Apex Digital PWDC-5 User manual

!

1!

!

!

!

!

Operations Manual

Model PWDC-5 Wet Collector

!

2!

PWDC-5 COLLECTOR

BY APEX MACHINE GROUP

WARRANTY AND SERVICE

APEX Machine Group warrants every product it sells. If you need service or repair, contact us

or one of our Service Dealers.

WARRANTY

Apex Machine Group machines carry a limited warranty which varies in duration based upon the product.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below.

.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The APEX Machine Group warranty is for a One Year Period (2000 hours) from the date of purchase.

WHAT IS NOT COVERED?

This warranty does not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal

wear-and-tear, improper repair or alterations, or lack of maintenance. Also, the warranty does not

cover those consumable items such as coolant or rust additives.

HOW TO GET SERVICE

Contact APEX Machine Group at (855-500-2739) (952-895-518) www.apexmachinegroup,com

or the dealer you purchased the machine from.

Manufacture or Distributor is not responsible for, and will not pay for, work done,

material furnished, or repairs made by others unless agreed to in writing prior to performing

work. All express delivery charges, repair labor and expenses are the responsibility of

the customer.

Parts repaired or replaced under warranty are covered for the balance of

the original machine warranty, or a standard 90-day parts warranty, whichever is longer.

Except as stated above, there are no warranties, expressed or implied, including the warranties

of merchantability and fitness for a particular purpose.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

Caution: Please read and understand this manual prior

to operation of this machine.

!

3!

MACHINE WARRANTY REGISTRATION

By e-mail at: www.apexmachinegroup.com

Or mail a registration card to:

Apex Machine Group

4700 Olson Memorial Highway

Golden Valley, Minnesota 55422

Warranty Registration Card

Model No. ______PWDC-5 Collector________

Serial No. ______________________________

Date Purchased: ________________________

Company Name:_________________________

Address:_______________________________

____________________________________

Phone No:______________________________

E-mail Address:__________________________

!

4!

TABLE OF CONTENTS

Warranty and Service .............................................................................................. 2/3

Table of Contents .................................................................................................... 4

Warning ................................................................................................................... 5/6

Introduction .............................................................................................................. 6

Specifications .......................................................................................................... 7

Unpacking ............................................................................................................... 7

Installation and Assembly of Unit ............................................................................ 7

230 Volt Operation .................................................................................................. 8

460 Volt Conversion ................................................................................................ 8

Operating Controls .................................................................................................. 9

Maintenance ............................................................................................................ 8

Connection Points ................................................................................................... 9

Electrical Diagram and Parts List ............................................................................ 10

Parts List ................................................................................................................. 16

!

5!

WARNINGS

Please note: You can be seriously injured working on or around machinery. Only do service work

for which you have the knowledge and proper equipment. If you have any doubt about your ability

to perform a service job, please call our toll free line at 877-754-7266 or 855-500-7239 or contact

an authorized dealer to schedule a qualified technician.

1. Read and understand the entire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to

comply with all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This collector is designed and intended for use by properly trained and experienced

personnel only. If you are not familiar with the proper and safe operation of this collector,

do not use until proper training and knowledge have been obtained.

5. Do not use this collector for anything other than its intended use. If used for other purposes.

Apex Machine Group disclaims any real or implied warranty and holds itself unaccountable

from any injury that may result from that use.

6. Always wear approved safety glasses/face shields while around collector. Everyday

eyeglasses only have impact resistant lenses; they are not safety glasses.

7. Before operating this collector, or while cleaning it be sure to wear proper gloves and

clothing.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, and other construction activities, contain chemicals

known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from Chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Make certain control switch is OFF before connecting the machine to the power supply.

11. Make certain the machine is properly grounded.

!

6!

12. Keep safety guards in place at all times when the collector is in use. If removed for

maintenance purposed, use extreme caution and replace the guards immediately.

13. Provide for adequate space surrounding work area.

14. Keep the floor around the machine clean and free of scrap material, oil and grease.

15. Keep visitors a safe distance from the work area. Keep children away.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury

and/or possible machine damage.

This means that if precautions are not heeded, it may result in serioius injury or

possibly even death.

INTRODUCTION

This manual is provided by APEX Machine Group covering the safe operation and maintenance

procedures for this collector. This manual contains instructions on installation, safety

precautions, general operating procedures, maintenance instructions and parts breakdown. This

collector has been designed and constructed to provide years of trouble free operation if used in

accordance with instructions set forth in this manual. If there are any questions or comments,

please contact either your local dealer or APEX Machine Group who can also be reached at our

web site: www.apexmachinegroup.com (855-500-2739) or (952-895-1518).

SPECIFICATIONS

Model Number:

PWDC-5

Main Motor:

5 HP, 3 HP, 208/230 V

Dust Collector Inlet:

6 inch

Dust Collection CFM:

1350

Overall Dimensions:

36 x 30 z 68” High

Gross Weight:

1,760 lbs

Net Weight:

1,650 lbs

Water Capacity:

32 Gallons

Solution Requirements:

82 Ounces of 1100 metalworking

solution for a 2% Solution

• NOTE: The collector is pre-wired 208 / 230V three phase. Conversion to 460V

requires the purchase and installation of additional parts.

!

7!

The above specifications were current at the time this manual was published, but because of

our policy of continuous improvement, APEX Machine Group, reserves the right to change

specifications at any time without prior notice.

UNPACKING

Open shipping container and check for shipping damage. Report any damage immediately to

your distributor and shipping agent. Do not discard any shipping material until the collector is

installed and running properly. Compare the contents of your container with the following parts

list to make sure all parts are intact. Missing parts, if any, should be reported to your distributor.

Read this instruction manual thoroughly for assembly, maintenance and other instructions.

Be sure to check inside the filter, by opening the door to find manual and sample of additive for

water.

INSTALLATION AND ASSEMBLY OF UNIT

ELECTRICAL INSTALLATION:

All electrical work must be done by a qualified electrician or qualified person according to local,

state and national codes.

Caution: Installation can cause exposure to live components. Be sure to disconnect electrical

power before proceeding with installation.

Determine the location where the collector will be installed. Be sure to allow sufficient room

around the unit to service the sludge collection bin, or roll the unit out of position. Allow for the

inlet ducting and the exhaust air also. When selecting a location consider the floor surface;

a smooth and level floor will be helpful when moving unit for cleaning.

1. Uncrate collector using caution not to damage the paint while lifting or dismantling the

crate.

2. Remove any other item that may be on the skid.

3. When using a forklift, be careful lifting the unit as it is top heavy.

4. After placing the unit onto its location be sure to lock the front caster so the unit does not

move.

5. When make the electrical connection, a quick power plug is recommended so it is easy to

disconnect when unit is required to be moved for cleaning.

6. Check blower for proper rotation direction; if blower rotation is backward, interchange two

of the motor lead connections. (L1 and L2)

7. Start unit by depressing the start button located on the starter box.

8. Check total current draw on the motor with water in the unit and at the proper level. If the

amperage is higher than the rating on the motor, either the water level or the inlet needs

to be blocked off to reduce the total amperage. (For best performance, the motor should

run a few amps lower than total listed on motor name plate).

9. Water is added as needed through the front-loading door. Water should be filled to a level

about ½ way up the water sight window. (Middle of sight glass or approx. 9” up). Note

!

8!

that if waters comes out of the top of the exhaust silencer the water level is too high and

you need to take out some of the water.

10. After water and rust additives are added, and the inlet pipe is connected, start unit and

check the current draw. See general maintenance for type of additive and amount.

230 VOLT OPERATION

This unit is factory built and tested at 230 / 3 / Phase / 60 HZ Voltage and overloads are

size for this voltage also. (Will also run on 208 / 3 / 60 current).

460 VOLT OPERATION

The 5 HP motor on this unit can run at 460 / 3 / 60 voltage also, however the starting unit

and overloads along with the rewiring of the motor are required. Contact your local dealer

or Apex Machine Group if you require the unit to run on 460 voltage.

230 SINGLE PHASE VOLTAGE

Requires unit to be purchased this way.

OPERATION CONTROLS

For Starting and Stopping of this collector: Press the green button labeled START. Press

the red button labeled STOP.

GENERAL MAINTENANCE

1. No lubrication of the main motor is required as it is permanent pre-lube type.

Keeping it clean is all that is required.

2. The sludge or sump should be raked or drained and washed out once the material

reaches a certain level and effects the air flow.

