belfab NBM-OP Instructions for use

Instruction And Maintenance Manual

For Dust Collector

Manuel D’Instructions Et De Maintenance

Pour Dépoussiéreur

Model /: NBM-OP

Modèle

erial Number /:

Numéro De érie

TABLE OF CONTENT / TABLE DE MATIÈRE

CAUTION ....................................................................................... 1

WARNING ...................................................................................... 2

DESCRIPTION ................................................................................. 3

INSTALLATION ............................................................................... 4

INITIAL START-UP .......................................................................... 7

OPERATING INSTRUCTIONS ............................................................. 8

MAINTENANCE ............................................................................... 9

TROUBLESHOOTING GUIDE ........................................................... 11

WARRANTY .................................................................................. 12

RECOMMENDED SPARE PARTS LIST .................................. APPENDIX 1

DRAWINGS .................................................................... APPENDIX 2

(OPTION PNEUMATIC DUST TRANSFER SYSTEM ................ APPENDIX 3

AVERTISSEMENT .......................................................................... 13

MISE EN GARDE ........................................................................... 14

DESCRIPTION ............................................................................... 15

INSTALLATION ............................................................................. 16

MISE EN MARCHE INITIALE ............................................................ 19

INSTRUCTIONS D'OPÉRATION ........................................................ 20

ENTRETIEN GÉNÉRAL .................................................................... 23

PROBLÈMES OCCASIONNELS ......................................................... 24

GARANTIE .................................................................................... 25

LISTE DE PIÈCES DE RECHANGE RECOMMENDÉES ................ ANNEXE 1

DESSINS .......................................................................... ANNEXE 2

(OPTION SYSTÈME DE TRANSFERT PNEUMTIQUE ................. ANNEXE 3

1

CAUTION

Make sure your installation complies with the local authorities and with the

appropriate NFPA Standards, which are available from the National Fire

Prevention Association.

These NFPA standards include, but are not limited to:

- Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food

Processing Facilities, NFPA 61

- Standard for Combustible Metals, Metal Powders and Metal Dusts, NFPA 484

- Standard for the Prevention of Fires and Explosions in Wood Processing and

Woodworking Facilities, NFPA 664

-

Standard for the Prevention of Fire and Dust Explosions from the Manufacturing,

Processing and Handling of Combustible Particulate Solids, NFPA 654

Notes for the province of Quebec

These regulations include the RSST (Règlement sur la santé et la sécurité du

travail). Below is an excerpt from article 59.1 regarding open dust collectors

installed inside in the woodworking industry. Please review the RSST for the

complete information (www.csst.qc.ca .

-Open dust collectors are located at least 20 ft away from any means of egress or

area routinely occupied by personnel or other dust collectors. When this distance

cannot be respected, a firewall (steel, fire resistant synthetic material or gypsum

can be used

-The maximum capacity of an open dust collector is limited to 5000 CFM

-

The collector is not used on sanders or abrasive planers having mechanical material

feed

Please note that a non-compliant installation can result in risks of fire and

explosion.

This information is valid as of November 2008, please

contact BELFAB @ 1-866-423-5322 for more complete and

up-to-date information.

2

WARNING

EVEN THOUGH YOUR NEW EQUIPMENT I DE IGNED AND

MANUFACTURED WITH THE BE T PO IBLE COMPONENT , IT I

TRONGLY RECOMMENDED NOT TO LEAVE THE EQUIPMENT

OPERATING WITHOUT ANY TRICT UPERVI ION; IN ORDER TO

AVOID ANY POTENTIAL DAMAGE RE ULTING FROM A DEFECTIVE

COMPONENT OR AN OPERATOR WRONG ETTING.

THE PRE ENCE OF AFETY COMPONENT ON YOUR EQUIPMENT

CANNOT, IN IT ELF, A URE AB OLUTE AFETY OF OPERATION.

FOR A AFE OPERATION, THERE I NO UB TITUTE FOR A DILIGENT,

CAPABLE, WELL TRAINED OPERATOR.

IT I THE OLE RE PON IBILITY OF THE U ER TO E TABLI H,

CHEDULE, AND ENFORCE THE FREQUENCY OF AND THE EXTENT OF

THE IN PECTION/MAINTENANCE PROGRAM BECAU E ONLY THE U ER

KNOW WHAT THE ACTUAL OPERATING CONDITION ARE.

3

DE CRIPTION

The collected dust enters the unit via the inlet into the plenum section to

remove the larger particles. The section immediately above is the secondary

filtration section where tubular bag filters remove the fine particles.

When the blower is stopped and the manual shaker mechanism shakes the

filter bags, the waste material falls to the storage section where it is removed

by either emptying 45-gallons drums or the optional dumping bins.

If the optional pneumatic dust transfer system (including modular hoppers and

blowers is connected to the dust collector, the dust will be continuously

transferred from the bottom of the hoppers to your external container.

4

IN TALLATION

CAUTION: Make sure your installation complies with the local

authorities and with the appropriate NFPA tandards,

which are available from the National Fire Prevention

Association.

FOUNDATION AND PACE REQUIREMENT

The foundation must be level and adequate to support the assembled

collector's operating weight plus any auxiliary equipment. Units must be

anchored properly to the ground with the use of the legs bolt down pads.

Adequate space must be allowed to connect inlet and outlet duct work and to

service all components easily. Refer to drawing 0886-BIA-00000 of

appendix 2.

LIFTING

Lift dust collector only by the underneath the unit. Never lift by the fan shaft

or fan housing outlet.

