CH Hanson NORSE 9686004 Instructions for use

650 CFM

Dust Collector

Operating Instructions & arts Manual

9643301.01 0318

Model 9686004

9686004_oipm_En011_9643301.01 03/21/18 Page 1

2

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9686004

Please read and save hese ins ruc ions. Read carefully before a emp ing o assemble, ins all,

opera e or main ain he produc described.

Pro ec yourself and o hers by observing all safe y informa ion. Failure o comply wi h ins ruc ions

could resul in personal injury and/or proper y damage! re ain ins ruc ions for fu ure reference.

Model #: ________________________

Serial #: _________________________

Purchase Da e: ___________________

9686004_oipm_En011_9643301.01 03/21/18 Page 2

GETTING STARTED

Structural Requirements

Make sure all supporting structures and load attaching devices are

strong enough to hold your intended loads. If in doubt, consult a

qualified structural engineer.

Electrical Requirements

The power supply to the Dust Collector needs to be 120 volt/ 8.0

amp, single phase, 60 Hz. The standard allowable voltage variation

is plus or minus 10%.

Tools Needed:

Standard mechanic’s hand tool set.

UN ACKING

Crates should be handled with care to avoid damage from

dropping, bumping, etc. Store and unpack crates with correct side

up. After uncrating Dust Collector, inspect carefully for any damage

that may have occurred during transit. Check for loose, missing or

damaged parts. If any damage or loss has occurred, claim must be

filed with carrier immediately. Check for completeness. Immediately

report missing parts to dealer.

Dust Collector is shipped partially assembled. End user will need to

assemble loose parts to machine.

Never use highly volatile solvents. Avoid

getting cleaning solution on paint as it

may tend to deteriorate these finishes. Use soap and water

on painted components.

Contents:

All loose parts are shipped inside the dust extractor tank. Locate

and account for the following components:

• Dust Collector Housing Assembly (1)

• Base Assembly (1)

• Filter Bag (1)

• Collector Bag (1)

• Bag Clamp (2)

• Left Support (1)

• Right Support (1)

• Support Brace (1)

• Hose (1)

• Hose Clamp (2)

• Filter Bag Hanger (1)

• Seven Piece Adapter Set (1)

• Hardware Bag (1), includes: Four M8 x 40 carriage bolts, four

M8 x 12 carriage bolts, eight M8 serrated flange hex nuts and

one 5mm hex wrench

• Operating Instructions and Parts Manual (1)

Unpack:

Open carton and carefully remove Dust Collector from packing

material. Do not discard packing materials until after machine has

been inspected for damage and completeness. Locate loose parts

and set aside.

Inspect:

• After unpacking the unit, carefully inspect for any damage that

may have occurred during transit. Check for loose, missing or

damaged parts. Shipping damage claims must be filed with the

carrier.

• All tools should be visually inspected before use, in addition to

regular periodic maintenance inspections.

• Be sure that the voltage labeled on the unit matches your

power supply.

SAFETY RULES

Do not use this dust collector in a

flammable or explosive atmosphere. Do

not use to collect aluminum or magnesium dust, nor any

other chemically reactive dusts. Consult National Fire

Protection Association (NFPA) standards before setting up a

dust collection system, especially NFPA 664.

For your own safety, read all of the

instructions and precautions before

operating tool.

PROPOSI ION 65 WARNING: Some dust created by

using power tools contain chemicals known to the state

of California to cause cancer, birth defects or other

reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry

products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area and work with approved safety

equipment. Always wear OSHA/NIOSH approved, properly fitting

face mask or respirator when using such tools.

Always follow proper operating

procedures as defined in this manual even

if you are familiar with the use of this or similar tools.

Remember that being careless for even a fraction of a

second can result in severe personal in ury.

3

NOR E Operating Manual & Parts List 9686004

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9686004_oipm_En011_9643301.01 03/21/18 Page 3

SAFETY RULES (CONTINUED)

Be repared for Job

• Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get

caught in moving parts of machine.

• Wear protective hair covering to contain long hair.

• Wear safety shoes with non-slip soles.

• Wear safety glasses complying with United States ANSI Z87.1.

Everyday glasses have only impact resistant lenses. They are

NO safety glasses.

• Wear face mask or dust mask if operation is dusty.

• Be alert and think clearly. Never operate power tools when tired,

intoxicated or when taking medications that cause drowsiness.

repare Work Area for Job

• eep work area clean. Cluttered work areas invite accidents.

• Do not use power tools in dangerous environments. Do not

use power tools in damp or wet locations. Do not expose

power tools to rain.

• Work area should be properly lighted.

• Proper electrical receptacle should be available for tool. Three-

prong plug should be plugged directly into properly grounded,

three-prong receptacle.

• Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

• eep visitors at a safe distance from work area.

• eep children out of workplace. Make workshop childproof.

Use padlocks, master switches or remove switch keys to

prevent any unintentional use of power tools.

Tool Should Be Maintained

• Always unplug tool prior to inspection.

• Consult manual for specific maintaining and adjusting

procedures.

• eep tool lubricated and clean for safest operation.

• Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before switching machine on.

• eep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

• Check for damaged parts. Check for alignment of moving

parts, binding, breakage, mounting and any other condition

that may affect a tool’s operation.

• A guard or other part that is damaged should be properly

repaired or replaced. Do not perform makeshift repairs. (Use

parts list provided to order repair parts.)

Know How to Use Tool

• Use right tool for job. Do not force tool or attachment to do a

job for which it was not designed.

• Disconnect tool when changing the Filter cartridge or filter bag.

• Avoid accidental start-up. Make sure that the tool is in the OFF

position before plugging in.

• Do not force tool. It will work most efficiently at the rate for

which it was designed.

• Leave hands free to operate machine. Protect hands from

possible injury.

• Never leave tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

• Do not overreach. eep proper footing and balance.

• Never stand on tool. Serious injury could occur if tool is tipped

over.

• eep hands away from moving parts.

• now your tool. Learn the tool’s operation, application and

specific limitations.

The operation of any power tool can

result in foreign ob ects being thrown into

the eyes, which can result in severe eye damage. Always

wear safety glasses complying with United States ANSI

Z87.1 (shown on package) before commencing power tool

operation.

S ECIFICATIONS

Motor 3/4 HP, 3450 RPM

Voltage 120VAC

Amps 4.5

Hertz 60

Air flow rate 650 CFM

Maximum static pressure 5.8 inches H2O

Sound level 90 dBA

Hose 4˝ dia. x 78˝

Bag capacity 20 gallons

Overall size 351/4˝ x 211/4˝ x 173/8˝

Weight 55 lbs

Shipping weight 62 lbs

4

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9686004

9686004_oipm_En011_9643301.01 03/21/18 Page 4

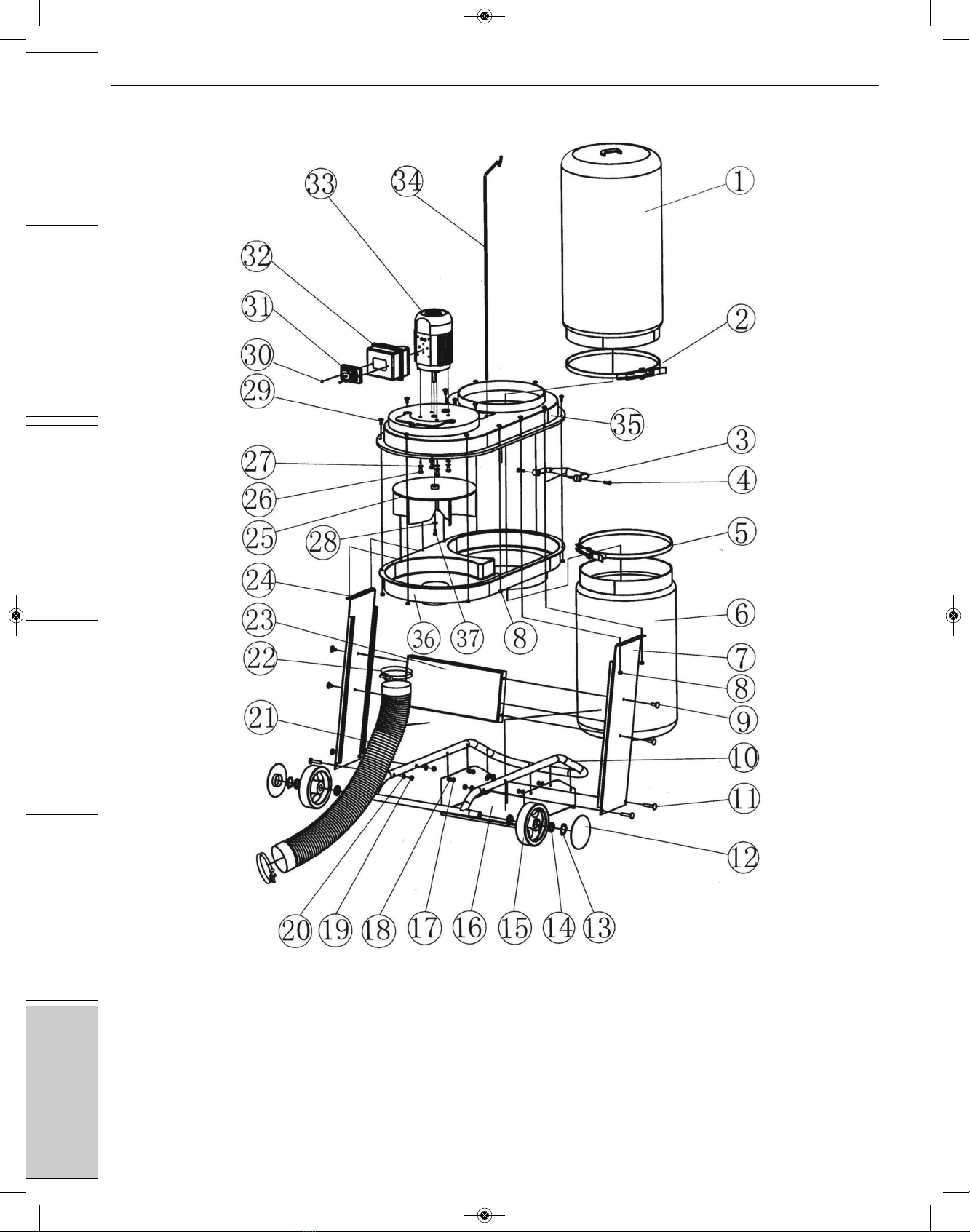

ASSEMBLY

Refer to Figure 3.

• Attach the wheel assembly (Ref. No. 12 through 15) to base

tube (Ref. No. 10) using M6 x12 bolts, 6mm washers.

• Attach the side panels (Ref. No. 7 & 24) loosely to the base

using M8x12 bolts, 8mm washers. Do not tighten.

• Attach the housing assembly to the side panels using M5x12

bolts and nuts. Tighten all nuts.

• Insert the dust container in the bore of the top air outlet.

• Slip the filter bag (Ref. No. 1) over the container and fasten

with the retaining strap (Ref. No. 2).

• Attach the collector bag (Ref. No. 6) to the lower air outlet

using the retaining strap (Ref. No. 5).

• Attach the hose (Ref. No. 21) to the nozzle on the housing and

fasten with a hose clamp (Ref. No. 22).

• Also fasten the adapter ring to the other end of the hose using

a hose clamp.

INSTALLATION

Do not permit fingers to touch terminals

of plug when installing or removing the

plug to or from the outlet.

Do not connect to power source until unit

is completely assembled.

ower Source

• Motor is designed for operation on 120V, 60Hz.

• Normal loads will be handled safely on voltages not more than

10% above or below the specified voltage.

• Running unit on voltages not within range may cause

overheating and motor burnout.

