TOOL SPECIFICATIONS

MODEL OF TOOL .................................................................. S-90D

TOOL LENGTH ....................................................................... 21.46" (545 mm)

TOOL HEIGHT ........................................................................ 14.17" (360 mm)

TOOL WIDTH .......................................................................... 5.00" (127 mm)

WEIGHT (WITHOUT FASTENERS) ...................................…8.16 lbs (3.7 kg)

AIR INLET ............................................................................... 1/4" NPT

COMPRESSED AIR :

Maximum permissible operating pressure ............................. 115 PSIG (8 bar)

Recommended operating pressure range ........................….. 75∼110 PSIG (5∼7.5 bar)

AIR CONSUMPTION.............................................................. 2.342 scfm with 25

nails per minute

@ 90 psi (6.2 bar)

Noise dB(A):

A-weighted sound pressure level LpA……………….……….. 87.21 dB(A)

A-weighted sound power level LwA………………….……..… 100.21 dB(A)

Measurement uncertainty: 3dB

Vibration (m/s2):

Hand-arm vibration value…………………………………..….. 5.43 m/s2

Measurement uncertainty: 1.5 m/s2

Warning:

The vibration emission during actualuse of the power tool can differ from the declared total

value depending on the waysin which the tool is used;and of the need to identifysafety

measuresto protect the operator that are based on an estimation ofexposure in the actual

conditions of use (taking account of all parts of the operation cycle such as the times when

the toolis switched off and when it isrunning idle in addition to the triggertime).

List of fasteners for S-90D:

Shank Dia. MAGAZINE

ψ2.9∼ψ4.2 mm ,ψ0.11∼ψ0.17 " 56∼70 pcs

Foreword:

This pneumatic framing nailer isdesigned

for truss building, blocking, pallet making

and crate and box assembling. Its well

balanced, ergonomic, comfort non-slip

cushioned grip and heavy duty driving

compatible staples to proper applications

ensure you a satisfactory tackle and enjoy

work.Rigid depth of drive adjustment isto

adjust nailing penetration.

Suitable applications:

Truss building, blocking, pallet making and

crate and box assembling.

Caution:

Framing nailers are only applying on wood. Not suitable for stapling or nailing into concrete,

masonry bricks or steel. Do not fire if staples are jammed, as this will cause damage to the

relevant parts.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

Indicatesan potentially hazardous situation which, if not avoided, will result in death or

serious injury.

NOTE

Alerts the operator to useful information.