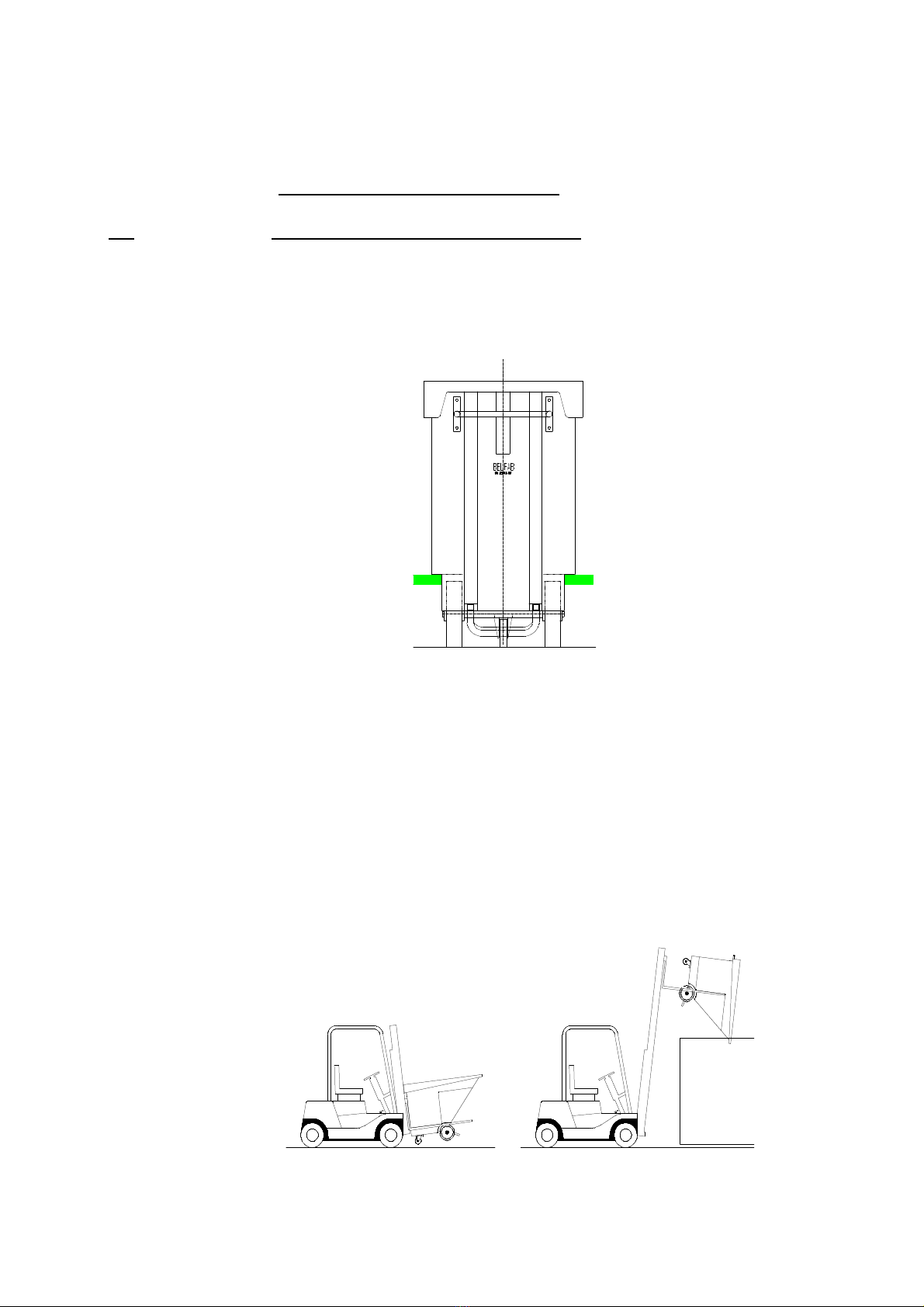

UNIT A EMBLY

Refer to drawing 0886-BIA-00000 of appendix 2.

FAN MODULE

Turn fan wheel by hand to verify that it rotates freely. Shortly start motor and

verify the direction of the rotation. If fan wheel is running in wrong direction,

have an electrician switch two (2 wires of the motor connections.

ELECTRICAL

Protect the fan motor with time delay fuses having a capacity ranging

between 125% and 150% of nominal amperage indicated on motor name

plate.

DUCTING

Connect fan intake to pick up points using rigid ducting and keep length of

flexible ducting, when necessary, to a minimum.

5

IN TALLATION (cont’d)

FORTY-FIVE (45) GALLON DRUM

Attach sleeves to the bottom of the dust collector with the fix band clamps and

to the top of the forty-five (45 gallons storage drums with the quick release

band clamps.

DUMPING BIN (option)

Assemble the quick coupling plate as per drawing 0482-AIC-00000 of

appendix 2. To help you, use the dumping bin to support the quick coupling

plate and follow these easy steps :

1. Slide the quick coupling plate, over the dumping bin but not completely.

Leave about two (2 feet at the end. If necessary have someone hold

the bin to prevent it from tilting forward.

2. Then roll the dumping bin under the filtration module until the upward

flap of the quick coupling plate is flush with front of the filtration module.

3. Install the first set of bolts situated at the far end, where the plate is

protruding from bin. You do not have to tighten completely the bolt at

this step.

4. Once the end bolts are secured, back up the dumping bin to gain access

to the second set of holes located in the middle of the coupling plate.

5. With four (4 bolts installed, remove slowly the dumping bin to gain

access to the last two (2 holes.

6. Now make sure that the six (6 bolts are tighten properly and seal to the

filtration unit, achieved.

Then simply glide the dumping bin through the quick coupling plate. The floor

should be level enough so that the wheels would not touch the floor when the

bin is in position. In fact the bulb trim seal should start to be compressed six

(6 to twelve (12 inches before the bin is completely in position (when de

front of the bin hits the back of the coupling plate . If the bin leaks when dust

collector is functioning, use the side adjustments, hidden under each side lip of

the bin, to better squeeze the gasket where needed. Note that optimum

sealing will be obtained when gasket is compressed of approximately one-

eighth of an inch (1/8” . An excessively squeezed gasket, will not seal better,

it will only shorten its life span or may damage it permanently.

6

IN TALLATION (cont’d)

PNEUMATIC DU T TRAN FER Y TEM (option)

Assemble the hoppers to the bottom of the modular filtering units. Follow

these easy steps:

1. The main dust collector blower(s should be installed first.

2. Use a forklift to hold the hoppers underneath the modular filtering units.

3. Install the six (6 bolts which will squeeze the bottom of the modular

filters to the top of the modular hoppers.

4. Make sure that the six (6 bolts are tighten properly and seal to the

filtration unit, achieved.

5. Installed each additional modular hopper the same way.

6. Install the two closing plates at each end of the modular hoppers.

Install the two blowers of the transfer system and the transfer piping as per

drawing 0482-BVD-00000 of appendix 3. Minimize as much as possible the

use of 90 degrees elbows and flexible ducting, in the piping.

When the system is in operation, verify that your container doesn’t leak. If it

does, a slide gate must be added at the inlet of the pull fan. It must be slightly

closed to compensate the fact that the container leaks.

7

INITIAL TART-UP

With the ducting installed and connected, an amperage reading should

immediately be taken upon start up to insure that the motor is not being

overloaded. Make sure forty-five (45 gal. drums are sealed.

On initial start up with clean filters and a minimum of ducting on fan inlet,

motor overload may trip. Should this occur, you must restrict the air flow on

the air inlet opening by installing a blast gate complete with locking device.

This is usually a temporary measure until filters build up a dust cake and

create the required resistance.

WARNING

Fan wheel is designed for light material loading (sanding dust, sawdust, etc. .

Severe damage may be caused to the fan by allowing blocks of wood or other

foreign objects to enter the fan.

8

OPERATING IN TRUCTION

HAKER

The shaker is manually operated by an handle. The frequency of operation is

normally 3 to 4 times per day (or more when high volume of fine dust are

involved . Operate the shaking mechanism by hand to make sure that no

parts are binding and that all parts are functioning properly. Verify that all

bolts are tight before operating.

To clean the filter bags, best results are obtained when shaking action takes

place while filter bags are partially inflated before total collapse and for a time

during total collapse. The above conditions of filter bags will take place during

coast down time of fan wheel after fan motor has been switched off.

If filter bags are plugged due to over filling of storage section, clean out

manually. DO NOT USE THE SHAKER.

FILTER BAG

The filter bags are hung on the bag shaker frame by their grommets and

attached to the hole sheet below by their snap ring cuffs (bi-bender . IT I

IMPORTANT THAT THE GROOVE ON THE NAP RING CUFF I

PROPERLY ENGAGED IN THE HEET HOLE.

The bag shaker frame is supported by at least four (4 posts of the required

length for proper bag tension.

When installing filter bags, first start with four (4 filter bags equally spaced on

the outer perimeter to verify that the bag tension is appropriate. TEN ION

I CHECKED BY PLACING THE BAG BETWEEN TWO (2) FINGER AND

THEN ROTATING THE FINGER 90

o

.

If tension is appropriate, then install the remaining filter bags, if not

communicate with the dust collector manufacturer.

9

OPERATING IN TRUCTION (cont'd)

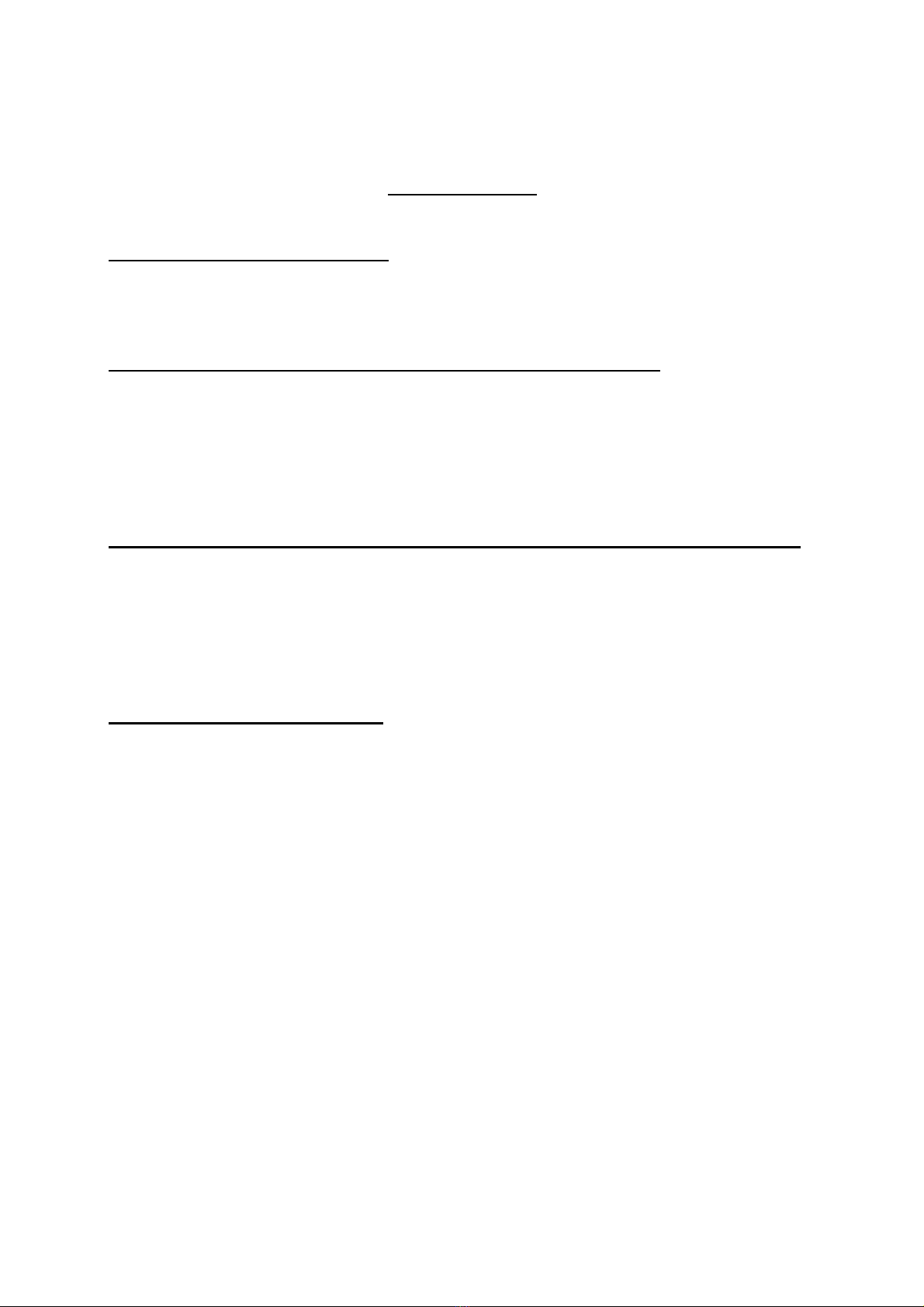

__ (OPTION) DUMPING BIN MANIPULATION

The bin has been designed not only to be moved and

emptied manually but also with the help of a fork lift. Simply

slide the forks under the lower shoulder as per shown

below.

For transportation, tilt the forks fully backward and lift until

bin wheels are off the ground. To dump, make sure the tip

of the forks will not hit the upper shoulder when the bin will

be tilted (total exceeding fork length may not be longer than

the vertical part of the shoulder . Keep the forks tilted

backward and elevate the bin as required. When positioned

and ready to dump, tilt the forks forward. You may have to

give the bin a boost, with an extending object, from

underneath (close to the swivel castor to initiate the

movement. If well positioned, the bin will rotate and

automatically stop in a perfect position to empty the load

completely.

10

MAINTENANCE

DU T COLLECTOR HOU ING

Protection against corrosion is required in the form of periodic repainting.

FAN IMPELLER AND MOTOR REMOVAL - IN TALLATION

The fan motor is bolted to a motor support plate. The impeller is installed

directly on the motor shaft. Unbolt and remove the piping installed at the fan

inlet. Remove the impeller from the motor shaft. Unbolt and remove the

motor from the motor support plate. For installation, reverse the above.

IN PECTION TO TAKE PLACE AFTER THE FIR T WEEK OF OPERATION

-Check the dust collector for filter bags failure and abrasion.

-During the first week of operation, check the storage section for waste

level and determine the emptying frequency that will be required.

EMI ANNUAL IN PECTION

-Lubricate all electric motors, exhaust fans, etc., as per manufacturer's

instructions.

-Check all filter bags for proper tension.

-Check the dust collector for filter bags failure and abrasion.

11

TROUBLE HOOTING GUIDE

1. Dust coming through the discharge of the unit:

•Check for improperly installed filter bags (be sure that the grooves on

the bi-benders are properly engaged in the hole sheet .

•Check for holes in filter bags.

