TruSteel AV30 User manual

Copyright © 2020 by TruSteel LLC. All Rights Reserved.

AV30 PRE-INSTALLATION

REQUIREMENTS

AV30 Pre-Installation Requirements

Version: 3.0

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

2 / 37

Table of contents

INTRODUCTION ................................................................................................ 3

AUTOVAP30 IMAGES ..................................................................................... 3

STAGE1: RECIEVE EQUIPMENT .......................................................................... 6

CHECKLISTS ................................................................................................. 6

EQUIPMENT MANIFEST .................................................................................. 7

STAGE 2: PLACE EQUIPMENT ............................................................................ 9

FACILITY LAYOUT ........................................................................................ 9

AV30 FLOW DIAGRAM ................................................................................. 10

STAGE 3: INSTALL ANCILLARY ........................................................................ 11

WATER HEATER INSTALLATION ................................................................. 12

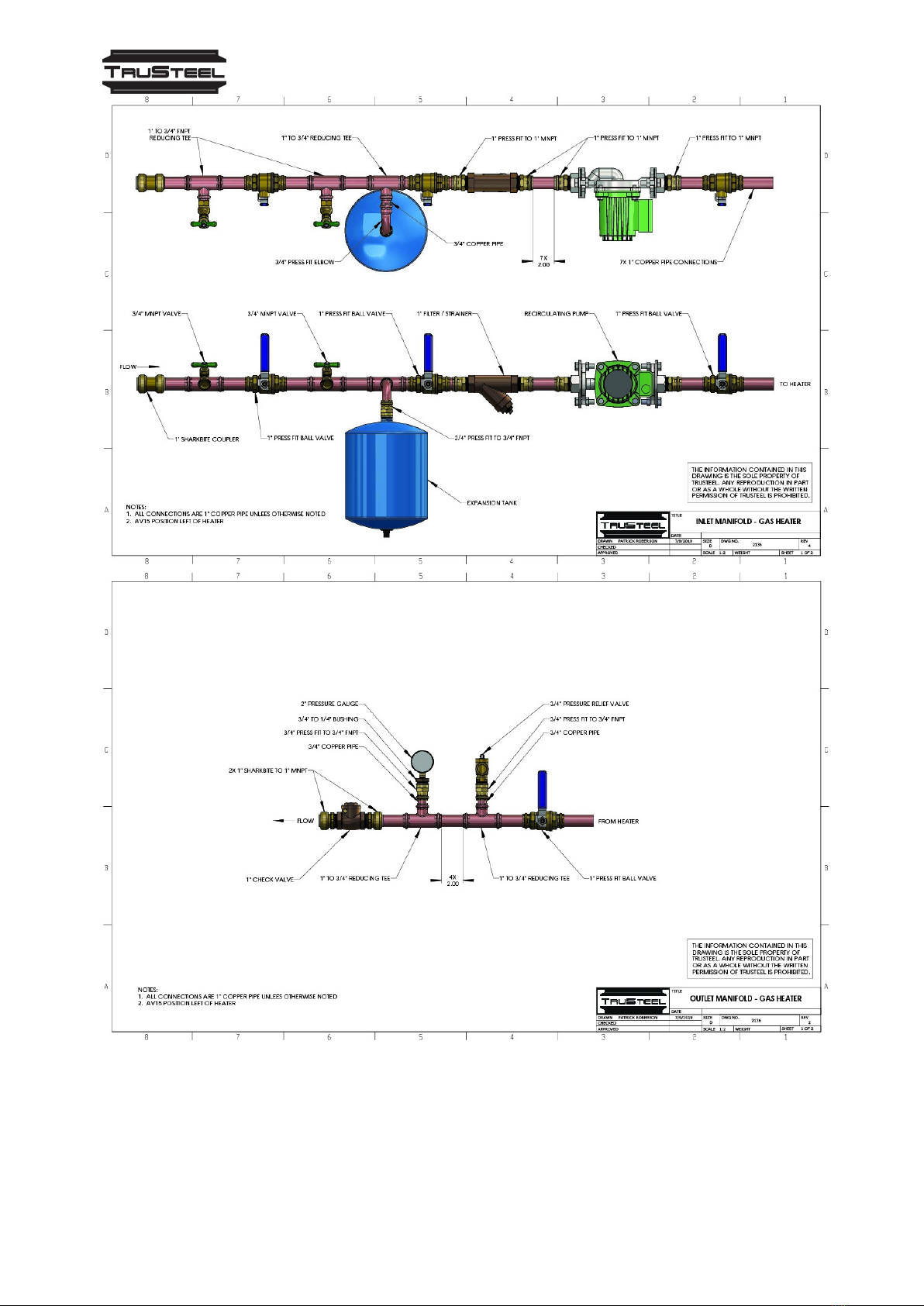

WATER HEATER MANIFOLD ..................................................................... 14

CHILLER INSTALLATION .............................................................................. 15

VACUUM PUMP INSTALLATION .................................................................... 17

STAGE 4: CONTROL PANEL WIRING ................................................................. 18

AutoVap30 System Startup ............................................................................ 18

Tools Needed .......................................................................................... 18

Check for loose connections ...................................................................... 18

Measure terminal resistance of the 3 motors (inside the PLC cabinet) ............. 18

Checking Voltage in PLC Cabinet ................................................................ 19

Powering on the Human Machine Interface (HMI) ........................................ 19

Contact Aqua Sierra .................................................................................. 20

STAGE 5: ASSEMBLE AV30 ............................................................................... 20

STAGE 6: PRIME WATER HEATER & CHILLER .................................................... 20

CHILLER FILLING & STARTUP ....................................................................... 21

System requirements ................................................................................ 21

Fill the Chiller .......................................................................................... 21

Troubleshooting ....................................................................................... 22

Alarm Reset Procedure ......................................................................... 22

b1AC Set Point .................................................................................... 23

ALc1 ALARM ON START-UP .................................................................. 24

Contact MTA ........................................................................................ 24

FILL & START WATER HEATING SYSTEM ...................................................... 24

Prepare Equipment ................................................................................... 26

Prepare To Fill PreHeater (Use Port #1) ...................................................... 26

Prepare To Fill Evaporator (Use Port #2) .................................................... 27

Allow Pressure To Rise In System .............................................................. 29

Power On Heater and Recirculating Pump and check system for leaks ............ 29

Adjust Pressure On System (To compensate for heat expansion) ................... 31

Contact Hubbell Support ........................................................................... 31

STAGE 7: VACUUM TEST AV30 ........................................................................ 31

STAGE 8: CLEAN SOLVENT RUN (VIDEO CALL WITH TRUSTEEL) ........................ 32

STAGE 9: TRUSTEEL TRAINING & IQ/OQ .......................................................... 33

APPENDIX ....................................................................................................... 33

REQUIRED COMMODITIES ........................................................................... 33

AV30 REQUIREMENT CHECKLIST .................................................................. 34

CONTACTS ................................................................................................. 37

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

3 / 37

INTRODUCTION

Congratulations on your TruSteel equipment purchase! We here at TruSteel are sure you're

going to be impressed at how efficient the the AutoVap recovers your solvent and how EASY

the system is to use.

But, before your AutoVap30 can be installed and run at maximum efficiency, we have to be

sure that your facility is properly set up with all the equipment TruSteel provides you with.

By following the requirements throughout this checklist, you can be sure you will have a quick,

easy install and your AutoVap system will run great for years to come. Setting the stage

properly the first time will save you valuable time and money in the future.

Please take the time to carefully review this manual and refer to it throughout your AutoVap

pre-Installation process.

It is suggested, but not required, to place all ancillary equipment (water heater, chiller, vacuum

pump, PLC) outside of your C1D2 solvent recovery lab.

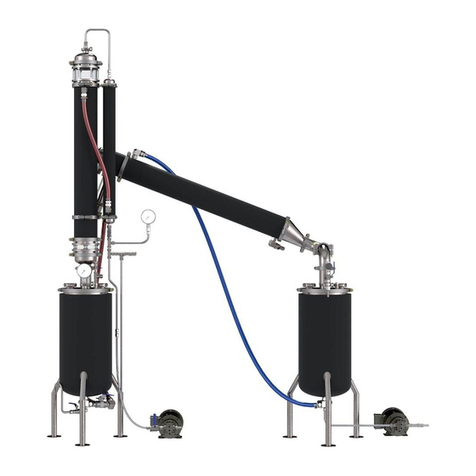

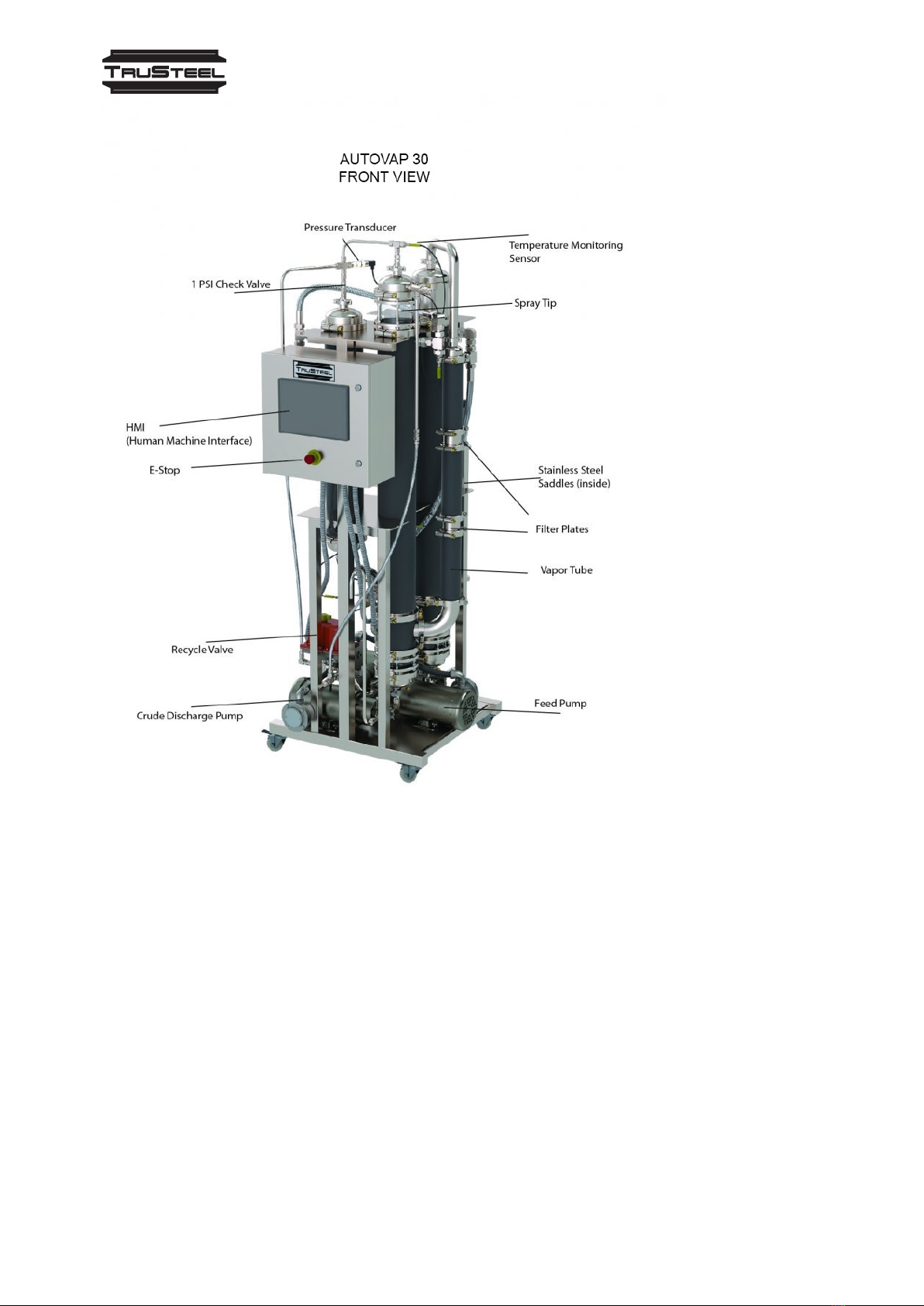

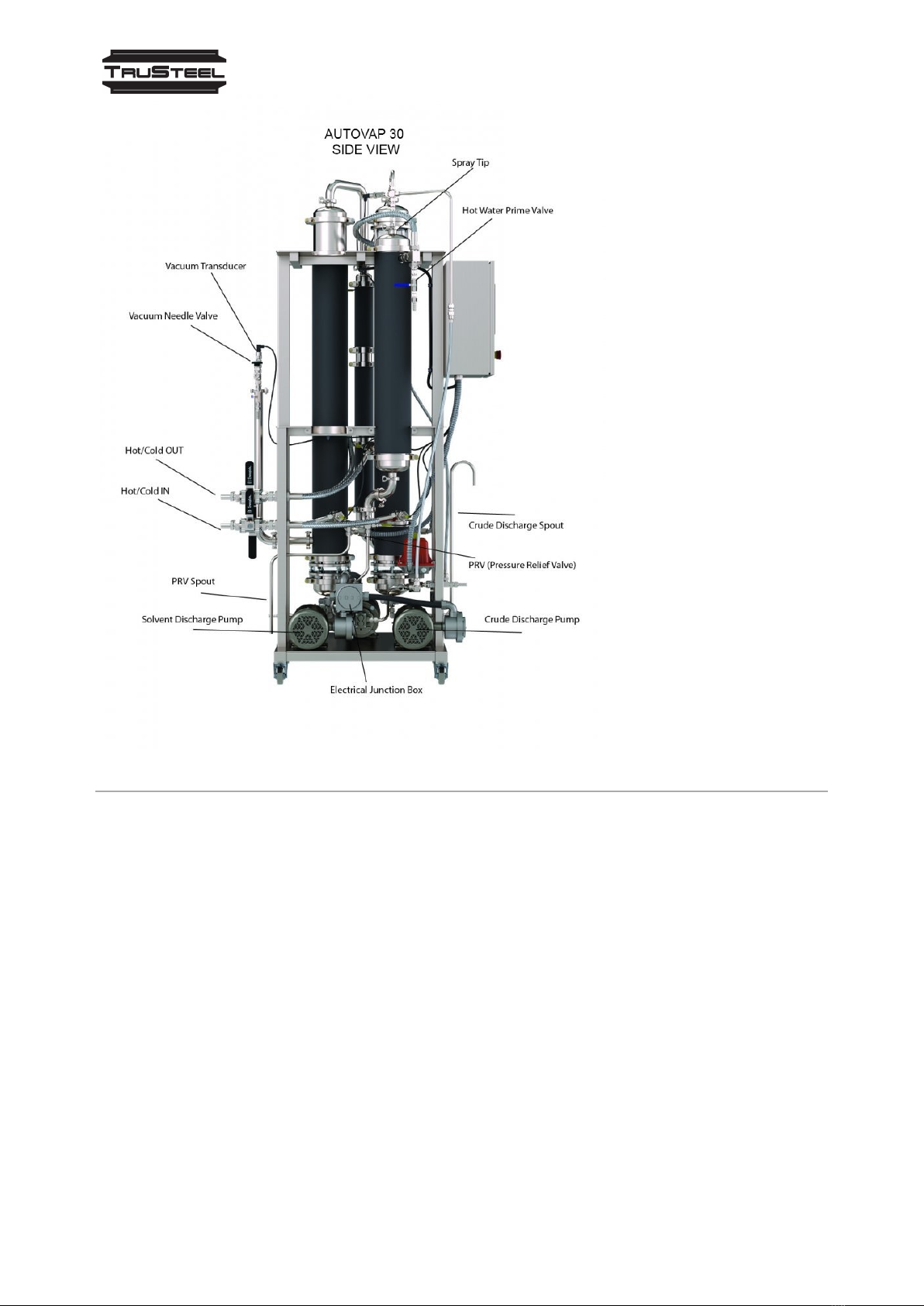

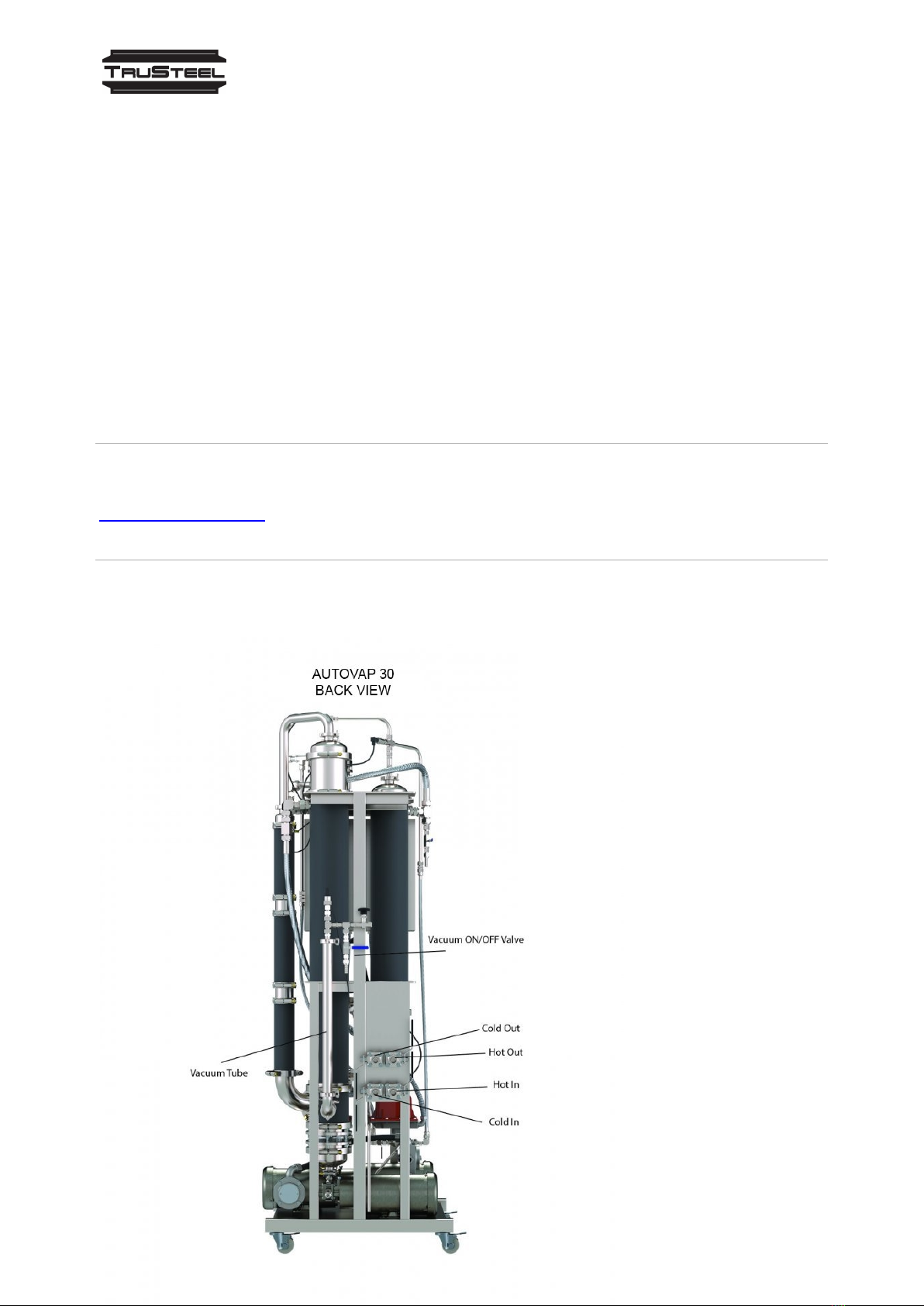

AUTOVAP30 IMAGES

The AV30 is the most efficient solvent recovery system when comparing throughput to

footprint.

With built in fail safes, alarms, data logging, and remote access, the AV30 stands alone as the

leader in the industry.

How the AutoVap30 Works

The AutoVap30 works by pumping your tincture up through a preheater before being

atomized through a sprayer. The material than falls through a heated, jacketed exchanger

where the solvent evaporates, and is "pulled" by vacuum into the condenser exchanger

which is cooled from a chiller.

The "crude" material is automatically discharge through a pump and the solvent is re-

condensed and automatically discharge through the solvent discharge pump.

The AutoVap30 has a easy to use cleaning cycle to ensure the longevity of your

AutoVap30 system.

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

4 / 37

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

5 / 37

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

6 / 37

STAGE1: RECIEVE EQUIPMENT

CHECKLISTS

Use the following checklists to keep track of your projects progress. Please print each of

the following checklists for your records.

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

7 / 37

EQUIPMENT MANIFEST

Use this checklist as a manifest to ensure all equipment is delivered and on site.

Chiller

Your chiller will most likely be shipping directly from the manufacturer via LTL freight.

TruSteel will provide tracking when available.

Please check the delivered chiller for damage before receiving.

