3

1. SAFETY PRINCIPLES

before you start to use t e device, become familiar wit t e present instructions;

in order to avoid electrocution or damage to t e device, its mec anical and electrical installation

must be performed by qualified staff;

before switc ing on t e power supply, make sure t at all cables and wires are properly connected;

before making any modifications to t e wire and cable connections, switc off t e device's power supply;

ensure proper operating conditions compliant wit t e tec nical specification of t e device (power supply

voltage, umidity, temperature - see c apter 5).

2. INSTALLATION GUIDELINES

T e device is designed so as to ensure an appropriate level of immunity to most interferences t at may occur in

industrial environments. In environments of unknown level of interferences, it is recommended to implement t e

following measures so as to prevent potential interference wit t e operation of t e device:

do not supply t e device from t e same lines as ig -power equipment wit out using appropriate power

line filters;

use cable s ields on power supply cables, sensor cables, and signal cables, w ereby t e eart ing of t e s ield

s ould be single-point and located as close to t e device as possible;

avoid running instrument (signal) cables in t e direct vicinity of and parallel to power distribution and power

supply cables;

it is recommended to use twisted pair signal cables;

in t e case of sensing resistors in 3-wire connections, use identical wires;

avoid locating remotely controlled, electromagnetic meters, and ig -power loads, loads wit p ase or group

power control, and ot er devices producing large impulse interferences close to one anot er;

ground or zero metal rails on w ic rail-mounted devices are installed.