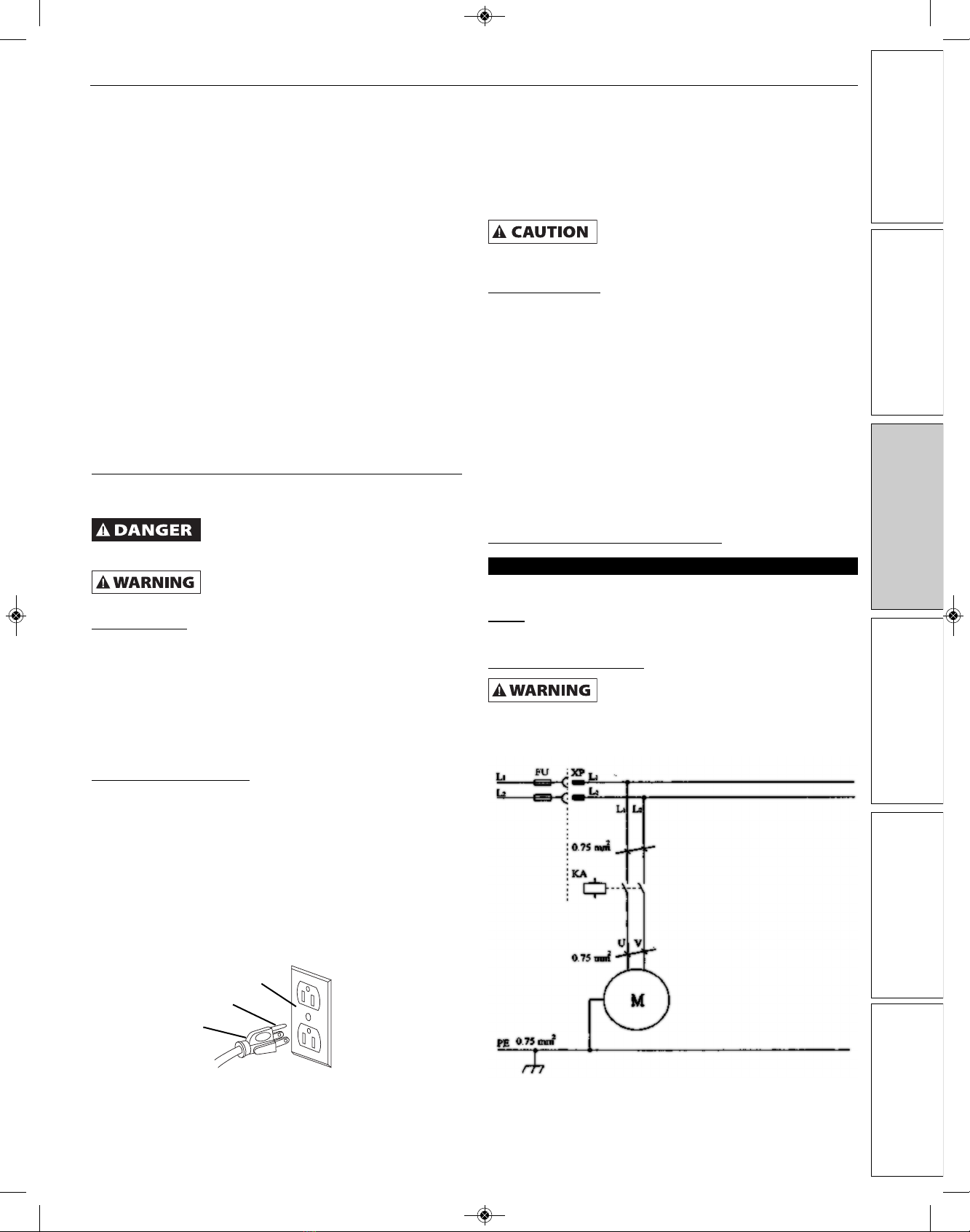

Grounding Instructions

Refer to Figure 1

• This tool is equipped with a 3-conductor cord.

• Do not remove or alter grounding prong in any manner. In the

event of malfunction or breakdown, grounding provides path of

least resistance for electrical current to reduce risk of electrical

shock.

• Plug must be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes and

ordinances.

• The conductor with insulation having an outer surface which is

green is equipment grounding conductor. If repair or

replacement is necessary, make sure equipment grounding

conductor is not connected to line terminal.

• If power cord is worn, cut or damaged in any way, have it

replaced immediately.

Improper connection of the equipment-

grounding conductor can result in a risk

of electrical shock.

Extension Cords

• The use of any extension cord will cause some drop in the

voltage and loss of power.

• Wires of the extension cord must be sufficient in size to carry

the current and maintain adequate voltage.

• Use the table below to determine the minimum wire size

(A.W.G.) extension cord.

• Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

• If extension cord is worn, cut or damaged in any way, have it

replaced immediately.

Extension Cord Length and Gauge

Length A.W.G.

Up to 25 ft. 15

NOTE: Using extension cords over 25 ft. long is not recommended.

Electrical Connections

All electrical connections must be

performed by a qualified electrician. Make

sure tool is off and disconnected from power source while

motor is mounted, connected, reconnected or anytime

wiring is inspected.