Chiller Model #:

Chiller Serial #:

☐ Chiller Arrived With No Damage

☐ Expansion Tank

☐ Remote Control

Water Heater

The heater unit will be delivered directly from the manufacturer. Please be aware that

the heater will take at least 2 weeks to be manufactured.

Tracking will be provided when available.

Heater Model #:

Heater Serial #:

☐ Electric Water Heater Arrived

Manifold Package

The manifold package will be shipped directly from TruSteel. It will

include: VFD [Variable Frequency Drives], Taco Recirculating Water Pump, Chiller Bypass

Manifold, Water Heater Manifold.

Note: If we determined are using your own chiller, or heater, we may not need to send

this package.

☐ Heater Manifold Pieces: Pressure Release/Gauge Section (Medium), Fill Port/Filter

Screen Section (Big)

☐ Expansion Tank (Blue Tank)

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

8 / 37

☐ Taco Pump (Green Recirculating Pump) and Flange Set

☐ Chiller Bypass Manifold

☐ Taco Pump Ball Valve (Small)

☐ (4) Hose Barbs

☐ (4) Sharkbite Valves

Inline Pump

Model #:

Inline Pump

Serial #:

Vacuum Pump

Vacuum Pump

Model #:

Vacuum Pump

Serial #:

☐ Vacuum Pump Received

AutoVap30 and Control Panel (2 Separate Crates)

Control Panel

Model #:

Control Panel

Serial #:

☐ AutoVap30 & Control Panel Received

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

9 / 37

STAGE 2: PLACE EQUIPMENT

Important things to consider when placing your equipment:

1) The chiller exhausts a large amount of hot air. We highly suggest placing the chiller

outside of your facility, either on a concrete slab or on the roof. If this is not possible,

please confirm with the chiller manufacturer if your facility has adequate air flow and

space for the chiller to run inside. Placing an HVAC exhaust system on the chiller is also

an option for indoor use.

2) The water heater is a crucial part of your AV30 system. It is important to get

maximum efficiency out of your water heater. The flow rate of the water heater will be a

determining factor of the efficiency of the heat as the AV30 recovers solvent.

To ensure maximum flow rate, the water heater should be placed as close to the AV30 as

possible and the plumbing should have a few 90 degree turns as possible. The plumbing

run should have as little vertical differential as well.

3) The recirculating water pump, which is part of the water heater manifold, is what

essentially powers on the water heater each day. It is advised to have your electrician

connect this pump to a wall switch that is easily accessible by your operators.

4) The vacuum pump, similar to the recirculating pump, should be placed on it's own wall

switch for convenience. Note: place on a separate wall switch from the recirculating

pump.

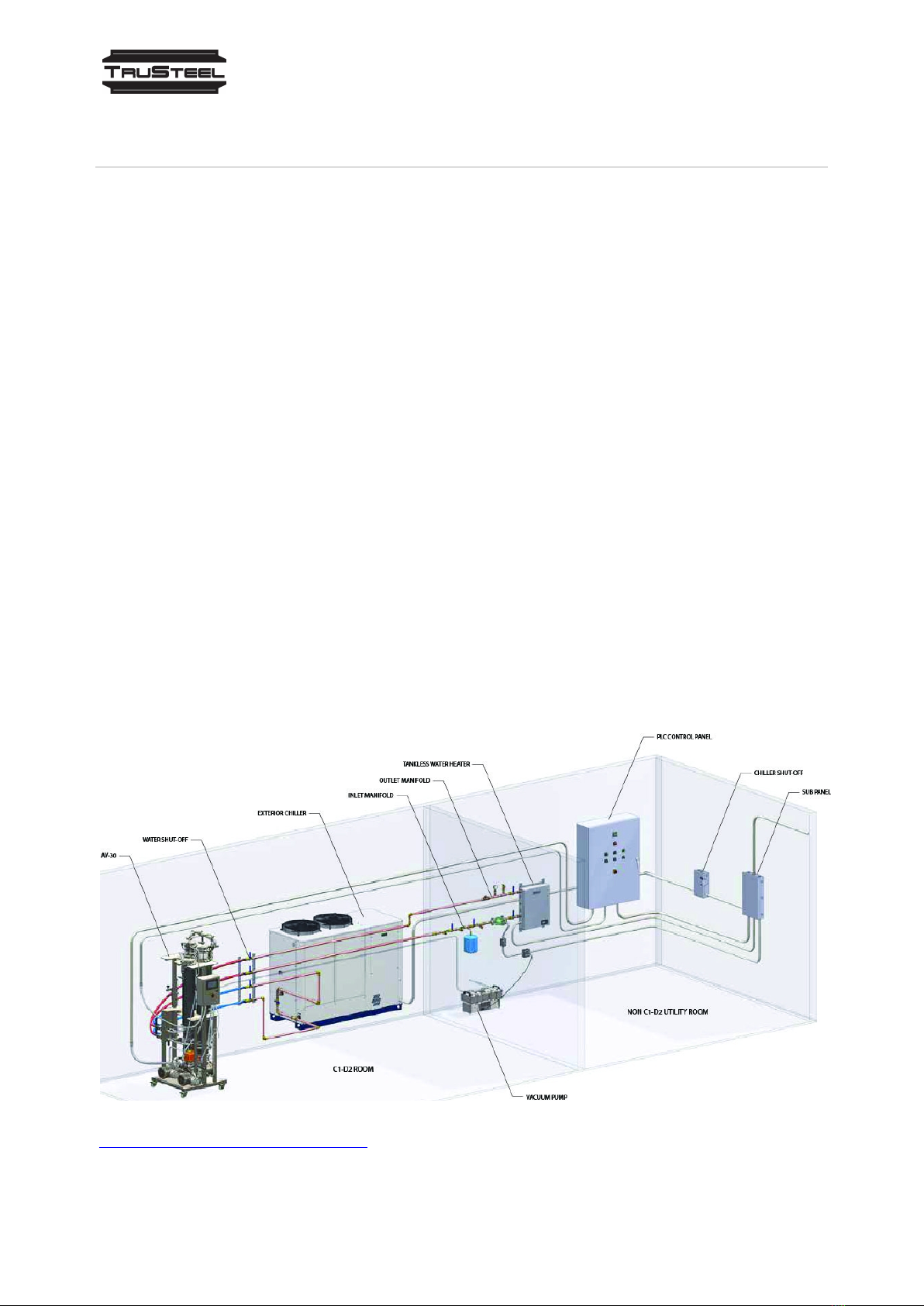

FACILITY LAYOUT

CLICK HERE FOR PDF VERSION

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

10 / 37

This layout diagram is only a suggestion to how a facility could lay out. The customer is

responsible for consulting with their local fire marshal in order to ensure code

compliance. TruSteel is not responsible for setting up the customer facility in order to

comply with any local codes.

The AutoVap30 is C1D2 compliant. The ancillary, however, is not and should be placed

outside of the solvent recovery room.

The chiller unit should be placed in a well ventilated area, preferably outside of the

facility in the open air (on a concrete slab or on the roof).

The chiller should be within 50 feet of the AutoVap30 unit in order to be most efficient.

The water heater should be placed outside of the C1D2 room. The electric water heater

does not require ventilation, while the gas heater will require proper ventilation. The

water heater, ideally, should be within 30 feet of the AutoVap30 for full efficiency.