3. When cleaning the tank or sump tank area, with this unit on casters, it ca be

pushed over to a drain to be emptied and washed out. The easy to open front door

gives you access to the inside of the unit.

4. The use of biodegradable additive is recommended to help in containing any order

and rust from water being inactive for a period of time. (Syn Kool 7000 #101-

41080-05 from Lubrication Technologies Inc. 763-545-0707) is a source. Once

Water level is determined add about 16 oz of additive and if excessive foaming

happens reduce the ratio of the additive.

CONNECTION POINTS:

Only two connections are required; power supply to the starter box, located on the right

side of the unit and inlet pipe (6”) located at the back of the unit.

!

9!

!

10!

!

11!

!

12!

SINGLE PHASE ELECRICAL BOM

PWDC EZ WC 52303-1

PWDC-5

ELECTRICAL PARTS LIST

5HP

1PH

230/1/60

24.4 FLA

2019/03/19

Sheng

Description

Symbol

q'ty

REFERENCE ITEMS

SEE ELECTRICAL NAMEPLATE FOR OPTIONS SUPPLIED WITH THIS MACHINE

ELECTRICAL DIAGRAM

52303-00-E1

COMMON PARTS

ELECTRICAL ENCLOSURE

1

HEAD NO. 1 (FLA 24.4)

FUKUTA 5 HP 3450 ,IP54, FR 112M, BI BY 230/1/60

1

NHD MS1-25D 1PH 5HP 230V 24-28A IP54 (MS1-25D1H7N282P)

1

!

13!

THREE PHASE ELECTRICAL DIAGRAM 230 OR 460

VOLTAGE

!

14!

THREE PHASE ELCTRICAL BOM 230 VOLT

PWC EZ WC 52303-1

PWDC-5

ELECTRICAL PARTS LIST

5HP

3PH

230/3/60

12.4 FLA

2012/06/19

Sheng

Description

Symbol

q'ty

REFERENCE ITEMS

SEE ELECTRICAL NAMEPLATE FOR OPTIONS SUPPLIED WITH THIS MACHINE

ELECTRICAL DIAGRAM

52303-1-E1.E2

COMMON PARTS

ELECTRICAL ENCLOSURE

1

HEAD NO. 1 (FLA 12.4)

FUKUTA 5 HP 3450 ,IP54, FR 112M, B3 MNT, F2 BOX, 230/460/3/60

1

NHD MS1-12D 3PH IP54

1

!

15!

THRE PHASE ELECTRICAL BOM 460 VOLT

PWC EZ WC 52303-1

PWDC-5

ELECTRICAL PARTS LIST

5HP

3PH

460/3/60

6.2 FLA

2012/06/19

Sheng

Description

Symbol

q'ty

REFERENCE ITEMS

SEE ELECTRICAL NAMEPLATE FOR OPTIONS SUPPLIED WITH THIS

MACHINE

ELECTRICAL DIAGRAM

52303-00-E2

COMMON PARTS

ELECTRICAL ENCLOSURE

1

HEAD NO. 1 (FLA 6.2)

FUKUTA 5 HP 3450 ,IP54, FR 112M, B3 MNT, F2 BOX,460/3/60

1

NHD MS1-12D 3PH 5HP 460V 7.5A IP54 (MS1-12D 3S7N82P)

1

!

16!

!

17!

