Toray NHP210 Series User manual

NIRE-170-1-6

Submerged Membrane Module

for MBR

TORAY “MEMBRAY”

“NHP210 Series”

Instruction Manual

Toray Industries, Inc.

Water Treatment Division

1-1, Nihonbashi-muromachi 2-chome, Chuo-ku, Tokyo 103-8666 Japan

Tel +81-3-3245-4542

Fax +81-3-3245-4913

URL www.toraywater.com

Published: August 2020

NIRE-170-1-6

Content

I. INTRODUCTION..................................................................................................................... 1

1. Features of MBR ................................................................................................................... 1

2. Outline of “NHP210 Series”................................................................................................... 2

II. FOR SAFE OPERATION OF “NHP210 SERIES” .................................................................. 5

1. Unpacking and Installation.................................................................................................... 5

2. Operation and Maintenance.................................................................................................. 6

3. Chemical Cleaning of Element.............................................................................................. 7

III. SPECIFICATIONS AND PERFORMANCE OF “NHP210 SERIES” ...................................... 9

1. Specifications of Element...................................................................................................... 9

2. Specifications of Filtrate Tube Assembly.............................................................................. 9

3. Specifications and Performance of “NHP210 Series” Module.............................................. 9

IV. MEMBRANE FILTRATION PROCESS DESIGN FOR “NHP210 SERIES” ......................... 12

1. Standard Time Chart........................................................................................................... 12

2. Flow Diagram of Membrane Filtration................................................................................. 13

3. Layout of “NHP210 Series” Modules in Membrane Tank................................................... 18

4. Piping................................................................................................................................... 21

V. INSTALLATION OF “NHP210 SERIES”............................................................................... 24

1. Preparatory Procedure........................................................................................................ 24

2. Unloading/lifting Products.................................................................................................... 24

3. Checking Products .............................................................................................................. 25

4. Storage Products................................................................................................................. 25

5. Installation Products............................................................................................................ 26

VI. START OF OPERATION...................................................................................................... 30

1. Clean Water Operation........................................................................................................ 30

2. Seeding Sludge Injection..................................................................................................... 31

3. Actual Filtration Operation................................................................................................... 32

VII. OPERATION CONTROL...................................................................................................... 33

1. Standard Operating Conditions........................................................................................... 33

2. Operating Parameters......................................................................................................... 35

3. Basic Control Philosophy .................................................................................................... 35

4. Daily Inspection................................................................................................................... 37

VIII. MAINTENANCE OF “NHP210 SERIES” .............................................................................. 40

1. Maintenance Items and Maintenance Frequency............................................................... 40

2. Air Diffuser Cleaning............................................................................................................ 41

3. Chemical Cleaning of Element............................................................................................ 43

4. Chemical Agents Available for Chemical Cleaning............................................................. 43

5. Handling of Chemical Agents.............................................................................................. 44

6. Chemical Cleaning Procedure............................................................................................. 47

7. Lifting Procedure ................................................................................................................. 52

NIRE-170-1-6

8. Storage Products after Use................................................................................................. 53

9. Disposing Procedure........................................................................................................... 54

IX. REPLACEMENT PARTS LIST............................................................................................. 55

X. TROUBLESHOOTING.......................................................................................................... 56

XI. APPENDIX............................................................................................................................ 57

Symbols used in this manual

This symbol is used to indicate an imminent hazardous situation

which, if not avoided, will result in serious injury or death.

This symbol is used to indicate a potentially hazardous situation

which, if not avoided, can result in serious injury or death.

This symbol is used to indicate a potentially hazardous situation

which, if not avoided, may result in injury or property damage.

DANGER

!

WARNING

!

CAUTION

!

NIRE-170-1-6

1

I. INTRODUCTION

Toray "MEMBRAY" is the submerged membrane module suitable for the membrane

bioreactor (MBR) that has been developed based on the polymer science and the membrane

fabrication technologies accumulated for a long time in Toray Industries, Inc.

"NHP210 Series" is a new model of "MEMBRAY" equipped with thin membrane elements

having higher packing density, while reliable performance of Toray PVDF membrane has

been kept unchanged. This manual explains MBR's features and describes the specifications

of "NHP210 Series" and its safe operations including installation, operation, maintenance

procedures and peripheral equipment. Operators should thoroughly read this manual to

ensure stable operation.

1. Features of MBR

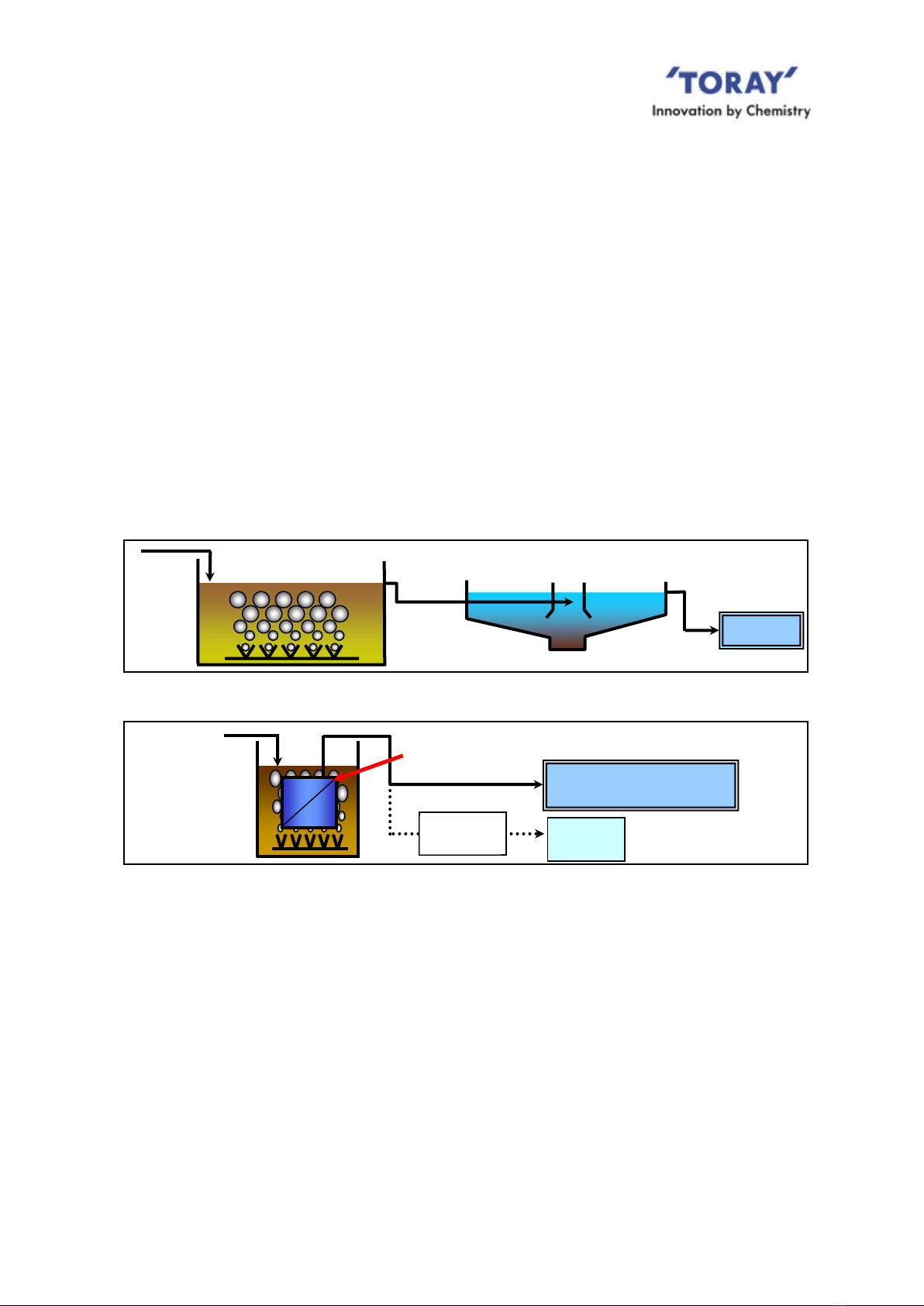

The process flow of the conventional activated sludge system (CAS) and MBR are shown in

Fig.I-1 and Fig.I-2, respectively.

MBR provides the following advantages:

(1) Small Footprint

Unlike CAS, MBR separates sludge within aeration tank using membranes, thus eliminate

the space for preparing sedimentation tank. Also with membrane, MBR can hold higher

concentration of activated sludge in the aeration tank, so its volume can be reduced. As a

result, MBR provides smaller footprint compared to CAS.

(2) High quality of treated water

MBR removes suspended solid (SS) from the sludge liquid with membrane much more

Sedimentation Tank

Waste

water

Aeration Tank

Discharge

Wastewater

Discharge or Reuse

Reuse

RO

membrane

Submerged Membrane

Module

Membrane

Tank

Fig. I-1 CAS Flow

Fig. I-2 MBR Flow

NIRE-170-1-6

2

certainly than conventional sedimentation process. MBR also rejects microorganisms such

as Escherichia coli and Cryptosporidium efficiently.

2. Outline of “NHP210 Series”

“NHP210 Series” is the membrane module composed of the element block and the aeration

block. The element block contains a number of cassettes and in the cassette membrane

elements are stacked at equal clearance, each of which has flat sheet membrane on both

sides. Each element is connected via plastic tube to the filtrated water manifold. The aeration

block consists of coarse-bubble air diffusers to supply scouring air (see Fig.I-3).

This module is used submerged in sludge liquid.

The following shows the features of “NHP210 Series”.

Fig. I-3 Components and appearance of “NHP210-300S”

Nozzle

Filtrate water manifold

Tubes

Module

Frame

Cassette

Element

50 sheets

Element

block

Aeration

block

Coarse

bubble

diffuser

6 pcs

NIRE-170-1-6

3

(1) Shape of Element

The membrane element is a flat sheet type as shown in Fig.I-4. At the normal filtration

operation, the sludge accumulated on the membrane surface is cleaned up effectively with

upward water stream generated with the scouring air supplied from the air diffusers installed

at the bottom side (Fig.I-5). This mechanism ensures stable filtration, since the membrane

does not easily admit of sludge adherence to its surface.

In addition, thin membrane element makes it possible to have higher membrane packing

density in the module similar to that of hollow fiber membrane, and also to improve

membrane cleaning efficiency thanks to vibration of elements by scouring air.

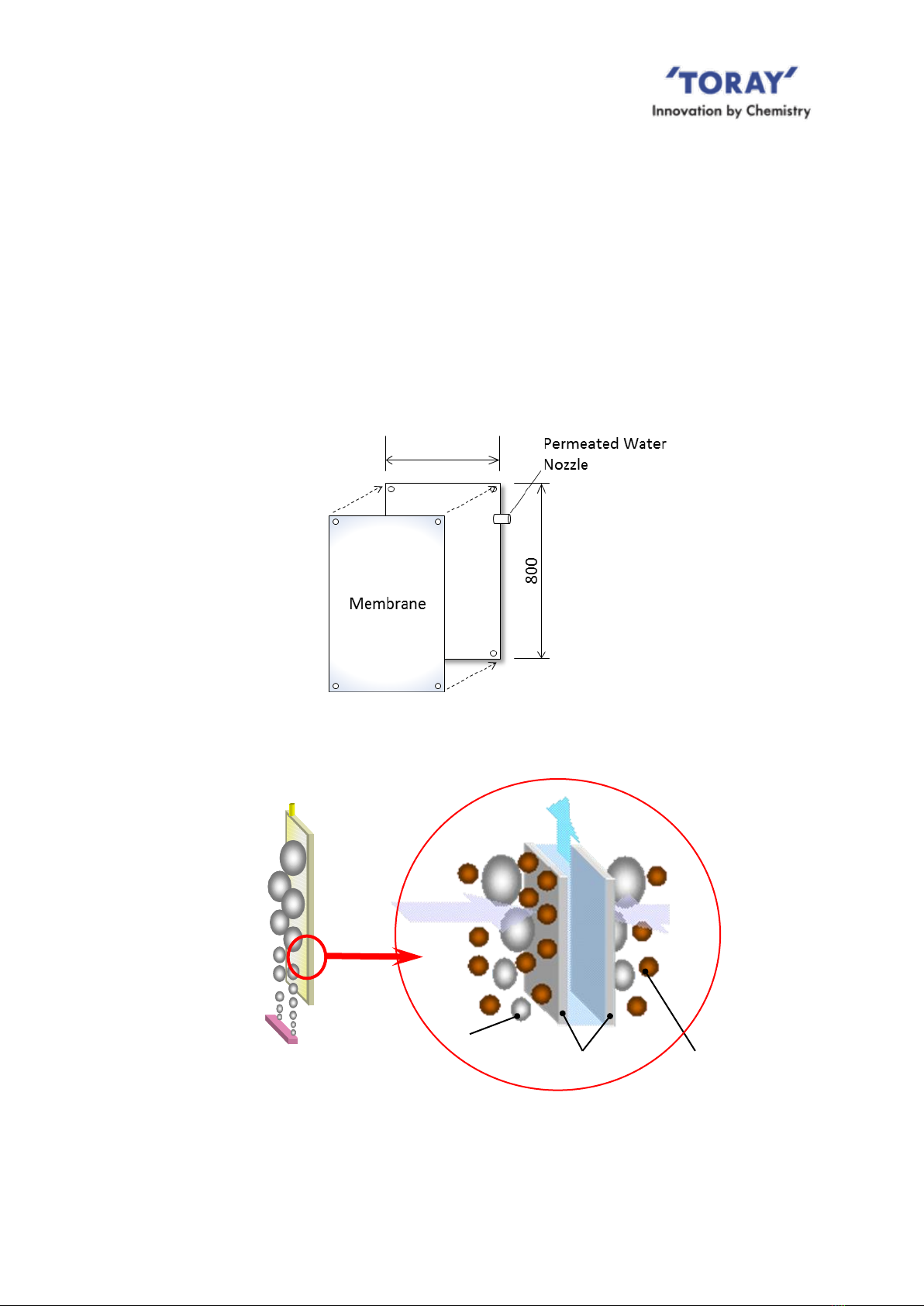

Fig. I-4 Structure of Element

Fig. I-5 Filtration Principle of Activated Sludge

Air

diffuser

Element

Filtrated water

Activated sludge particle

Membrane

Air

480

NIRE-170-1-6

4

3.0 micron

Fig. I-6 Membrane Surface

(photo)

Fig. I-7 Pore Size Distribution

(2) Membrane Structure

The flat sheet membrane consists of PVDF (Polyvinylidene Fluoride) functional layer and the

base layer of PET (polyester) non-woven fabric. This structure gives the membrane superior

physical strength and high chemical resistance.

(3) Membrane Pore Size

Numerous small-size pores are distributed evenly over the membrane surface with a sharp

pore-size distribution. This structure gives an outstanding high treated water quality and

excellent water permeability, making the membrane highly resistant to clogging (see Fig.I-6

and Fig.I-7) compared to other membranes. The average pore size is 0.08 micron meter.

Pore size (micron)

東レ

BF014

クボタ

0

0.5

1.0

1.5

0.2

0.4

0.6

0.8

0

Number of pore (1012/m2)

0.08 micron

NIRE-170-1-6

5

II. FOR SAFE OPERATION OF “NHP210 SERIES”

Before using “NHP210 Series”, please thoroughly read this Instruction Manual and follow the

instructions described in this manual, especially the safety precautions shown below. The

details of each precaution are described in the relevant chapter

1. Unpacking and Installation

When lifting “NHP210 Series”, attach chains or slings to the lifting

lugs. Slowly raise the module straight up. Avoid sudden changes in

movement to minimize shaking the module. Never allow

personnel to stand under the “NHP210 Series”during lifting

Use chains or slings rated for the weight being lifted. Check the

condition of each part before lifting. Never lift or operate the

module with worn or damaged parts.

When lifting double-decker module, do not lift upper element

blocks and lower element blocks as one unit. Lift the upper and

lower element block separately.

When installing “NHP210 Series”module, make provisions, in

advance, to access the upper portions of the membrane module

via a scaffold or ladder.. Do not climb on the module structure.

Never step on the air diffuser/manifold. Use protective equipment

to ensure the safety of workers.

Please wear the appropriate personal protective equipment (e.g.

work gloves) in order not to cut hand on the edge of the module

frame.

During transportation, storage and installation, take appropriate

measures to protect "NHP210 Series" or associated components

from damage. Do not put any heavy objects directly on the module.

Store the module in an area that will minimize the potential for

damage from moving equipment like fork lifts etc.

Exposing the “NHP210 Series” and membrane elements to

temperatures above 40 degree C or direct sun light should be

avoided. Exposure to direct sun light/UV radiation will cause the

polypropylene air diffuser/manifold to deteriorate.

Take adequate measures, during the installation process, to

protect the “NHP210 Series” from: sparks emitted from welding

equipment, fusion cutting or grinding.

Protect “NHP210 Series” from freezing at all time.

Avoid pressurizing the filtrate side of "NHP210 Series”.

DANGER

!

DANGER

!

DANGER

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

DANGER

!

CAUTION

!

NIRE-170-1-6

6

Install the screen with openings of 3.0 mm or under before the

membrane tank. Mesh type screen is recommended. Overflow or

waste carryover must be avoided at all time.

Connect the flanges of air diffuser/manifold to the piping with the

tightening torque of 20 N.m, in order to avoid distortion, leakage or

breakage of the plastic air diffuser/manifold.

Consider piping material and regulate the load to the flange

connection points less than 20 kg per flange, in order to avoid

distortion, leakage or breakage of the plastic air diffuser/manifold. If

the load is higher than the limit above shown, put some supports

on the piping to reduce the load.

2. Operation and Maintenance

Filtrated water is not for potable uses. Do not drink the MBR

filtrate.

Before discharging the treated water to the environment or reusing

it, make sure to analyze its quality and confirm that the water

quality meets the intended purpose.

Do not burn the membranes without appropriate facilities since

harmful Hydrogen fluoride (HF) gas will be generated. When

disposing of the membrane elements, hire a professional solid

waste disposal company to perform the task.

When first filling the membrane tank with clean water make certain

the air discharge valve is in the open position to assure any

accumulated air is released. After the tank is full with clean water

close the air discharge valve.

Do not use ground water for the initial filling of the membrane tank.

Ground water may contain considerable concentrations of iron,

manganese, calcium or silica. Naturally occurring compounds of

these elements can clog the membrane pores.

When using clean water in the MBR tank do not operate the

membranes any longer than is necessary to purge the system of

entrained air. Prolonged clean water operation can clog the

membrane pores.

Keep the membranes wet once they get wet. If the membranes are

allowed to dry out, the permeability of the membranes may be

permanently reduced.

When feeding the seeding sludge, be sure to pass the seeding

sludge through a screen to remove large foreign materials. It is

recommended that the screen mesh be 3 mm or smaller.

Make certain sufficient air is being supplied to the membrane

module air diffuser before operating in the filtration mode. Failure

to do so will result in the membrane becoming clogged.

WARNING

!

WARNING

!

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

NIRE-170-1-6

7

Do not allow chemicals, toxic agents, oils or any other substances

into the MBR tank that may adversely affect the condition of the

activated sludge.

