Installation, Operation and Maintenance manual

5

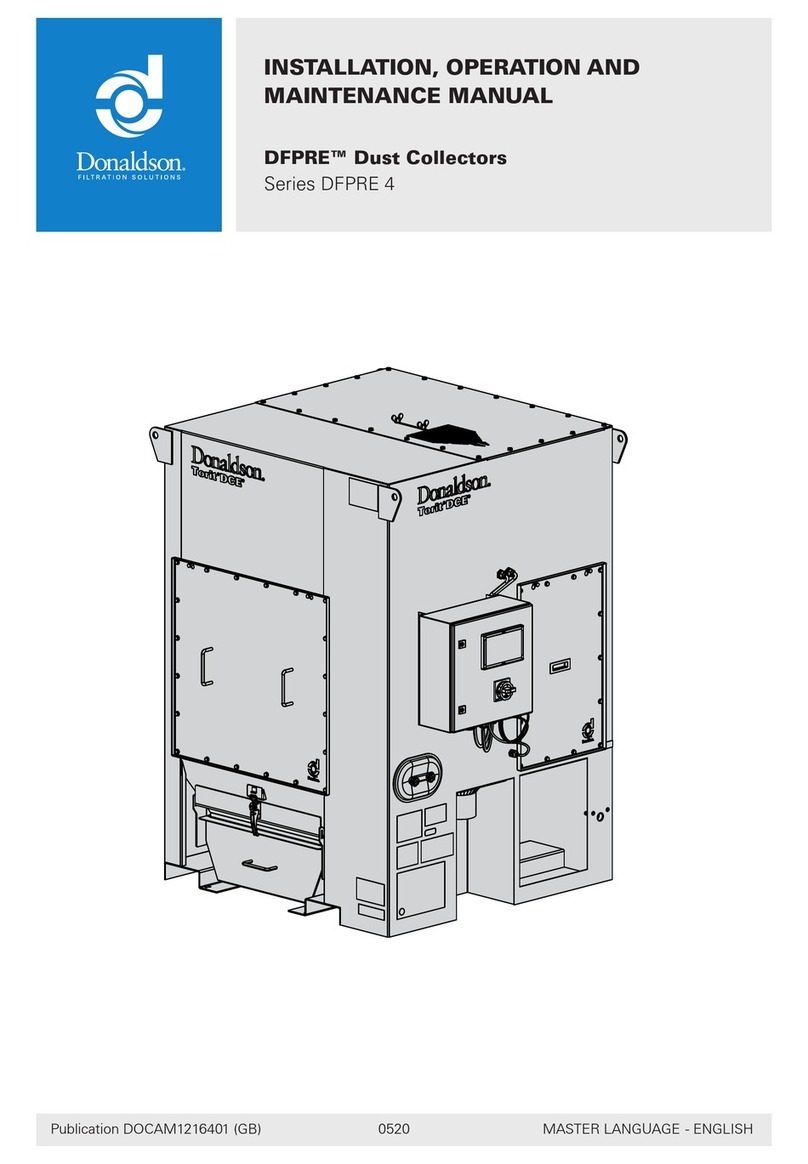

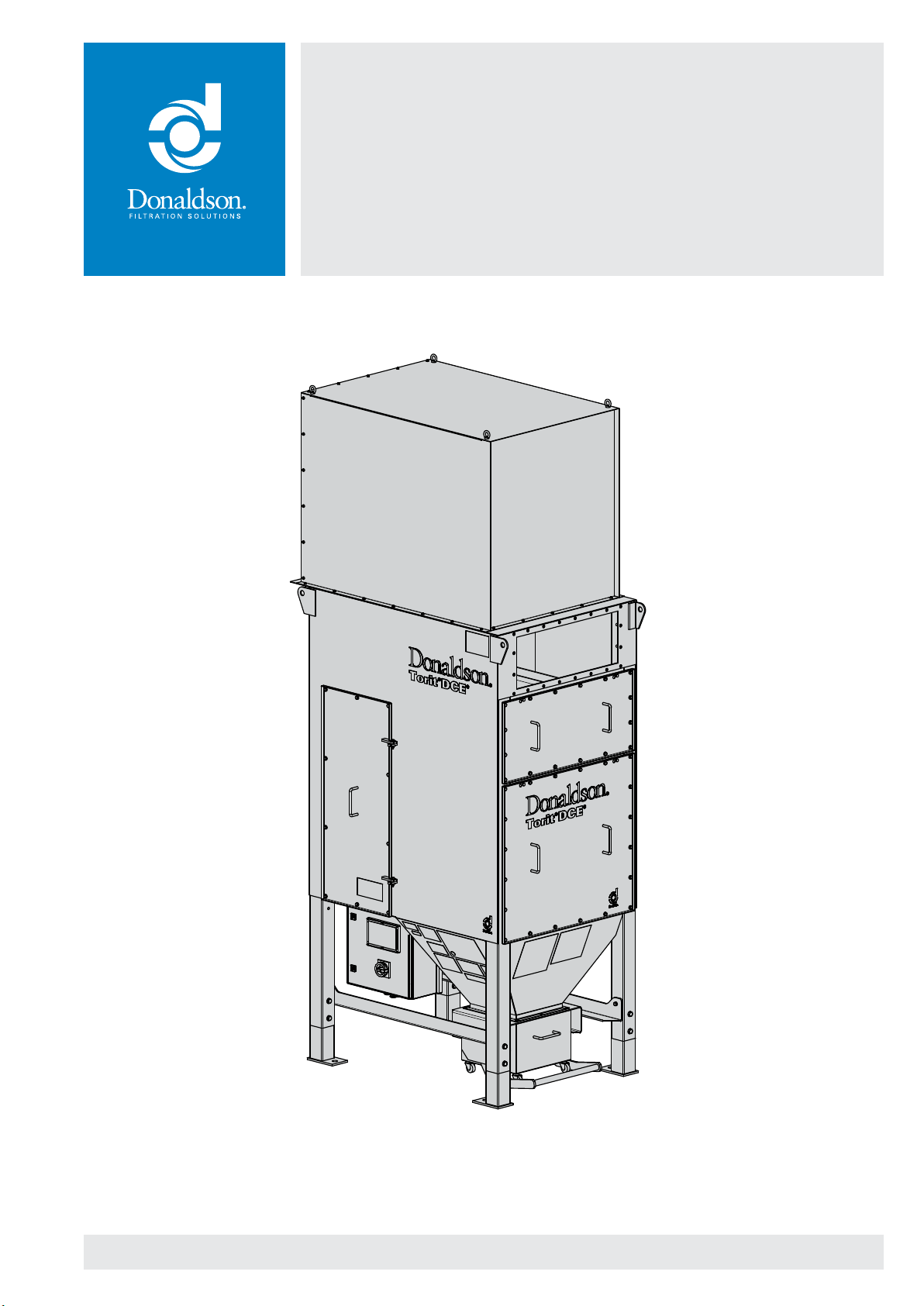

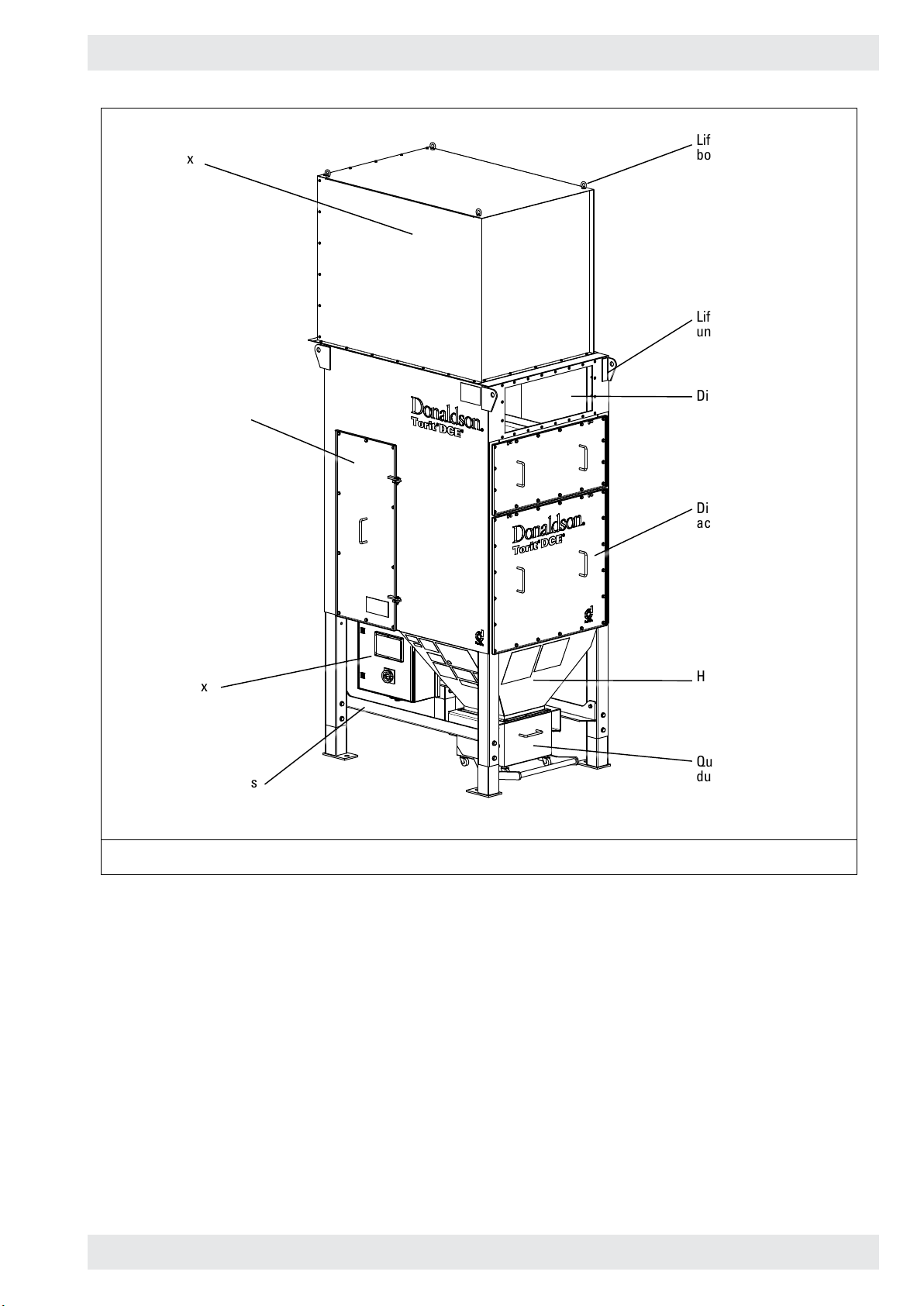

DFPRE 6L Dust Collectors

GENERAL SAFETY REQUIREMENTS

The collector should be stored as supplied. Only remove packaging to install.

For the purposes of storage:

•

Collector with specification for inside use = IP50.

•

Collector with specification for outside use = IP54.

The dust collector has been built in accordance with state-of-the-art standards

and recognised safety rules. Nevertheless if not handled carefully it may put

people at risk and also cause damage.

The dust collector should be used only when it is in a technically acceptable

condition. Regular maintenance, as set out in this manual, is required to

minimise technical failure. Third party supplied components (for example

motors) should be maintained according to the manufacturer’s instructions.

You should ensure any persons carrying out work on the supplied equipment

follow any relevant recognised standards/codes, have received adequate

training and are competent to do so. Areas requiring a competent person

include:

•

Maintenance on any component identified as a potential ignition source.

