4

IV. OPERATION SAFETY

1. The noise level of the applicator at the

operator station, unshielded, is above

80dBA. Take the following precautions:

Always keep doors and windows of the tow

vehicle closed

Use ANSI S3 19-1975 approved hearing

protectors with a noise reduction rating

(NRR) of 25 dB (A)

Ear plugs (disposable or re-useable)

2. Avoid Power Lines. Serious

injury or death can result from

contact with electric lines.

Never move any part of the

equipment closer than 10 ft.

(3 m) plus twice the line insulator length to

an electric line. Use a signal person to guide

the operator. Use shrouds or insulators as

necessary.

3. It is the operator’s responsibility to ensure the

tow vehicle is properly maintained, including

safety lighting and notifications. Do not use

a tow vehicle before properly testing the

road-worthiness.

Tire Pressure

Functioning traffic lights

Properly attached

Break-Away Switch

Tongue weight

Ensure that the tow

vehicle has the capacity

to control the fully-loaded XA unit. Applicator

weights are listed in this manual.

4. Handle the battery with care. When removing

or installing the battery, check which is the

negative and positive terminal.

Removing Batteries:

1. Disconnect the (-) terminal connected to

the ground wire

2. Disconnect the (+) terminal connected to

the starter

When installing the batteries, follow this

procedure in reverse order.

Tighten the battery terminals securely; check

that the terminals are not lose by trying

to move the cables by hand. Loosened

cables can generate sparks and lead to an

explosion.

5. Never enter the tank through the loading

hatch or riser atop the tank. Remove

the fasteners securing the access panel

adjacent to the loading hatch and utilize a

ladder or steps to enter here.

Your slurry tank may be considered a

confined space by OSHA under 29 CFR

1910.146. Before entering any confined

space, your company must develop a

procedure for safe entry. Make sure your

company’s plan meets all the requirements

of 29 CFR 1910.146, and/or all applicable

laws and regulations.

6. Before loosening any clamps or opening any

valves, determine if material in the line is hot

by feeling the pipe. Do NOT allow material

to come in contact with personnel. Severe

bodily injury could result.

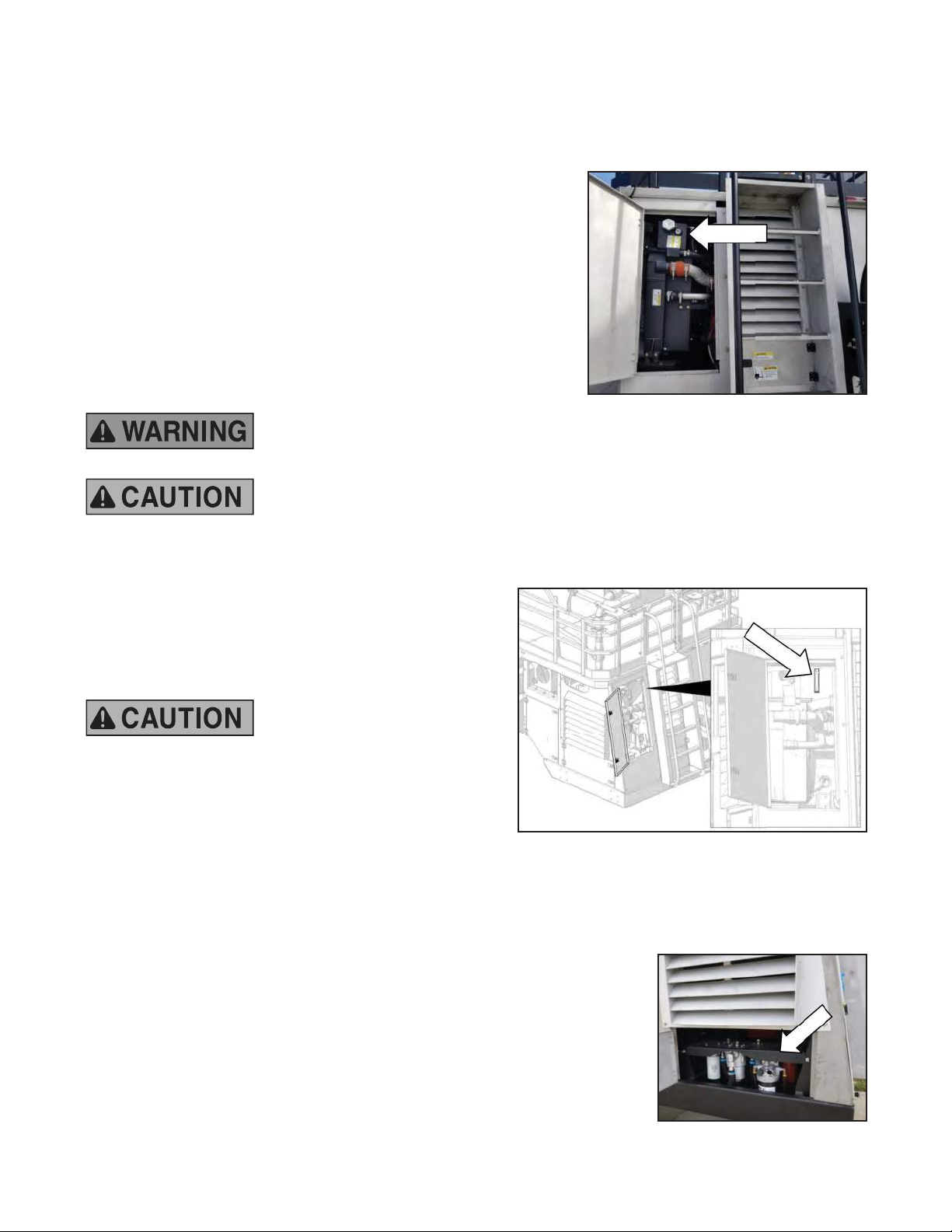

7. Radiator maintenance: Liquid cooling systems

build up pressure as the engine gets hot.

Before removing radiator cap, stop the

engine and let the system cool. Remove

radiator cap only after the coolant is cool.

8. Filling of fuel: Never fill the tank with the

engine running, while smoking, or when

near an open flame. Never smoke while

handling fuel or working on the fuel system.

The fumes in an empty fuel container are

explosive. Never cut or weld on fuel lines,

tanks, or containers. Move at least 10 ft.

(3 m) away from fueling point before starting

engine. Wipe off any spilled fuel and let dry

before starting engine.

IMPORTANT: Be careful not to allow fuel,

lubricant, hydraulic fluid, or cooling fluids to

penetrate into the ground or be discharged

into the water system. Collect all fluids

and dispose of them in accordance with all

applicable laws and regulations.

9. To prevent fires, remove all fiber mulch,

leaves, paper and other flammable material

accumulated in the engine compartment or

other places on the applicator. This could

cause a fire.

Marshland, when dry, is highly flammable.

Marshland can self-ignite even in low

temperatures. Always keep the engine

compartment and engine clean.

SAFETY SUMMARY SECTION (CONTINUED)