When operating in the filtration mode, avoid abrupt changes to

especially pH, temperature and suction pressure, even if these

changes are within acceptable operating guidelines.

When it is obvious that a module part is worn and potential for

failure is high, promptly replace that part with approved

replacement parts.

Never expose the “NHP210 Series” to freezing temperatures at

any time.

When removing the “NHP210 Series” module from the activated

sludge for inspection or maintenance, take measures to keep the

membrane elements wet. Allowing the membrane elements to dry

out will adversely affect the membrane’s permeability.

The air scour should be stopped when the filtration process is

suspended. There are two exceptions:

1) Do not stop the air scour during the normal relaxation period.

2) Do not stop the air scour if the activated sludge requires air for

normal metabolic processes. However, under these conditions the

amount of air flow directed to the diffuser should be reduced to just

the amount required to maintain sludge viability.

Once a filtrate tube has been removed or disconnected from either

the element nozzle or filtrate manifold it should be replaced with a

Toray approved replacement part. Old filtrate tubes lose their

elasticity and the integrity of the seal can be compromised.

Never use a pressure washer machine when washing the

membrane module and element which can cause fatal

delamination of membrane element edge.

3. Chemical Cleaning of Element

Chemical agents used for chemical cleaning can be harmful to

one’s health. When handling chemicals, wear protective goggles,

protective gloves and other safety gear. Make sure to check the

details of its material safety data sheet (SDS) beforehand.

If chemicals should come in contact with your skin or clothes,

immediately wash the contacted area with a large volume of

running water.

If chemicals splash into your eyes, immediately flush with large

volumes of running water and contact a doctor.

WARNING

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

!

WARNING

!

WARNING

!

CAUTION

!

NIRE-170-1-6

8

Immediately stop the chemical cleaning operation if any of the

associated cleaning equipment appears to be malfunctioning.

Do not inject any chemical into the membrane directly from the

chemical pump discharge. Excessive membrane element internal

pressure will damage the element. Be sure to inject chemicals at a

pressure less than 10 kPa (100 mbar).

Before starting injecting chemical to elements, confirm that the

membrane tank liquid level is more than 500 mm above the top of

the module.

Store chemicals in a dark, cold place free from direct sunlight.

Use chemical storage tanks constructed of chemically compatible

materials to prevent corrosion.

Never mix sodium hypochlorite with heavy metals or acids. The

resulting chemical reaction will generate toxic chlorine gas.

To avoid scattering of chemical solution turn off the air scour during a

chemical cleaning.

CAUTION

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

NIRE-170-1-6

9

III. SPECIFICATIONS AND PERFORMANCE OF “NHP210 SERIES”

1. Specifications of Element

TableIII-1 and Fig.III-1 show the specifications and the physical dimensions for the NHP210

Series element. Table III-1 Specifications of Element (TSP-50080)

Model name

TSP-50080

Membrane configuration

Flat sheet

Application

Filtration of activated sludge

Filtration method

Suction filtration

Nominal pore diameter (m)

0.08

Effective membrane area (m2)

0.7

Dimensions (mm)

Total width

480

Total height

800

Thickness

1.8

Weight (kg)

Dry

0.25

Wet (Reference)

0.5

Main material

Membrane

PVDF and PET non-woven fiber

Nozzle

PE

Fig.III-1 Element Appearance (mm)

2. Specifications of Filtrate Tube Assembly

Table III-2 and Fig. III-2 show the specifications and appearance of

Tube Assembly.

Table III-2 Specifications of Filtrate Tube Assembly

Material

Thermoplastic polyether-polyurethane (tube)

Polypropylene (connector)

Tube Inside diameter (mm)

Tube outside diameter (mm)

Dimensions (mm)

8

10

Approx. 125 x 155

Fig.III-2 Tube Assembly Appearance

*Two elements are connected to one manifold nozzle via tubes and connector

Nozzle

480

Connector

NIRE-170-1-6

10

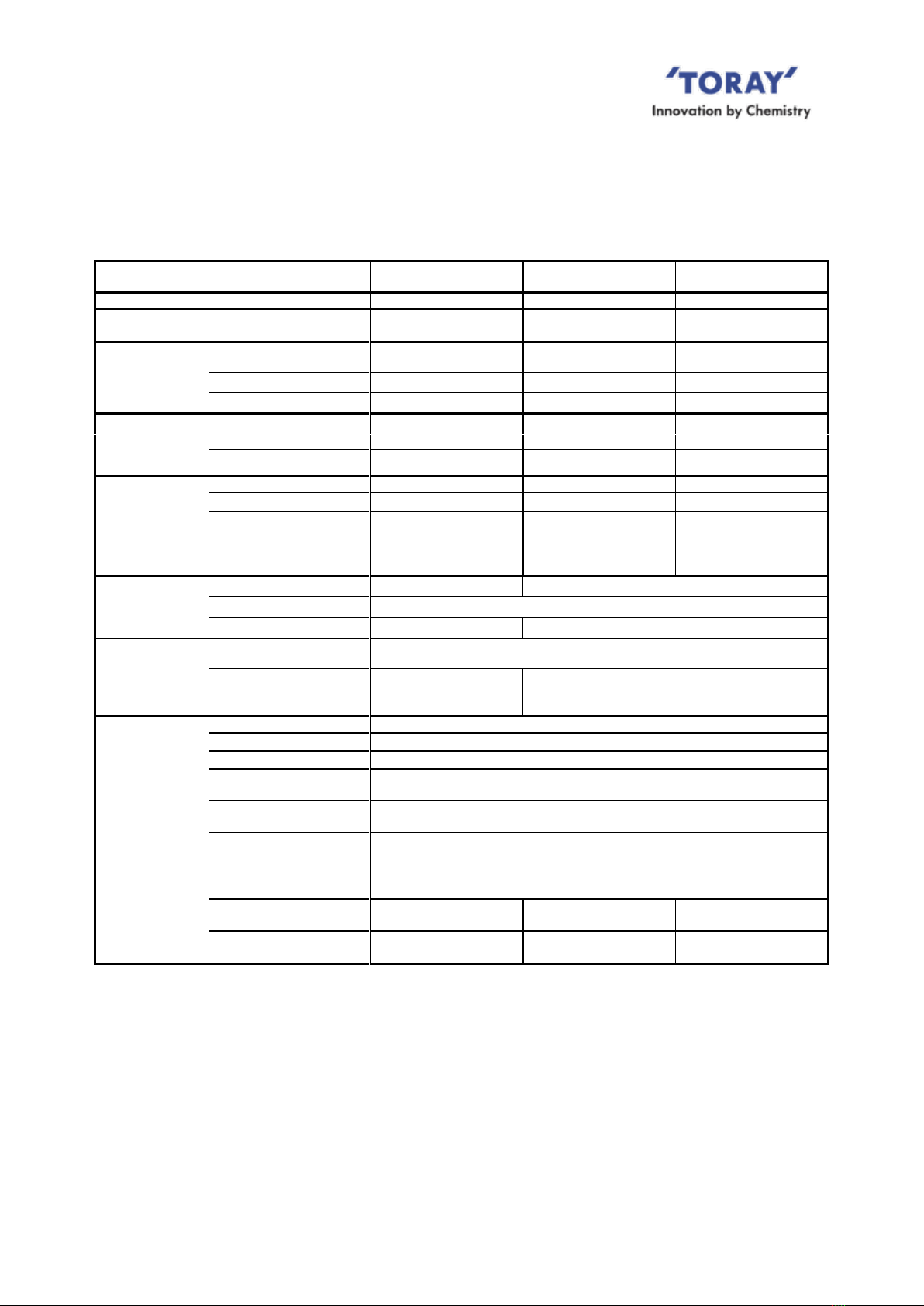

3. Specifications and Performance of “NHP210 Series”Module

Table III-3 shows the specifications of “NHP210 Series”cassette and module.

Table III-3 Specifications of Cassette and Module

Model name

ECS035

(Cassette)

NHP210-300S

(Standard module)

NHP210-600D

(Double-decker)

Number of membrane elements

50

300

600

Cassette structure

-

3 cassettes x 2 decks

3 cassettes x 4 decks

Overall

dimensions (mm)

Width

485

(excluding nozzle&hose)

770

770

Length

440

1,635

1,635

Height

820

2,175

3,845

Dimensions

excluding filtrate header

pipes and air diffuser

pipe

(mm)

Width

-

565

565

Length

-

1,460

1,460

Height

-

2,090

3,760

Weight

(kg)

Module (dry)

N/A

235

430

Aeration block (dry)

N/A

40

40

Cassette/Element block

(dry)

17

195

390

Cassette/Element block

(sludge clogging)*1

145

970

1,940

Material

Frame

-

304SS (316LSS is available as option)

Filtrate water manifold

Polypropylene

Air diffuser,

-

Polypropylene (SS is available as option)

Connection

Manifold

ANSI 1 1/2 inch flange using M12 bolts/nuts

One flange per each deck (300S: 2 pcs per module, 600D: 4 pcs per module)

Air diffuser

-

ANSI 1 1/2 inch flange

Using M12 bolts/nuts

Two flanges per Aeration block

Operating range*3

Temperature

5-40 degree C

pH*2 of liquid

5-10

MLSS

Not higher than 18,000 mg/L

Trans-membrane

pressure

Not higher than 20 kPa (200 mbar)

Cleaning chemicals feed

pressure

Not higher than 10 kPa (100 mbar)

Cleaning chemicals and

chemicals concentration

Sodium hypochlorite (effective chlorine concentration)

:2,000-6,000 mg/L(10<pH<12)

Oxalic acid :0.5-1.0wt%

Citric acid :1.0-3.0wt%

Scouring Air Flow rate

(NL/min/Module)*4

-*5

1,000 - 2,000

1,300 - 2,000

Scouring Air Flow rate

(Cubic feet/min/Module)*4

-*5

35 - 71

46 - 71

*1 The weight assumed in the case of sludge clogging between elements.

*2 Except when the chemical cleaning with the designated chemical agents.

*3 For the standard operating condition please refer Table VII-1.

*4 Air volume as being 0 degree C and 101.325 kPa (1 atm).

*5 MBR operation only by Cassette is not assumed.

NIRE-170-1-6

11

Table III-4 and III-5 shows the performance of ”NHP210 Series”modules.

Table III-4 Filtrate water quality

Model name

All models

Filtrate

water

quality*1

TSS (mg/L)*2

Not higher than 3.0

Turbidity (NTU)*3

Not higher than 1.0

*1 This value can be attained when operated under the standard operating conditions as specified in this

Instruction Manual and Operation and Maintenance guideline during a period specified separately by

Toray.

*2 Measuring method of TSS is complied with Standard Method of Examination of Water and Wastewater

20th Edition (1998), Section 2540D, Total Suspended Solids Dried at 103-105 degree C or ISO 11923.

*3 Measuring method of NTU is complied with Standard Method of Examination of Water and Wastewater

20th Edition (1998), Section 2130, Turbidity or ISO 7027.

Table III-5 Flow capacity (Reference value)

Model name

NHP210-300S

NHP210-600D

Filtration

Flow (m3/d)

*4

Sewage

20 - 150

40 - 300

Industrial wastewater

20 - 100

40 - 200

*4 This value is just a reference value and not a guarantee value of Toray. Sustainable operating filtration

flow capacity varies among the plant depending on the type of wastewater, total process design and

operating condition. In case of industrial wastewater application, it is strongly recommended to conduct

a pilot test before membrane tank designing.

NIRE-170-1-6

12

IV. MEMBRANE FILTRATION PROCESS DESIGN FOR “NHP210 SERIES”

This section will address the following for the Toray “NHP210 Series”: Standard sequence of

operation/time chart, illustrated piping and flow schematic, and module(s) layout in the

membrane tank.

