3

Introduction and Warranty

1. READTHE MANUAL FROM COVERTO COVER

BEFORE USINGTHETOOL.

2. FOLLOW ALL INSTRUCTIONS INTHE MANUAL.

This Cordless Nailer should be handled like other

power fastening tools that you use. Like most tools, when

used improperly injury could result. If you are going to

allow others to use this Cordless Nailer, it is your

responsibility to make sure that they also read and comply

with the instructions in this manual before attempting to

operate the tool.

Should you have questions about this Cordless Nailer,

or wish to obtain additional copies of this manual,

please contact your Paslode®Representative.

The space below is provided so that you may record

your representative's name, address, and telephone

number.

Name

Address

City State Zip

Telephone Number

Paslode Cordless 1-1/2"

Positive Placement®Nailer

Operating Manual

Paslode CordlessWarranty and Limitations

Paslode warranties that new Cordless power fastening tools,

parts and accessories will be free from defects in material and

workmanship for the period shown below, after the date of

delivery to the original user.

FIVE-YEAR EXTENDED LIMITED WARRANTY

A five-year warranty will apply to all molded nylon parts:

• Motor Housing,Cap and Grille

•Handle Halves and Actuator

• Trigger

WARRANTY STATEMENT

This warranty is limited to tools sold and service requested in the

United States. To obtain information on warranty service in the

United States, refer to the Service Center listing that was provided

with your tool.

Paslode's sole liability hereunder will be to replace any part or accessory

which proves to be defective within the specific time period.Any replacement

part or accessory provided in accordance with this warranty will carry a

warranty for the balance of the period of warranty applicable to the part

it replaces. This warranty does not apply to part replacement required

due to normal wear.

This warranty is void on any tool which has been subjected to misuse,

abuse, accidental or intentional damage, use with fasteners, fuel,

batteries, or battery chargers not meeting Paslode specification, size, or

quality, improperly maintained, repaired with other than genuine Paslode

replacement parts, damaged in transit or handling, or which, in Paslode's

opinion, has been altered or repaired in a way that affects or detracts from

the performance of the tool.

•Magazine Parts

battery and charger system) which have failed during normal

CORDLESS 2 YEAR SERVICE PROMISE

Paslode will service the tool and replace all parts (including

use for FREE, for a period of 2 years from date of purchase.

For 2 Year Service Promise details and limitations see

servicepromise.paslode.com.

PASLODE MAKES NO WARRANTY, EXPRESSED OR IMPLIED,

RELATING TO MERCHANTABILITY, FITNESS, OR OTHERWISE,

EXCEPT AS STATED ABOVE, and Paslode's liability AS STATED ABOVE

AND AS ASSUMED ABOVE is in lieu of all other warranties arising out of,

or in connection with, the use and performance of the tool, except to the

extent other wise provided by applicable law. PASLODE SHALL IN NO

EVENT BE LIABLE FORANY DIRECT, INDIRECT, OR CONSEQUENTIAL

DAMAGES, INCLUDING, BUT NOT LIMITED TO, DAMAGES WHICH

MAY ARISE FROM LOSS OF ANTICIPATED PROFITS OR

PRODUCTION, SPOILAGE OF MATERIALS,, INCREASED COST OF

OPERATION, OR OTHERWISE.

Paslode reserves the right to change specifications, equipment, or designs

at any time without notice and without incurring obligation.

