APEN GROUP SPA reserves the right to make changes deemed to be required to its products or documentation

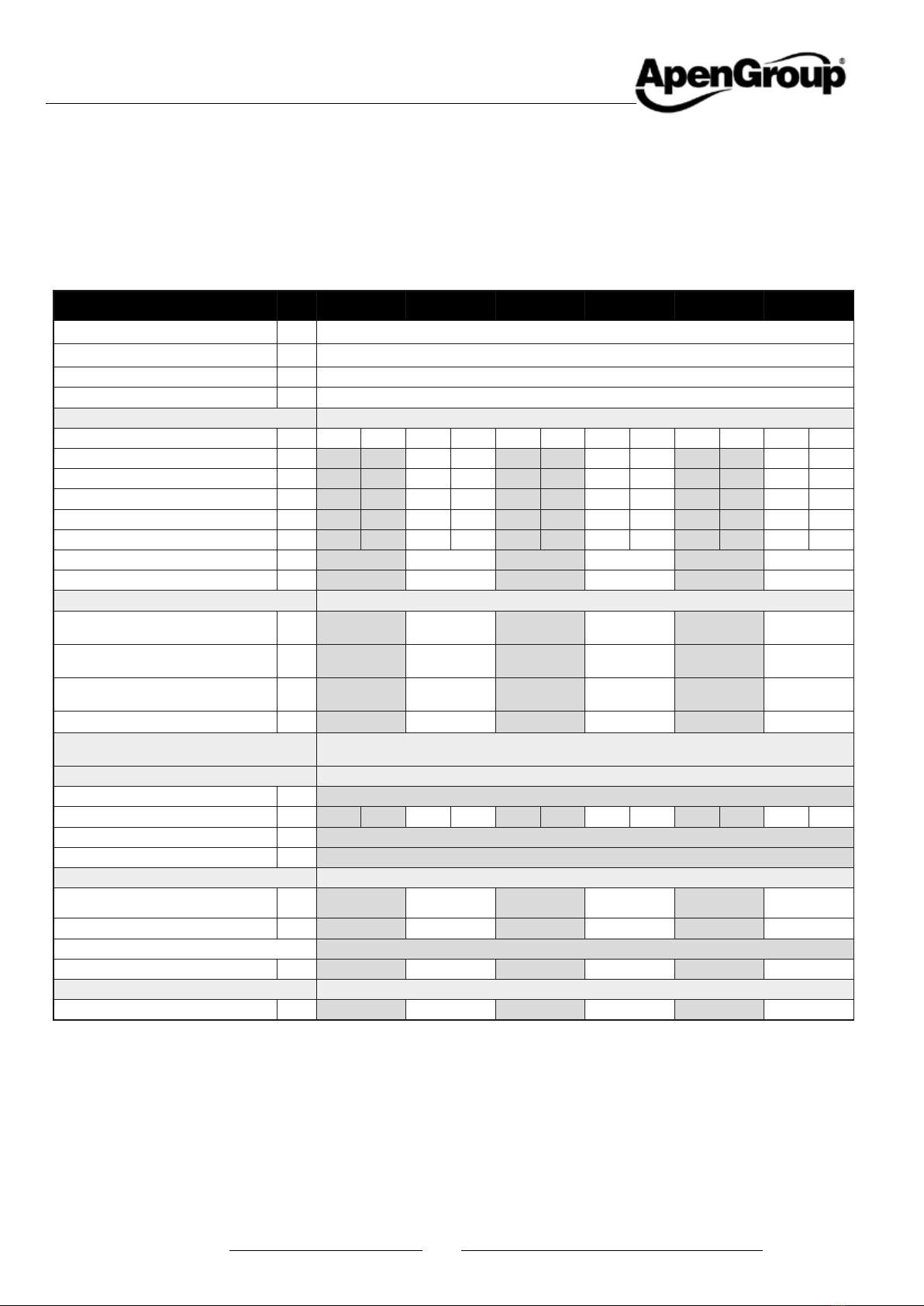

Condensing warm air heater module PCH

4

cod. HG0131.10GB ed.A-2205 PCH 5cod. HG0131.10GB ed.A-2205

PCH

1. GENERAL CAUTIONS

This manual is an integral part of the product and must always

accompany it.

Should the equipment be sold or passed on to someone else,

always make sure that this manual is supplied with the equipment

for future reference by the new owner and/or installer.

The manufacturer shall not be held civilly or criminally responsible

for injuries to people or animals or damages to things caused

by incorrect installation, calibration and maintenance or by

failure to follow the instructions contained in this manual or by

This product must be used only for the applications for which

it was designed or approved. Any other use must be regarded

as hazardous. Improper use may impair the operation, service

life and safety of the unit.

During the installation, operation and maintenance of the

equipment described in this manual, the user must always

strictly follow the instructions given in all the chapters of this

use and instruction manual.

The condensing warm air heater must be installed

in compliance with current regulations, according to

the manufacturer's instructions and by qualied sta,

technically specialised in the heating eld.