5

NOR E Operating Manual & Parts List 9686004

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

Figure 1 – roperly grounded outlet 120 Volt.

Grounding prong

3-Prong plug

Properly grounded outlet

Figure 2 - Circuit diagram.

9686004_oipm_En011_9643301.01 03/21/18 Page 5

O ERATION

Refer to Figure 3.

• Do not suck pieces of metal, large blocks of wood or pieces of

batten into the collector.

• Use only accessories designed for this Dust Collector.

• It is more efficient to use the filter cartridge than the dust bag to

collect wood chips.

1. Position dust extractor near dust producing machine on a flat

level surface.

2. Connect hose (Ref. No. 21) to dust producing machine using

hose clamp (Ref. No. 22). Use adaptors if needed.

3. Turn dust collector on before starting dust producing machine.

Emptying Collector Bag

Turn switch off and remove plug from

power source outlet before emptying

collector bag.

• The collection container should be emptied as required, but at

least after each use.

1. Empty collector bag by lifting bag clamp handle and releasing

spring connector from latch. Slide bag away from housing.

Dispose of dust properly.

2. Mount collector bag by sliding bag over opening on housing

bottom. Position the spring connector into one of the slots on

the latch and lock the clamp handle. Make sure collector bag is

secure.

MAINTENANCE

Turn switch off and remove plug from

power source outlet before maintaining

your dust extractor.

• The dust collector and filtering bag should be cleaned each

time the collection bag is changed.

• Damaged filters and bags must be replaced immediately in

order to minimize dust dispersion in the work area.

• Clean motor of dust, chips or other particles. If operation is

excessively dusty or dirty, frequent inspection of motor is

required. Vacuum any particles that may have entered the

motor.

• Replace worn, cut or damaged line cord.

• Replace worn or damaged collector hose.

• Replace worn or damaged bags.

• Frequently check that all nuts, bolts, screws, etc. have not

loosened due to vibration.