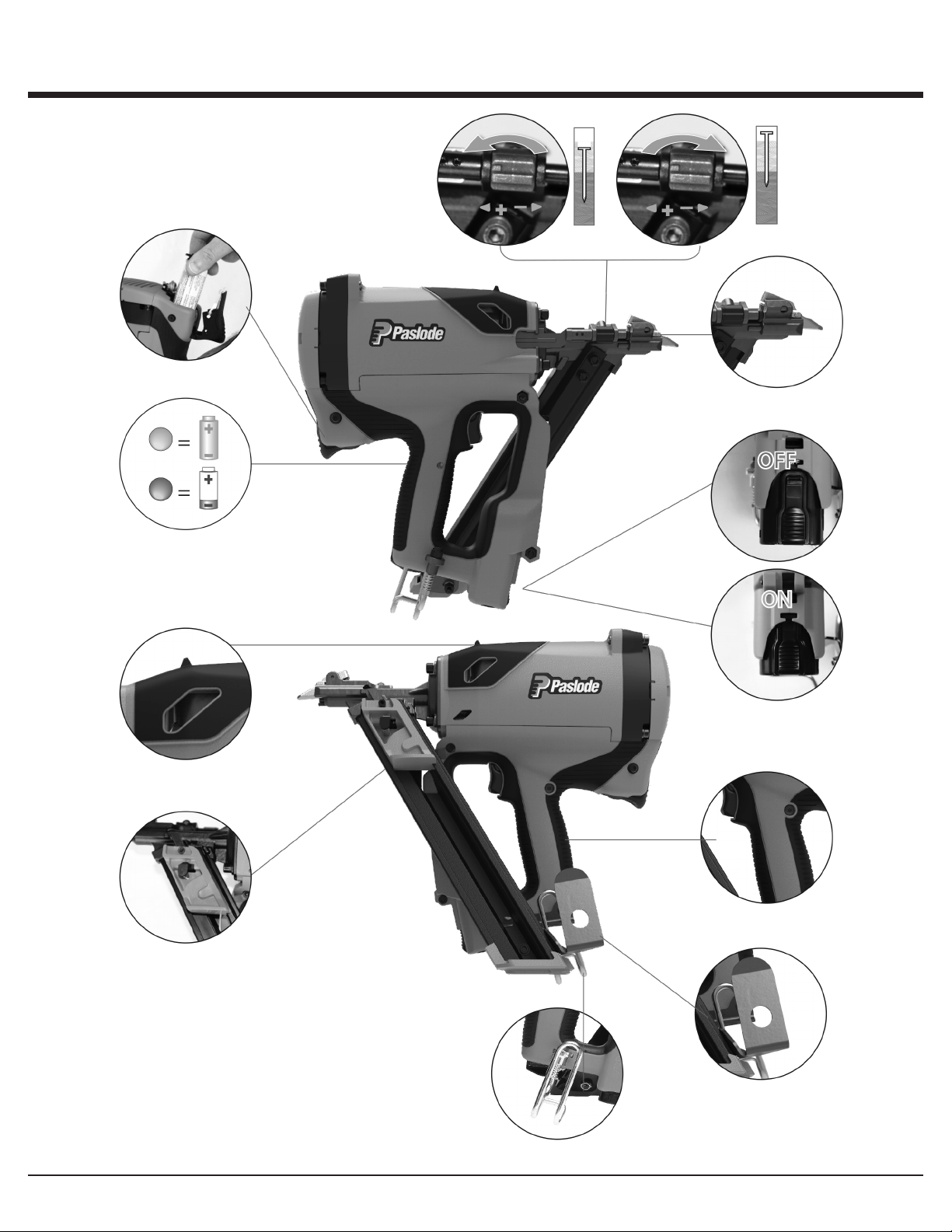

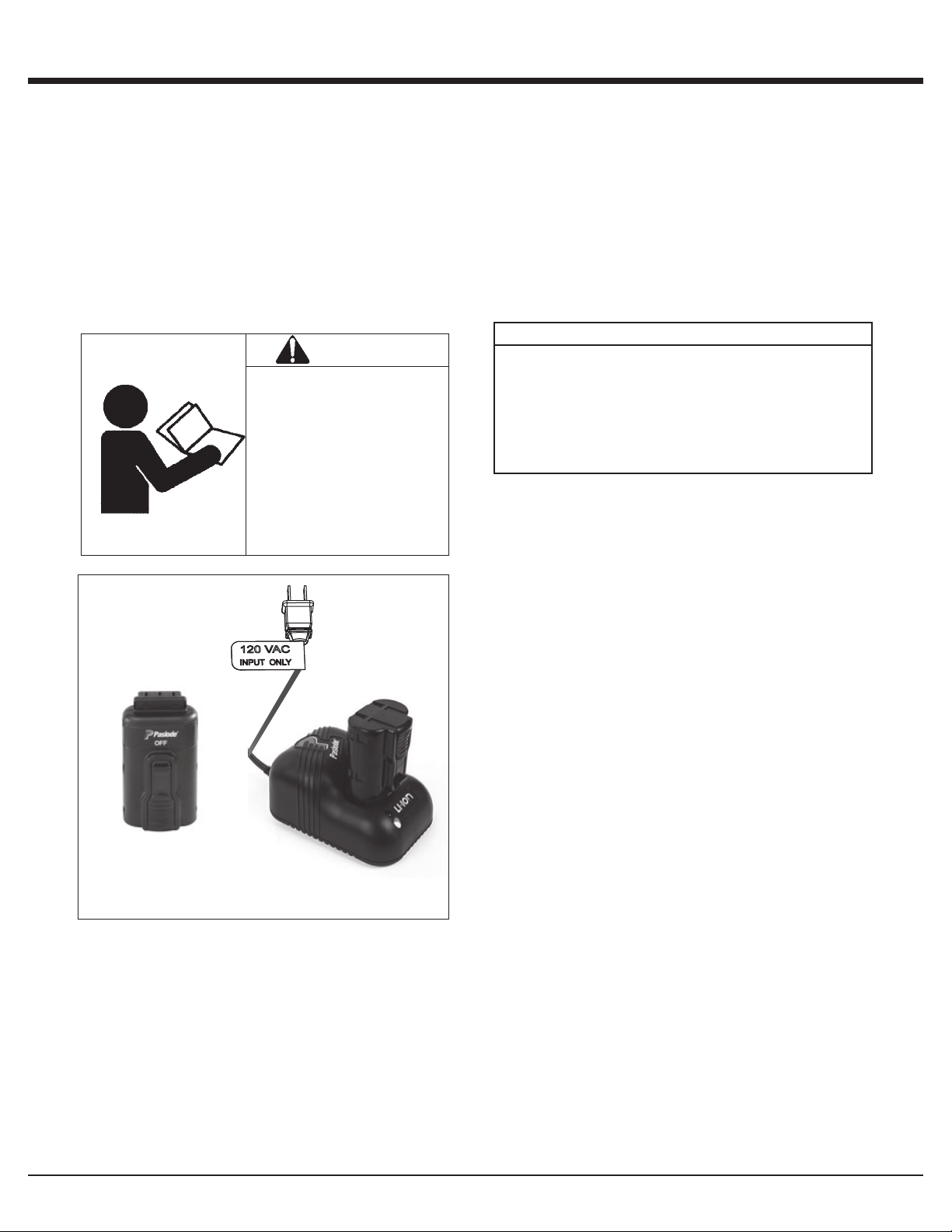

This manual is intended to acquaint you with the Paslode

Cordless 1-1/2” Positive Placement®Nailer. Unlike other

power fastening tools, this Cordless Nailer is powered by

an internal combustion linear motor. In simpler terms,

your Cordless Nailer is powered by a motor similar to the

one that powers an automobile. This Cordless Nailer

ignites a fuel and air mixture to product the energy to

power the motor, which in turn drives the fastener. This

Cordless Nailer is totally self-contained. It carries its own

fuel supply and battery, along with a supply of fasteners.

For ease of use, this manual is divided into sections (see

Contents). Each section of the manual is written with you,

the tool operator, in mind. We have left out many of the

technical terms so that you can easily understand how to get

the maximum performance from your CordlessNailer, and

how to avoid damaging the tool or injuring yourself. But, to

accomplish this, we need you to do two things: