3

1. SAFETY PRINCIPLES

before you start to use the device, become familiar with the present instructions;

in order to avoid electrocution or damage to the device, its mechanical and electrical installation

must be performed by qualified workers;

before switching on the power supply, make sure that all cables and wires are properly connected;

before making any modifications to the wire and cable connections, switch off the voltage supplied

to the device;

ensure proper operating conditions compliant with the technical specification of the device (chapter 5,

power supply voltage, humidity, temperature).

2. INSTALLATION GUIDELINES

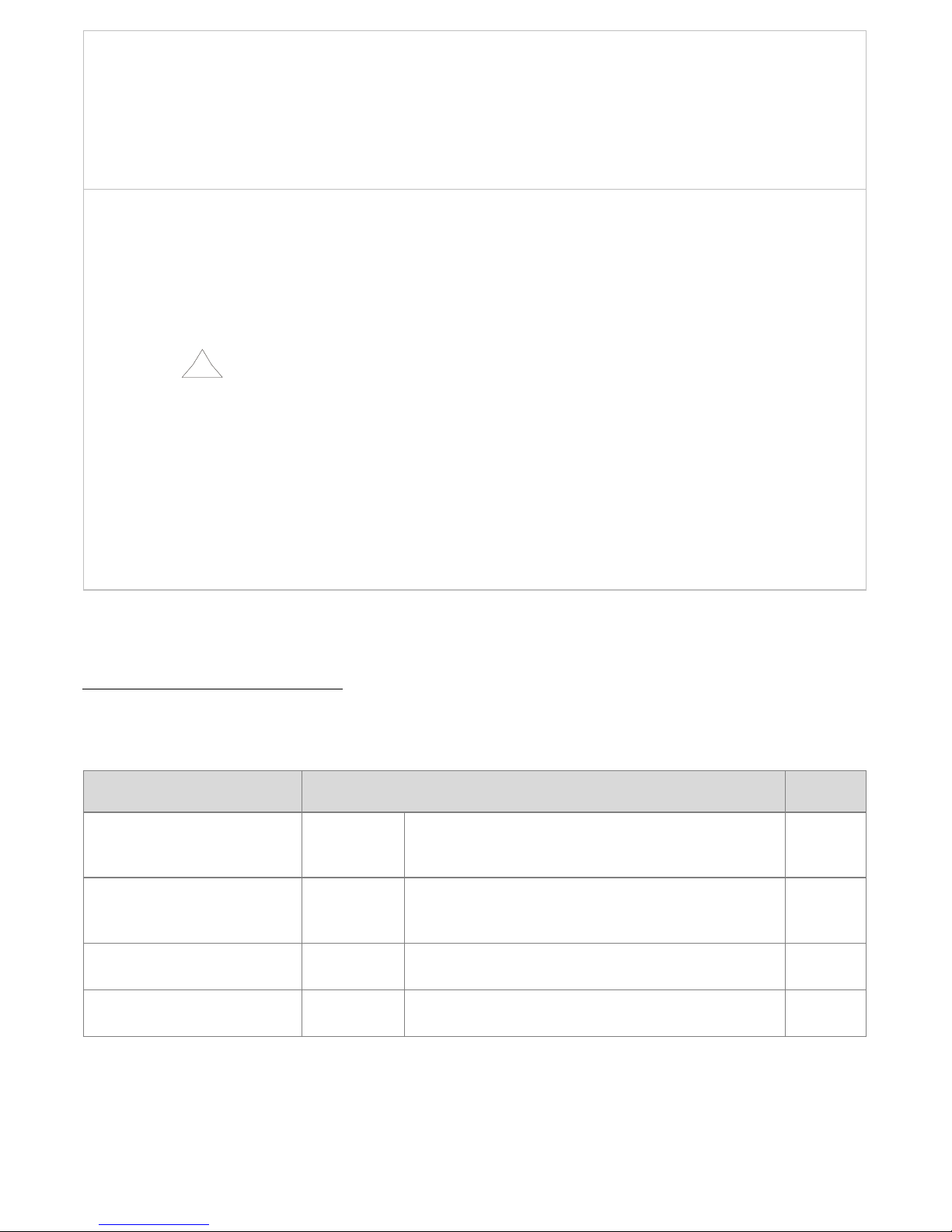

The device is designed so as to ensure an appropriate level of immunity to most interferences that may occur in

industrial and household environments. In environments of unknown level of interferences, it is recommended to

implement the following measures so as to prevent potential interference with the operation of the device:

a) do not supply the device from the same lines as high-power equipment without using appropriate

power line filters;

b) use shielded supply, sensor, and signal cables, whereby the earthing of the shield should be single-point

and located as close to the device as possible;

c) avoid running measurement (signal) cables in the direct vicinity of and parallel to power and supply cables;

d) it is recommended to twist the signal wires in pairs or to use a finished twisted-pair cable;

e) avoid proximity of remotely controlled devices, electromagnetic meters, high power loads, loads with phase

or group power control, and other devices that cause high impulse disturbances;

f) ground or zero metal rails on which rail-mounted devices are installed.