•

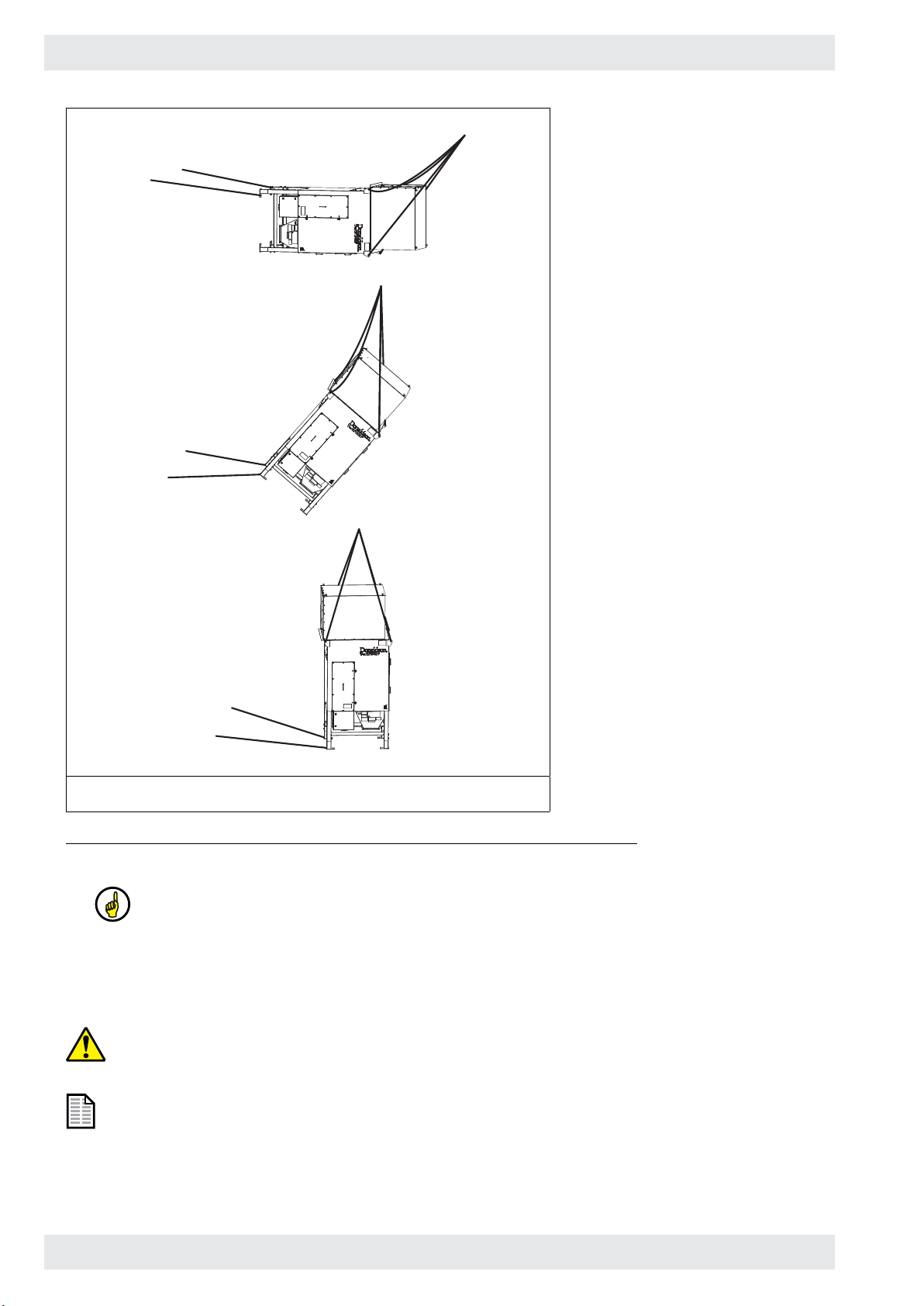

Lifting and erection.

•

Electrical installation, inspection and maintenance work.

•

Pneumatic installation, inspection and maintenance work.

•

Any access to internal classified potentially explosive atmospheres where

there may be a risk due to explosion.

During assembly/installation or dismantling of equipment, potential ignition

sources may occur that were not considered in the risk assessment of the

unit in operation (for example, grinding, welding sparks, etc.)

You should use the dust collector in full accordance with the conditions set

out in the Order Acknowledgment and relevant Scope of Delivery. Failure to

do so may compromise product reliability, warranty and safety. The Scope of

Delivery is an integral part of the manual.

Other items of equipment, not supplied under the Scope of Delivery from

Donaldson, should be installed, operated and maintained according to the

documentation supplied with the respective equipment.

Any modification carried out on the ‘as supplied’ equipment may reduce

reliability and safety, and will nullify warranty; such actions fall outside the

responsibility of the original supplier.

The hopper should not be used as a storage vessel. To prevent damage to

the collector, care should be taken to avoid an excessive build up of heavy

materials.

Where necessary for safety, the dust collector is fitted with safety guards.

Removal of these guards and any subsequent work should only be carried

out after adequate precaution is taken to ensure it is safe to do so. All guards

should be refitted before re-energising.