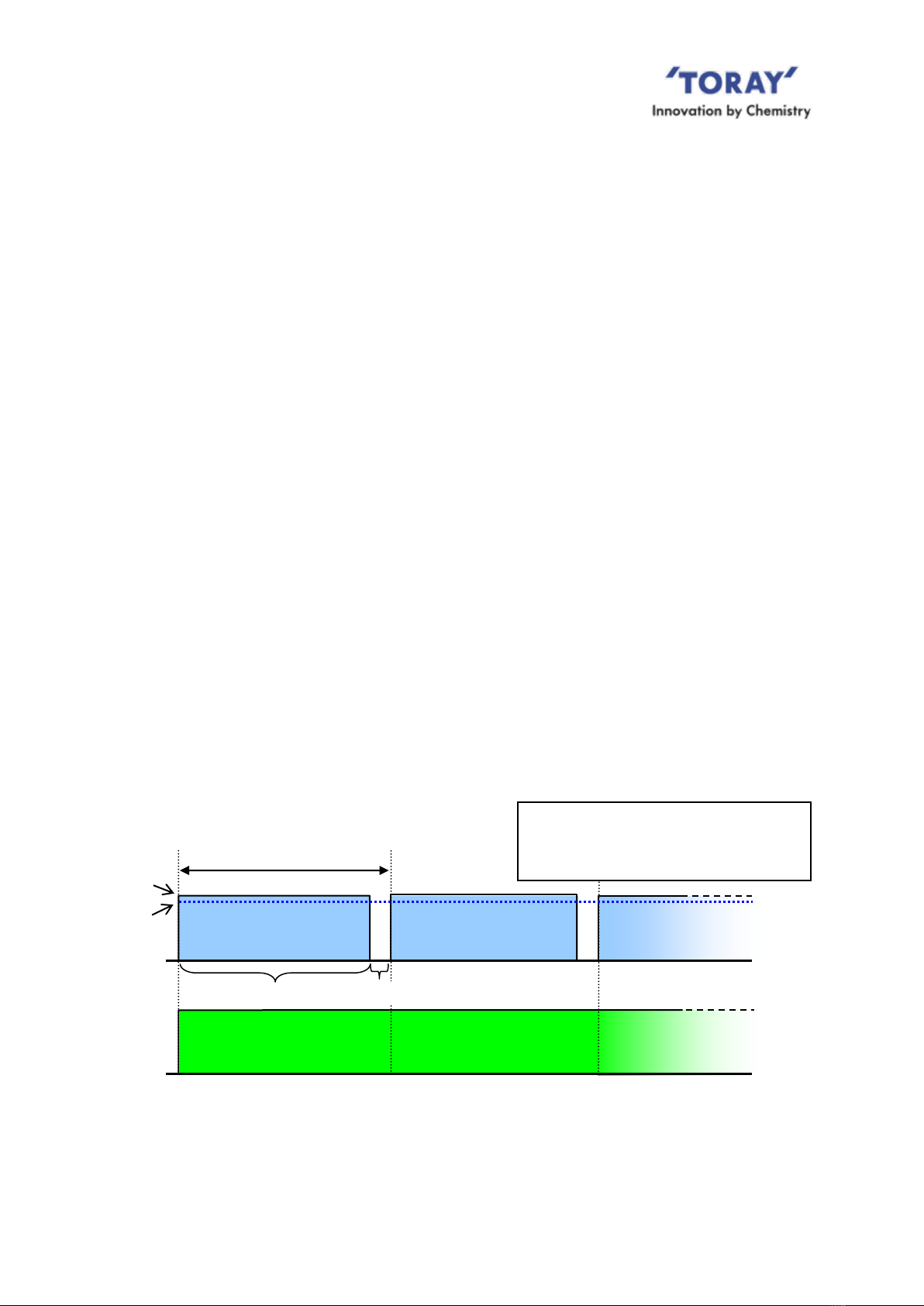

1. Standard Time Chart

Usually intermittent filtration (filtration with relaxation) is recommended. The most common

mode of filtration operation is nine (9) minutes of filtration followed by one (1) minute

of suspended membrane filtration (membrane relaxation) with continued air scour, as

shown in Fig.IV-1. This period of relaxation, with no filtration, allows the continued air scour

to be more effective at removing solids that may have accumulated on the surface of the

membrane. Intermittent filtration followed by a relaxation period is recommended for stable

and efficient membrane filtration.

The air scour should be suspended when the filtration process is stopped except for the

following conditions:

1) During normal membrane relaxation periods.

2) During suspended filtration operation unless aeration is required for mixing or biological

demand requirements. For the latter the air flow should be reduced to minimum flow

rates to prevent membrane damage.

* During low wastewater supply period, basically all modules should be in operation at lower

flux rate, considering maintaining viable activated sludge. In case operation of some or all

modules will be shut down, the air scour for those modules should be suspended or applied

intermittently following above description. For long-term shutdown please refer to the

following chapter 8 “Storage Products after Use”.

Fig.IV-1 Recommended Time Chart for Intermittent Filtration

Filtration

Air diffusion

Continuous

Filtration: 9 min.

Relaxation: 1 min.

Cycle of 10 minutes

F1: Average flow rate for treatment capacity

and membrane area calculation

F2: Filtration flow rate for suction pump

capacity calculation

F1

F2

NIRE-170-1-6

13

Membrane Module

FIC

FI

L

H

L:CLOSE

H:OPEN

L:OPEN

H:CLOSE

Filtrate water outlet

Manifold

Lower Limit alarm

Air Outlet

Feed

Chemical

Air Diffuser

Membrane

Tank

PIA

PIA

“U-shape”