The vacuum pump, AutoVap30 PLC, and heater manifold inline pump should all be

outside of the C1D2 solvent recovery room.

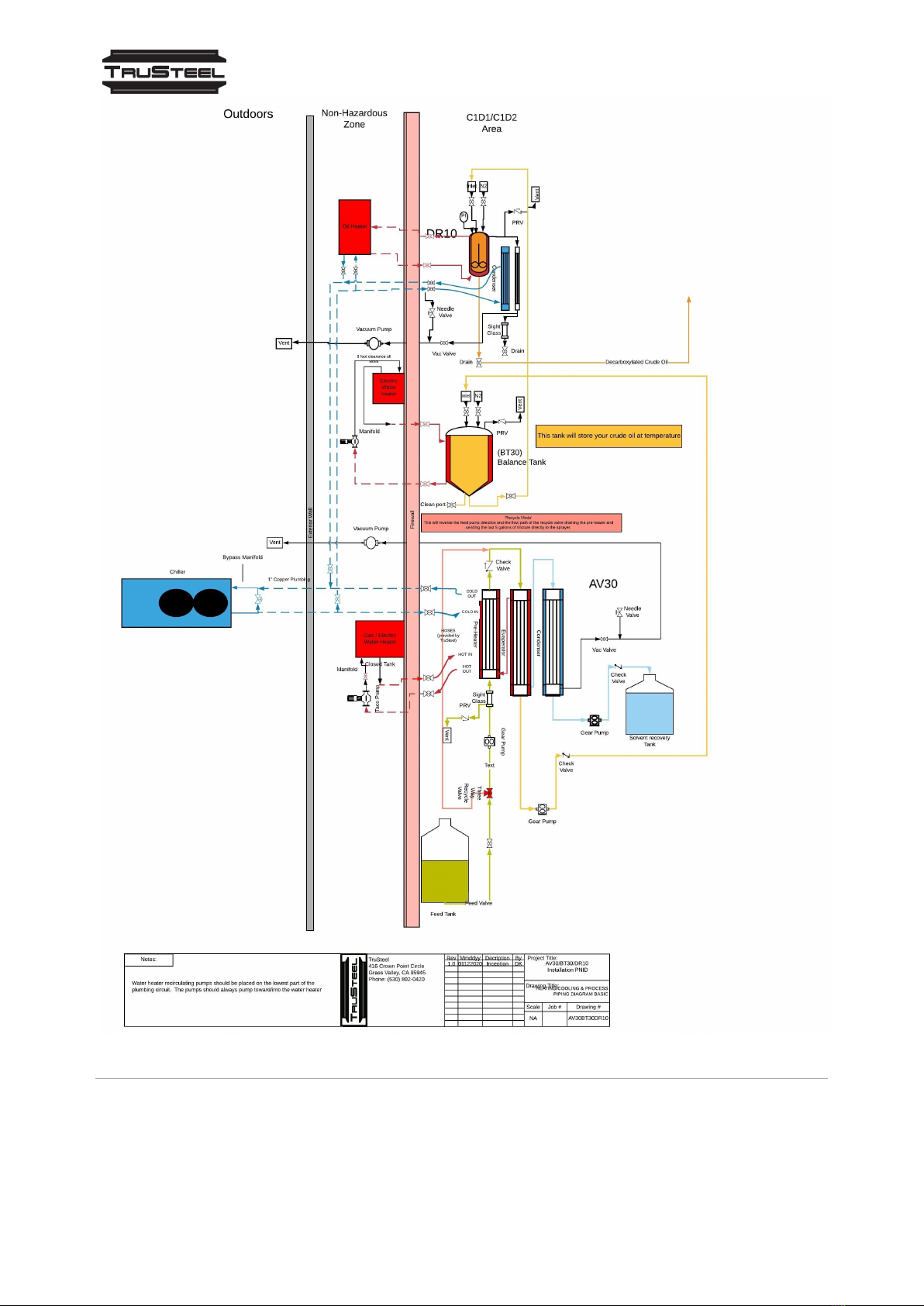

AV30 FLOW DIAGRAM

Click here for PDF Version of AV30 Flow Diagram

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

11 / 37

STAGE 3: INSTALL ANCILLARY

This section provides important information for each piece of equipment that needs to

be installed. Most equipment will have manuals with them when they arrive, but we

have also provided links to the manuals and, in some cases, some extra installation

materials.

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

12 / 37

WATER HEATER INSTALLATION

[Picture Caption: Hubbell HX Electric Water Heater (left), Hubbell NX Gas Water

Heater (right)]

ELECTRIC WATER HEATER: Model HX

Tankless Electric Water Heater

Available in 33-36 KW Three Phase Voltages

The Hubbell model HX Tankless electric water heater is a highly reliable and easily

maintained heater designed for operation in a commercial or industrial application.

The Hubbell HX Tankless heater is compact, extremely efficient, takes up minimal

space and reduces operating costs.

Electric Water Heater Technical Documents

·Model HX / TX Brochure PDF

·Model HX / TX Written Spec PDF

·Model HX / TX O&M Manual PDF

GAS WATER HEATER: Model NX300

Tankless Electric Water Heater

Available in 33-36 KW Three Phase Voltages

The Hubbell model HX Tankless electric water heater is a highly reliable and easily

maintained heater designed for operation in a commercial or industrial application. The

Hubbell HX Tankless heater is compact, extremely efficient, takes up minimal space and

reduces operating costs.

Important Note!! Gas Heater will require an external flow switch AND an strap-on

aquastat. Your plumber can provide these or you can purchase them below.

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

13 / 37

Where to Purchase:

1) Flow Switch

2) High or Low Limit & Circulator Strap-On Aquastat

Gas Water Heater Technical Documents

·Hubbell Model NX Brochure PDF

·Hubbell NX O&M PDF

·Hubbell NX300 Submittal Sheet PDF

·Model NX300 Spec PDF

Water Heater Requirements

See Water Heater Requirements (Section AV30 REQUIREMENTS CHECKLIST)

Link To Helpful Video

Important Information

1. For C1D2 compliance, the water heater should be placed OUTSIDE of the room that

the AutoVap will be running in. The heater is NOT C1D2. Place the heater on

the outside of the wall from the AutoVap with the manifold attached, and then plumb

your copper (NO FLUX), or PEX, through the wall, into the room.

Important Note: The closer your heater, and the more direct the plumbing run is, the

more efficient your heater will work with the AutoVap. The flow rate of your closed loop

to the AutoVap is VERY important. A short, straight path will ensure a higher flow rate.

2. The heater manifold, provided by TruSteel, will be installed directly into the water

heater. To Install Manifold:

a. Remove plastic pex fitting inside of the Sharkbite fitting on the water heater

inlet and outlet.

b. Insert straight copper end into Sharkbite fitting.

c. Make sure manifold is securely mounted with unistrut

3. The copper (NO FLUX) will be run to the shark bite side of the ball valves provided.

The ball valves are mounted on a unistrut.

4. The TACO inline water pump will be used to recirculate the water in the system. This

will essentially power up the heater since it needs flow to run.

