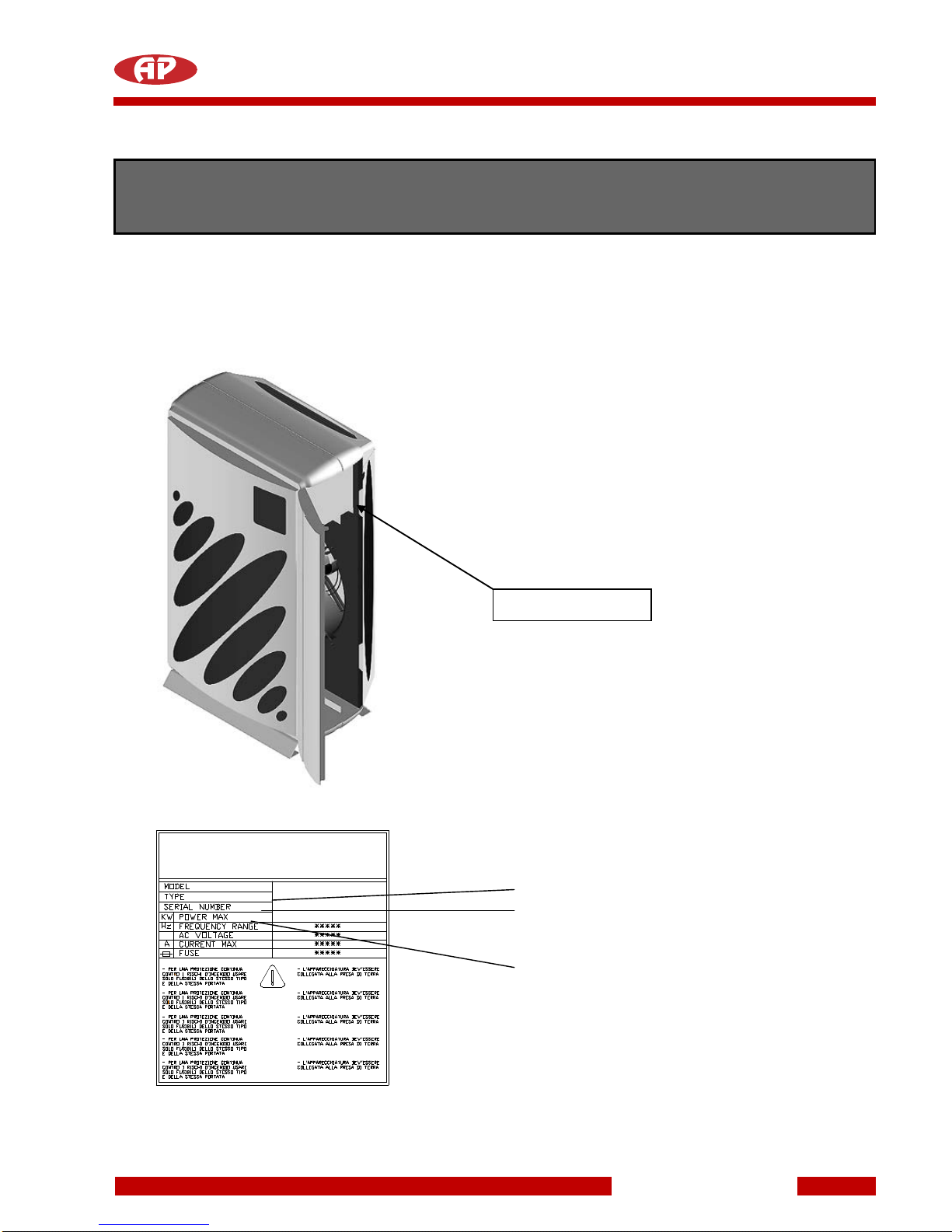

1.1 IDENTIFICATION OF THE MACHINE .................................................................................................5

1.2 MARKING OF THE MACHINE.............................................................................................................6

1.2.1 Opening the door ..........................................................................................................................6

2 PACKAGING AND TRANSPORT...............................................................................................................7

2.1 PACKAGING........................................................................................................................................7

2.2 TRANSPORT.......................................................................................................................................7

3 INSTALLATION OF THE MACHINE ..........................................................................................................8

3.1 VENTILATING THE PREMISES ..........................................................................................................9