2. Flow Diagram of Membrane Filtration

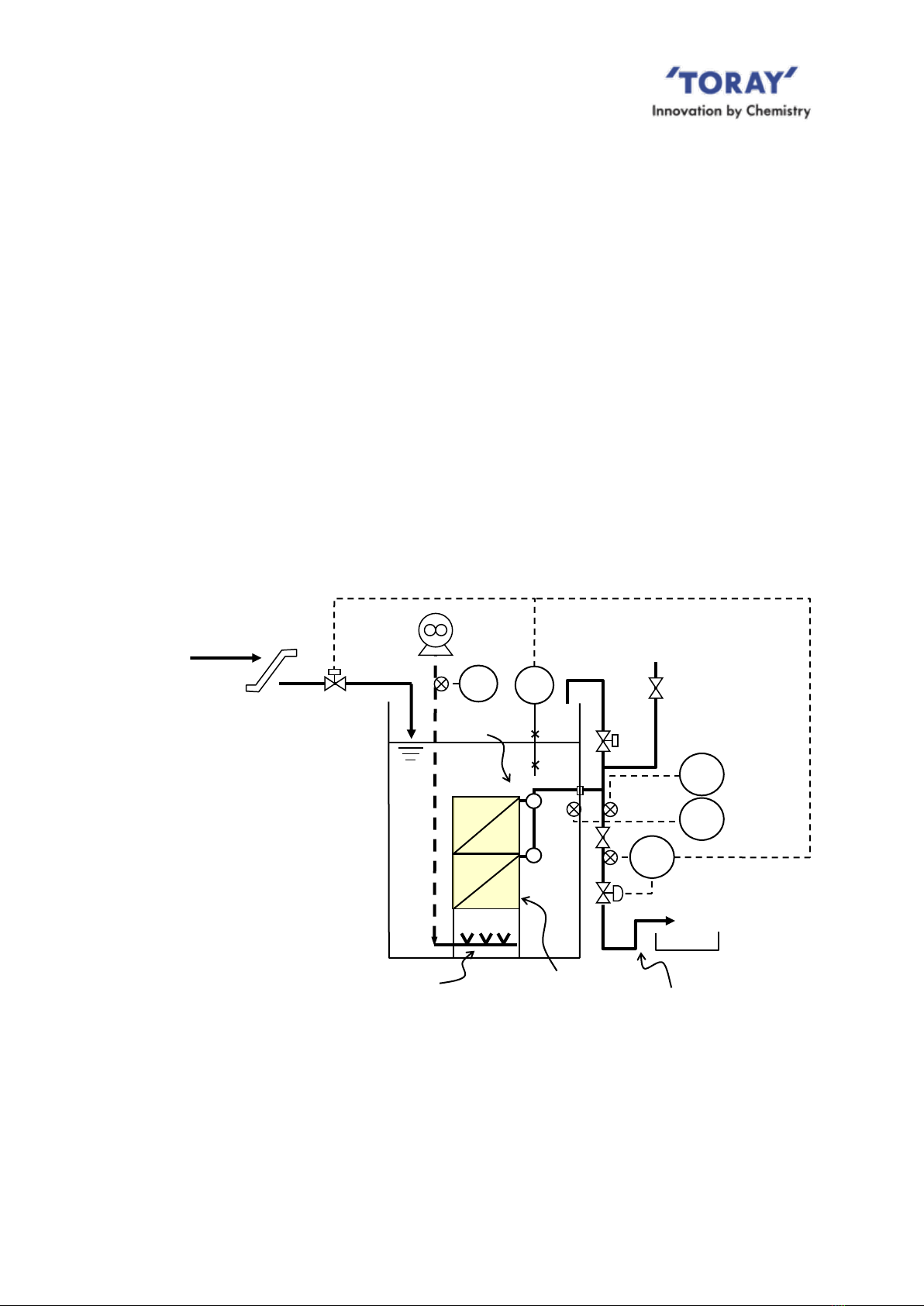

Two (2) flow diagrams of the membrane filtration process are shown below. One is for gravity

filtration (when site conditions permit) and the other using a suction pump. Also depicted are

major ancillary devices required for the membrane filtration process.

To reduce the potential for membrane clogging, all activated sludge should pass

through a fine mesh screen having openings of 3 mm or less prior to being introduced

into the membrane tank. Failure to incorporate the screen device may result in large

solids clogging or causing physical damage to the membrane surfaces.

In order to equalize BOD load and filtration flow capacity it is recommended that a

buffer/equalization tank be installed to help stabilize operation of the biological treatment and

membrane filtration process.

(1) Gravity filtration configuration

The filtration process can be accomplished by using elevation differences between the liquid

level of the membrane tank and the level of the filtrate outlet (see Fig. IV-2).

Fig. IV-2 Schematic Flow Diagram for Gravity Filtration

In order to obtain enough suction pressure for the filtration process, consider friction loss of

all pipes and valves. In addition, the filtrate water outlet should be located at least 3 m below

the surface of membrane tank water level.

LS

Wastewater

Fine Screen

FIC: Flow Rate Indicator/Controller

LS : Level Switch

PIA: Pressure Indicator/Alarm

FI : Flow Meter

NIRE-170-1-6

14

It is recommended that the piping from the filtrate water manifold to the filtrate water

outlet should directly penetrate the tank wall, as shown in Fig.IV-2. In addition, if the

filtrate water outlet is an open air discharge, it is recommended that a U-shaped “trap” be

constructed to seal the filtrate piping with water.

The filtrate water flow rate is controlled with the automatic control valve (filtrate control valve).

When the liquid level of the membrane tank gets to the designed low level limit, the filtrate

control valve fully closes to effectively stop the filtration process. When the liquid level of the

membrane tank reaches the designed high level the automatic shut off valve on the raw

water influent line closes to stop raw water flow to the membrane tank.

In the gravity filtration mode air may accumulate in the filtrate water lines. To prevent

reduction or loss of suction the air in the filtrate line should be purged to atmosphere at least

once per day. The air purge nozzle should be installed at the highest position of the filtrate

water line. The line should also be fitted with an automatic shut off valve (the air purge valve)

just upstream of the air purge nozzle (As shown in Fig.IV-2). The filtration process should be

suspended for a few minutes while purging any entrained air from the filtrate line. Close the

filtrate control valve and open the air purge valve. After all air has been purged return the air

purge valve to the closed position and open the filtrate control valve.