We suggest putting the Taco pump on wall switch, rather than a plug outlet, for

convenience. This will essentially be your on/off switch for your heater since the flow

powers up the heater.

Be sure the Taco pump is facing the correct direction (the control panel should be facing

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

14 / 37

out from the wall) and the flow arrow should be going toward the water heater.

Commodities Needed By Customer

Needed to prime the system and for maintenance

1. You will need a sump pump (minimum 25 ft. head pressure) to prime the system.

Click Here to Purchase a Sump Pump (or see example)- Amazon.com

2. Short piece of garden hose, with hose fittings to connect sump pump to manifold

intake.

Click Here to Purchase (or see example) - Amazon.com

3. Distilled Water (about 20 gallons): You'll need around 50-60 gallons total, including the

chiller requirements.

4. ~35 gallon reservoir

Click Here to Purchase a Reservoir (or see example)-Amazon.com

Contact Hubbell Heaters

Call: (800) 647-3165

Or: (203) 378-2659

WATER HEATER MANIFOLD

The TACO Inline Recirculating Pump is part of the heater manifold that is supplied by TruSteel.

It is highly suggested to connect the power of the pump to a wall switch. Place the wall switch

in a convenient locati on for your facility operators. This pump essentially powers on the water

heater by supplying fl ow.

RECIRCULATING PUMP

MODEL ELECTRICAL HORSEPOWER UNIT DIMENSIONS

VR3452-HY1-

FC1A00 115V 1Ø 2.5A 1/100 to 1/4 See Submittal Data

Information

CLICK HERE FOR PDF VERSION

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

15 / 37

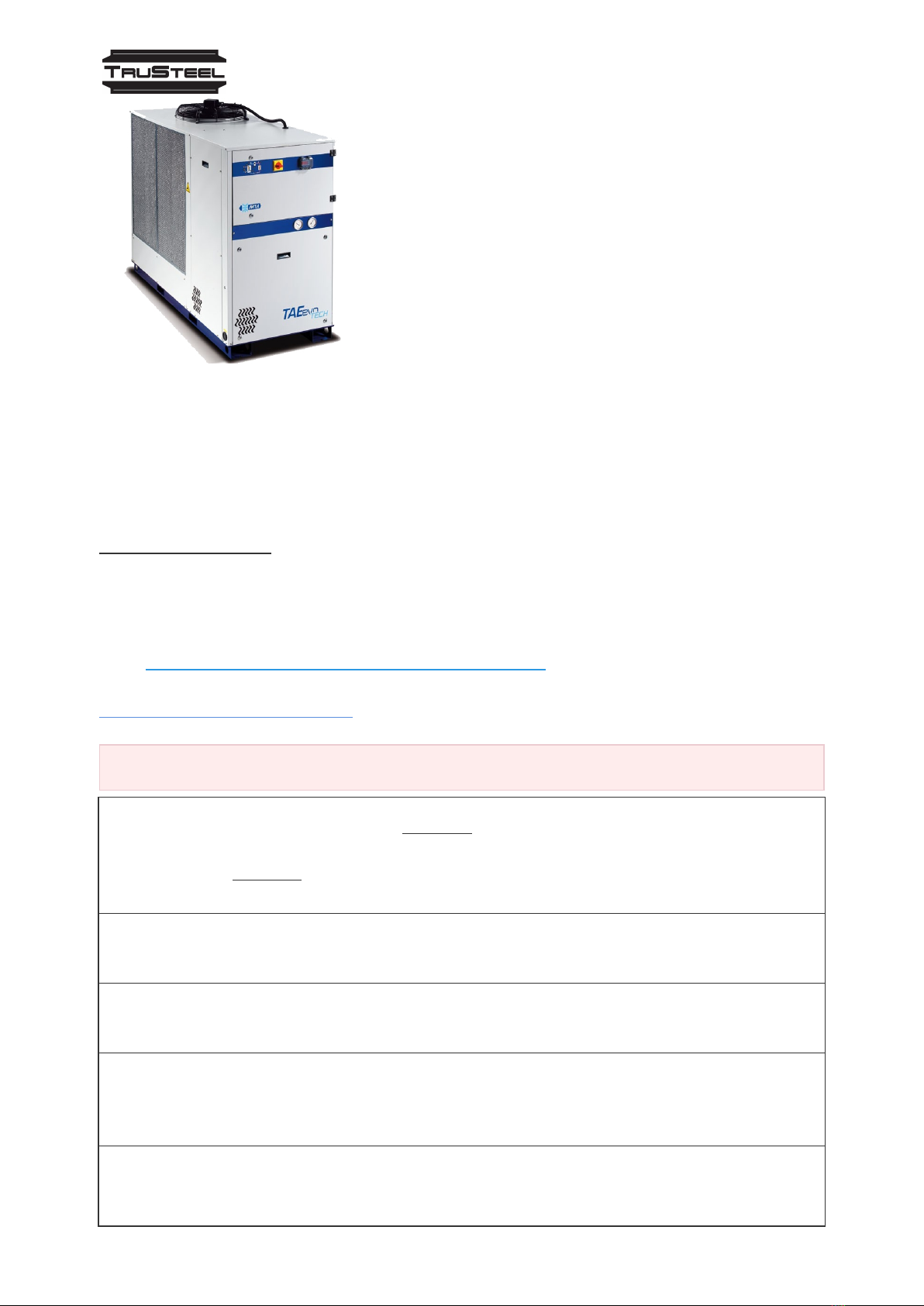

CHILLER INSTALLATION

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

16 / 37

MODEL TaeEvoTECH

Air Cooled Chillers

The TAEevo range of air-cooled chillers are a packaged unit

designed for industrial applicati ons. They are supplied with

hermetic scroll or reciprocati ng compressors and an

innovative finned pack evaporation inside the storage tank.

Technical Documents

Note: The installation instructions should be in the upper cabinet of the unit.

·Installation Instructions (PDF) [2 MB]

·Alarm Resets and Other Important Info (PDF) [5 MB]

SEE CHILLER REQUIREMENTS

Important Information

1. The chiller should be placed OUTSIDE of the facility, either on a roof, or a concrete

slab. If placed inside, proper HVAC ventilation is required. The

chiller CANNOT operate in a closed space; the unit dissipates a lot of heat. Please

contact MTA (Manufacturer) if you have any doubt of chiller placement.

2. The bypass manifold, provided by TruSteel, should be properly installed by a

plumber. Use plumbers dope AND plumbers tape.

3. The copper plumbing(Crimped or Push Connect – NO FLUX) will be run to the shark

bite side of the ball valves provided. The ball valves are mounted on a unistrut.

4. The chiller requires a propylene glycol/water mixture. Please refer to the

Installation Instructions to verify how much propolyene glycol your unit will require.

(Ratio is climate dependant) Link to Purchase

5. Please note that the chiller IS NOT powered by the AutoVap30 Control Panel. The

chiller is not controlled by the AutoVap30. The AutoVap30 only monitors, not

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

17 / 37

controls, the temperatures supplied by the chiller. If the chiller is not supplying

enough cool fluid, the AutoVap30 sensors will alarm you.