6

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9686004

9686004_oipm_En011_9643301.01 03/21/18 Page 6

7

NOR E Operating Manual & Parts List 9686004

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

TROUBLESHOOTING GUIDE

Symptom ossible Cause(s) Corrective Action

Motor will not run

Excessive dust in air

Excessive impeller noise

Excessive motor noise

Motor fails to develop full power

or motor stalls

Motor slow to start or

fails to reach full speed

Motor overheats

Tripping circuit breaker or fuses

1. Defective plug, cord, switch or motor

2. Blown fuse or circuit breaker

1. Leaking bag or hose connection

2. Filter or collector bag leaks

1. Large debris or piece of wood in

impeller housing

2. Loose impeller

Defective motor

1. Low voltage to collector caused by

circuit overload

2. Low voltage to collector caused by

undersized extension cords

3. Low voltage from power source

1. Burned or defective motor

2. Defective motor capacitor switch

1. Motor overload

2. Improper motor cooling

1. Motor overloaded

2. Improper capacity of circuit breaker

or fuses

1. Check wiring, replace defective parts

2. Check fuse or breaker, replace

1. Check filter and collector bag connections.

Check collector hose connections

2. Dust trapped under bag clamp or collector bag

not sealed on flange

1. Do not vacuum metal materials. Turn collector

off and let debris settle in collector bag

2. Disconnect collector from power source. Re-

move lower housing (Figure 3, Ref. No. 36) and

tighten impeller

Have motor checked by qualified motor service

technician

1. Remove other electric machines or appliances

from circuit

2. Increase wire gauge size of extension cords or

shorten extension cords

3. Request voltage check from power company

1. Check motor, replace if necessary

2. Check switch, replace if necessary

1. Reduce load by slowing dust production

2. Clean sawdust from motor

1. Reduce load by slowing dust production

2. Use proper capacity circuit breaker or fuse

9686004_oipm_En011_9643301.01 03/21/18 Page 7

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9686004

8

RE AIR ARTS ILLUSTRATION FOR 9686004 650 CFM DUST COLLECTOR

Figure 3 – Repair parts illustration for Dust Collector

9686004_oipm_En011_9643301.01 03/21/18 Page 8

NOR E Operating Manual & Parts List 9686004

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9

RE AIR ARTS LIST FOR 9686004 650 CFM DUST COLLECTOR

1 Filter bag 9635427.00 1

2 Locking strap 9635428.00 1

3 Handgrip 9643302.01 1

4 Tapping bolt ST5.530 *

5 Locking strap 9635428.00 1

6 Collector bag 9686008.00 1

7 Left side panel 9643303.01 1

8 Nut M5 *

9 Square neck bolt M8x12 *

10 Base tube 9643304.01 1

11 Square neck bolt 40 *

12 Wheel cover 9635430.00 1

13 Circlip *

14 Washer #8 *

15 Wheel 9635430.00 1

16 Bottom plate 9643305.01 1

17 Screw M5x6 *

18 Washer #5 *

19 Nut M8 *

20 Washer #8 *

21 Hose 9635431.00 1

22 Hose clamp 9635432.00 1

23 Horizontal plate 9643306.01 1

24 Right side panel 9643307.01 1

25 Impeller 9635433.00 1

26 Hex bolt M8x12 *

27 Washer #8 *

28 Washer #6 *

29 Cup square neck bolt M5x12 *

30 Pan head tapping screw ST4.8x15 *

31 Switch 9635434.00 1

32 Switch box 9643308.01 1

33 Motor 9635435.00 1

34 Bag support 9635436.00 1

35 Upper housing 9643309.01 1

36 Lower housing 9643310.01 1

37 Screw M616 *

∆ Hose connector 9635437.00 1

∆ Connector adaptor 9635438.00 1

∆ Operating Instructions & Parts Manual 9643301.01 1

Ref.

No. Description art No. Qty.

(∆) Not shown.

(*) Standard hardware item, available locally.

(NA) Not available as replacement part.

9686004_oipm_En011_9643301.01 03/21/18 Page 9

NOTES

10

GE ING S AR ED

SAFE Y / SPECIFICA IONS

ASSEMBLY / INS ALLA ION

OPERA ION

ROUBLESHOO ING

MAIN ENANCE / REPAIR

NOR E Operating Manual & Parts List 9686004

9686004_oipm_En011_9643301.01 03/21/18 Page 10

11

NOTES

NOR E Operating Manual & Parts List 9686004

GE ING S AR ED SAFE Y / SPECIFICA IONS ASSEMBLY / INS ALLA ION OPERA ION ROUBLESHOO ING MAIN ENANCE / REPAIR

9686004_oipm_En011_9643301.01 03/21/18 Page 11

NOR E by C.H. Hanson warrants their products to be free of defects in material or workmanship. This

warranty does not cover defects due directly or indirectly to misuse, abuse, normal wear and tear, failure

to properly maintain the product, heated, ground or otherwise altered, or used for a purpose other than

that for which it was intended.

The warranty does not cover expendable and/or wear part (i.e. v-belts, screws, abrasives, jaws), damage to

tools arising from alteration, abuse or use other than their intended purpose, packing and freight. The

duration of this warranty is expressly limited to the terms noted below beginning from the date of

delivery to the original user.

The NOR E branded items carry the following warranties on parts:

All NOR E branded Tools and Accessories 1 YEAR

The obligation of NOR E by C.H. Hanson is limited solely to the repair or replacement, at our option, at its

factory or authorized repair agent of any part that should prove inoperable. Purchaser must lubricate and

maintain the product under normal operating conditions at all times. Prior to operation become familiar

with product and the included materials, i.e. warnings, cautions and manuals.

Failure to follow these instructions will void the warrant .

This warranty is the purchaser's exclusive remedy against C. H. Hanson for any inoperable parts in its

product. Under no circumstances is C. H. Hanson liable for any direct, indirect, incidental , special or

consequential damages including loss of profits in any way related to the use or inability to use our

products. This warranty gives you specific legal rights which may vary from state to state.

SERVICE & REPAIR

1. If a NOR E product requires a repair or warranty service DO NOT return the product to

the place of purchase.

2. All warranty related work must be evaluated and approved by NOR E.

3. Prior to returning any item the user must obtain factory approval and a valid RGA number.

4. For instructions and RGA number call toll free (800) 827-3398.

NORSE - a C.H. Hanson Brand

2000 N. Aurora Rd., Naperville, IL 60563 U.S.A.

or call: 1-800-827-3398

NOR E Operating Manual & Parts List 9686004

NORSE Warranty

9686004_oipm_En011_9643301.01 03/21/18 Page 12