Make sure to remove the protective film from the LCD display before the first use of the device.

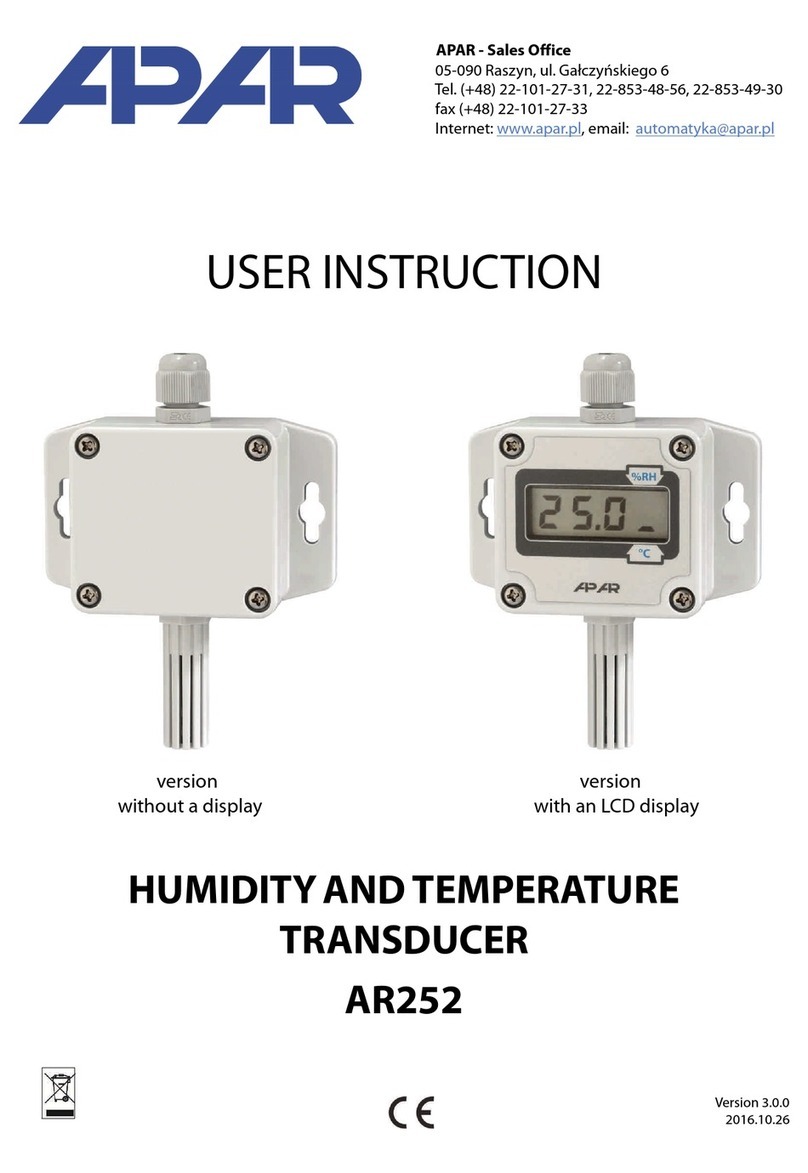

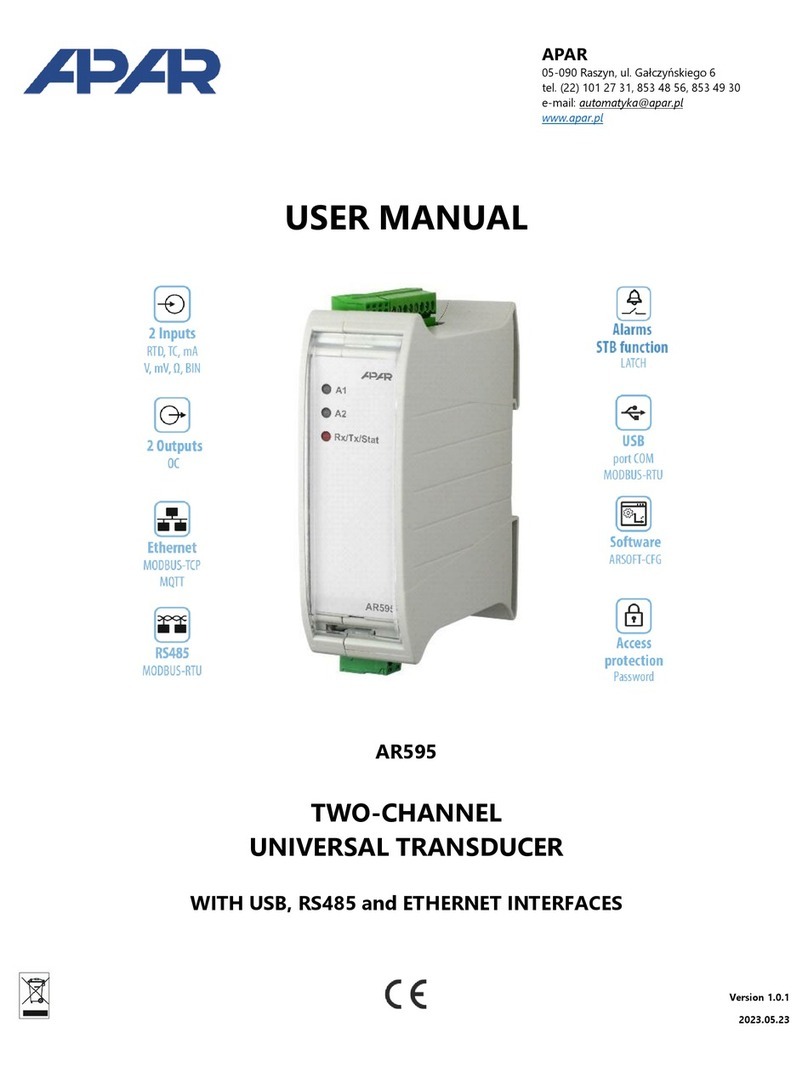