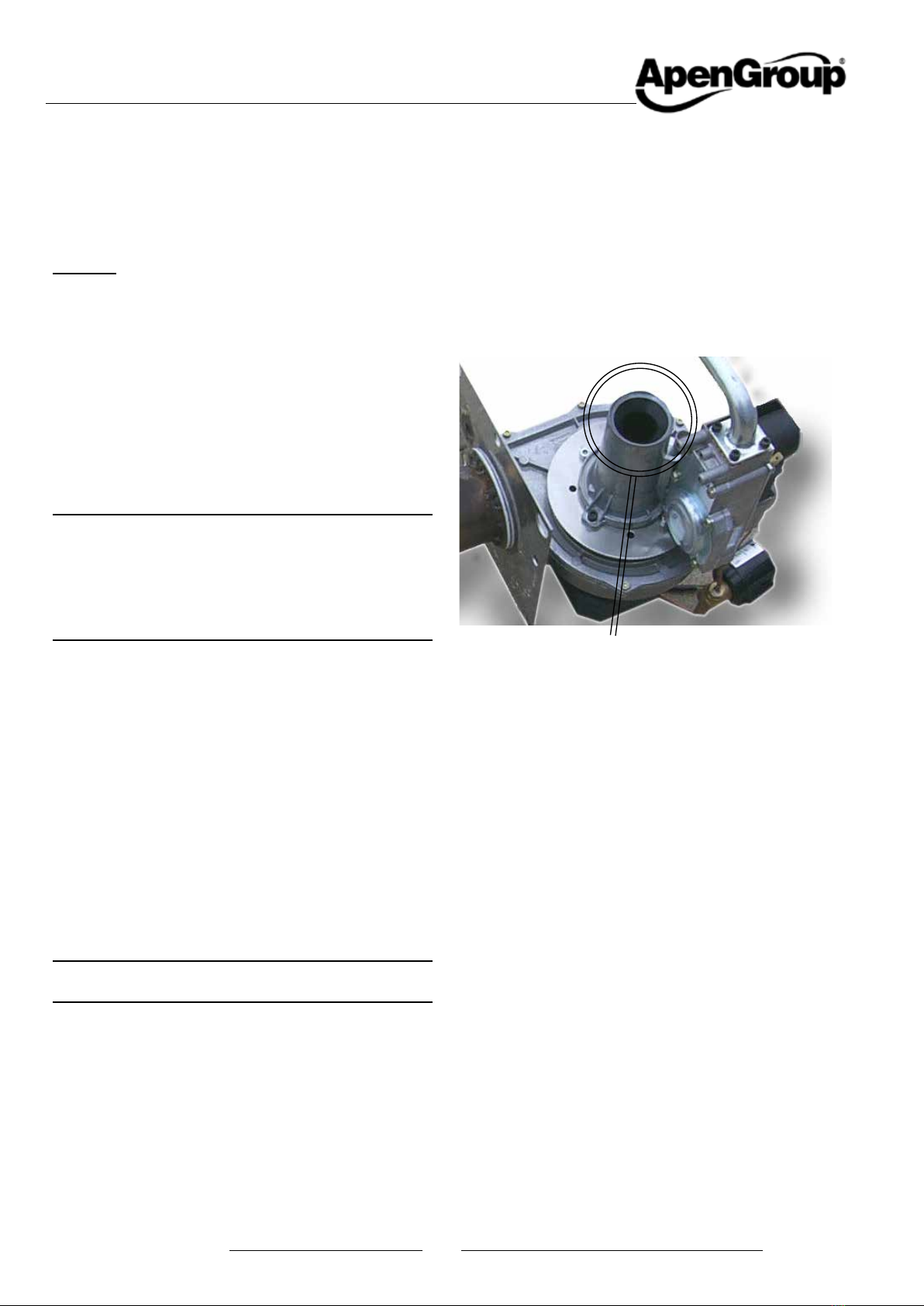

ATTENTION:Due to the physics of the thermal exchange

and the intrinsic functioning of the PCH modules, the

surface temperatures of the exchanger, as they depend

on dierent factors such as the installation of the module

inside the AHU/Roof-top unit and the dimensioning of

the air distribution ducts and/or terminals cannot be

guaranteed by the controls on board the PCH alone.

If the PCH modules are used in combination with

ammable or slightly ammable refrigerant gases (A2L),

precautions must be taken to ensure that accidental

refrigerant leaks do not lead to dangerous situations. In

case of doubt, please contact APEN GROUP SPA

maintenance operations must be carried out only by suitably

requisites required by the regulations in force in their country.

Maintenance must be carried out with methods and timescales

in compliance with the regulations in force in the country where

the appliance is installed.

For Italy, the “technical service” tab ofApen Group website www.

apengroup.com indicates several Technical Service Centres

and maintenance of the product carried out according to law

37/2007 (ex 46/90)

For more information, visit our website www.apengroup.com or

contact Apen Group directly.

supplied with this equipment.

2. SAFETY-RELATED WARNINGS

This chapter describes the safety instructions to be followed

by machine operators.

2.1. Fuel

Before starting up the heater, make sure that:

• the gas mains supply data are compatible with the data

stated on the nameplate;

•

• the combustion air is supplied in such a way as to avoid

even partial obstructions of the intake grille (caused by

leaves etc.);

• the gas seal of the feeding system has been tested and

approved in compliance with the applicable standards;

• the heater is supplied with the same type of fuel it has

been designed for;

•

applicable standards;

• the inside of the gas pipes and air distribution ducts for

ducted heaters have been thoroughly cleaned;

•

heater;

•

on the nameplate.

2.2. Gas Leaks

If you smell gas:

• do not operate electrical switches, the telephone or any other

•

to vent the gas out of the room;

• close the gas valves;

•

the unit;

• move away from the unit

• call for qualied sta.

• call the Fire Brigade.

NOTE: IT is strictly prohibited to supply gas to the circuit

with pressures higher than 60 mbar. Such pressures

could cause the valve to break