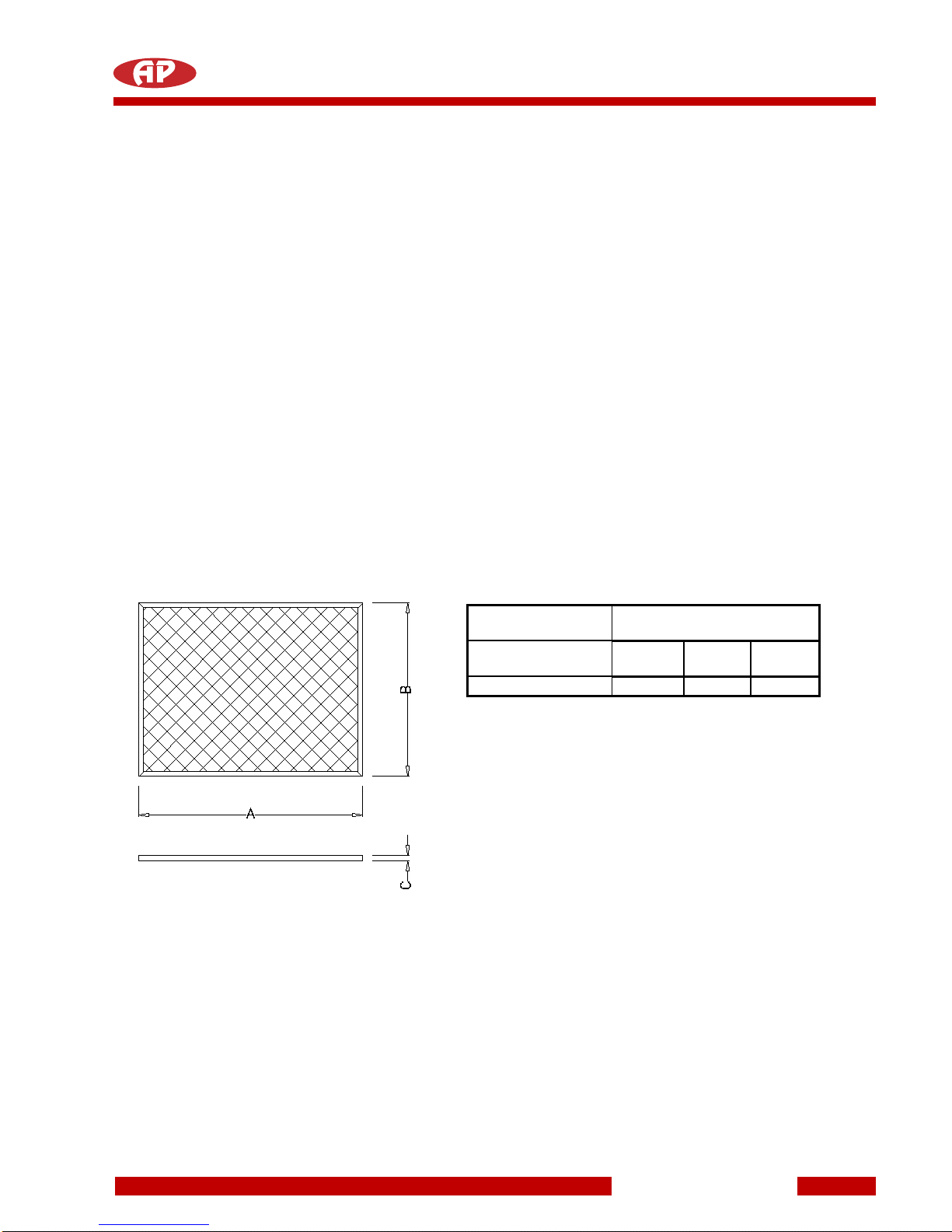

3.2 FILTER UNIT........................................................................................................................................9

3.3 METAL PRE-FILTER............................................................................................................................9