3. GENERAL CHARACTERISTICS OF THE TRANSDUCER

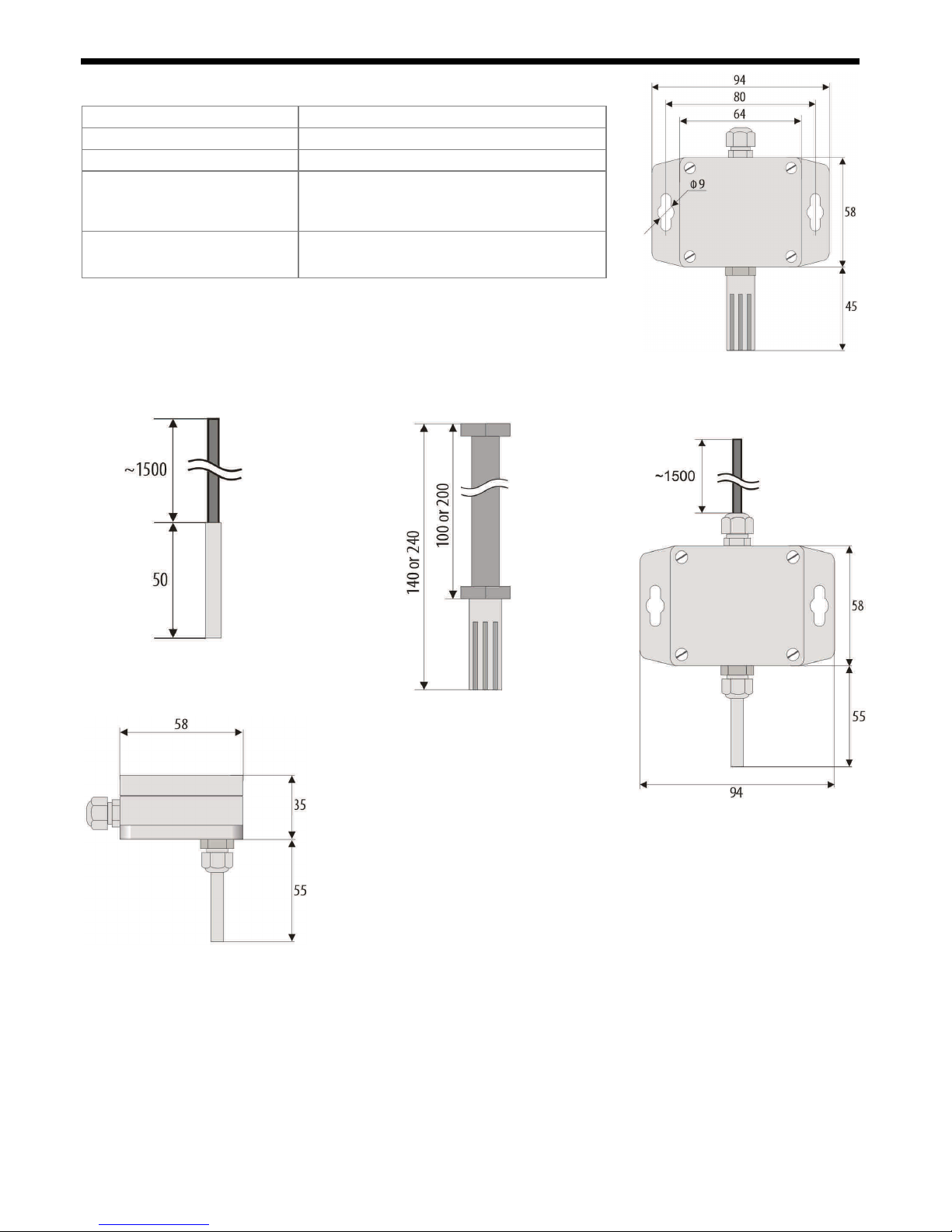

a probe integrated with the enclosure, external probe with a wire, external in the enclosure with a wire