NIRE-170-1-6

15

Membrane Module

Air diffuser

FIC

Filtrate water

Manifold

PIA

Lower limit alarm

Air outlet

Feed

chemical

FI

L

H

L:OPEN

H:CLOSE

L:CLOSE

H:OPEN

VFD or auto valve

PIA

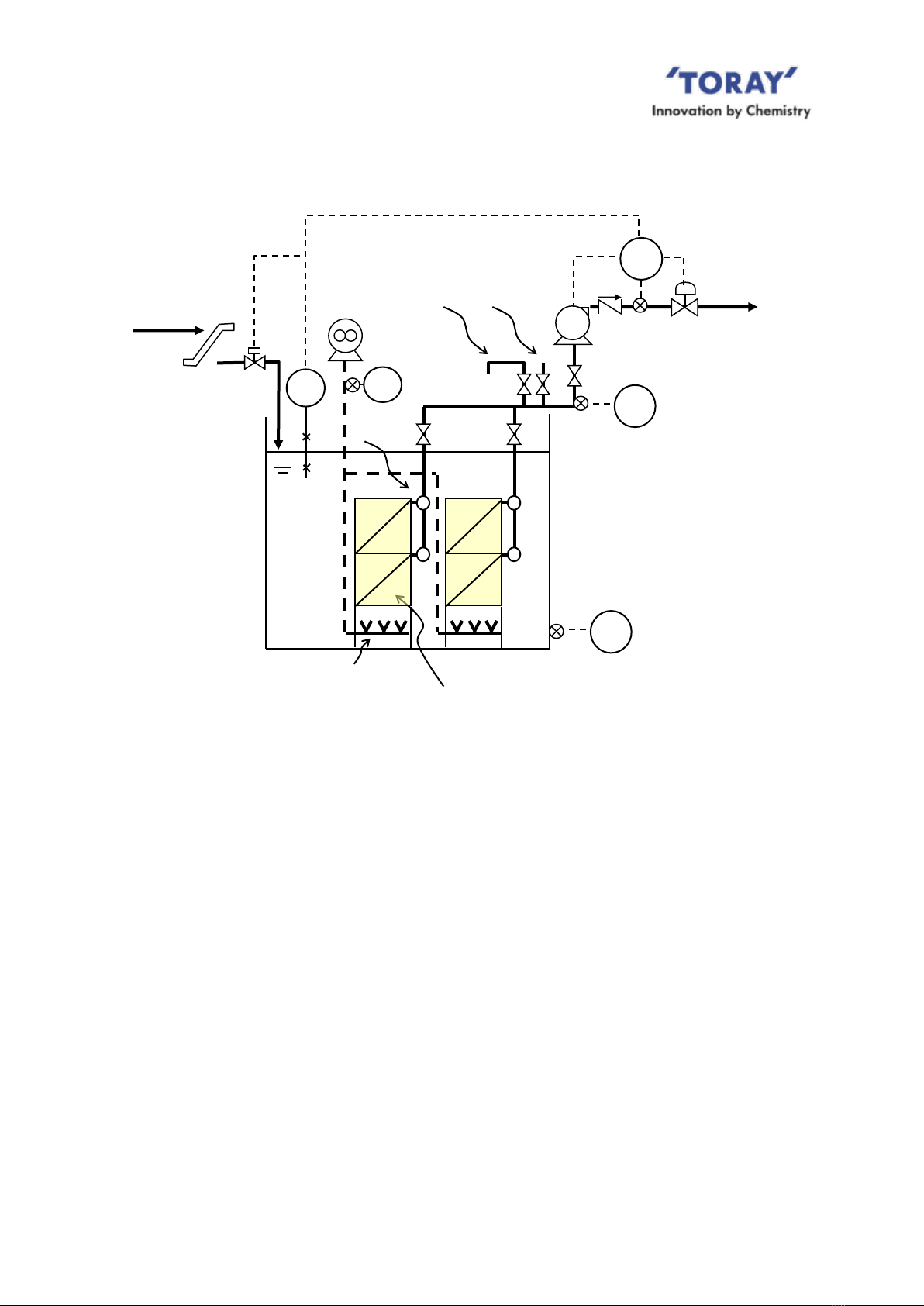

(2) Pump suction configuration

Fig. IV-3 illustrates the general configuration for pump suction filtration.

Fig.IV-3 Schematic Flow Diagram for Pump Suction Operation

When incorporating a suction pump to facilitate water flow through the membrane, the filtrate

water flow rate should be controlled using a flow meter fitted with control output signals and a

suction pump fitted with a VFD device or an automatic control valve. In the event the

membrane tank water level reaches the lower level design set point the filtration mode

should be stopped. As with the gravity filtration mode previously discussed, should the

membrane tank water level reach the upper designed liquid level set point, the high level

controller will close the raw water inlet control valve.

Since the liquid in the tank contains a significant amount of dissolved air, some of that

dissolved air will accumulate in the filtrate pump suction line. It would be necessary to

periodically purge the filtrate line of any accumulated air and in this context it is quite

beneficial to locate the pump at the highest point of filtrate piping. A range of methods

can be used to remove air from the filtrate line: vacuum pump, ejector or manual water

injection. Contact Toray or refer to the engineering manual for the additional details.

Raw water

Fine screen

FIC : Flow rate indicator/Controller

LS : Level Switch

PIA : Pressure indicator/Alarm

FI : Flow indicator

LS

NIRE-170-1-6

16

PIA

a mm

P1

P2

PIA

b mm

(3) Required ancillary devices for membrane filtration process are listed below. In some

instances additional components may be required.

a. Fine screen

Incoming wastewater to the membrane tank should pass through a screen having

3.0 mm or less openings. Failure to incorporate a screening device will result in

clogging or permeant damage to the membrane. Mesh type screens are

recommended. Overflow or waste carryover into the submerge membrane tank must

be avoided at all times.

b. Flow control device

A flow rate controller, a flow meter combined with an automatic control valve, or a

flow meter combined with VFD controlled suction pump should be installed on the

filtrate water line to control the flow rate of filtrate water. When operating more than

one “NHP210 Series” module simultaneously it is recommended that each train be

fitted with its own discreet filtrate flow rate controller.

c. Trans-membrane pressure (TMP) measurement & calculation

For trans-membrane pressure (TMP) determination the differential pressure (in the

filtrate line and water level) needs to be measured and calculated. This can be

accomplished by either installing two pressure sensors and calculating the

difference in the readings in the PLC or using a differential pressure gauge.

When using two pressure gauges, one pressure gauge should be installed on the

filtrate water line and the other on the membrane tank, to monitor the

trans-membrane pressure. When operating a number of “NHP210 Series” modules

simultaneously in one train, it is advised to install one differential pressure

measuring instrument for each train.

[Example]

Fig.IV-4 Trans-Membrane Pressure Measurement & Calculation

NIRE-170-1-6

17

➢a = 1,000 mm (= 10 kPa, 100 mbar), b = 3,000 mm (= 30 kPa, 300 mbar)

➢PIA readings;

Filtration (pump ON)

Relaxation (pump OFF)

P1 (kPa)

29

30

P2 (kPa)

-15

-10

In this case, TMP is calculated as follows;

TMP= (P1Filtration - P1Relaxation) - (P2Filtration - P2Relaxation)= (29) - (30) - [(-15)-(-10)]= 4 kPa

* In case water level is stable, P1Filtration is equal to P1Relaxation. Then TMP is;

TMP = P2Relaxation - P2Filtration = -a - P2Filtration

d. Air supply unit (such as a blower)

This unit supplies air to the air diffusers of "NHP210 Series" module. The air flow

rate supplied to the module should be always within the range of "Scouring Air Flow

Rate" indicated in Table III-3.

e. Air flow meter.

An air flow meter is recommended to be installed to check the flow rate of the

scouring air supplied to the module. In case of operating a number of “NHP210

Series” modules simultaneously in a train, it is advised to install, at a minimum, one

air flow meter for each train.

f. Suction pump

A suction pump is required in the case of pump suction configuration. To achieve an

accurate designed filtrate flow rate the suction pump should be fitted with a VFD

controller. The use of a volute pump (centrifugal pump) or volumetric pump (screw

pump) with self-priming functions is recommended.

g. Level sensor

Level sensors are required to be installed in the membrane tank to monitor and

control the liquid level of the membrane tank and to facilitate calculating TMP via the

PLC.

h. Siphon breaking device on filtrate piping

When using a suction pump it may be necessary to have a means to break the

filtrate siphon if the filtrate discharge point is lower than water level of the membrane

tank. This siphon flow has to be avoided and filtrate flow has to be stopped

whenever pump stops.

It is required that a screen with openings of 3.0 mm or less be

installed prior to the membrane tank. A mesh type screen is

recommended. Avoid any overflow or waste carryover at all times.

CAUTION

!

Table of contents

Other Toray Industrial Equipment manuals