6. Don't forget to wire up your remote control for the chiller. The remote will make it

very convenient to put the chiller into STANDBY mode when not in use.

Helpful Information

Link To Purchase Propylene Glycol

Contact MTA for Installation Inquiries

West Coast Customer Service

Joel Gordon (206) 851-8456

jgordon@mta-usa.com

East Coast Customer Service

Jim Kirchoff (248) 880-4025

jkirchoff@mta-usa.com

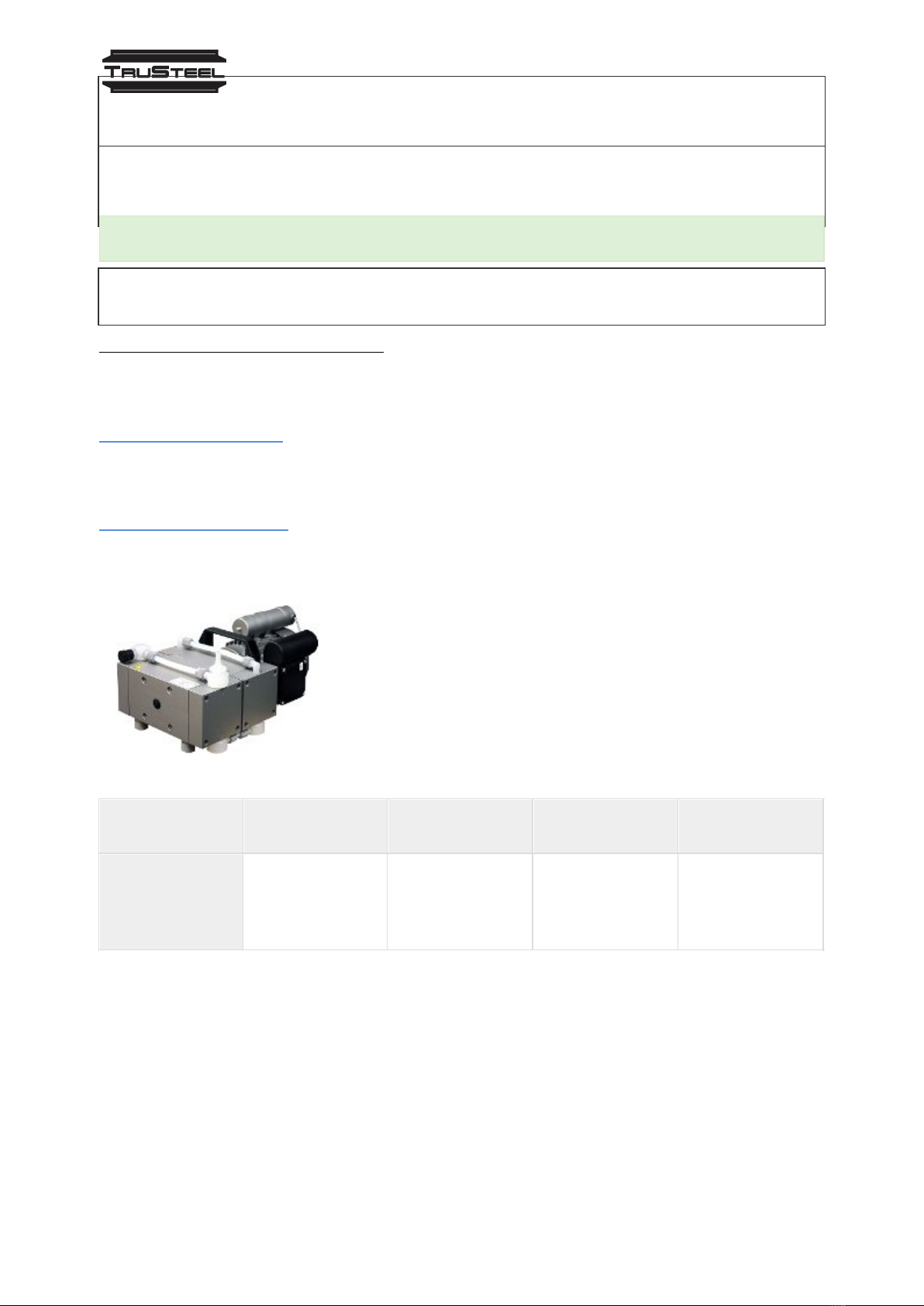

VACUUM PUMP INSTALLATION

Model Welch 2052

Welch 2052 2.3 cfm Full Chemical-Resistant 4-Head

Diaphragm Pump

The original Welch 2052 is a full chemical-resistant (not like

its cheaper version), 4-head, oil-free dry diaphragm vacuum

pump with all-PTFE contact surfaces and deep vacuum

capability. Oil-Free, portable, full chemical-resistant, means

less maintenance and no more frequent and costly oil

change, or cross contaminati on.

MODEL ELECTRICAL RE

QUIREMENTS PUMPING RATE UNIT DIMENSIO

NS WEIGHT

WELCH 2052

110V 60Hz

single phase

0.53 HP, 390

watts

2.3 cfm 9 × 15 × 7

inches 40.3 Lb

Vacuum pump is connected to AutoVap with a braided silicone hose (provided by TruSteel)

The customer may choose to run a discharge line from the vacuum pump in the event that

solvent gets “pulled” through the vacuum.

TruSteel suggests putting the vacuum pump on a wall switch to make easy on/off for facility

operators.

Technical Document

·Welch 2052 Operation Manual

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

18 / 37

SEE VACUUM PUMP REQUIREMENTS

STAGE 4: CONTROL PANEL WIRING

Technical Documents

·Technical Wiring Diagram

Helpful Links & Important Information

Purchase Link For K-Type Wire

Your electricianshould provide youwithall the wiring and conduit.

ContactAqua Sierra for Support, Call: 530.823.3241

SEE CONTROLPANELREQUIREMENTS CHECKLIST

Link To Help Video

AutoVap30 System Startup

WARNING! DO NOT TURN ANY POWER ON BEFORE CHECKING

VOLTAGE AND MEASURING TERMINAL RESISTANCE

Tools Needed

·Volt/Ohm multimeter

·Small terminal block screwdriver

·Standard flat head screwdriver

·½” wrench

·⅝” wrench and/or ⅝” ratchet and socket

·⅞” wrench

·13/16” wrench

·Wire strippers

·Crescent wrench

Check for loose connections

Start by checking the wire connections made inside the Operator Panel(HMI) and in the PLC cabinet.

Pull softly but firmly on each of the wires for the 24v inputs and for VFD motor leads.

Reconnect any loose wires.

Measure terminal resistance of the 3 motors (inside the PLC cabinet)

Using a multimeter, measure the resistance(ohms) of the terminals to make sure that the motors are

landed correctly in the junction box.

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

19 / 37

If all three resistance readings for each pump are relatively close then the motor wiring in the

junction box is most likely correct.

Test each pump individually and as follows:

Using your multimeter put one test lead on U and the other on V. Note the resistance. Then leave the

lead on U and put the other lead on W. Note the resistance. Lastly, leave the lead on W and put the

other lead on V. Note the resistance. Do this for all 3 pumps. (See resistance ranges below for

reference)

**If one of the three readings has a difference of more than 0.5 ohms. Check motor wiring at junction

box.