or external on a stainless steel pipe

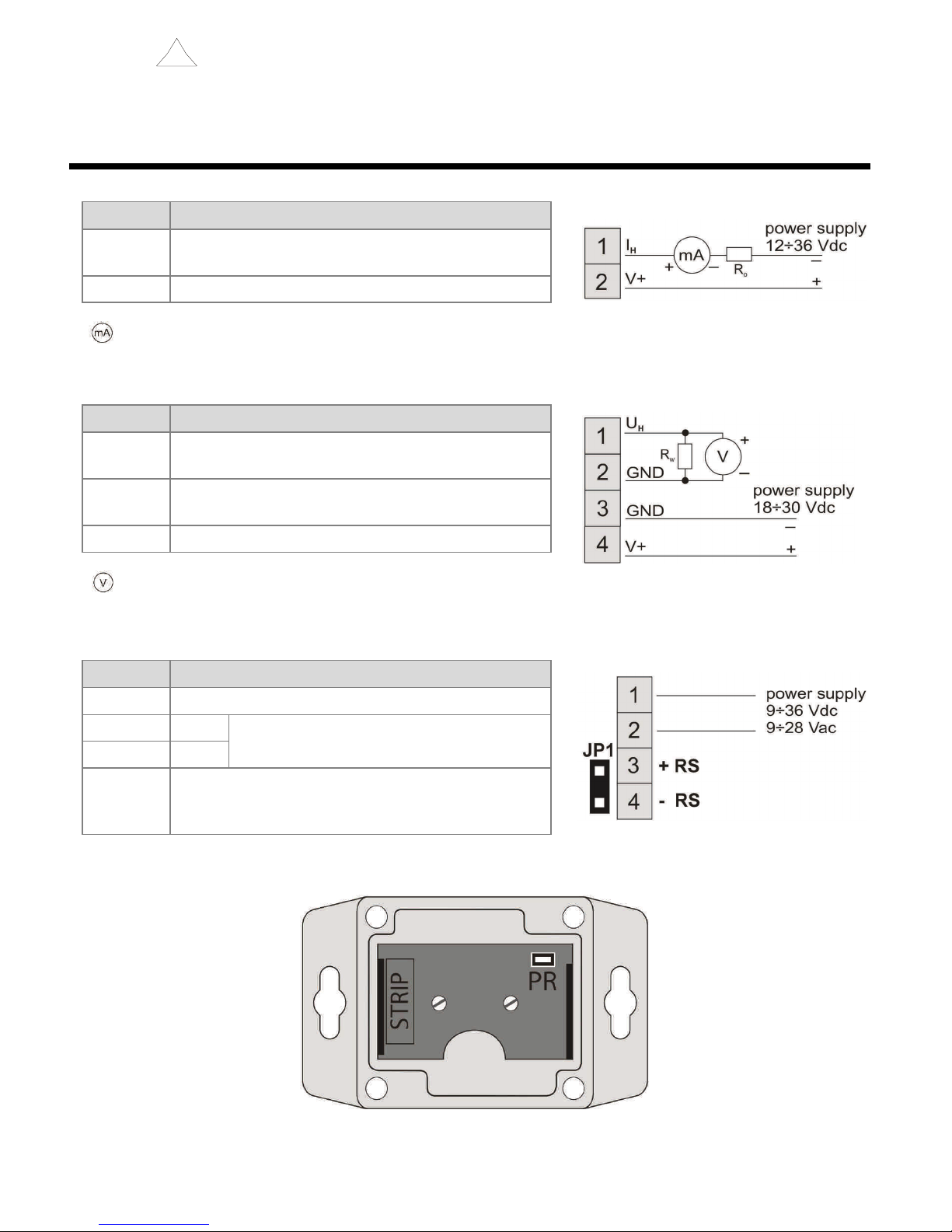

a current output 4- 0 mA ( -wire, with power supply from the current loop); a voltage output 0-10 V

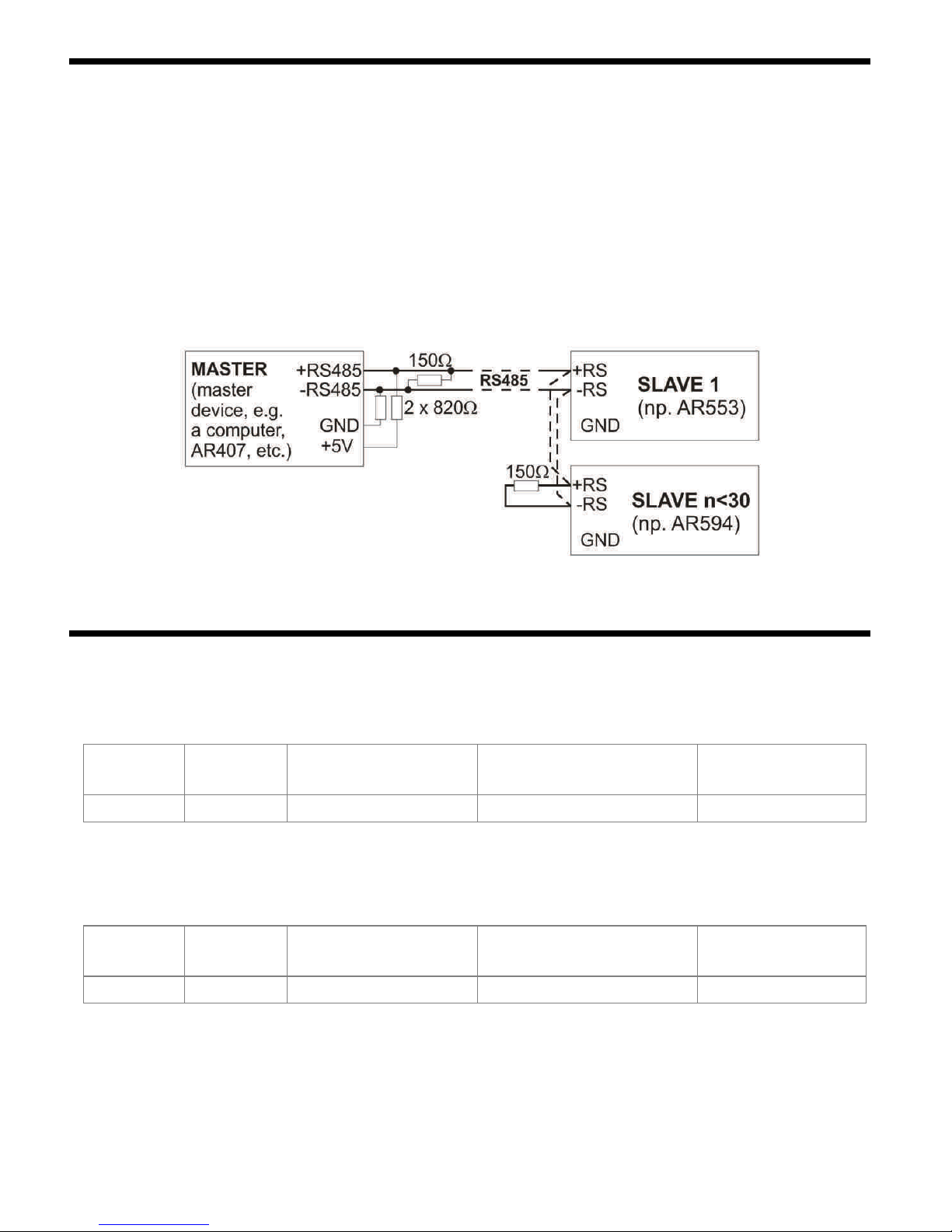

(3-wire), or an RS485 interface

programmable processing ranges for temperature

without galvanic separations outputs/power supply

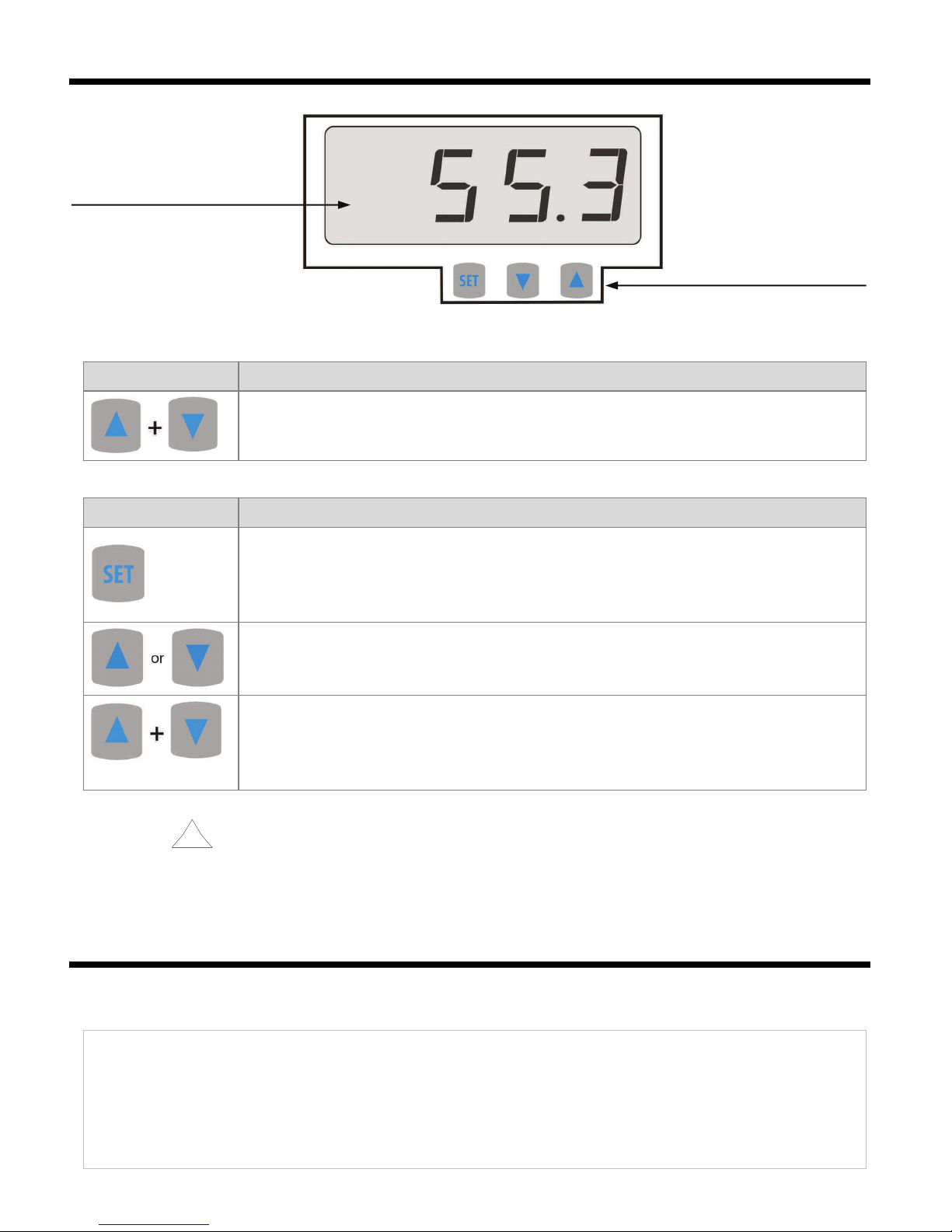

an LCD display with a keypad (option) that enables configuration of parameters;

configuration of parameters with the keypad, through the RS485 or PRG port (programmer AR956 or AR955)

and free ARsoft-CFG software that enables quick setting and copying of all configuration parameters

protection rating IP65 provided by the enclosure which improves reliability of operation thanks to high

resistance to penetration of water and dust and surface condensation of steam inside of the device

possible power supply from the programmer AR956 during configuration parameters

!

!