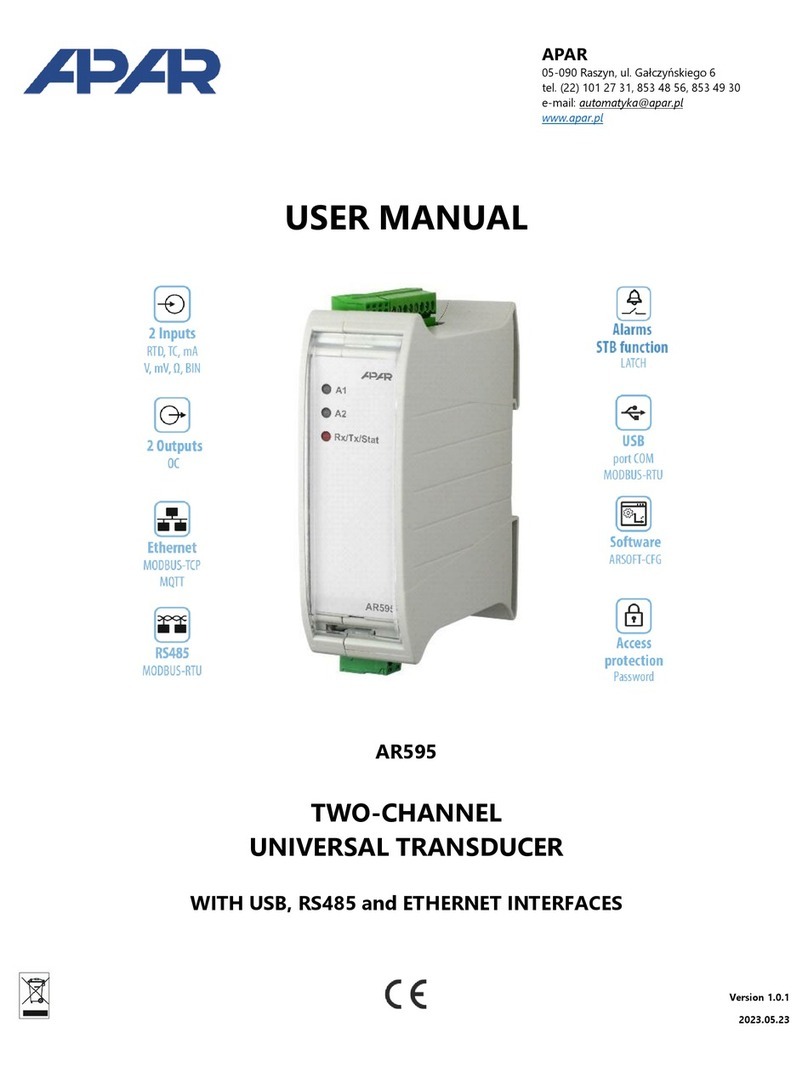

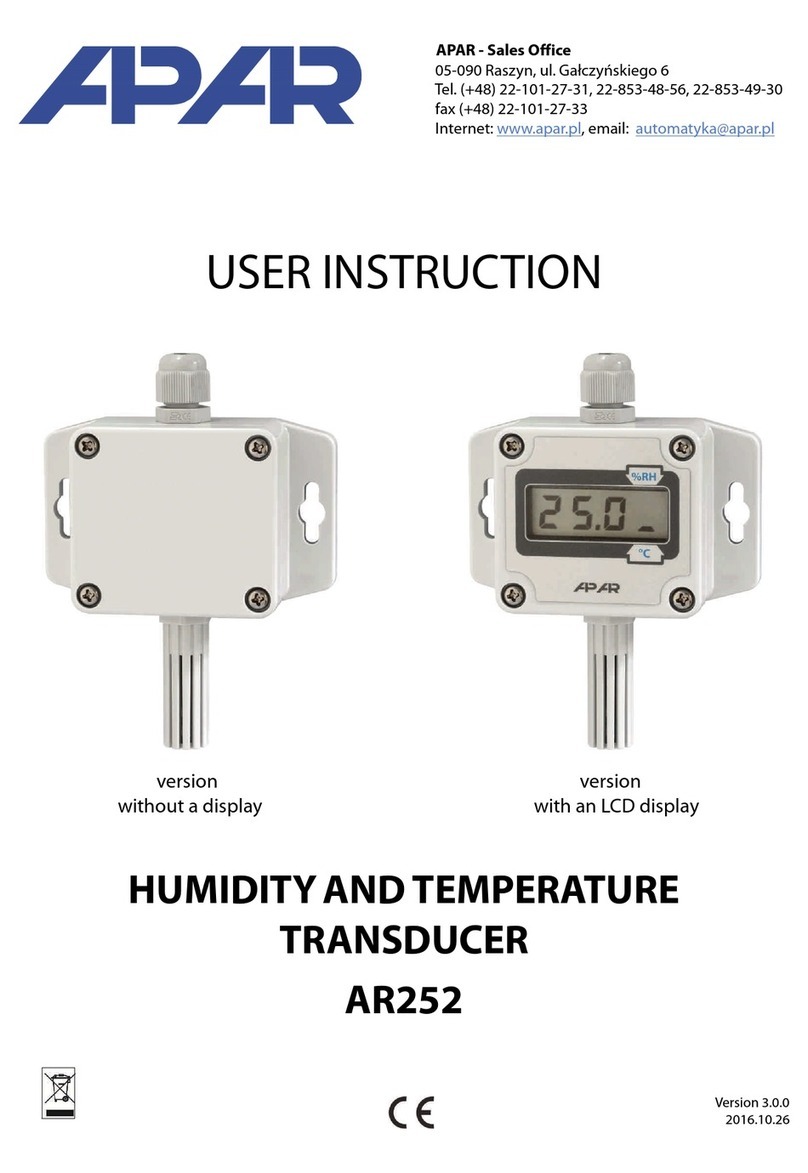

3. GENERAL CHARACTERISTICS OF THE TRANSDUCER

linear processing of measured temperature or anot er p ysical value transformed into a digital signal;

ig accuracy, long-term stability, and immunity to interferences;

universal input:

- t ermoresistance... Pt100, Ni100, Pt500, Pt1000

- t ermocouple ..................... J, K, S, B, R, T, E, N

- analog ....................... 0/4÷20mA, 0÷10V, 0÷60mV, resistance 0÷2500o m

digital serial interface (RS232 or RS485, MODBUS-RTU protocol)

triple galvanic isolation (input/output/supply)

narrow enclosure for installation on t e TS35 rail (DIN rail)

scope of processing, input type, and ot er parameters configured wit :

- ARSOFT-CFG series software and t e AR956 programmer;

- a user application;

- an autonomous AR950 programmer;

a programmable exceeded processing range and set value alarm wit ysteresis (type on/off, OC output)

LED signaling of exceeded processing range, sensor error, or alarm output status (on/off type)

ig accuracy and immunity to interferences;

available ARSOFT-CFG series software t at enables visualization and recording of measurements

!

!