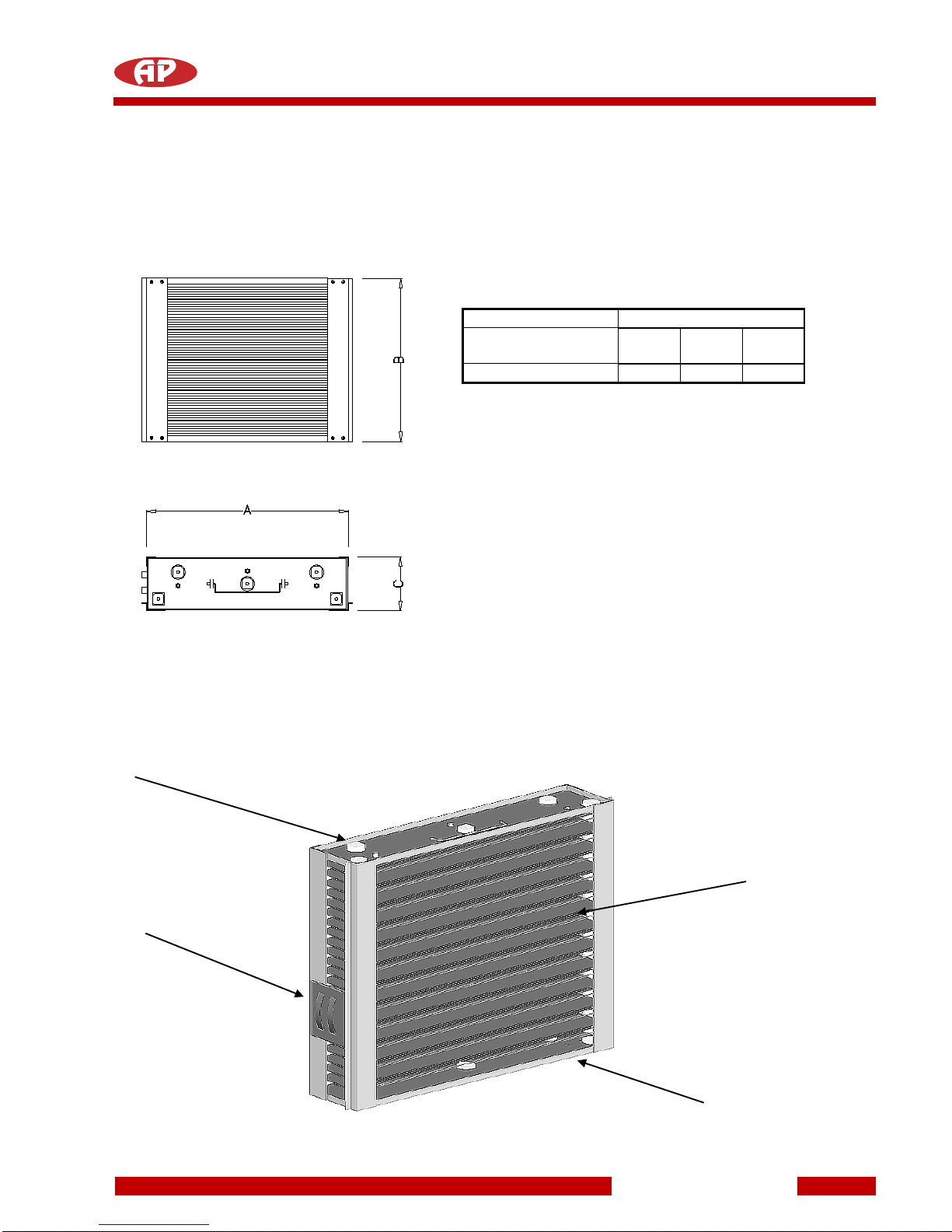

3.4 ELECTROSTATIC CELL....................................................................................................................10

3.4.1 ionisation wires............................................................................................................................11

3.4.2 collection blades..........................................................................................................................11

3.4.3 insulators.....................................................................................................................................11

3.4.4 contact terminal strip...................................................................................................................11

4 SAFETY DEVICES....................................................................................................................................11

4.1 MECHANICAL SAFETY DEVICES....................................................................................................11

4.2 ELECTRICAL SAFETY DEVICES......................................................................................................12

4.2.1 Electronic circuit protection devices............................................................................................12

4.3 FUSE ...................................................................................................................................................12

5 ORDINARY MAINTENANCE....................................................................................................................13

5.1 FILTER MAINTENANCE....................................................................................................................13

5.1.1 Access Door................................................................................................................................13

5.1.2 Washing the filters.......................................................................................................................14

5.2 GENERAL INSPECTION OF THE FILTERS......................................................................................15

5.3 CLEANING THE MACHINE................................................................................................................15

6 AVAILABLE VERSIONS...........................................................................................................................16

7 NATURE SYSTEM .................................................................................................................................18

7.1 CONTROL PANEL.............................................................................................................................19

7.1.1 DISPLAY.....................................................................................................................................19

7.1.2 RECEIVER..................................................................................................................................19

7.1.3 MANUAL, TEST, ON-OFF FILTER AND RESET BUTTONS.....................................................20

7.1.4 OPERATION OF THE MACHINE...............................................................................................20

7.1.5 FILTERING STATUS..................................................................................................................21

7.2 INFRARED REMOTE CONTROL UNIT.............................................................................................21

7.3 POWER SUPPLY AND ANTI BLACK-OUT SYSTEM........................................................................21

7.4 ENVIRONMENTAL REVITALISATION (RIVITALIZZAZIONE AMBIENTALE®).................................22

7.5 PURIFICATION..................................................................................................................................22

7.6 NORMAL CONDITIONS OF OPERATION ........................................................................................22

7.7 NIGHT-TIME REVITALISATION WITH ENVIRONMENTAL DEODORIZATION...............................23

7.8 SIGNALS............................................................................................................................................23

7.9 STATE OF FILTRATION EFFICIENCY..............................................................................................23

7.10 OPTIMAL APPLICATION OF THE REVITALIZER.............................................................................24

7.11 ELECTRONIC CIRCUIT ALARM SIGNALS.......................................................................................25

7.12 ELECTRONIC CIRCUIT ANOMALOUS SIGNALS ............................................................................26

8 AFC SYSTEM..........................................................................................................................................27

8.1 CONTROL PANEL.............................................................................................................................28

8.1.1 DISPLAY.....................................................................................................................................28

8.1.2 (RECEIVER) ...............................................................................................................................28