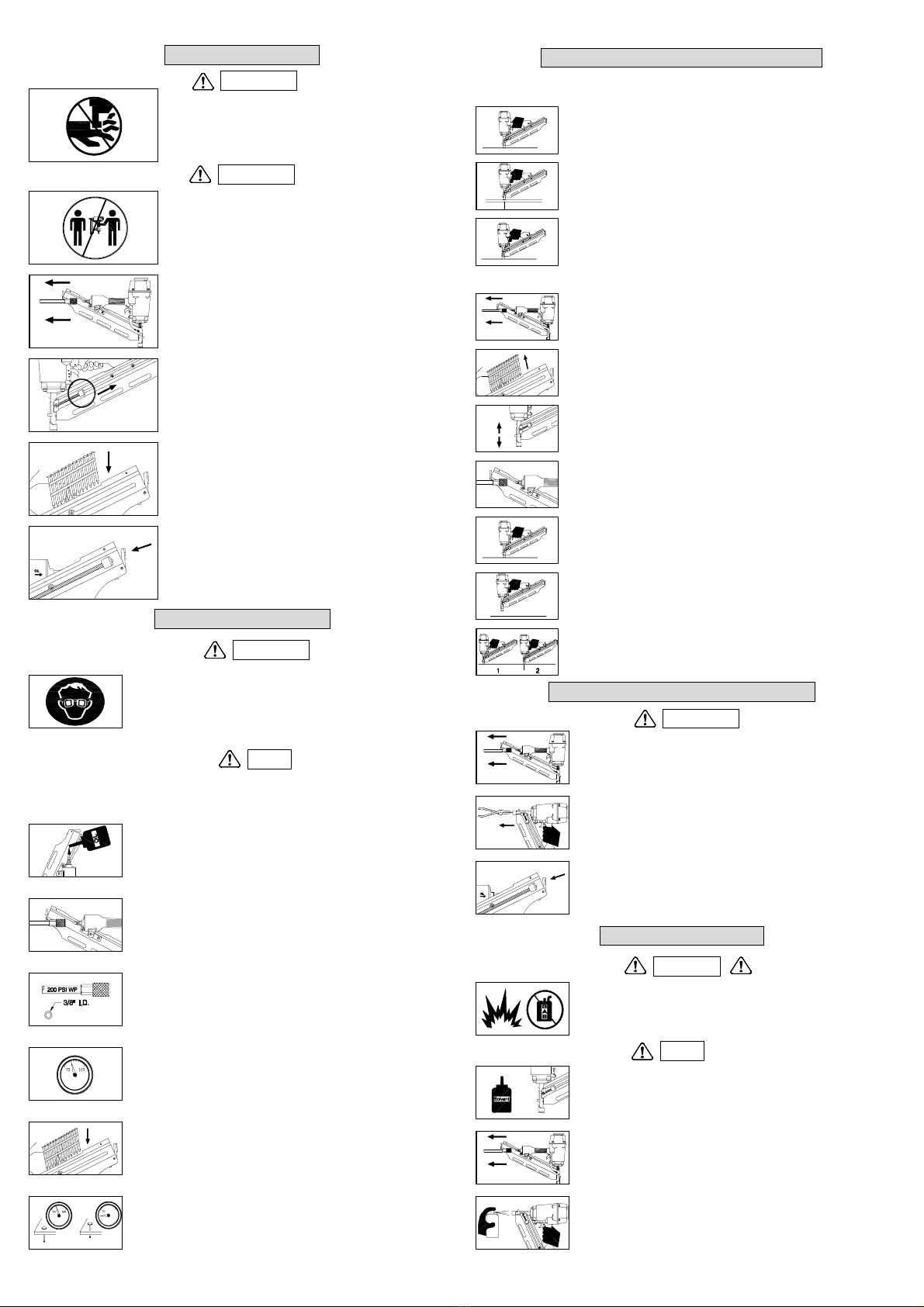

SAFETY INSTRUCTIONS

DANGER

1. Read this manualand understand allsafetyinstructions before operation the tool. Ifyou

have any questions, please contact our authorized representatives.

2. Onlythose fastenerslisted in the operating instructions may be used in the fastener driv-

ing tools.

3. Onlythe main energy and the lubricantslisted in the operating instructions may be used.

4. Fastener driving tools marked with an inverted equilateral triangle standing on one point

may onlybe used with an effective safetyyoke.

5. Fastener driving tools equipped with contact actuation or continuous contact actuation,

marked with the symbol" Do not use on scaffoldings,ladders", shall notbe used for spe-

cific application for example:

─when changing one driving location to another involves the use of scaffoldings, stairs,

ladders, or ladder alike constructions, e.g. roof laths,

─closing boxes or crates,

─fitting transportation safety systems e.g. on vehicles and wagons.

6. For the maintenance of fastener driving tools, only spare parts specified by the manufac-

turer or his authorized representative shall be used.

7. Repairs shall carried out by agents authorized by the manufacturer or by other specialis-

ts,having due regard to the information given in the operating instruction.

8. Standsfor mounting the fastener driving toolsto a support for example a work table shall

be designed and constructed by the stand manufacturer in such a waythat the fastener

driving toolcan be safelyfixed for the intended use,thus forexample avoiding damage,

distortion or displacement.

9. Fastener driving tools operated bycompressed air shall only be connected to compress-

ed air lines where the maximum allowable pressure cannotbe exceed by a factorof

more than 10%, which can for example be achieved by a pressure reduction valve

which includesa downstream safetyvalve.

10. When using fastener driving tools operated bycompressed air,particular attention must

be paid to avoid exceeding the maximum allowable pressure.

11. When using fastener driving toolsoperated by compressed air should onlybe operated

at the lowest pressure required for the workprocessat hand, in order to prevent unnece-

ssarilyhigh noise levels, increased wear and resulting failures.

12. Hazards caused by fire and explosion when using oxygen or combustible gasesfor ope-

rating compressed airoperated fastener driving tools.

13. Carry the fastenerdriving tool atworkpiece using onlythe handgrip,and never with the

trigger actuated. Never carrythe tool by the hose orpull the hose to move the tool.

14. Disconnectthe tool from air supply before cleaning jams,

servicing, adjusting, and during non-operation.

15. Wear eye protection.

16. Do not use a check valve or anyother fitting which allows

air to remain in the tool.

17. Do not place your hand or any part of your body in the

fastener discharge area of the tool when connecting or

disconnecting air supply.

18. Never point tool at yourself or at any other person.

19. Do not use on scaffoldings, ladders.

AIR SUPPLY AND CONNECTION

NOTE

•Many airtool usersfind it convenient to use oilerto help provide oil

circulation through tool and increase the efficiencyand useful life of

the tool. Check oil level in the oiler daily.

•Many airtool user find itconvenient to use a filterto remove liquid

and impurities which can rust or wear internal parts of the tool. A

filter also increase the efficiency and usefulof the tool.The filter

must be checked on a dailybasis and if necessary drained.

•For better performance, install a 3/8" quick connector (1/4" NPT

threads) with an inside diameterof .315" on yourtool and a 3/8"

quick coupler on the air hose.

The following illustration shows the correct mode of connection to the air

supply system which will increase the efficiency and useful life of the tool.

LUBRICATION AND MAINTENANCE

NOTE

•Disconnect the air supplyfrom the toolbefore lubricating.

•Your tool requires lubrication before you use it for the first time.

•Wipe off excessive oil at the exhaust. Excessive oil will damage

O-ringsof tool. If in-line oiler is used, manual lubrication through the

air inlet is not required on a daily basis.

•Turn the tool so the inletis facing up and put one drop ofhigh

speed spindle oil,UNOCAL RX22, or 3-IN-1 oil into airinlet. Never

use detergent oil or additives. Operate the tool briefly after adding

oil.