2. Inadequate uction:

•Fan is running in wrong direction - Electrical wiring should be reversed.

•Forty-five (45 gallon storage drums or dumping bins are not sealed

properly – Adjust for proper seal.

•Filter bags are dirty - Clean or replace filter bags.

•Dampers or gates are closed - Open dampers or gates.

•Duct work is leaking or blocked - Repair or unblock ducts.

•Worn Impeller - Replace Impeller.

•The storage bin is full and the filter bags are blocked - Empty storage

and manually clean filter bags before restarting unit. DO NOT USE THE

SHAKER.

3. Unit is unduly noisy or has excessive vibration:

•Broken or damaged fan blade - Replace fan impeller.

•Fan is unbalanced - Check for wear or missing balance weight, if

applicable.

•Loose mounting bolts on unit - Tighten bolts.

•Loose fan impeller - Adjust and tighten.

•Loose guards - Tighten bolts.

•Bent shaft - Replace motor.

12

WARRANTY

Pyradia/Belfab is proud of the equipment which it manufactures. We have put

a great deal of thought, efforts and experience into the design and

construction of our units with the intention of providing you with the best

equipment for its purpose we know how to build. Experience indicates that if

you, the customer, will provide reasonable care and maintenance in the

operation of this equipment, it will provide you with a long, trouble-free,

reliable life.

Pyradia/Belfab warrants its equipment to be free from defects in material and

workmanship for a period of one year from the date of original shipment.

Without limiting what follows, Pyradia/Belfab will repair or replace (at its

discretion any such defective equipment or parts if they are returned to us

within the warranty period. However, the customer, must pay the

transportation cost. Should the customer require the inspection or work to be

done on his site by our qualified technicians, the customer will have to assume

the traveling expenses (mileage, traveling time and logging of the

technicians. Without limiting what follows, Pyradia/Belfab will assume the

labor to execute the repair to be done on site under warranty. To protect

yourself, you must let us know as soon as a problem arises, thereby avoiding

possible further damage.

Many parts in this equipment are normally replaced with use. Because these

parts may be easily damaged or consumed in normal operation, these parts

(such as straps, filter bags, filter cartridges, etc. are not covered by this

warranty. Nor does this warranty apply to equipment or components

manufactured by others (such as electric motors, starters, and other similar

items ; normally these items carry individual warranties of their own issued by

the original manufacturer. In the event of problems with third party

components (such as above , we will be pleased to help you obtain repair or

replacement and to advise you on installation.

If you have a problem, please contact us at once so we may promptly correct

the problem. Attempting your own repairs or operating the equipment in a

damaged condition may well make matters worse, and those resulting repairs

will unfortunately be at your own expense.

THI LIMITED WARRANTY I BEING MADE IN PLACE OF ALL OTHER

EXPRE WARRANTIE , AND IN PLACE OF ALL IMPLIED WARRANTIE OF

MERCHANTABILITY AND FITNE . THI LIMITED WARRANTY I IN LIEU OF

ALL OBLIGATION OR LIABILITIE ON THE PART OF PYRADIA/BELFAB FOR

DAMAGE , INCLUDING, BUT NOT LIMITED TO, CON EQUENTIAL AND

INCIDENTAL DAMAGE ARI ING OUT OF OR IN CONNECTION WITH THE U E

OF THI EQUIPMENT.

13

AVERTI EMENT

Assurez-vous que votre installation répond aux normes applicables selon les

autorités locales et les standards de NFPA qui sont disponibles auprès de la

National Fire Prevention Association.

Ces standards incluent, mais ne sont pas limités à:

- Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food

Processing Facilities, NFPA 61

- Standard for Combustible Metals, Metal Powders and Metal Dusts, NFPA 484

- Standard for the Prevention of Fires and Explosions in Wood Processing and

Woodworking Facilities, NFPA 664

-

Standard for the Prevention of Fire and Dust Explosions from the Manufacturing,

Processing and Handling of Combustible Particulate Solids, NFPA 654

Notes pour la province de Québec

Les normes applicables au Québec incluent le RSST (Règlement sur la santé

et la sécurité du travail). Ci-dessous se trouve un extrait des principaux

points de l’article 59.1 applicable aux dépoussiéreurs ouverts installés à

l’intérieur, utilisés dans l’industrie du bois. Consulter le RSST pour

l’information complete (www.csst.qc.ca .

-

Le dépoussiéreur n'est pas relié à une ponceuse ou une raboteuse par abrasion à

alimentation mécanique

-

La capacité ne dépasse pas 2,4 mètres cube par seconde (5000 PCM

-Le dépoussiéreur est installé à au moins 6 mètres d'un poste de travail, d'une voie

de circulation ou d'une sortie de secours, à moins qu'un écran de protection contre la

déflagration, tel une feuille d'acier, une feuille en matériau synthétique résistant au

feu ou un mur de gypse, ne soit installé entre le poste, la voie ou la sortie et le

collecteur ouvert, si cette distance ne peut être respectée

-S’ il y a plus d'un collecteur ouvert, il doit y avoir au moins 6 mètres entre les

collecteurs, à moins qu'un écran de protection contre la déflagration, tel une feuille

d'acier, une feuille en matériau synthétique résistant au feu ou un mur de gypse, ne

soit installé entre les collecteurs, si cette distance ne peut être respectée

Prenez note qu’une installation non-conforme pourrait présenter des risques

d’incendie et d’explosion.

Ces informations sont valides en date de novembre 2008,

veuillez contacter BELFAB au 1-866-423-5322 pour des

informations complémentaires et plus récentes.

14

MI E EN GARDE

MÊME I VOTRE NOUVEL ÉQUIPEMENT E T CONÇU ET FABRIQUÉ AVEC

LE MEILLEURE COMPO ANTE PO IBLE , IL E T FORTEMENT

RECOMMANDÉ DE NE PA LAI ER L’ÉQUIPEMENT FONCTIONNER

AN URVEILLANCE AFIN D’ÉVITER TOUT DOMMAGE POTENTIEL

POUVANT URVENIR UITE À UNE DÉFAILLANCE D’UNE COMPO ANTE

OU D’UN MAUVAI RÉGLAGE DE L’OPÉRATEUR.

LA PRÉ ENCE UR L’ÉQUIPEMENT DE COMPO ANTE DE ÉCURITÉ

N’E T PA UNE GARANTIE AB OLUE D’UN FONCTIONNEMENT ÛR.

POUR UN FONCTIONNEMENT ÉCURITAIRE, RIEN NE REMPLACE UN

OPÉRATEUR BIEN ENTRAÎNÉ ET ATTENTIONNÉ.

PUI QUE EUL L’OPÉRATEUR CONNAÎT LE CONDITION RÉELLE

D’UTILI ATION DE L’ÉQUIPEMENT, IL E T DE VOTRE

RE PON ABILITÉ D’ÉTABLIR UN PROGRAMME D’IN PECTION /

ENTRETIEN ET D’EN RE PECTER LA FRÉQUENCE ET L’ÉTENDUE.

15

DE CRIPTION

La poussière aspirée par le ventilateur entre dans l'appareil par l’entrée situé

sur le côté du dépoussiéreur et pénètre dans la section de séparation primaire

où les grosses particules sont précipitées. La section immédiatement au-

dessus est la section de filtration secondaire où les particules fines sont

retenues dans les sacs de filtration.

Lorsque le ventilateur s'arrête, et que l'on secoue les sacs de filtration, les

rebuts tombent soi dans les barils de rétention, dans les chariots dompeurs

(option ou dans le système de transfert pneumatique (option .

Si le système optionnel de transfert de poussière pneumatique (incluant les

trémies modulaires et les ventilateurs est branché sur les modules de

filtration, la poussière sera continuellement transférée des trémies jusqu’au

conteneur externe fourni par le client.

16

IN TALLATION

ATTENTION : Assurez-vous que votre installation répond aux

normes applicables selon les autorités locales et les

standards de NFPA qui sont disponibles auprès de la

National Fire Prevention Association.

FONDATION ET E PACE REQUI

Le ventilateur et les modules de filtration doivent être installés sur une base

nivelée suffisamment grande et solide pour supporter le poids du

dépoussiéreur, y compris tous les accessoires. L’unité doit être ancré

adéquatement au sol à l’aide des pieds d’ancrage (foot pads soudés au bas

des pattes. Il faut allouer suffisamment d'espace pour brancher la tuyauterie

d'admission, la tuyauterie d'évacuation et pour effectuer facilement les travaux

de d'entretien et de réparation. Se référer au dessin 0948-DAB-00000 de

l’annexe 2.

LEVAGE

Levez le dépoussiéreur par le dessous. Ne jamais lever l'appareil par l'arbre

du ventilateur ou la sortie du ventilateur.

A EMBLAGE DE L’UNITÉ

Se référer au dessin 0886-BIB-00000 de l’annexe 2.

VENTILATEUR

Tourner manuellement la roue du ventilateur afin de s'assurer qu'elle tourne

librement. Alimenter le moteur un bref instant et vérifier le sens de rotation

de la roue du ventilateur. Si la roue tourne dans la mauvaise direction, appeler

un électricien pour inverser deux fils d’alimentation au moteur.

ÉLECTRIQUE

Protéger le moteur du ventilateur par des fusibles temporisés ayant une

capacité entre 125% et 150% de l’ampérage nominal indiqué sur la plaque

signalétique du moteur.

CONDUIT

Relier l’entrée du ventilateur aux points de succion en utilisant des conduits

rigides. Lorsque l’utilisation de tuyaux flexible est nécessaire, réduire sa

longueur au minimum.

17

IN TALLATION (suite)

BARIL DE RÉTENTION DE 45 GALLON

Fixer les manchons au-dessous du dépoussiéreur au moyen des collets de

serrage fixes et au-dessus des barils de rétention de 45 gallons au moyen des

collets de serrage à dégagement rapide.

CHARIOT DOMPEUR (option)

Fixer la plaque d’accouplement rapide en se référant au dessin 0482-AIF-

00000 de l’annexe 2. Pour vous aider, utiliser le chariot dompeur en suivant

les directives suivantes :

1. Glisser la plaque d’accouplement rapide sur le chariot dompeur, mais

sans aller jusqu’au fond. Laisser la plaque d’accouplement rapide

dépasser d’environ deux (2 pieds. Au besoin, demander de l’aide pour

retenir le chariot dompeur et l’empêcher de culbuter vers l’avant.

2. Rouler ensuite le chariot dompeur sous le module de filtration jusqu’à ce

que le repli vers le haut de la plaque d’accouplement arrive à égalité

avec le devant du module de filtration.

3. Fixer les boulons se trouvant à l’arrière de l’unité (là où la plaque

d’accouplement dépasse le module de filtration . Il n’est pas nécessaire

de serrer complètement les boulons à cette étape.

4. Lorsque les boulons à l’arrière sont posés, reculer le chariot dompeur

afin d’atteindre les trous situés au centre de la plaque d’accouplement

rapide.

5. Lorsque les quatre (4 boulons sont installés, sortir complètement le

chariot dompeur. Les deux (2 derniers boulons sont maintenant

accessibles et peuvent être installés.

6. Serrer adéquatement les six (6 boulons et vérifier l’étanchéité entre la

plaque d’accouplement rapide et l’unité de filtration.

Diriger ensuite le chariot dompeur dans la plaque d’accouplement rapide.

Le sol doit être relativement nivelé, pour que les roues du chariot ne

touchent plus au sol lorsqu’il est en position. Le chariot dompeur devrait

commencer à écraser le joint d’étanchéité lorsqu’il se trouve à environ six

(6 à douze (12 pouces de sa position finale au fond de la plaque

d’accouplement rapide. Si le joint d’étanchéité du chariot dompeur fuit

lorsque le dépoussiéreur est en fonction, descendre aux endroits

nécessaires les guides d’ajustement, cachés sous les rebords du chariot.

Noter que le scellement optimum est obtenu lorsque le joint d’étanchéité

est écrasé d’environ un huitième de pouce (1/8” . Un joint trop écrasé ne

scellera pas mieux, cela ne fera que diminuer sa durée de vie et pourrait

l’endommager de façon permanente.

This manual suits for next models

1

Table of contents

Languages:

Other belfab Dust Collector manuals