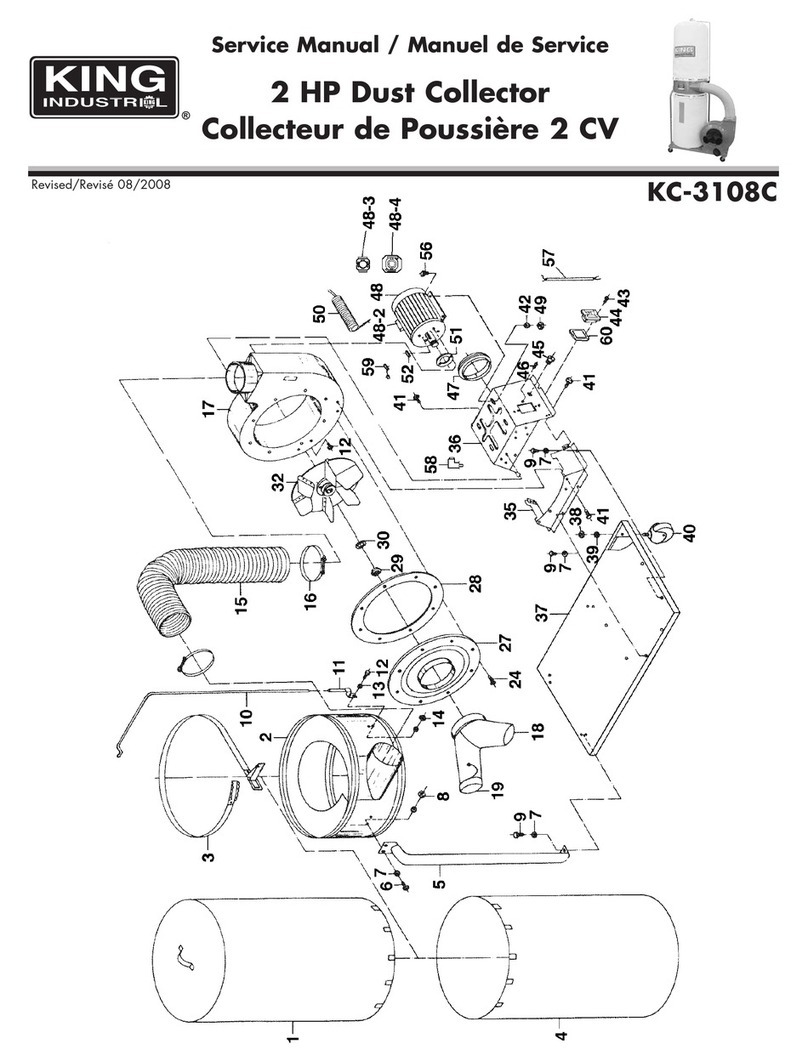

Parts&List&for&

PWDC-5&&

!

!

!

!

!

!

!

!

!

Item&

No.&

!

Part&

No...&

!

Descriptio

n&&

!

!

!

!

!

!

!

1!

!

P-0009!

!

Blower!Fan!

2!

!

P-0005!

!

Blower!Housing!!

3!

!

!

!

!

!

4!

!

P-0007!

!

Blower!Housing!Mounting!!Plate!

5!

!

!

!

!

!

6!

!

!

!

!

!

7!

!

P-0018!

!

Straight!Caster!

8!

!

!

!

!

!

9!

!

!

!

!

!

10!

!

!

!

!

!

11!

!

P-0001!

!

Diffusor!Mounting!Tube!

12!

!

P-0002!

!

Silencer!!

!

13!

!

P-0012!

!

Separator!Tube!

14!

!

!

!

Sealing!Gasket!

15!

!

P-0024!

!

Support!Bracket!

16!

!

!

!

!

!

17!

!

P-0027!

!

Knob!

!

18!

!

!

!

!

!

19!

!

P-0026!

!

Support!Rod!

20!

!

P-0008!

!

Separator!

21!

!

P-0003!

!

Front!door!

22!

!

P-0014!

!

Separator!Sprt!Bracket!

23!

!

P-0015!

!

Separator!Sprt!Bracket!

24!

!

P-0004!

!

Silencer!top!screen!

25!

!

P-0017!

!

Control!Box!

26!

!

P-0006!

!

Unit!Frame!!

!

18!

!

19!

!

20!

Table of contents

Popular Dust Collector manuals by other brands

National Flooring Equipment

National Flooring Equipment DL1000 Service manual

Donaldson

Donaldson DFPRE 6L Series Installation, operation and maintenance manual

Imperial Systems

Imperial Systems CMAXX Installation, operation & maintenance manual

Ermator

Ermator S26 operating instructions

Diamatic

Diamatic 3140 DBP instruction manual

CH Hanson

CH Hanson NORSE 9686004 Operating instructions & parts manual

Smith

Smith MV1000 Parts and operation manual

Quatro

Quatro SPH Vac Series Instruction & maintenance manual

belfab

belfab NBM-OP Instruction and maintenance manual

AQC

AQC MAXIFLO-VC owner's manual

RoboVent

RoboVent VentBoss 100 Series owner's manual

Powermatic

Powermatic 1792200HK Operating instructions and parts manual