Resistance Ranges:

Residue Pump

U1A-V1A = 8-10 ohms

V1A-W1A = 8-10 ohms

W1A-U1A = 8-10 ohms

Ethanol Pump

U2B-V2B = 8-10 ohms

V2B-W2B = 8-10 ohms

W2B-U2B = 8-10 ohms

Feed Pump

U3C-V3C = 8-10 ohms

V3C-W3C = 8-10 ohms

W3C-U3C = 8-10 ohms

Checking Voltage in PLC Cabinet

***WARNING! DO NOT POWER ON THE MAIN BREAKER UNTIL YOU VERIFY THE CORRECT VOLTAGE

(208-240V)

Measure (A phase-B phase) leg-to-leg by testing the two wires landed in the top side of Main

Breaker(CB1) with your multimeter. Make sure you have 208-230v. If you don't have the proper

voltage, first make sure the breaker or disconnect for PLC is powered “ON”. If you still don't have the

correct voltage(208-230V) STOP and get an electrician for assistance. DO NOT CONTINUE UNTIL YOU

RESOLVE THE ISSUE AS YOU COULD POSSIBLY DAMAGE THE PLC.

After confirming the correct voltage, check that all Circuit Breakers in the PLC are set to “OFF” or

Green(safe).

Make sure all circuit breakers are set to “OFF/GREEN”. Once all circuit breakers are off, turn on Main

Breaker(CB1).

Test the 120V wiring in the PLC cabinet with your multimeter by touching one lead to the Neutral and

the other lead to the top side of Circuit Breaker # 5 (CB5). It is located in the top left side of the PLC

cabinet.

If 120v is present you may turn on all circuit breakers and can now power on the HMI. If 120V is not

present, STOP and call Aqua Sierra.

Powering on the Human Machine Interface (HMI)

AV30 PRE-INSTALLATION REQUIREMENTS | AV30 Pre-Installati on Requirements | v. 3.0

20 / 37

Make sure the jumper wire in the PLC is removed. Itʼs landed in terminals +24Q and +24R.

For the HMI to power up, terminals +24O and -24V must be landed in both the HMI and PLC panels.

Pull out the 2 the E-Stops to start the AutoVap. One is on the PLC cabinet and one is on the HMI.

If HMI powers up but does not display any data this means that PLC is not communicating with the

HMI. Check the ethernet cable connections and re-crimp each end if necessary.

Contact Aqua Sierra

For questions/concerns/troubleshooting the PLC or HMI, please call Aqua Sierra (located

in Pacific Standard Time)

Call: 530.823.3241

STAGE 5: ASSEMBLE AV30

Link to Video Online

STAGE 6: PRIME WATER HEATER & CHILLER

Before proceeding to fill the water heater and chiller, you must have the RED and BLUE

hoses connected to the AV30.

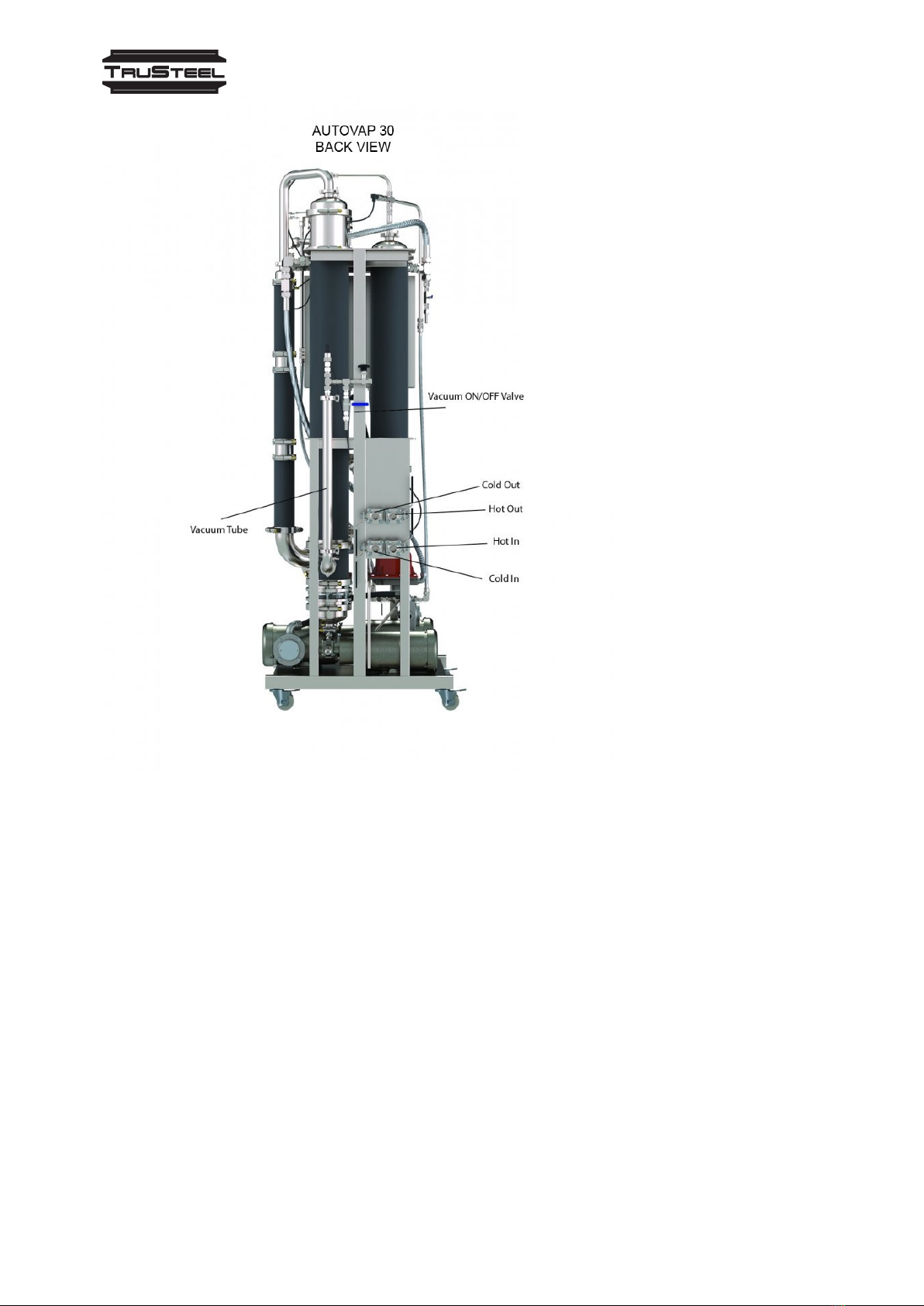

In the image of the

AV30, locate the Cold

Out and Cold In. These

will be the BLUE hose

connections to/from

the chiller.

Cold In: From the chiller

Cold Out: Back to the

chiller

In the image of the

AV30, locate the Hot

Out and Hot In. These

will be the RED hose

connections to/from

the water heater.

Hot In: From the water

heater

Hot Out: Back to the

water heater

Table of contents

Other TruSteel Industrial Equipment manuals